Abstract

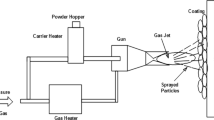

Nickel-based coatings deposited by high-velocity flame spray (HVFS) process have been widely used to overcome the slurry erosion in a hydro turbine, where many turbine components are subjected to severe erosion failure. In this work, new kind of multi-dimensional Ni-40TiO2 and Ni-20TiO2-20Al2O3 coatings consisting of nanostructured and micron-sized particles of TiO2 and Al2O3 were developed by HVFS process on CA6NM(13Cr4Ni) turbine steel. The in-depth characterization of the synthesized nanostructured powders, prepared coating compositions and the deposited coating was done through dynamic light scattering, scanning electron microscopy, energy-dispersive spectroscopy and x-ray diffraction techniques. The mechanical and microstructural properties of the as-sprayed specimens were evaluated and discussed in this paper. The results showed that the multi-dimensional Ni-40TiO2 coating possessed lower porosity (0.8-2.0%), higher avg. microhardness (605 ± 37 HV0.1), and better bond strength (66.4 MPa) than the Ni-20TiO2-20Al2O3 coating.

Similar content being viewed by others

References

V. Sharma, M. Kaur, and S. Bhandari, Slurry Jet Erosion Performance of High-Velocity Flame-Sprayed Nano Mixed Ni-40Al2O3 Coating in Aggressive Environment, Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2019, https://doi.org/10.1177/1350650118822426

M.K. Padhy and R.P. Saini, Effect of Size and Concentration of Silt Particles on Erosion of Pelton Turbine Buckets, Energy, 2009, 34(10), p 1477-1483. https://doi.org/10.1016/j.energy.2009.06.015

M.K. Padhy and R.P. Saini, A Review on Silt Erosion in Hydro Turbines, Renew. Sustain. Energy Rev., 2008, 12(7), p 1974-1987

V. Sharma, M. Kaur, and S. Bhandari, Slurry Erosion Performance Study of High Velocity Flame Sprayed Ni-Al2O3 Coating Under Hydro Accelerated Conditions, Mater. Res. Express, 2019, 2019(6), p 1-17. https://doi.org/10.1088/2053-1591/ab1927

H.S. Grewal, A. Agrawal, H. Singh, and B.A. Shollock, Slurry Erosion Performance of Ni-Al2O3 based Thermal-Sprayed Coatings: Effect of Angle of Impingement, J. Therm. Spray Technol., 2014, 23(3), p 389-401

H.S. Grewal, H. Singh, and A. Agrawal, Microstructural and Mechanical Characterization of Thermal Sprayed Nickel-Alumina Composite Coatings, Surf. Coat. Technol., 2013, 216, p 78-92. https://doi.org/10.1016/j.surfcoat.2012.11.029

R. Kumar, S. Bhandari, and A. Goyal, Slurry Erosion Performance of High-Velocity Flame-Sprayed Ni-20Al2O3 and Ni-10Al2O3-10TiO2 Coatings Under Accelerated Conditions, J. Therm. Spray Technol., 2017, 26(6), p 1279-1291

B.E. Naveena, R. Keshavamurthy, and N. Sekhar, Slurry Erosive Wear Behaviour of Plasma-Sprayed Flyash–Al2O3 Coatings, Surf. Eng., 2017, 33(12), p 925-935

R. Kumar, S. Bhandari, and A. Goyal, Synergistic Effect of Al2O3/TiO2 Reinforcements on Slurry Erosion Performance of Nickel-Based Composite Coatings, Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2017, https://doi.org/10.1177/1350650117736487

D. Wang, Z. Tian, S. Wang, L. Shen, and Y. Huang, Solid Particle Erosion Behaviour of Plasma-Sprayed Conventional and Nanostructured Al2O3-13 wt% TiO2 Ceramic Coatings, Trans. Indian Ceram. Soc., 2015, 74(2), p 90-96. https://doi.org/10.1080/0371750X.2015.1036169

M. Benegra, M. Magnani, H. Goldenstein, O. Maranho, and G. Pintaude, Abrasion and Corrosion Resistance of New Ni-Based Coating Deposited by HVOF Thermal Spray Process, Surf. Eng., 2010, 26(6), p 463-468. https://doi.org/10.1179/026708410X12550773058144

B. Thiyagarajan and V. Senthilkumar, Experimental Studies on Fly-Ash Erosion Behavior of Ni-Cr Based Nanostructured Thermal Spray Coating in Boiler Tubes, Mater. Manuf. Process., 2017, 32(11), p 1209-1217. https://doi.org/10.1080/10426914.2016.1257798

C. Suryanarayana, Mechanical Alloying and Milling, Prog. Mater. Sci., 2001, 46(1–2), p 1-184. https://doi.org/10.1016/s0079-6425(99)00010-9

W. Chen, Y. He, and W. Gao, Electrodeposition of Sol-Enhanced Nanostructured Ni-TiO2 Composite Coatings, Surf. Coat. Tech., 2010, 204(15), p 2487-2492. https://doi.org/10.1016/j.surfcoat.2010.01.036

S. Lajevardi and T. Shahrabi, Effects of Pulse Electrodeposition Parameters on the Properties of Ni-TiO2 Nanocomposite Coatings, Appl. Surf. Sci., 2010, 256(22), p 6775-6781. https://doi.org/10.1016/j.apsusc.2010.04.088

G. Parida, D. Chaira, M. Chopkar, and A. Basu, Synthesis and Characterization of Ni-TiO2 composite Coatings by Electro-Co-Deposition, Surf. Coat. Technol., 2011, 205(21–22), p 4871-4879. https://doi.org/10.1016/j.surfcoat.2011.04.102

M.L. Benea and L.P. Benea, Characterization of the WC Coatings Deposited by Plasma Spraying, IOP Conf. Ser. Mater. Sci. Eng., 2015, 85(1), p 012004

G.E. Kim, J. Falzon, J. Walker, F. Michael, and P. Nikki, Use of Nano-Particle Titanium Dioxide (n-TiO2) Thermal Spray Coatings for Abrasion Resistance in Severe Service Applications, in International Titanium Association, 2010.

Y. Yang, D. Yan, Y. Dong, X. Chen, L. Wang, Z. Chu, J. Zhang, and J. He, Preparing of Nanostructured Al2O3-TiO2-ZrO2 composite Powders and Plasma Spraying Nanostructured Composite Coating, Vacuum, 2013, 96, p 39-45. https://doi.org/10.1016/j.vacuum.2013.03.010

D. Thibault, P. Bocher, M. Thomas, J. Lanteigne, P. Hovington, and P. Robichaud, Reformed Austenite Transformation during Fatigue Crack Propagation of 13%Cr-4%Ni Stainless Steel, Mater. Sci. Eng. A, 2011, 528(21), p 6519-6526. https://doi.org/10.1016/j.msea.2011.04.089

L.A. Espitia, L. Varela, C.E. Pinedo, and A.P. Tschiptschin, Cavitation Erosion Resistance of Low Temperature Plasma Nitrided Martensitic Stainless Steel, Wear, 2013, 301(1–2), p 449-456. https://doi.org/10.1016/j.wear.2012.12.029

E. Furlani, E. Aneggi, C. de Leitenburg, and S. Maschio, High Energy Ball Milling of Titania and Titania-Ceria Powder Mixtures, Powder Technol., 2014, 254, p 591-596. https://doi.org/10.1016/j.powtec.2014.01.075

X. Chen and S.S. Mao, Titanium Dioxide Nanomaterials: Synthesis, Properties, Modifications and Applications, Chem. Rev., 2007, 107(7), p 2891-2959

M.R. Ranade, A. Navrotsky, H.Z. Zhang, J.F. Banfield, S.H. Elder, A. Zaban, P.H. Borse, S.K. Kulkarni, G.S. Doran, and H.J. Whitfield, Energetics of Nanocrystalline TiO2, Proc. Natl. Acad. Sci. USA, 2002, 99(2), p 6476-6481. https://doi.org/10.1073/pnas.251534898

A.K. Zak, W.H.A. Majid, M.E. Abrishami, and R. Yousefi, X-Ray Analysis of ZnO Nanoparticles by Williamson-Hall and Size-Strain Plot Methods, Solid State Sci., 2011, 13(1), p 251-256

R. Tomaszek, L. Pawlowski, J. Zdanowski, J. Grimblot, and J. Laureyns, Microstructural Transformations of TiO2, Al2O3 + 13TiO2 and Al2O3 + 40TiO2 at Plasma Spraying and Laser Engraving, Surf. Coat. Technol., 2004, 185(2–3), p 137-149. https://doi.org/10.1016/j.surfcoat.2004.01.010

P. Baghery, M. Farzam, A.B. Mousavi, and M. Hosseini, Ni-TiO2 Nanocomposite Coating with High Resistance to Corrosion and Wear, Surf. Coat. Technol., 2010, 204(23), p 3804-3810. https://doi.org/10.1016/j.surfcoat.2010.04.061

J.J. Hao, Y.A. Bai, C.R. Wang, and X.Y. Liu, Fabrication and Characterization of Ni-TiO < Sub > 2</Sub > Nanocomposite Coatings and Their Corrosion Resistance Behaviors, Mater. Sci. Forum, 2011, 688, p 217-222. https://doi.org/10.4028/www.scientific.net/MSF.688.217

S. Singh and M. Kaur, Mechanical and Microstructural Properties of NiCrFeSiBC/Cr3C2 Composite Coatings—Part I, Surf. Eng., 2014, 32, p 1-11

C.R.C. Lima and J.M. Guilemany, Adhesion Improvements of Thermal Barrier Coatings with HVOF Thermally Sprayed Bond Coats, Surf. Coat. Technol., 2007, 201(8), p 4694-4701

G. Sundararajan and P.G. Shewmon, A New Model for the Erosion of Metals at Normal Incidence, Wear, 1983, 84(2), p 237-258. https://doi.org/10.1016/0043-1648(83)90266-1

Acknowledgment

The authors thankfully acknowledge all the essential research facilities required for the completion of this project provided by Indian Institute of Technology Ropar, India, and Indian Institute of Technology, Roorkee. The authors would like to express sincere thanks to IKG, Punjab Technical University, Punjab, India, for supporting this research work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharma, V., Kaur, M. & Bhandari, S. Development and Characterization of High-Velocity Flame Sprayed Ni/TiO2/Al2O3 Coatings on Hydro Turbine Steel. J Therm Spray Tech 28, 1379–1401 (2019). https://doi.org/10.1007/s11666-019-00918-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00918-5