Abstract

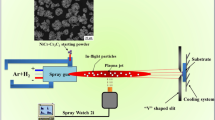

Thermal spraying of Cr3C2-NiCr composites generates varying degrees of carbide dissolution into the Ni binder. During high-temperature exposure, the carbide dissolution zones precipitate high concentrations of small carbides which develop into finely structured networks. This raises the possibility of producing unique tailored carbide composite structures through the generation of controlled carbide dissolution and appropriate heat treatment. The first step in this process is to produce a supersaturated Ni-Cr-C solid solution from which the carbide phase could be precipitated. In a previous work, a broad range of plasma parameters were trialed to assess their effect on the degree of carbide dissolution at a fixed spray distance of 100 mm. The current two-part work builds on the most promising plasma parameters from those trials. Part 2 of this article series investigated the effect of spray distance on the compositional development in Cr3C2-NiCr coatings during high-energy plasma spraying. The coating compositions were analyzed in detail and quantified through Rietveld fitting of the coating XRD patterns. Coating microstructural features were correlated with the observed variations in composition. The effect of the spray parameters and spray distance on the equilibrium coating compositions is discussed.

Similar content being viewed by others

References

L.-M. Berger, Hardmetals as Thermal Spray Coatings, Powder Metall., 2007, 50(3), p 205-214

S. Matthews, B. James, and M. Hyland, The Role of Microstructure in the High Velocity Erosion of Cr3C2-NiCr Thermal Spray Coatings: Part 1—As-Sprayed Coatings, Surf. Coat. Technol., 2009, 203, p 1086-1093

F. Otsubo, H. Era, T. Uchida, and K. Kishitake, Properties of Cr3C2-NiCr Cermet Coating Sprayed by High Power Plasma and High Velocity Oxy-fuel Processes, J. Therm. Spray Technol., 2000, 9(4), p 499-504

D. Poirier, J.-G. Legoux, and R. Lima, Engineering HVOF-Sprayed Cr3C2-NiCr Coatings: The Effect of Particle Morphology and Spraying Parameters on the Microstructure, Properties and High Temperature Wear Performance, J. Therm. Spray Technol., 2013, 22(2-3), p 280-289

S. Zimmermann and H. Kreye, Chromium Carbide Coatings Produced with Various HVOF Spray Systems, Thermal Spray: Practical Solutions for Engineering Problems, C.C. Berndt, Ed., ASM International, Novelty, 1996, p 147-152

S. Matthews, “Erosion-Corrosion of Cr3C2-NiCr High Velocity Thermal Spray Coatings,” Ph.D. Thesis, Department of Chemical and Materials Engineering, The University of Auckland, 2004

S. Matthews, M. Hyland, and B. James, Long-Term Carbide Development in High Velocity Oxygen Fuel/High Velocity Air Fuel Cr3C2-NiCr Coatings Heat Treated at 900°C, J. Therm. Spray Technol., 2004, 13(4), p 526-536

S. Matthews, Development of High Carbide Dissolution/Low Carbon Loss Cr3C2-NiCr Coatings by Shrouded Plasma Spraying, Surf. Coat. Technol., 2014, 258, p 886–900

S. Matthews, Carbide Dissolution/Carbon Loss as a function of Spray Distance in Unshrouded/Shrouded Plasma Sprayed Cr3C2-NiCr Coatings, J. Therm. Spray Technol., 2014, doi:10.1007/s11666-014-0210-2

E. Bouzy, G. le Caer, and E. Bauer-Grosse, New Metastable Carbides Produced by Crystallization of Amorphous CrC Alloys, Mater. Sci. Eng., A, 1991, 133(C), p 640-643

L. He, Hexagonal Close-Packed Nickel or Ni3C?, J. Magn. Magn. Mater., 2010, 322(14), p 1991-1993

A. Inoue and T. Masumoto, Formation of Nonequilibrium Cr3C Carbide in CrC Binary Alloys Quenched Rapidly from the Melt, Scr. Metall., 1979, 13(8), p 711-715

A. Inoue, S. Sakai, H. Kimura, and T. Masumoto, Crystallization Temperature and Hardness of New Chromium-Based Amorphous Alloys, Trans. Jpn. Inst. Met., 1979, 20(5), p 255-262

S. Loubière, C. Laurent, J.P. Bonino, and A. Rousset, A Metastable Chromium Carbide Powder Obtained by Carburization of a Metastable Chromium Oxide, J. Alloy. Compd., 1996, 243(1-2), p 59-66

P. Nash, The Cr-Ni (Chromium-Nickel) System, Bull. Alloy Phase Diagrams, 1986, 7(5), p 466-476

Z.L. Schaefer, K.M. Weeber, R. Misra, P. Schiffer, and R.E. Schaak, Bridging hcp-Ni and Ni 3C Via a Ni 3C 1-x Solid Solution: Tunable Composition and Magnetism in Colloidal Nickel Carbide Nanoparticles, Chem. Mater., 2011, 23(9), p 2475-2480

R. Sinclair, T. Itoh, and R. Chin, In Situ TEM Studies of Metal-Carbon Reactions, Microsc. Microanal., 2002, 8(4), p 288-304

M. Singleton and P. Nash, The C-Ni (Carbon-Nickel) System, Bull. Alloy Phase Diagrams, 1989, 10(2), p 121-126

T.Y. Velikanova, A.A. Bondar, and A.V. Grytsiv, Chromium-Nickel-Carbon (Cr-Ni-C) Phase Diagram, J. Phase Equilib., 1999, 20(2), p 125-147

M. Venkatraman and J.P. Neumann, The C-Cr (Carbon-Chromium) System, Bull. Alloy Phase Diagrams, 1990, 11(2), p 152-159

B.J. Lee, On the Stability of Cr Carbides, Calphad, 1992, 16(2), p 121-149

D.Y. Kim, M.S. Han, and J.G. Youn, Characterisation of Erosion Resistant Cr3C2-NiCr Plasma Sprayed Coatings, Practical Solutions for Engineering Problems—Proceedings of the 9th National Thermal Spray Conference, C.C. Berndt, Ed., ASM International, 1996, p. 123-128

S.R. Nishitani, K.N. Ishihara, R.O. Suzuki, and P.H. Shingu, Metastable Solid Solubility Limit of Carbon in the Ni-C System, J. Mater. Sci. Lett., 1985, 4(7), p 872-875

T. Tanaka, K.N. Ishihara, and P.H. Shingu, Formation of Metastable Phases of Ni-C, Metall. Trans. A, 1992, 23(9), p 2431-2435

J.K. Chen, D. Farkas, and W.T. Reynolds, Jr., Atomistic Simulation of an f.c.c/b.c.c Interface in Ni-Cr Alloys, Acta Mater., 1997, 45(11), p 4415-4421

A.A. Bondar, V.A. Maslyuk, T.Y. Velikanova, and A.V. Grytsiv, Phase Equilibria in the Cr-Ni-C System and Their Use for Developing Physicochemical Principles for Design of Hard Alloys Based on Chromium Carbide, Powder Metall. Met. Ceram., 1997, 36(5-6), p 242-252

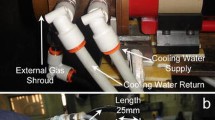

S. Matthews, Shrouded Plasma Spray of Ni-20Cr Coatings Utilizing Internal Shroud Film Cooling, Surf. Coat. Technol., 2014, 249, p 56-74

L. Lutterotti, Total Pattern Fitting for the Combined Size-Stress-Texture Determination in Thin Film Diffraction, Nuclear Inst. Methods Phys. Res, 2010, 2(268), p 334-340

M.H. Staia, M. Suárez, D. Chicot, J. Lesage, A. Iost, and E.S. Puchi-Cabrera, Cr3C2-NiCr VPS Thermal Spray Coatings as Candidate for Chromium Replacement, Surf. Coat. Technol., 2013, 220, p 225-231

B.D. Cullity, Elements of X-ray Diffraction, 2nd ed., Addison-Wesleym Publishing Company, Inc, Reading, 1978

S. Graulis, D. Chateigner, R.T. Downs, A.F.T. Yokochi, M. Quirós, L. Lutterotti, E. Manakova, J. Butkus, P. Moeck, and A. Le Bail, Crystallography Open Database—An open-access collection of crystal structures, J. Appl. Crystallogr., 2009, 42(4), p 726-729

L. Lutterotti, R. Ceccato, R. Dal Maschio, and E. Pagani, Quantitative Analysis of Silicate Glass in Ceramic Materials by the Rietveld Method, Mater. Sci. Forum, 1998, 278, p 87-92

S. Sampath and H. Herman, Rapid Solidification and Microstructure Development During Plasma Spray Deposition, J. Therm. Spray Technol., 1996, 5(4), p 445-456

G. Espie, A. Denoirjean, P. Fauchais, J.C. Labbe, J. Dubsky, O. Schneeweiss, and K. Volenik, In-Flight Oxidation of Iron Particles Sprayed Using Gas and Water Stabilized Plasma Torch, Surf. Coat. Technol., 2005, 195, p 17-28

J.R. Fincke, W.D. Swank, and D.C. Haggard, Entrainment and demixing in subsonic argon/helium thermal plasma jets, Proceedings of the 1993 National Thermal Spray Conference, 1993, p. 49-54

R.A. Neiser, M.F. Smith, and R.C. Dykhuizen, Oxidation in Wire HVOF-Sprayed Steel, J. Therm. Spray Technol., 1998, 7(4), p 537-545

Acknowledgments

The author gratefully acknowledges the support of Associate Professor Brian Gabbitas and the University of Waikato for their collaboration in the development and manufacture of the shrouds and for allowing their use in this work. The assistance of Holster Engineering in performing the spray trials is sincerely appreciated. The support in the preparation and analysis of the coatings provided by the Department of Chemical and Materials Engineering at the University of Auckland is also gratefully appreciated. Funding for this work was provided by the Marsden Fund Council from New Zealand Government funding, administered by the Royal Society of New Zealand.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Matthews, S. Compositional Development as a Function of Spray Distance in Unshrouded/Shrouded Plasma-Sprayed Cr3C2-NiCr Coatings. J Therm Spray Tech 24, 515–533 (2015). https://doi.org/10.1007/s11666-014-0212-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0212-0