Abstract

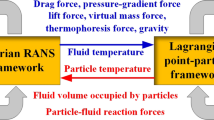

In cold spraying, a powder material is accelerated and heated in the gas flow of a supersonic nozzle to velocities and temperatures that are sufficient to obtain cohesion of the particles to a substrate. The deposition efficiency of the particles is significantly determined by their velocity and temperature. Particle velocity correlates with the amount of kinetic energy that is converted to plastic deformation and thermal heating. The initial particle temperature significantly influences the mechanical properties of the particle. Velocity and temperature of the particles have nonlinear dependence on the pressure and temperature of the gas at the nozzle entrance. In this contribution, a simulation model based on the reactingParcelFoam solver of OpenFOAM is presented and applied for an analysis of particle velocity and temperature in the cold spray nozzle. The model combines a compressible description of the gas flow in the nozzle with a Lagrangian particle tracking. The predictions of the simulation model are verified based on an analytical description of the gas flow, the particle acceleration and heating in the nozzle. Based on experimental data, the drag model according to Plessis and Masliyah is identified to be best suited for OpenFOAM modeling particle heating and acceleration in cold spraying.

Similar content being viewed by others

References

A. Papyrin, V. Kosarev, S. Klinkov, A. Alkimov, and V. Fomin, Cold Spray Technology, 1st ed., Elsevier, Amsterdam, 2007 (ISBN 978-0-008-045155-8)

V.K. Champagne, The Cold Spray Materials Deposition Process—Fundamentals and Applications, CRC Press, Boca Raton, 2007 (ISBN 978-1-4200-6670-8)

T. Stoltenhoff, Kaltgasspritzen von Kupfer—Eine strömungsmechanische und werkstoffkundliche Analyse und Optimierung des Spritzprozesses, Dissertation Universität Hamburg, Shaker Verlag, 2004 (ISBN 3-8322-2302-9)

T. Schmidt, Kaltgasspritzen—Eine Analyse des Materialverhaltens beim Partikelaufprall und die daraus abgeleitete Prozessoptimierung, Dissertation Universität Hamburg, Shaker Verlag, 2007 (ISBN 978-3-8322-6399-7)

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18, p 794-808

H. Assadi, H. Kreye, F. Gärtner, and T. Klassen, Cold Spraying—A Materials Perspective, Acta Mater., 2016, 116, p 382-407

P. Fauchais and M. Vardelle, Sensors in Spray Processes, J. Therm. Spray Technol., 2010, 19(4), p 668-694

K.-H. Leitz, M. O’Sullivan, A. Plankensteiner, H. Kestler, and L.S. Sigl, OpenFOAM Modelling of Particle Heating and Acceleration in Cold Spraying, in Proceedings of the International Thermal Spray Conference, vol. 336 (DVS-Berichte, Düsseldorf, Germany), pp. 589-594, 7-9 June 2017 (ISBN 978-3-96144-000-9)

J.D. Andersion, Modern Compressible Flow, McGraw-Hill, New York, 1982 (ISBN 0-07-001654)

L. Schiller and A. Naumann, Über die grundlegenden Berechnungen bei der Schwerkraftaufbereitung, Z. Ver. Dtsch. Ing., 1933, 77(12), p 318-320

J. Lundberg and B. M Halvorsen, A review of some existing drag models describing the interaction between phases in a bubbling fluidized bed, in Proceedings of 49th Scandinavian Conference on Simulation and Modeling, 2008

C.Y. Wen and Y.H. Yu, Mechanics of Fluidization, Chem. Eng. Prog. Symp., 1966, 62(62), p 100-111

S. Ergun, Fluid Flow Through Packed Columns, Chem. Eng. Prog., 1952, 48(2), p 89-94

A. Haider and O. Levenspiel, Drag Coefficient and Terminal Velocity of Spherical and Nonspherical Particles, Powder Technol., 1989, 58, p 63-70

J.P. du Plessis and J.H. Masliyah, Mathematical Modelling of Flow Through Consolidated Isotropic Porous Media, Transp. Porous Media, 1988, 3, p 145-161

W.E. Ranz and W.R. Marschall, Evaporation From Drops Part I, Chem. Eng. Prog., 1952, 48(3), p 141-146

W.E. Ranz and W.R. Marschall, Evaporation From Drops Part II, Chem. Eng. Prog., 1952, 48(4), p 173-180

K.-H. Leitz, M. O’Sullivan, A. Plankensteiner, T. Lichtenegger, S. Pirker, H. Kestler, and L. S. Sigl, CFDEM Modelling of Particle Heating and Acceleration in Cold Spraying, in Proceedings of the 19th Plansee Seminar, (Reutte, Austria) 29 May-2 June 2017

K.-H. Leitz, M.O’Sullivan, A. Plankensteiner, H. Kestler, and L.S. Sigl, Comprehensive Modelling of the Cold Spray Process—from the Heating and Acceleration of the Particle in the Nozzle to its Impact on the Substrate, in Proceedings of the Euro PM2017, 1-4 October 2017, Milan (in press)

D.L. Koch and R.J. Hill, Inertial Effects in Suspension and Porous-Media Flows, Annu. Rev. Fluid Mech., 2001, 33, p 619-647

G.R. Johnson and W.H. Cook, A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures, in Proceedings of the 7th International Symposium on Ballistics, vol. 21 (1983), pp. 541-547

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2017 International Thermal Spray Conference, held June 7-9, 2017, in Düsseldorf, Germany, that has been expanded from the original presentation.

Rights and permissions

About this article

Cite this article

Leitz, KH., O’Sullivan, M., Plankensteiner, A. et al. OpenFOAM Modeling of Particle Heating and Acceleration in Cold Spraying. J Therm Spray Tech 27, 135–144 (2018). https://doi.org/10.1007/s11666-017-0644-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0644-4