Abstract

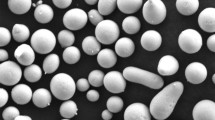

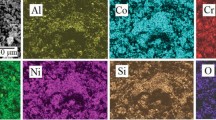

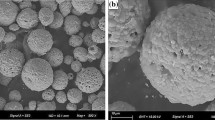

Surface remelting is an important technique for modifying the microstructure of thermally sprayed coatings as it reduces the porosity and promotes a metallurgical bond between substrate and coating. Many studies have been carried out in the field of materials selection and surface engineering in an attempt to reduce cavitation damage. In this work, an Fe-Mn-Cr-Si alloy was deposited by arc spraying and then remelted by a plasma-transferred arc process. The base metal was a soft martensitic stainless steel. The influence of remelting current on coating and base metal microstructure and cavitation resistance was studied. The use of a lower mean current and a pulsed arc reduced the thickness of the heat-affected zone. In specimens remelted with constant arc current, dendrites were aligned parallel to the path followed by the plasma torch; while in those remelted with a pulsed plasma arc, the alignment of the microstructure was disrupted. The use of a higher peak current in pulsed-current plasma transferred arc remelting reduced mass loss due to cavitation. Fe-Mn-Cr-Si coatings exhibited cavitation-induced hardening, with martensite formation during cavitation tests. This transformation helps to increase the cavitation resistance of the remelted coating compared with the soft martensitic stainless steel base metal.

Similar content being viewed by others

References

L.L. Sheir, R.A. Jarman, and G.T. Burstein, Corrosion: Metal/Environment Reactions vol. 1, 3rd ed., Butterworth Heinemann, Oxford, 1994

P. March, J. Hubble, Jerry: Evaluation of Relative Cavitation Erosion Rates For Base Materials, Weld Overlays, and Coatings. Report No. WR28-1-900-282, Tennessee Valley Authority Engineering Laboratory, Norris, TN, 1996

R.L.P. Simoneau, Cavitation Erosion and Deformation Mechanism of Ni and Co Austenitic Stainless Steel, Proceedings of 7th Conference on Erosion by Liquid and Solid Impact, Cambridge, England, 1987

Z. Wang and J. Zhu, Effect of Phase Transformation on Cavitation Erosion Resistance of Some Ferrous Alloys, Mater. Sci. Eng. A, 2003, 358(1-2), p 273-278

Y. Arai, M. Hikuchi, T. Wtanabe, and M. Nakagaki, Residual Stress Due to Welding and Its Effect on the Assessment of Cracks Near the Weld Interface, Int. J. Press. Vessel Pip., 1995, 63(3), p 237-248

C.T. Kwok, F.T. Cheng, and H.C. Man, Laser Surface Modification of UNS S31603 Stainless Steel Using NiCrSiB Alloy for Enhancing Cavitation Erosion Resistance, Surf. Coat. Technol., 1998, 107(1), p 31-40

B.G. Gireń, M. Szkodo, and J. Steller, Cavitation Erosion of Some Laser Produced Iron Base Corrosion Resistant Alloys, Wear, 2005, 258(1-4), p 614-622

C.T. Kwok, H.C. Man, and F.T. Cheng, Cavitation Erosion-Corrosion Behaviour of Laser Surface Alloyed AISI, 1050 Mild Steel Using NiCrSiB, Mater. Sci. Eng. A, 2001, 303(1-2), p 250-261

S. Kou, Welding Metallurgy, 2nd ed., Wiley, Hoboken, 2003

K. Sivaprasada, S. Ganesh Sundara Ramana, P. Mastanaiah, and G. Madhusudhan Reddy, Influence of Magnetic Arc Oscillation and Current Pulsing on Microstructure and High Temperature Tensile Strength of Alloy 718 TIG Weldments, Mater. Sci. Eng. A, 2006, 428(2), p 327-331

R. Santos, R.S.C. Paredes, and A.S.C.M. D′Oliveira, Pulsed Current Plasma Transferred Arc Hardfacing, J. Mater. Process. Technol., 2006, 171(2), p 167-174

N. Bergeon, G. Guenin, and C. Esnouf, Characterization of the Stress-Induced o Martensite in a Fe-Mn-Si-Cr-Ni Shape Memory Alloy: Microstructural Observation at Different Scales, Mechanism of Formation and Growth, Mater. Sci. Eng. A, 1997, 238(2), p 309-316

H. Otsuka, H. Yamada, T. Maruyama, H. Tanahashi, S. Matsuda, and M. Murakami, Effects of Alloying Additions on Fe-Mn-Si Shape Memory Alloys, J. Iron Steel Inst. Jpn. Int., 1990, 8(30), p 674-679

S. Sundaresan, G.D. Janaki Ram, and G. Madhusudhan Reddy, Microstructural Refinement of Weld Fusion Zones in α-β Titanium Alloys Using Pulsed Current Welding, Mater. Sci. Eng. A, 1999, 262(1-2), p 88-100

S. L. Henke, Effect of Pulsed Plasma Welding on Microstructure and Fatigue Resistance of a Supermartensitic Stainless Steel, PhD, Mechanical Engineering, Federal University of Paraná, Curitiba, Paraná, Brazil, 2010

K.H. Tseng and C.P. Chou, The Effect of Pulsed GTA Welding on the Residual Stress of a Stainless Steel Weldment, J. Mater. Process. Technol., 2002, 123(3), p 346-353

D. Carrouge, Phase Transformations in the Heat-Affected Zone of Low Carbon 13% Cr stainless steels, PhD, Materials Science and Metallurgy Department, Cambridge University, 2002

J.F. Santa, J.A. Blanco, J.E. Giraldo, and A. Toro, Cavitation Erosion of Martensitic and Austenitic Steel Welded Coatings, Wear, 2011, 271(9-10), p 1445-1453

B.G. Girén, Material Properties Essential for Cavitation Erosion of Laser Produced Surface Alloys, J. Mater. Sci., 2004, 39(1), p 295-297

Z. Xiaojun, L.A.J. Procopiak, N.C. Souza, and A.S.C.M. d’Oliveira, Phase Transformation During Cavitation Erosion of a Co Stainless Steel, Mater. Sci. Eng. A, 2003, 358(1-2), p 199-204

S.M. Ahmed, K. Hokkirigawa, and R. Oba, Fatigue Failure of SUS304 Caused by Vibratory Cavitation Erosion, Wear, 1994, 177(2), p 129-137

C. Haosheng and L. Shihan, Inelastic Damages by Stress Wave on Steel Surface at the Incubation Stage of Vibration Cavitation Erosion, Wear, 2009, 266(1-2), p 69-75

Acknowledgments

The authors wish to thank the Fundação Araucária for providing financial support; the Institute of Technology for Development; LACTEC for assisting with the characterization of the coatings; DURUM for providing the wires; and Voith for providing the ASTM A743-CA6NM used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2013 International Thermal Spray Conference, held May 13-15, 2013, in Busan, South Korea, and has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Pukasiewicz, A.G.M., Alcover, P.R.C., Capra, A.R. et al. Influence of Plasma Remelting on the Microstructure and Cavitation Resistance of Arc-Sprayed Fe-Mn-Cr-Si Alloy. J Therm Spray Tech 23, 51–59 (2014). https://doi.org/10.1007/s11666-013-0001-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-0001-1