Abstract

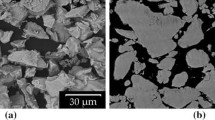

Fatigue crack growth in self-standing plasma-sprayed tungsten and molybdenum beams with artificially introduced notches subjected to pure bending was studied. Fatigue crack length was measured using the differential compliance method, and fatigue crack growth rate was established as a function of stress intensity factor. Crack opening under compressive stress was detected. Fractographic analysis revealed the respective crack formation mechanisms. At low crack propagation rates, the fatigue crack growth takes place by intergranular splat fracture accompanied by splat decohesion in Mo coating, eventually by void interconnection in W coating. Frequently, the crack deflected from the notch plane being attracted to stress concentrators formed by voids or favorably oriented splat interfaces. At higher values of the stress intensity factor, the intergranular cracking of splats becomes more common and the crack propagated more perpendicularly to the specimen surface.

Similar content being viewed by others

References

J.G. La Barbera-Sosa, Y.Y. Santana, C. Villalobos-Gutiérrez, S. Cabello-Sequera, M.H. Staia, and E.S. Puchi-Cabrera, Effect of Spray Distance on the Corrosion-Fatigue Behavior of a Medium-Carbon Steel Coated with a Colmonoy 88 Alloy Deposited by HVOF Thermal Spray, Surf. Coat. Technol., 2010, 205(4), p 1137-1144. https://doi.org/10.1016/j.surfcoat.2010.01.038

A. Vackel and S. Sampath, Fatigue Behavior of Thermal Sprayed WC-CoCr-Steel Systems: Role of Process and Deposition Parameters, Surf. Coat. Technol., 2017, 315, p 408-416. https://doi.org/10.1016/j.surfcoat.2017.02.062

O. Kovářík, J. Siegl, J. Nohava, and P. Chráska, Young’s Modulus and Fatigue Behavior of Plasma-Sprayed Alumina Coatings, J. Therm. Spray Technol., 2005, 14(2), p 231-238. https://doi.org/10.1361/105996304523809

O. Kovářík, J. Siegl, and Z. Procházka, Fatigue Behavior of Bodies with Thermally Sprayed Metallic and Ceramic Deposits, J. Therm. Spray Technol., 2008, 17(4), p 525-532. https://doi.org/10.1007/s11666-008-9205-1

R. Musalek, O. Kovarik, L. Tomek, J. Medricky, Z. Pala, P. Hausild, J. Capek, K. Kolarik, N. Curry, and S. Bjorklund, Fatigue Performance of TBCs on Hastelloy X Substrate During Cyclic Bending, J. Therm. Spray Technol., 2016, 25(1-2), p 231-243. https://doi.org/10.1007/s11666-015-0321-4

J. Cizek, O. Kovarik, J. Siegl, K.A. Khor, and I. Dlouhy, Influence of Plasma and Cold Spray Deposited Ti Layers on High-Cycle Fatigue Properties of Ti6Al4V Substrates, Surf. Coat. Technol., 2013, 217, p 23-33. https://doi.org/10.1016/j.surfcoat.2012.11.067

O. Kovářík, P. Haušild, J. Medřický, L. Tomek, J. Siegl, R. Mušálek, N. Curry, and S. Björklund, Fatigue Crack Growth in Bodies with Thermally Sprayed Coating, J. Therm. Spray Technol., 2016, 25(1-2), p 311-320. https://doi.org/10.1007/s11666-015-0329-9

O. Kovářík, P. Haušild, J. Siegl, Z. Pala, J. Matějíček, and V. Davydov, The Influence of Plasma Sprayed Multilayers of Cr2O3 and Ni10wt%Al on Fatigue Resistance, Surf. Coat. Technol., 2014, 251, p 143-150. https://doi.org/10.1016/j.surfcoat.2014.04.018

F. Kroupa and J. Plesek, Nonlinear Elastic Behavior in Compression of Thermally Sprayed Materials, Mater. Sci. Eng. A, 2002, 328(1-2), p 1-7. https://doi.org/10.1016/S0921-5093(01)01653-7

R. Musalek, J. Matejicek, M. Vilemova, and O. Kovarik, Non-Linear Mechanical Behavior of Plasma Sprayed Alumina Under Mechanical and Thermal Loading, J. Therm. Spray Technol., 2010, 19(1-2), p 422-428. https://doi.org/10.1007/s11666-009-9362-x

P. Cavaliere, A. Silvello, N. Cinca, H. Canales, S. Dosta, I. Garcia Cano, and J.M. Guilemany, Microstructural and Fatigue Behavior of Cold Sprayed Ni-Based Superalloys Coatings, Surf. Coat. Technol., 2017, 324, p 390-402. https://doi.org/10.1016/j.surfcoat.2017.06.006

P. Cavaliere, A. Perrone, and A. Silvello, Fatigue Behaviour of Inconel 625 Cold Spray Coatings, Surf. Eng., 2018, 34(5), p 380-391. https://doi.org/10.1080/02670844.2017.1371872

O. Kovářík, P. Haušild, J. Čapek, J. Medřický, J. Siegl, R. Mušálek, Z. Pala, N. Curry, and S. Björklund, Resonance Bending Fatigue Testing with Simultaneous Damping Measurement and Its Application on Layered Coatings, Int. J. Fatigue, 2016, 82, p 300-309. https://doi.org/10.1016/j.ijfatigue.2015.07.026

C. Benz, Fatigue Crack Growth at Negative Stress Ratios: On the Uncertainty of Using Δ K and R to Define the Cyclic Crack Tip Load, Eng. Fract. Mech., 2018, 189, p 194-203. https://doi.org/10.1016/j.engfracmech.2017.11.001

J. Zhang, X.D. He, B. Suo, and S.Y. Du, Elastic–plastic Finite Element Analysis of the Effect of Compressive Loading on Crack Tip Parameters and Its Impact on Fatigue Crack Propagation Rate, Eng. Fract. Mech., 2008, 75(18), p 5217-5228. https://doi.org/10.1016/j.engfracmech.2008.08.006

M. Yu, T. Topper, D. Duquesnay, and M. Levin, The Effect of Compressive Peak Stress on Fatigue Behaviour, Int. J. Fatigue, 1986, 8(1), p 9-15. https://doi.org/10.1016/0142-1123(86)90041-1

C. Benz and M. Sander, Reconsiderations of Fatigue Crack Growth at Negative Stress Ratios: Finite Element Analyses, Eng. Fract. Mech., 2015, 145, p 98-114. https://doi.org/10.1016/j.engfracmech.2015.07.022

T.G. Chondros, A.D. Dimarogonas, and J. Yao, A Continuous Cracked Beam Vibration Theory, J. Sound Vib., 1998, 215(1), p 17-34. https://doi.org/10.1006/jsvi.1998.1640

V.P. Golub, V.P. Butseroga, and A.D. Pogrebnyak, Study of the Kinetics of Fatigue Cracks by the Method of Differential Compliance, Int. Appl. Mech., 1995, 31(12), p 1018-1025. https://doi.org/10.1007/BF00847262

O. Kovarik, A. Janca, and J. Siegl, Fatigue Crack Growth Rate in Miniature Specimens Using Resonance, Int. J. Fatigue, 2017, 102, p 252-260. https://doi.org/10.1016/j.ijfatigue.2017.02.015

O. Kovářík, P. Haušild, J. Siegl, T. Chráska, J. Matějíček, Z. Pala, and M. Boulos, The Influence of Substrate Temperature on Properties of APS and VPS W Coatings, Surf. Coat. Technol., 2015, 268, p 7-14. https://doi.org/10.1016/j.surfcoat.2014.07.041

K. Geels, “Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing,” (West Conshohocken, PA), ASTM International, 2007, https://doi.org/10.1520/mnl46-eb

M. Tenenbaum and H. Pollard, Ordinary Differential Equations: An Elementary Textbook for Students of Mathematics, Engineering, and the Sciences, Dover Publications, New York, 1985

J. Cizek, T. Chraska, O. Kovarik, J. Siegl, and J. Kondas, “Fatigue Crack Propagation in Cold Sprayed Metallic Coatings,” ITSC 2018—Proceedings of the International Thermal Spray Conference, F. Azarmi, K. Balani, T. Eden, T. Hussain, Y.-C. Lau, H. Li, K. Shinoda, F.-L. Toma, and J. Veilleux, Eds., (Orlando, FL, USA), ASM International, 2018

Acknowledgments

This study was supported by the Czech Science Foundation Grant Project GAČR 14-36566G.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2018 International Thermal Spray Conference, held May 7-10, 2018, in Orlando, Florida, USA, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Kovarik, O., Materna, A., Siegl, J. et al. Fatigue Crack Growth in Plasma-Sprayed Refractory Materials. J Therm Spray Tech 28, 87–97 (2019). https://doi.org/10.1007/s11666-018-0790-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0790-3