Abstract

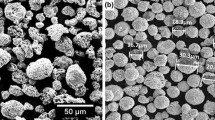

The cavitation wear process is one of the major wear mechanisms in turbines and rotors of hydroelectric power plants in Brazil. An effective way to increase the cavitation resistance is the use of coatings, applied by thermal spraying. The high-velocity oxy-fuel process (HVOF) is one of the most used thermal spraying processes, and it is widely adopted for applying coatings for protection against wear and in maintenance components. A FeCrMnSiB experimental alloy was deposited onto SAE 1020 substrate by HVOF process, in order to evaluate the influence of the powder particle size range on the morphology and cavitation resistance of the coatings. The morphology of the coatings showed an increase in oxide content with powder size reduction. The increase in the powder particle size reduced the wettability of the particles, observed by the increase in the quantity of non-melted particles. Higher particle size distribution led to an increase in erosion rate, due to higher presence of non-melted particles in the coatings and consequently reduction of splats adhesion. The cavitation damage was perceived mainly by the mechanism of lamellae detachment; however, part of the damage was also absorbed by strain hardening due to the γ-ε martensitic transformation.

Similar content being viewed by others

References

C.M. Hansson and L.H. Hansson, Cavitation Erosion, ASM Handbook, 1992, 18, p 214-220

P.V. Marques and C.R.C. Lima, Studies of Cavitation Resistant Thermal Sprayed and Welded Coatings, in Thermal Spray 2003: Advancing the Science and Applying the Technology, 2003, 1, p 389-393

J.H. Kim and M.H. Lee, A Study on Cavitation Erosion and Corrosion Behavior of Al-, Zn-, Cu-, and Fe-Based Coatings Prepared by Arc Spraying, J. Therm. Spray Technol., 2010, 19, p 1224-1230

W. Yuping, L. Pinghua, C. Chenglin, W. Zehua, C. Ming, and H. Junhua, Cavitation Erosion Characteristics of a Fe-Cr-Si-B-Mn Coating Fabricated by HVOF Thermal Spray, Mater. Lett., 2007, 61, p 1867-1872

L.A. Espitia and A. Toro, Cavitation Resistance, Microstructure and Surface Topography of Materials Used for Hydraulic Components, Tribol. Int., 2010, 43, p 2037-2045

J.P. Tullis and B.P. Tullis, Hydraulics of PIPE Systems, in The CRC handbook of mechanical engineering, 2005

X. Escaler, E. Egusquiza, M. Farhat, F. Avellan, and M. Coussirat, Detection of Cavitation in Hydraulic Turbines, Mech. Syst. Signal Process., 2006, 20, p 983-1007

R.L.P. Simoneau, Cavitation Erosion and Deformation Mechanism of Ni and Co Austenitic Stainless Steel, in Proceedings of 7th Conference on Erosion by Liquid and Solid Impact, 1987

Z. Wang and J. Zhu, Effect of Phase Transformation on Cavitation Erosion Resistance of Some Ferrous Alloys, Mater. Sci. Eng. A, 2003, 358(1-2), p 273-278

S. Martin, C. Ullrich, D. Simek, U. Martin, and D. Rafaja, Stacking Fault Model of ε-Martensite and Its DIFFaX Implementation, J. Appl. Crystallogr., 2011, 44(4), p 779-787

F. Lecroisey and A. Pineau, Martensitic Transformations Induced by Plastic Deformation in the Fe-Ni-Cr-C System, Metall. Mater. Trans., 1972, 3, p 391-400

W.S. Lee and C.F. Lin, Impact Properties and Microstructure Evolution of 304L Stainless Steel, Mater. Sci. Eng. A, 2001, 308(1-2), p 124-135

S. Allain, J.P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C alloys, Mater. Sci. Eng. A, 2004, 387-389, p 158-162

D.A. Woodford, Cavitation-Erosion-Induced Phase Transformations in Alloys, Metall. Mater. Trans., 1972, 3(5), p 1137-1145

M. Park, K. Kim, G. Shin, J. Yun, M. Shin, and S. Kim, Effects of Ni and Mn on the Cavitation Erosion Resistance of Fe-Cr-C-Ni/Mn Austenitic Alloys, Tribol. Lett., 2013, 52(3), p 477-484

J.Y. Yun, G.S. Shin, M.C. Park, H.S. Lee and W.S. Kang, Effect of Strain-Induced ε and α′-Martensitic Transformation on Cavitation Erosion Resistance in Austenitic Fe-Cr-C-MnFe-Cr-C-Mnti Alloys, Wear, 2015, 338-339, p 379-384

F.T. Cheng, K.H. Lo, and H.C. Man, NiTi Cladding on Stainless Steel by TIG Surfacing Process Part I. Cavitation Erosion Behavior, Surf. Coat. Technol., 2003, 172, p 308-315

K. Jafarzadeh, Z. Valefi, and B. Ghavidel, The Effect of Plasma Spray Parameters on the Cavitation Erosion of Al2O3-TiO2 coatings, Surf. Coat. Technol., 2010, 205, p 1850-1855

R.K. Kumar, M. Kamaraj, S. Seetharamu, T. Pramod, and P. Sampathkumaran, Effect of Spray Particle Velocity on Cavitation Erosion Resistance Characteristics of HVOF and HVAF Processed 86WC-10Co4Cr Hydro Turbine Coatings, J. Therm. Spray Technol., 2016, 25(6), p 1217-1230

Z. Wang, X. Zhang, J. Cheng, J. Lin, and Z. Zhou, Cavitation Erosion Resistance of Fe-Based Amorphous/Nanocrystal Coatings Prepared by High-Velocity Arc Spraying, J. Therm. Spray Technol., 2013, 23, p 742-749

A.G.M. Pukasiewicz, P.R.C. Alcover, Jr., A.R. Capra, and R.S.C. Paredes, Influence of Plasma Remelting on the Microstructure and Cavitation Resistance of Arc-Sprayed Fe-Mn-Cr-Si Alloy, J. Therm. Spray Technol., 2013, 23, p 51-59

B. Kushner and E. Novinski, Thermal Spray Coatings, ASM Handbook Vol. 18: Friction, lubrication and wear technology, P.J. Blau, Ed., ASM International, Materials Park, 1992

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, Wiley, London, 1995

R. Kromer, J. Cormier, and S. Costil, Role of Powder Granulometry and Substrate Topography in Adhesion Strength of Thermal Spray Coatings, J. Therm. Spray Technol., 2016, 25, p 933-945

M. Li and P.D. Christofides, Feedback Control of HVOF Thermal Spray Process Accounting for Powder Size Distribution, J. Therm. Spray Technol., 2004, 13(1), p 108-120

K. Bobzin, M. Öte, T.F. Linke, and K.M. Malik, Wear and Corrosion Resistance of Fe-Based Coatings Reinforced by TiC Particles for Application in Hydraulic Systems, J. Therm. Spray Technol., 2015, 25, p 365-374

Y. Qin, Y. Wu, J. Zhang, S. Hong, W. Guo, L. Chen, and H. Liu, Optimization of the HVOF Spray Parameters by Taguchi Method for High Corrosion-Resistant Fe-Based Coatings, J. Mater. Eng. Perform., 2015, 24, p 2637-2644

G. Taillon, F. Pougoum, S. Lavigne, L. Ton-That, R. Schulz, E. Bousser, S. Savoie, L. Martinu, and J.-E. Klemberg-Sapieha, Cavitation Erosion Mechanisms in Stainless Steels and in Composite Metal–Ceramic HVOF Coatings, Wear, 2016, 364-365, p 201-210

T. Varis, T. Suhonen, A. Ghabchi, A. Valarezo, S. Sampath, X. Liu, and S.-P. Hannula, Formation Mechanisms, Structure, and Properties of HVOF-Sprayed WC-CoCr Coatings: An Approach Toward Process Maps, J. Therm. Spray Technol., 2014, 23, p 1009-1018

T.C. Hanson and G.S. Settles, Particle Temperature and Velocity Effects on the Porosity and Oxidation of an HVOF Corrosion-Control Coating, J. Therm. Spray Technol., 2002, 12, p 403-415

M. Gaona, R.S. Lima, and B.R. Marple, Influence of Particle Temperature and Velocity on the Microstructure and Mechanical Behavior of High Velocity Oxy-Fuel (HVOF)-Sprayed Nanostructured Titania Coatings, J. Mater. Process. Technol., 2008, 198, p 426-435

D. Poirier, J.-G. Legoux, and R.S. Lima, Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties, and High Temperature Wear Performance, J. Therm. Spray Technol., 2012, 22, p 280-289

B. Rajasekaran, G. Mauer, R. Vassen, A. Röttger, S. Weber, and W. Theisen, Coating of High-Alloyed, Ledeburitic Cold Work Tool Steel Applied by HVOF Spraying, J. Therm. Spray Technol., 2009, 19, p 642-649

A. Röttger, S.L. Weber, W. Theisen, B. Rajasekaran, and R. Vaßen, High Velocity Oxy Fuel Spraying of Cold Work Tool Steels—A Novel Approach to Thick Coatings for Wear Protection Applications, Adv. Eng. Mater., 2009, 11(12), p 1015-1022

L. Ajdelsztajn, J. Dannenberg, J. Lopez, N. Yang, J. Farmer, and E.J. Lavernia, High-Velocity Oxygen Fuel Thermal Spray of Fe-Based Amorphous Alloy: A Numerical and Experimental Study, Metall. Mater. Trans. A, 2009, 40A, p 2231-2240

G.B. Sucharski, A.G.M. Pukasiewicz, R.F. Váz, and R.S.C. Paredes, Optimization of the Deposition Parameters of HVOF FeMnCrSi+Ni+B Thermally Sprayed Coatings, Soldag. Insp., 2015, 20(2), p 238-252

M. Tanaka and C.S. Choi, Trans. ISIJ, 1972, 12, p 16-18

D.-S. Leem, Y.-D. Lee, J.-H. Jun, and C.-S. Choi, Amount of Retained Austenite at Room Temperature After Reverse Transformation of Martensite to Austenite in an Fe-13%Cr-7%Ni-3%Si Martensitic Stainless Steel, Scr. Mater., 2001, 45, p 767-772

I.M. Zylla, Gefügeoptimierung von metastabilen austenitischen Cr-Mn-Stählen zur Erhöhung der Kavitationsbeständigkeit durch verformungsinduzierte martensitische Umwandlung. Dissertation/PhD Thesis, 1991, VDI-Verlag GmbH.

I. Astm, ASTM E2109-2014, Standard Test Methods for Determining Area Percentage Porosity in Thermal Sprayed Coatings, 2014

I. Astm, ASTM E384-11, Standard Test Method for Knoop and Vickers Hardness of Materials, 2011

A.G. Evans and T.R. Wilshaw, Quasi-Static Solid Particle Damage in Brittle Solid. I. Observations Analysis and Implications, Acta Metall., 1976, 24, p 939-956

T. Varis, T. Suhonen, A. Ghabchi, A. Valarezo, S. Sampath, X. Liu, and S.P. Hannula, Formation Mechanisms, Structure, and Properties of HVOF-Sprayed WC-CoCr Coatings: An Approach Toward Process Maps, J. Therm. Spray Technol, 2014, 23(6), p 1009-1018

I. Astm, ASTM G32-03, Standard Test Method for Cavitation Erosion Using Vibratory Apparatus, 2003

A. Zambon, B. Badani, K. Eckler, F. Gärtner, A.F. Norman, A.L. Greer, D.M. Herlach, and E. Ramous, Microstructure and Phase Selection in Containerless Processing of Fe-Ni Droplets, Acta Mater., 1998, 46(13), p 4657-4670

D. Dunne, Shape Memory in Ferrous Alloys. In: E. Pereloma, D. Edmonds. Phase Transformations in Steel, Vol. 2: Diffusionless Transformations, High Strength Steels, Modeling and Advanced Analytical Techniques. Woodhead Publishing, 2012, p 83-125

M.H. Amushahi, F. Ashrafizadeh and F.M. Shamanian, Characterization of Boride-Rich Hardfacing on Carbon Steel by Arc Spray and GMAW Processes, Surf. Coat. Technol., 2010, 204(16-17), p 2723-2728

V.V. Sobolev and J.M. Guilemany, Investigation of Coating Porosity Formation During High Velocity Oxy-Fuel (HVOF) Spraying, Mater. Lett., 1994, 18(5-6), p 304-308

M.P. Planche, H. Liao, B. Normand, and C. Coddet, Relationships Between NiCrBSi Particle Characteristics and Corresponding Coating Properties Using Different Thermal Spraying Processes, Surf. Coat. Technol., 2005, 200(7), p 2465-2473

M. Oksa and J. Metsäjoki, Optimizing NiCr and FeCr HVOF Coating Structures for High Temperature Corrosion Protection Applications, J. Therm. Spray Technol., 2015, 24(3), p 436-453

C.-J. Li and Y.-Y. Wang, Effect of Particle State on the Adhesive Strength of HVOF Sprayed Metallic Coating, J. Therm. Spray Technol., 2002, 11(4), p 523-529

M.C. Morris, H.F. McMurdie, E.H. Evans, B. Paretzkin, H.S. Parker, and N.C. Panagiotopoulos, Standard X-ray Diffraction Powder Patterns Section 18: Data for 58 Substances, Nat Bureau Stand. (U.S.) Monogr., 1981, 25(18), p 37

S. Kuroda, Y. Tashiro, H. Yumoto, S. Taira, H. Fukanuma, and S. Tobe, Peening Action and Residual Stresses in High-Velocity Oxygen Fuel Thermal Spraying of 316L Stainless Steel, J. Therm. Spray Technol., 2001, 10(2), p 642-649

Acknowledgments

The authors thank the Federal University of Technology Paraná, Ponta Grossa, Brazil (UTFPR-PG), the Thermal Spray and Special Welding Laboratory from Federal University of Paraná, Curitiba, Brazil (LABATS - UFPR), and the Institutos LACTEC, Curitiba, Brazil, for the availability of research structure. The Clausthal University of Technology, Germany, for the atomization of powder for this research. The Revesteel Metallization Company, Brazil, for the HVOF deposition. The Copel Geração e Transmissão S/A, for funding the research Project ANEEL PD-6491-0023/2010. The Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES) for the provision of the scholarship, which assisted in the development of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Silveira, L.L., Sucharski, G.B., Pukasiewicz, A.G.M. et al. Influence of Particle Size Distribution on the Morphology and Cavitation Resistance of High-Velocity Oxygen Fuel Coatings. J Therm Spray Tech 27, 695–709 (2018). https://doi.org/10.1007/s11666-018-0708-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0708-0