Abstract

Existing modeling techniques can determine the heat transfer within idealized spherical particles with homogenous morphology. Agglomerated particles are not homogenous and consist of multiple smaller particles which are packed together. The reduced contact area between the individual smaller particles results in a drastic reduction in the effective thermal conductivity of the agglomerate. Conversely, it can enhance the heat transfer due to the increased particle surface area and gas penetration into the agglomerate. Moreover, the momentum transfer from the plasma to the agglomerate differs from that of a homogenous spherical particle, which can significantly affect the heating dynamics of the agglomerate. All of the mentioned phenomena have been taken into account in a novel particle modeling approach by resolving the 3-D geometry of the agglomerates and the flow around it. The presented model is coupled with the particle-laden free jet model. Differences in kinematics and heating dynamics of the agglomerates have been analyzed with regard to their packing densities. The presented model was compared to a simplified approach where the agglomerates were represented by spherical particles with their mass corresponding to the agglomerates with different packing distances. The comparison proved the necessity of 3-D resolution of the particle morphology.

Similar content being viewed by others

References

P. Fauchais et al., Knowledge Concerning Splat Formation. An Invited Review, J. Therm. Spray Technol., 2004, 13(3), p 337-360

H. Voggenreiter et al., Influence of Particle Velocity and Molten Phase on the Chemical and Mechanical Properties of HVOF-Sprayed Structural Coatings of Alloy 316L, ASM International, Materials Park, 1995

P. Fauchais and M. Vardelle, Sensors in Spray Processes, J. Therm. Spray Technol., 2010, 19(4), p 668-694

D.Y.C. Wei, B. Farouk, and D. Apelian, Melting Metal Powder Particles in an Inductively Coupled R.F. Plasma Torch, Metall. Trans., 1988, 19(2), p 213-226

E. Bourdin, P. Fauchais, and M.I. Boulos, Transient Heat Conduction Under Plasma Conditions, Int. J. Heat Mass Transf., 1983, 26, p 567-582

P. Fauchais, Understanding Plasma Spraying, J. Phys. D Appl. Phys., 2004, 37(9), p 86-108

D. Khelfi, A.A. El-Hadj, and N. Aït-Messaoudène, Modeling of a 3D Plasma Thermal Spraying and the Effect of the Particle Injection Angle, in Conference Proceeding of Revue des Energies Renouvelables CISM’08 (2008), p 205-216

M. Pasandideh-Fard et al., Splat Shapes in a Thermal Spray Coating Process: Simulations and Experiments, J. Therm. Spray Technol., 2002, 11(2), p 206-217

M. Vardelle et al., Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., 1995, 4(1), p 50-58

R. Djebali, A Confrontation of Lattice Boltzmann, Finite Difference and Taguchi Experimental Design Results for Optimizing Plasma Spraying Operating Conditions Toward Deposit Requirements, Int. J. Energy Optim. Eng., 2017, 6(4), p 16-34

R. Djebali, Optimization Study of the Operating Conditions to Improve the Quality of Surfaces Coating Obtained by Plasma Spraying Process, J. Therm. Eng., 2017, 3(4), p 1411-1418

R. Djebali et al., Scrutiny of Spray Jet and Impact Characteristics Under Dispersion Effects of Powder Injection Parameters in APS Process, Int. J. Therm. Sci., 2016, 100, p 229-239

R. Djebali, B. Pateyron, and M. El Ganaoui, A Lattice Boltzmann Based Investigation of Powder In-Flight Characteristics During APS Process, Part II. Effects of Parameter Dispersions at Powder Injection, Surf. Coat. Technol., 2013, 220, p 157-163

R. Djebali, B. Pateyron, and M. ElGanaoui, Scrutiny of Plasma Spraying Complexities with Case Study on the Optimized Conditions Toward Coating Process Control, Case Stud. Therm. Eng., 2015, 6, p 171-181

H. Zhang, S. Hu, and G. Wang, Simulation of Powder Transport in Plasma Jet via Hybrid Lattice Boltzmann Method and Probabilistic Algorithm, Surf. Coat. Technol., 2006, 201(3-4), p 886-894

Y.Z. Sun and Y.B. Dang, Numerical Simulation of Atmospheric Pressure Plasma Jet Using Lattice Boltzmann Method, AMM, 2010, 44-47, p 1838-1842

Z. Driss, B. Necib, and H.-C. Zhang, Thermo-Mechanics Applications and Engineering Technology, Springer, Cham, 2018

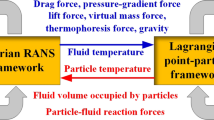

K. Bobzin et al., Macroscopic Particle Modeling in Air Plasma Spraying, Surf. Coat. Technol., 2019, 364, p 449-456

Y. Borisov, A. Bushma, and I. Krivtsun, Modeling of Motion and Heating of Powder Particles in Laser, Plasma, and Hybrid Spraying, J. Therm. Spray Technol., 2006, 15(4), p 553-558

I. Ahmed and T.L. Bergman, Three-Dimensional Simulation of Thermal Plasma Spraying of Partially Molten Ceramic Agglomerates, J. Therm. Spray Technol., 2000, 9(2), p 215-224

X. Chen et al., Heat Transfer to a Particle under Plasma Conditions with Vapor Contamination from the Particle, Plasma Chem. Plasma Process., 1985, 5(2), p 119-141

S. Dyshlovenko et al., Modelling of Plasma Particle Interactions and Coating Growth for Plasma Spraying of Hydroxyapatite, Surf. Coat. Technol., 2005, 200(12), p 3757-3769

K. Bobzin et al., Simulation of the Particle Melting Degree in Air Plasma Spraying, in Proceedings HTPP: 14th High-Tech Plasma Processes Conference, vol 89 (2017)

F. Ben Ettouil et al., Fast Modeling of Phase Changes in a Particle Injected Within a DC Plasma Jet, J. Therm. Spray Technol., 2007, 16(5-6), p 744-750

J.W. McKelliget et al., An Integrated Mathematical Model of the Plasma Spraying Process, in Thermal Spray 1998: Meeting the Challenges of the Twenty First Century, vol 15 (1998), p 335-340

D.K. Das and R. Sivakumar, Modelling of the Temperature and the Velocity of Ceramic Powder Particles in a Plasma Flame—I. Alumina, Acta Metall. Mater., 1990, 38(11), p 2187-2192

K. Saha, S. Chaudhuri, and B.M. Cetegen, Modeling of Ceramic Particle Heating and Melting in a Microwave Plasma, J. Heat Transf., 2010, 133(3), p 10

“Thermal Spray Materials Guide V2017.04,” 04.2017, https://www.oerlikon.com/metco/en/products-services/coating-materials/coating-materials-thermal-spray/. Accessed 21 Jan 2019

M. Öte, Understanding Multi-Arc Plasma Spraying, Shaker Verlag, Aachen, 2016

K. Bobzin et al., Development of Simulative Approaches for Precisely Designing the Properties of Plasma Sprayed Coatings for Application in Injection Moulding, in 3rd ECCOMAS Young Investigators Conference Proceedings, vol 3, (2015), p 6-10

K. Bobzin et al., Modelling the Plasma Jet in Multi-arc Plasma Spraying, J. Therm. Spray Technol., 2016, 25(6), p 1111-1126

K. Bobzin and M. Öte, Modeling Multi-arc Spraying Systems, J. Therm. Spray Technol., 2016, 25(5), p 920-932

K. Bobzin and M. Öte, A Numerical Investigation: Air Plasma Spraying by Means of a Three-Cathode Spraying Torch, in Thermal Spray 2015: Proceedings from the International Thermal Spray Conference (2015), p 217-222

K. Bobzin et al., A Numerical Investigation: Influence of the Operating Gas On the Flow Characteristics of a Three-Cathode Air Plasma Spraying System, in Thermal Spray 2013: Proceedings of International Thermal Spray Conference (2013), p 400-405

J.E. Bardina, P.G. Huang, and T.J. Coakley, Turbulence Modeling Validation: Testing and Development, NASA Technical Memorandum 110446 (1997)

M. Vardelle et al., Plasma–Particle Momentum and Heat Transfer: Modelling and Measurements, AlChE J., 1983, 29(2), p 236-243

S. Dyshlovenko et al., Numerical Simulation of Hydroxyapatite Powder Behaviour in Plasma Jet, Surf. Coat. Technol., 2004, 179(1), p 110-117

D.-Y. Xu, X.-C. Wu, and X. Chen, Motion and Heating of Non-spherical Particles in a Plasma Jet, Surf. Coat. Technol., 2003, 171(1-3), p 149-156

J. Mostaghimi et al., Modeling Thermal Spray Coating Processes. A Powerful Tool in Design and Optimization, Surf. Coat. Technol., 2003, 163-164, p 1-11

M.P. Planche, R. Bolot, and C. Coddet, In-Flight Characteristics of Plasma Sprayed Alumina Particles. Measurements, Modeling, and Comparison, J. Therm. Spray Technol., 2003, 12(1), p 101-111

T.K. Thiyagarajan et al., Simulation Studies to Optimize the Process of Plasma Spray Deposition of Yttrium Oxide, J. Phys. Conf. Ser., 2010, 208, p 12116

K. Bobzin and M. Öte, Numerical Coupling of the Particulate Phase to the Plasma Phase in Modeling of Multi-Arc Plasma Spraying, in Proceedings HTPP: 14th High-Tech Plasma Processes Conference (2017)

K. Bobzin and M. Öte, Modelling the Plasma–Particle Interaction in Multi-arc Plasma Spraying, J. Therm. Spray Technol., 2016, 26(3), p 279-291

K. Bobzin et al., A Numerical Parameter Study on Plasma Jet and Particle Behavior in Multi-Arc Plasma Spraying, J. Therm. Spray Technol. (JTST), 2017, 26, p 811-830

K. Bobzin et al., Numerical Study on Plasma Jet and Particle Behavior in Multi-arc Plasma Spraying, J. Therm. Spray Technol., 2017, 26(5), p 811-830

L.-Z. Zhang, Conjugate Heat and Mass Transfer in Heat Mass Exchanger Ducts, Elsevier Academic Press, Amsterdam, 2014

T.L. Perelman, On Conjugated Problems of Heat Transfer, Int. J. Heat Mass Transf., 1961, 3(4), p 293-303

A. Burcat and B. Ruscic, Third Millennium Ideal Gas and Condensed Phase Thermochemical Database for Combustion with Updates from Active Thermochemical Tables, Argonne National Laboratory, Lemont, 2005

Acknowledgments

This work was supported by the German Research Foundation (DFG) conducted in the context of the Collaborative Research Centre SFB1120 “Precision Melt Engineering” at RWTH Aachen University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bobzin, K., Öte, M., Knoch, M.A. et al. Macroscopic Modeling of an Agglomerated and Sintered Particle in Air Plasma Spraying. J Therm Spray Tech 29, 13–24 (2020). https://doi.org/10.1007/s11666-019-00964-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00964-z