Abstract

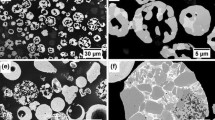

In most applications, the performance of thermally sprayed Cr3C2-NiCr cermet coatings is known to be adversely affected by the presence of the NiCr binder phase. A processing technique for the rapid synthesis of Cr3C2 on industrial-scale components could improve the functionality of these coatings by eliminating the metallic binder phase. To form a thick, continuous surface layer of adherent, binder-free Cr3C2, the reduction of plasma-sprayed Cr2O3 with methane-containing gas was investigated. Conversion of the plasma-sprayed Cr2O3 to carbide resulted in a significant increase in coating porosity, yielding a highly microporous Cr3C2 surface layer. The physical characteristics of the reduction process appear to be dependent on the coating defect structure at the reduction temperature. Phase morphology and porosity evolution throughout the reduction process were qualitatively examined using x-ray diffraction and scanning electron microscopy. The utility of the resultant Cr3C2 coating is discussed with respect to these microstructural characterizations and microindentation hardness measurements.

Similar content being viewed by others

References

N. Anacleto and O. Ostrovski, Solid-State Reduction of Chromium Oxide by Methane-Containing Gas, Metall. Mater. Trans. B, 2004, 35B(4), p 609-615

P.J. Read, D.A. Reeve, J.H. Walsh, and J.E. Rehder, Reduction of Chromites in Methane-Hydrogen Mixtures-Chromium Sesquioxide, Can. Metall. Q., 1974, 13(4), p 587-595

M.A. Qayyum and D.A. Reeve, Reduction of Chromites to Sponge Ferrochromium in Methane-Hydrogen Mixtures, Can. Metall. Q., 1976, 15(3), p 193-200

R. Ebrahimi-Kahrizsangi, H. Monajati Zadeh, and V. Nemati, Synthesis of Chromium Carbide by Reduction of Chromium Oxide with Methane, Int. J. Refract. Met. Hard Mater., 2010, 28(3), p 412-415

B. Khoshandam, R.V. Kumar, and E. Jamshidi, Producing Chromium Carbide Using Reduction of Chromium Oxide with Methane, Am. Inst. Chem. Eng. J., 2006, 52(3), p 1094-1102

L.-M. Berger, S. Stolle, W. Gruner, and K. Wetzig, Investigation of the Carbothermal Reduction Process of Chromium Oxide by Micro- and Lab-Scale Methods, Int. J. Refract. Met. Hard Mater., 2001, 19(2), p 109-121

W. Gruner, S. Stolle, and K. Wetzig, Formation of COx Species During the Carbothermal Reduction of Oxides of Zr, Si, Ti, Cr, W, and Mo, Int. J. Refract. Met. Hard. Mater., 2000, 18(2-3), p 137-145

G.-C. Ji, C.-J. Li, Y.-Y. Wang, and W.-Y. Li, Erosion Performance of HVOF-Sprayed Cr3C2 NiCr Coatings, J. Therm. Spray Technol., 2007, 16(4), p 557-565

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Characterizations and Hot Corrosion Resistance of Cr3C2-NiCr Coating on Ni-base Superalloys in an Aggressive Environment, J. Therm. Spray Technol., 2006, 15(4), p 811-816

G. Matthäus, J.A. Picas, and A. Forn, Effect of Feedstock Powder Size on the Sliding Wear Behavior of Thermal Sprayed HVOF Cr3C2-NiCr Coatings. Thermal Spray 2004: Advances in Technology and Application, Proceedings of the International Thermal Spray Conference, 2004. ASM International, May 10-12, 2004 (Osaka, Japan), ASM International, 2004, p 529-533

M.C. Brupbacher, D. Zhang, W.M. Buchta, J.B. Spicer, and D.C. Nagle, Formation of Molten Fluoride Salt Corrosion Resistant Coatings on Nickel-Based Alloys, ANS Transactions, Vol. 111, (Anaheim, CA), ANS, 2014, p 584-587

C.-J. Li and A. Ohmori, Relationship Between the Microstructure and Properties of Thermally Sprayed Deposits, J. Therm. Spray Technol., 2002, 11(3), p 365-374

S. Kuroda and T.W. Clyne, The Quenching Stress in Thermally Sprayed Coatings, Thin Solid Films, 1991, 200(1), p 49-66

S. Rundqvist and G. Runnsjö, Crystal Structure Refinement of Cr3C2, Acta Chem. Scand., 1969, 23(4), p 1191-1199

M.C. Brupbacher, D. Zhang, W.M. Buchta, M.L. Graybeal, Y.-R. Rhim, D.C. Nagle, and J.B. Spicer, Synthesis and Characterization of Binder-Free Cr3C2 Coatings on Nickel-Based Alloys for Molten Fluoride Salt Corrosion Resistance, J. Nucl. Mater., 2015, 461, p 215-220

J. He, M. Ice, and E.J. Lavernia, Synthesis of Nanostructured Cr3C2-25(Ni20Cr) Coatings, Metall. Mater. Trans. A, 2000, 31A(2), p 555-564

J.J. Carberry, Fluid-Solid Noncatalytic Reactions, Chemical and Catalytic Reaction Engineering, General Publishing Company, Ltd, Toronto, Ontario, 2001, p 310-356

P.A. Ramachandran and L.K. Doraiswamy, Modeling of Noncatalytic Gas-Solid Reactions, Am. Inst. Chem. Eng. J., 1982, 28(6), p 881-900

J. Knuuttila, P. Sorsa, and T. Mäntylä, Sealing of Thermal Spray Coatings by Impregnation, J. Therm. Spray Technol., 1999, 8(2), p 249-257

F.F.P. Medeiros, S.A. De Oliveira, C.P. De Souza, A.G.P. Da Silva, U.U. Gomes, and J.F. De Souza, Synthesis of Tungsten Carbide through Gas-Solid Reaction at Low Temperatures, Mater. Sci. Eng. A, 2001, 315(1-2), p 58-62

Acknowledgment

The authors gratefully acknowledge the support of the U.S. Department of Energy (DOE) through the Nuclear Energy University Program (NEUP) Contract No. 101630.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Brupbacher, M.C., Zhang, D., Buchta, W.M. et al. Post-treatment of Plasma-Sprayed Cr2O3 with Methane-Containing Gas for Conversion to Binder-Free Cr3C2 . J Therm Spray Tech 24, 1513–1519 (2015). https://doi.org/10.1007/s11666-015-0348-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-015-0348-6