Abstract

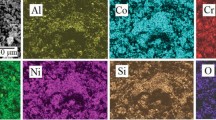

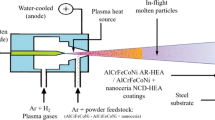

CoCrFeNiMn high-entropy alloy (HEA) has great potential for industrial application due to its excellent mechanical properties and remarkable fracture toughness. In this study, CoCrFeNiMn HEA coatings (HEACs) were deposited on 316L stainless steel by detonation spraying technique, and annealed at two different temperatures. Phase structures, microhardness, and wear resistance of the as-sprayed and annealed HEACs were systematically investigated. It was found that both as-sprayed and annealed coatings were in a face-centered cubic solid solution structure, and contained a small amount of oxides, which would be easy to precipitate at the high annealing temperature. The microhardness of as-sprayed HEACs showed a high average value of ~520 HV, which increased to ~551 HV after annealing at 600 °C. And it decreased significantly to ~307 HV at annealing temperature of 900 °C as a result of grain growth. The wear tests demonstrated that the HEACs annealed at 900 °C had excellent wear resistance, while the as-sprayed HEACs had a high volumetric wear rate as compared with the annealed ones, which is ascribed to the improvement of cohesive strength of the splats by annealing: a strong metallurgical bonding between the splats was formed, and the splats of the annealed coatings were more difficult to peel off.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater, 2004, 6(5), p 299–303.

W. Zhang, P.K. Liaw and Y. Zhang, Science and Technology in High-entropy Alloys, Sci. China Mater., 2018, 61(1), p 2–22.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw and Z.P. Lu, Microstructures and Properties of High-entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1–93.

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu and Y. Yang, High-entropy Alloys: Challenges and Prospects, Mater. Today, 2016, 19, p 349–362.

J.W. Qiao, M.L. Bao, Y.J. Zhao, H.J. Yang, Y.C. Wu, Y. Zhang, J.A. Hawk and M.C. Gao, Rare-earth High Entropy Alloys with Hexagonal Close-packed Structure, J. Appl. Phys., 2018, 124, p 195101.

T. Yang, Y.L. Zhao, Y. Tong, Z.B. Jiao, J. Wei, J.X. Cai, X.D. Han, D. Chen, A. Hu, J.J. Kai, K. Lu, Y. Liu and C.T. Liu, Multicomponent Intermetallic Nanoparticles and Superb Mechanical Behaviors of Complex Alloys, Science, 2018, 362(6417), p 933–937.

W.L. Hsu, Y.C. Yang, C.Y. Chen and J.W. Yeh, Thermal Sprayed High-entropy NiCo0.6Fe0.2Cr1.5SiAlTi0.2 Coating with Improved Mechanical Properties and Oxidation Resistance, Intermetallics, 2017, 89, p 105–110.

O. Senkov, G. Wilks, D. Miracle, C. Chuang and P.K. Liaw, Refractory High-entropy Alloys, Intermetallics, 2010, 18, p 1758–1765.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

M. Laurent-Brocq, A. Akhatova, L. Perrière, S. Chebini, X. Sauvage, E. Leroy and Y. Champion, Insights into the Phase Diagram of the CrMnFeCoNi High Entropy Alloy, Acta Mater., 2015, 88, p 355–365.

G. Bracq, M. Laurent-Brocq, L. Perrière, R. Pirès, J. Joubert and I. Guillot, The FCC Solid Solution Stability in the Co-Cr-Fe-Mn-Ni Multi-component System, Acta Mater., 2017, 128, p 327–336.

F. Otto, Y. Yang, H. Bei and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-entropy Alloys, Acta Mater., 2013, 61, p 2628–2638.

Z. Wu, H. Bei, F. Otto, G.M. Pharr and E.P. George, Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-structured Multi-component Equiatomic Solid Solution Alloys, Intermetallics, 2014, 46, p 131–140.

Z. Zhang, M.M. Mao, J. Wang, B. Gludovatz, Z. Zhang, S.X. Mao, E.P. George, Q. Yu and R.O. Ritchie, Nanoscale Origins of the Damage Tolerance of the High-entropy Alloy CrMnFeCoNi, Nat. Commun., 2015, 6, p 10143.

H. Luo, Z. Li, A.M. Mingers and D. Raabe, Corrosion Behavior of an Equiatomic CoCrFeMnNi High-entropy Alloy Compared with 304 Stainless Steel in Sulfuric Acid Solution, Corros. Sci., 2018, 2018(134), p 131–139.

C.M. Barr, J.E. Nathaniel, K.A. Unocic, J. Liu, Y. Zhang, Y. Wang and M.L. Taheri, Exploring Radiation Induced Segregation Mechanisms at Grain Boundaries in Equiatomic CoCrFeNiMn High Entropy Alloy under Heavy Ion Irradiation, Scr. Mater., 2018, 156, p 80–84.

L. Yang, H. Ge, J. Zhang, T. Xiong, Q. Jin, Y. Zhou, X. Shao, B. Zhang, Z. Zhu, S. Zheng and X. Ma, High He-ion Irradiation Resistance of CrMnFeCoNi High-entropy Alloy Revealed by Comparison Study with Ni and 304SS, J. Mater. Sci. Technol., 2019, 35(03), p 300–305.

T.W. Lu, C.S. Feng, Z. Wang, K.W. Liao, Z.Y. Liu, Y.Z. Xie, J.G. Hu and W.B. Liao, Microstructures and Mechanical Properties of CoCrFeNiAl0.3 High-entropy Alloy Thin Films by Pulsed Laser Deposition, Appl. Surf. Sci., 2019, 494, p 72–79.

A. Anupam, R.S. Kottada, S. Kashyap, A. Meghwal, B.S. Murty, C.C. Berndt and A.S.M. Ang, Understanding the Microstructural Evolution of High Entropy Alloy Coatings Manufactured by Atmospheric Plasma Spray Processing, Appl. Surf. Sci., 2020, 505, p 144117.

C.S. Feng, T.W. Lu, T.L. Wang, M.Z. Lin, J. Hou, W. Lu and W.B. Liao, A Novel High-entropy Amorphous Thin Film with High Electrical Resistivity and Outstanding Corrosion Resistance, Acta Metall. Sin. (Engl. Lett.), 2021, https://doi.org/10.1007/s40195-021-01255-9

A. Meghwal, A. Anupam, V. Luzin, C. Schulz, C. Hall, B.S. Murty, R.S. Kottada, C.C. Berndt and A.S.M. Ang, Multiscale Mechanical Performance and Corrosion Behaviour of Plasma Sprayed AlCoCrFeNi High-entropy Alloy Coatings, J. Alloy Compd., 2021, 854, p 157140.

L. Wang, F. Zhang, S. Yan, G. Yu, J. Chen, J. He and F. Yin, Microstructure Evolution and Mechanical Properties of Atmosphere Plasma Sprayed AlCoCrFeNi High-entropy Alloy Coatings under Post- annealing, J. Alloy Compd., 2021, 872, p 159607.

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A. Anupam, S. Praveen, R.S. Kottada and B.S. Murty, Plasma-sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi, Metall. Mater. Trans. A-Phys. Metall. Mater. Sci., 2015, 46A, p 791–800.

J.K. Xiao, H. Tan, Y.Q. Wu, J. Chen and C. Zhang, Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying, Surf. Coat. Technol., 2020, 385, p 125430.

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003–1007.

C. Wang, J. Yu, Y. Zhang and Y. Yu, Phase Evolution and Solidification Cracking Sensibility in Laser Remelting Treatment of the Plasma-sprayed CrMnFeCoNi High Entropy Alloy Coating, Mater. Des., 2019, 182, p 108040.

B. Huang, C. Zhang, G. Zhang and H. Liao, Wear and Corrosion Resistant Performance of Thermal-sprayed Fe-based Amorphous Coatings: A Review, Surf. Coat. Technol., 2019, 377, p 124896.

W.B. Liao, Z.X. Wu, W.J. Lu, M.J. He, T. Wang, Z.X. Guo and J.J. Huang, Microstructures and Mechanical Properties of CoCrFeNiMn High-entropy Alloy Coatings by Detonation Spraying, Intermetallics, 2021, 132, p 107138.

M. Xue, X. Mao, Y. Lv, Y. Chi, Y. Yang, J. He and Y. Dong, Comparison of Micro-nano FeCoNiCrAl and FeCoNiCrMn Coatings Prepared from Mechanical Alloyed High-entropy Alloy Powders, J. Therm. Spray. Tech., 2021, 30, p 1666–1678.

N. Stepanov, M. Tikhonovsky, N. Yurchenko, D. Zyabkin, M. Klimova, S. Zherebtsov, A. Efimov and G. Salishchev, Effect of Cryo-deformation on Structure and Properties of CoCrFeNiMn High-entropy Alloy, Intermetallics, 2015, 59, p 8–17.

A.S. Rogachev, S.G. Vadchenko, N.A. Kochetov, S. Rouvimov, D.Y. Kovalev, A.S. Shchukin, D.O. Moskovskikh, A.A. Nepapushev and A.S. Mukasyan, Structure and Properties of Equiatomic CoCrFeNiMn Alloy Fabricated by High-energy Ball Milling and Spark Plasma Sintering, J. Alloys Compd., 2019, 805, p 1237–1245.

M.S. Mehranpour, H. Shahmir and M. Nili-ahmadabadi, CoCrFeNiMn High Entropy Alloy Microstructure and Mechanical Properties after Severe Cold Shape Rolling and Annealing, Mater. Sci. Eng. A, 2020, 793, p 139884.

J.M. Wu, S.J. Lin, J.W. Yeh, S.K. Chen, Y.S. Huang and H.C. Chen, Adhesive Wear Behavior of AlxCoCrCuFeNi High-entropy Alloys as a Function of Aluminum Content, Wear, 2006, 261(5–6), p 513–519.

M.M. Khruschov, Principles of Abrasive Wear, Wear, 1974, 28, p 69–88.

J.K. Xiao, W. Zhang, L.M. Liu, X.P. Gan, K.C. Zhou and C. Zhang, Microstructure and Tribological Properties of Plasma Sprayed Cu-15Ni-8Sn Coatings, Surf. Coat. Technol., 2018, 337, p 159–167.

Acknowledgment

This research was supported by the National Natural Science Foundation of China (Grant No. 51801128), Guangdong Basic and Applied Basic Research Foundation (Grant No. 2021A1515012278), Shenzhen Science and Technology Innovation Committee (Peacock Plan 827-000351), Natural Science Foundation of Shenzhen University (Grant No. 860-000002110212). Wei-Bing Liao would like to acknowledge the technical support from the Instrumental Analysis Center of Shenzhen University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part ofa special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of TechnologyHyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Wu, ZX., He, MJ., Feng, CS. et al. Effects of Annealing on the Microstructures and Wear Resistance of CoCrFeNiMn High-Entropy Alloy Coatings. J Therm Spray Tech 31, 1244–1251 (2022). https://doi.org/10.1007/s11666-021-01292-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01292-x