Abstract

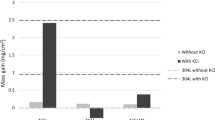

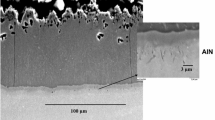

There are over 1000 biomass boilers and about 500 plants using waste as fuel in Europe, and the numbers are increasing. Many of them encounter serious problems with high-temperature corrosion due to detrimental elements such as chlorides, alkali metals, and heavy metals. By HVOF spraying, it is possible to produce very dense and well-adhered coatings, which can be applied for corrosion protection of heat exchanger surfaces in biomass and waste-to-energy power plant boilers. Four HVOF coatings and one arc sprayed coating were exposed to actual biomass co-fired boiler conditions in superheater area with a probe measurement installation for 5900 h at 550 and 750 °C. The coating materials were Ni-Cr, IN625, Fe-Cr-W-Nb-Mo, and Ni-Cr-Ti. CJS and DJ Hybrid spray guns were used for HVOF spraying to compare the corrosion resistance of Ni-Cr coating structures. Reference materials were ferritic steel T92 and nickel super alloy A263. The circulating fluidized bed boiler burnt a mixture of wood, peat and coal. The coatings showed excellent corrosion resistance at 550 °C compared to the ferritic steel. At higher temperature, NiCr sprayed with CJS had the best corrosion resistance. IN625 was consumed almost completely during the exposure at 750 °C.

Similar content being viewed by others

References

M. Döing, et al., Biomass to Energy, The World Market for Biomass Power Plants 2012/2013, Cologne, October 2012, Ecoprog

A.A. Khan, W. de Jong, P.J. Jansens, and H. Spliethoff, Biomass Combustion in Fluidized Bed Boilers: Potential Problems and Remedies, Fuel Process. Technol., 2009, 90, p 21-50

J. Sandberg, C. Karlsson, and R.B. Fdhila, A 7 Year Long Measurement Period Investigating the Correlation of Corrosion, Deposit and Fuel in a Biomass Fired Circulated Fluidized Bed Boiler, Appl. Energy, 2011, 88, p 99-110

A. Zahs, M. Spiegel, and H.J. Grabke, Chloridation and Oxidation of Iron, Chromium, Nickel and Their Alloys in Chloridizing and Oxidizing Atmospheres at 400-700°C, Corros. Sci., 2000, 42, p 1093-1122

H.P. Michelsen, F. Frandsen, K. Dam-Johansen, and O.H. Larsen, Deposition and High Temperature Corrosion in a 10 MW Straw Fired Boiler, Fuel Process. Technol., 1998, 54, p 95-108

M. Montgomery, T. Vilhelmsen, and S.A. Jensen, Potential High Temperature Corrosion Problems Due to Co-firing of Biomass and Fossil Fuels, Mater. Corros., 2008, 59, p 783-793

K. Nakagawa and Y. Matsunaga, The Effect of Chemical Composition of Ash Deposit on the Corrosion of Boiler Tubes in Waste Incinerators, Mater. Sci. Forum, 1997, 251–254, p 535-542

M. Schütze, M. Malessa, V. Rohr, and T. Weber, Development of Coatings for Protection in Specific High Temperature Environments, Surf. Coat. Technol., 2006, 201, p 3872-3879

Y. Kawahara, Application of High Temperature Corrosion-Resistant Materials and Coatings Under Severe Corrosive Environment in Waste-to-Energy Boilers, J. Therm. Spray Technol., 2007, 162, p 202-213

T. Hussain, T. Dudziak, N.J. Simms, and J.R. Nicholls, Fireside Corrosion Behavior of HVOF and Plasma-Sprayed Coatings in Advanced Coal/Biomass Co-fired Power Plants, J. Therm. Spray Technol., 2013, 22(5), p 797-807

M. Oksa, S. Tuurna, and T. Varis, Increased Lifetime for Biomass and Waste to Energy Power Plant Boilers with HVOF Coatings: High Temperature Corrosion Testing Under Chlorine-Containing Molten Salt, J. Therm. Spray Technol., 2013, 22(5), p 783-796

M. Oksa, J. Kärki and J. Metsäjoki, Coating Solutions Against High Temperature Corrosion—Performance Validation and Feasibility at Biomass Fired Boilers, Baltica IX. International Conference on Life Management and Maintenance for Power Plants. P. Auerkari and J Veivo (eds.). VTT Technology, Espoo, 2013, p 656–670

J. Sandberg, C. Karlsson, and R. Bel Fdhila, A 7 Year Long Measurement Period Investigating the Correlation of Corrosion, Deposit and Fuel in a Biomass Fired Circulated Fluidized Bed Boiler, Appl. Energy, 2011, 88, p 99-110

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564-1583

T. Varis, T. Suhonen, A. Ghabchi, A. Valarezo, S. Sampath, X. Liu, and S.-P. Hannula, Formation Mechanisms, Structure, and Properties of HVOF-Sprayed WC-CoCr Coatings: An Approach Toward Process Maps, J. Therm. Spray Technol., 2014, 23(6), p 1009-1018

M. Spiegel, Salt Melt Induced Corrosion of Metallic Materials in Waste Incineration Plants, Mater. Corros., 1999, 50, p 373-393

B.-J. Skrifvars, R. Backman, M. Hupa, K. Salmenoja, and E. Vakkilainen, Corrosion of Superheater Steel Materials Under Alkali Salt Deposits, Part 1, The Effect of Salt Deposit Composition and Temperature, Corros. Sci., 2008, 50, p 1274-1282

K. Natesan and J.H. Park, Fireside and Steamside Corrosion of Alloys for USC Plants, Int. J. Hydrogen Energy, 2007, 32, p 3689-3697

M. Montgomery, O. Biede, and O.H. Larsen, Experiences with Inconel 625 in Biomass and Waste Incineration Plants, Mater. Sci. Forum, 2006, 522–523, p 523-530

B. Geddes, H. Leon, and X. Huang, Superalloys–Alloying and Performance, ASM International, Materials Park, 2010

S.A. Sajjadi, S.M. Zebarjad, R.I.L. Guthrie, and M. Isac, Microstructure Evolution of High-Performance Ni-Base Superalloy GTD-111 with Heat Treatment Parameters, J. Mater. Proc. Technol., 2006, 175, p 376-381

P.N. Singh and V. Singh, Influence of Ageing Treatment on Work Hardening Behaviour of a Ni-Base Superalloy, Scr. Mater., 1996, 34, p 1861-1865

M. Montgomery, A.N. Hansson, S.A. Jensen, T. Vilhelmsen, and N.H. Nielsen, In Situ Corrosion Testing of Various Nickel Alloys at Måbjerg Waste Incineration Plant, Mater. Corros., 2013, 64, p 14-25

S. Enestam, C. Boman, J. Niemi, D. Boström, B. Backman, K. Mäkelä, and M. Hupa, Occurrence of Zinc and Lead in Aerosols and Deposits in the Fluidized-Bed Combustion of Recovered Waste Wood, Part 1, Samples from Boilers, Energy Fuels, 2011, 25, p 1396-1404

H.T. Ma, C.H. Zhou, and L. Wang, High Temperature Corrosion of Pure Fe, Cr and Fe-Cr Binary Alloys in O2 Containing Trace KCl Vapour at 750 °C, Corros. Sci., 2009, 51, p 1861-1867

Acknowledgments

This work was performed in the FP7 EU project NextGenPower—Efficiency increases in existing and new build pulverized coal power plants with a view to CCS. The authors would like to thank Alholmens Kraft Ab for the opportunity for performing the testing in the power plant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Oksa, M., Metsäjoki, J. & Kärki, J. Thermal Spray Coatings for High-Temperature Corrosion Protection in Biomass Co-Fired Boilers. J Therm Spray Tech 24, 194–205 (2015). https://doi.org/10.1007/s11666-014-0155-5

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0155-5