Abstract

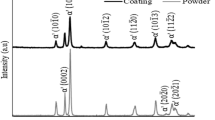

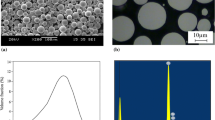

Ti-6Al-4V is widely used in the aerospace industry, however, Ti-6Al-4V repairs are challenging to perform via cold spray due to the material’s limited capacity for plastic deformation. To promote particle deformation, this study investigated the influence of Ti-6Al-4V powder heat treatment on the powder microstructure, cold spray deposition behavior, and, ultimately, on the coating microstructure and properties. Plasma-atomized Ti-6Al-4V powder was subjected to three different heat treatments (i.e., 540 °C for 5 h, 750 °C for 2 h, and 950 °C for 2.5 h) and subsequently deposited on Ti-6Al-4V substrates using a high-pressure cold spray system. Scanning electron microscopy revealed that the as-received microstructure was primarily characterized by a martensitic alpha microstructure. After low-temperature heat treatment (540 °C), the microstructure retained the original martensitic alpha microstructure. Intermediate heat treatment (750 °C) resulted in the formation of needle-like alpha and acicular alpha with fine beta precipitates. High-temperature treatment (950 °C) resulted in the formation of needle-like alpha, acicular alpha, and plate-like alpha with coarse and fine beta precipitates. The hardness of the powder increased after heat treating at 550 °C and 750 °C but decreased when treated at 950 °C. After cold spray deposition, particle interiors retained the as-processed powder microstructure while regions near particle boundaries exhibited either a featureless microstructure (as-received powder and low-temperature heat treatment) or elongated β (high-temperature heat treatment). With the exception of 750 °C powder heat treatment, all coatings were nearly dense (< 1% porosity). Ultimately the results showed that 950 °C heat treatments have the potential to improve powder deformation behavior and coating properties.

Similar content being viewed by others

References

B. Dutta, F.H.S. Froes, The additive manufacturing (AM) of titanium alloys, Titanium powder metallurgyed. (Elsevier, 2015) p. 447-468

C. Widener, M. Carter, O. Ozdemir, R. Hrabe, B. Hoiland, T. Stamey, V. Champagne and T.J. Eden, Application of high-pressure cold spray for an internal bore repair of a navy valve actuator, J. Therm. Spray Technol., 2016, 25(1–2), p 193–201.

R. Jones, N. Matthews, C. Rodopoulos, K. Cairns and S. Pitt, On the use of supersonic particle deposition to restore the structural integrity of damaged aircraft structures, Int. J. Fatigue, 2011, 33(9), p 1257–1267.

V. Champagne and D. Helfritch, Critical assessment 11: structural repairs by cold spray, Mater. Sci. Technol., 2015, 31(6), p 627–634.

A. Moridi, S.M. Hassani-Gangaraj, M. Guagliano and M. Dao, Cold spray coating: review of material systems and future perspectives, Surf. Eng., 2014, 30(6), p 369–395.

M. Rokni, C. Widener, G. Crawford and M. West, An investigation into microstructure and mechanical properties of cold sprayed 7075 Al deposition, Mater. Sci. Eng., A, 2015, 625, p 19–27.

H. Assadi, H. Kreye, F. Gärtner and T. Klassen, Cold spraying–A materials perspective, Acta Mater., 2016, 116, p 382–407.

F. Gärtner, T. Stoltenhoff, J. Voyer, H. Kreye, S. Riekehr and M. Kocak, Mechanical properties of cold-sprayed and thermally sprayed copper coatings, Surf. Coat. Technol., 2006, 200(24), p 6770–6782.

P.S. Phani, D.S. Rao, S. Joshi and G. Sundararajan, Effect of process parameters and heat treatments on properties of cold sprayed copper coatings, J. Therm. Spray Technol., 2007, 16(3), p 425–434.

C. Borchers, F. Gärtner, T. Stoltenhoff and H. Kreye, Microstructural bonding features of cold sprayed face centered cubic metals, J. Appl. Phys., 2004, 96(8), p 4288–4292.

D. Goldbaum, J.M. Shockley, R.R. Chromik, A. Rezaeian, S. Yue, J.-G. Legoux and E. Irissou, The effect of deposition conditions on adhesion strength of Ti and Ti6Al4V cold spray splats, J. Therm. Spray Technol., 2012, 21(2), p 288–303.

M.V. Vidaller, A. List, F. Gaertner, T. Klassen, S. Dosta and J.M. Guilemany, Single impact bonding of cold sprayed Ti-6Al-4V powders on different substrates, J. Therm. Spray Technol., 2015, 24(4), p 644–658.

A.W.-Y. Tan, W. Sun, A. Bhowmik, J.Y. Lek, I. Marinescu, F. Li, N.W. Khun, Z. Dong and E. Liu, Effect of coating thickness on microstructure, mechanical properties and fracture behaviour of cold sprayed Ti6Al4V coatings on Ti6Al4V substrates, Surf. Coat. Technol., 2018, 349, p 303–317.

A.W.-Y. Tan, W. Sun, Y.P. Phang, M. Dai, I. Marinescu, Z. Dong and E. Liu, Effects of traverse scanning speed of spray nozzle on the microstructure and mechanical properties of cold-sprayed Ti6Al4V coatings, J. Therm. Spray Technol., 2017, 26(7), p 1484–1497.

P. Vo, E. Irissou, J.-G. Legoux and S. Yue, Mechanical and microstructural characterization of cold-sprayed Ti-6Al-4V after heat treatment, J. Therm. Spray Technol., 2013, 22(6), p 954–964.

W.Y. Li, C. Zhang, X. Guo, J. Xu, C.J. Li, H. Liao, C. Coddet and K.A. Khor, Ti and Ti-6Al-4V coatings by cold spraying and microstructure modification by heat treatment, Adv. Eng. Mater., 2007, 9(5), p 418–423.

X.-T. Luo, Y.-K. Wei, Y. Wang and C.-J. Li, Microstructure and mechanical property of Ti and Ti6Al4V prepared by an in-situ shot peening assisted cold spraying, Mater. Des., 2015, 85, p 527–533.

M. Garrido, P. Sirvent and P. Poza, Evaluation of mechanical properties of Ti6Al4V cold sprayed coatings, Surf. Eng., 2018, 34(5), p 399–406.

D. Boruah, B. Robinson, T. London, H. Wu, H. de Villiers-Lovelock, P. McNutt, M. Doré and X. Zhang, Experimental evaluation of interfacial adhesion strength of cold sprayed Ti-6Al-4V thick coatings using an adhesive-free test method, Surf. Coat. Technol., 2020, 381, p 125130.

V.S. Bhattiprolu, K.W. Johnson, O.C. Ozdemir and G.A. Crawford, Influence of feedstock powder and cold spray processing parameters on microstructure and mechanical properties of Ti-6Al-4V cold spray depositions, Surf. Coat. Technol., 2018, 335, p 1–12.

H. Zhou, C. Li, H. Yang, X. Luo, G. Yang, W. Li, T. Hussain and C. Li, Pores structure change induced by heat treatment in cold-sprayed Ti6Al4V coating, J. Therm. Spray Technol., 2019, 28(6), p 1199–1211.

V.S. Bhattiprolu, K.W. Johnson and G.A. Crawford, Influence of powder microstructure on the microstructural evolution of as-sprayed and heat treated cold-sprayed Ti-6Al-4V coatings, J. Therm. Spray Technol., 2019, 28(1–2), p 174–188.

A. Birt, V. Champagne Jr., R. Sisson Jr. and D. Apelian, Microstructural analysis of Ti–6Al–4V powder for cold gas dynamic spray applications, Adv. Powder Technol., 2015, 26(5), p 1335–1347.

A. Birt, V. Champagne, R. Sisson and D. Apelian, Microstructural analysis of cold-sprayed Ti-6Al-4V at the micro-and nano-scale, J. Therm. Spray Technol., 2015, 24(7), p 1277–1288.

V.N.V. Munagala, V. Akinyi, P. Vo and R.R. Chromik, Influence of powder morphology and microstructure on the cold spray and mechanical properties of Ti6Al4V coatings, J. Therm. Spray Technol., 2018, 27(5), p 827–842.

J.Y. Lek, A. Bhowmik, A.W.-Y. Tan, W. Sun, X. Song, W. Zhai, P.J. Buenconsejo, F. Li, E. Liu and Y.M. Lam, Understanding the microstructural evolution of cold sprayed Ti-6Al-4V coatings on Ti-6Al-4V substrates, Appl. Surf. Sci., 2018, 459, p 492–504.

D. Goldbaum, R.R. Chromik, S. Yue, E. Irissou and J.-G. Legoux, Mechanical property mapping of cold sprayed Ti splats and coatings, J. Therm. Spray Technol., 2011, 20(3), p 486–496.

D. Goldbaum, R.R. Chromik, N. Brodusch and R. Gauvin, Microstructure and mechanical properties of Ti cold-spray splats determined by electron channeling contrast imaging and nanoindentation mapping, Microsc. Microanal., 2015, 21(3), p 570.

A. Sabard, H. de Villiers Lovelock and T. Hussain, Microstructural evolution in solution heat treatment of gas-atomized Al alloy (7075) powder for cold spray, J. Thermal Spray Technol., 2018, 27(1), p 145–158.

A. Sabard, P. McNutt, H. Begg and T. Hussain, Cold spray deposition of solution heat treated, artificially aged and naturally aged Al 7075 powder, Surf. Coat. Technol., 2020, 385, p 125367.

W.A. Story and L.N. Brewer, Heat treatment of gas-atomized powders for cold spray deposition, Metall. and Mater. Trans. A., 2018, 49(2), p 446–449.

H. Chandler, Heat treater's guide: practices and procedures for nonferrous alloys, ASM Int. (1996)

V.S. Bhattiprolu and G.A. Crawford, Microstructural evolution and mechanical behavior of heat treated Ti-6Al-4V powders, Metallogr. Microstruct. Anal., 2018, 7(6), p 761–768.

W.C. Oliver and G.M. Pharr, An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, 7(6), p 1564–1583.

E. ASTM, 2109-01, Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings

F. Kaschel, R. Vijayaraghavan, A. Shmeliov, E. McCarthy, M. Canavan, P. McNally, D. Dowling, V. Nicolosi, M. Celikin, Mechanism of stress relaxation and phase transformation in additively manufactured Ti-6Al-4V via in situ high temperature XRD and TEM analyses. Acta Materialia (2020)

T. Schmidt, F. Gärtner, H. Assadi and H. Kreye, Development of a generalized parameter window for cold spray deposition, Acta Mater., 2006, 54(3), p 729–742.

M. Smagorinski and P. Tsantrizos, Production of spherical titanium powder by plasma atomization, Adv. Powder. Metall. Part. Mater., 2002, 3, p 3–248.

T. Ahmed and H. Rack, Phase transformations during cooling in α+ β titanium alloys, Mater. Sci. Eng., A, 1998, 243(1–2), p 206–211.

Z.Z. Fang, Sintering Adv. Mater. (Elsevier, 2010)

W. Xu, M. Brandt, S. Sun, J. Elambasseril, Q. Liu, K. Latham, K. Xia and M. Qian, Additive manufacturing of strong and ductile Ti–6Al–4V by selective laser melting via in situ martensite decomposition, Acta Mater., 2015, 85, p 74–84.

B. Vrancken, L. Thijs, J.-P. Kruth and J. Van Humbeeck, Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties, J. Alloy. Compd., 2012, 541, p 177–185.

R. Pederson, O. Babushkin, F. Skystedt and R. Warren, Use of high temperature X-ray diffractometry to study phase transitions and thermal expansion properties in Ti-6Al-4V, Mater. Sci. Technol., 2003, 19(11), p 1533–1538.

J. Bray, Properties and selection: nonferrous alloys and special purpose materials, ASM Metals Handbook, 92, (1990)

C. Lee and J. Kim, Microstructure of kinetic spray coatings: a review, J. Therm. Spray Technol., 2015, 24(4), p 592–610.

M. Rokni, C. Widener and G. Crawford, Microstructural evolution of 7075 Al gas atomized powder and high-pressure cold sprayed deposition, Surf. Coat. Technol., 2014, 251, p 254–263.

X.-T. Luo, C.-X. Li, F.-L. Shang, G.-J. Yang, Y.-Y. Wang and C.-J. Li, High velocity impact induced microstructure evolution during deposition of cold spray coatings: a review, Surf. Coat. Technol., 2014, 254, p 11–20.

G. Bae, K. Kang, J.-J. Kim and C. Lee, Nanostructure formation and its effects on the mechanical properties of kinetic sprayed titanium coating, Mater. Sci. Eng., A, 2010, 527(23), p 6313–6319.

K. Kim, M. Watanabe, J. Kawakita and S. Kuroda, Grain refinement in a single titanium powder particle impacted at high velocity, Scripta Mater., 2008, 59(7), p 768–771.

F.J. Humphreys, M. Hatherly, Recrystallization and related annealing phenomena. (Elsevier, 2012)

R. Ghelichi, S. Bagherifard, D. Mac Donald, M. Brochu, H. Jahed, B. Jodoin and M. Guagliano, Fatigue strength of Al alloy cold sprayed with nanocrystalline powders, Int. J. Fatigue, 2014, 65, p 51–57.

D. Goldbaum, J. Ajaja, R.R. Chromik, W. Wong, S. Yue, E. Irissou and J.-G. Legoux, Mechanical behavior of Ti cold spray coatings determined by a multi-scale indentation method, Mater. Sci. Eng., A, 2011, 530, p 253–265.

Acknowledgments

This work was supported by US Army Research, Development and Engineering Command under grant number W15QKN-16-C0094 and in part by the U.S. Army Research Laboratories under the grant number W911NF-19-20329. Any opinions, findings, and conclusions or recommendations expressed in this material are those of the author(s) and do not necessarily reflect the views of the U.S. Government.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bhattiprolu, V.S., Johnson, K.W. & Crawford, G.A. Influence of Powder Heat Treatment on the Microstructure and Mechanical Properties of Cold Sprayed Ti-6Al-4V Coatings. J Therm Spray Tech 30, 2050–2068 (2021). https://doi.org/10.1007/s11666-021-01276-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-021-01276-x