Abstract

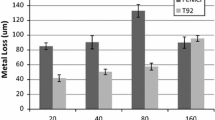

This article presents a systematic evaluation of coatings for advanced fossil fuel plants and addresses fireside corrosion in coal/biomass-derived flue gases. A selection of four candidate coatings: alloy 625, NiCr, FeCrAl and NiCrAlY were deposited onto superheaters/reheaters alloy (T91) using high-velocity oxy-fuel (HVOF) and plasma spraying. A series of laboratory-based fireside corrosion exposures were carried out on these coated samples in furnaces under controlled atmosphere for 1000 h at 650 °C. The tests were carried out using the “deposit-recoat” test method to simulate the environment that was anticipated from air-firing 20 wt.% cereal co-product mixed with a UK coal. The exposures were carried out using a deposit containing Na2SO4, K2SO4, and Fe2O3 to produce alkali-iron tri-sulfates, which had been identified as the principal cause of fireside corrosion on superheaters/reheaters in pulverized coal-fired power plants. The exposed samples were examined in an ESEM with EDX analysis to characterize the damage. Pre- and post-exposure dimensional metrologies were used to quantify the metal damage in terms of metal loss distributions. The thermally sprayed coatings suffered significant corrosion attack from a combination of aggressive combustion gases and deposit mixtures. In this study, all the four plasma-sprayed coatings studied performed better than the HVOF-sprayed coatings because of a lower level of porosity. NiCr was found to be the best performing coating material with a median metal loss of ~87 μm (HVOF sprayed) and ~13 μm (plasma sprayed). In general, the median metal damage for coatings had the following ranking (in the descending order: most to the least damage): NiCrAlY > alloy 625 > FeCrAl > NiCr.

Similar content being viewed by others

References

J. Skea and P. Ekins, Making the Transition to a Secure and Low-Carbon Energy System, UKERC Energy 2050 Project; S3097:30, 2009

DTI, Biomass Strategy—Economic Analysis of Biomass Energy, DTI Report URN 07/950, 2007, p 1-70

J. Stringer and I.G. Wright, Current Limitations of High-Temperature Alloys in Practical Applications, Oxid. Met., 1995, 44(1), p 265-308

N.J. Simms, Environmental Degradation of Boiler Components, Power Plant Life Management and Performance Improvement, J.E. Oakey, Ed., Woodhead Publishing, 2011, p 145-179

N.J. Simms, P.J. Kilgallon, and J.E. Oakey, Fireside Issues in Advanced Power Generation Systems, Energy Mater. Mater. Sci. Eng. Energy Syst., 2007, 2(3), p 154-160

N.J. Simms, P.J. Kilgallon, and J.E. Oakley, Degradation of Heat Exchanger Materials Under Biomass Co-firing Conditions, Mater. High Temp., 2007, 24(4), p 333-342

T. Hussain, A.U. Syed, and N.J. Simms, Fireside Corrosion of Superheater Materials in Coal/Biomass Co-fired Advanced Power Plants, Oxid. Met., in press

A.U. Syed, T. Hussain, N.J. Simms, and J.E. Oakey, Microscopy of Fireside Corrosion on Superheater Materials for Oxy-Fired Pulverised Fuel Power Plants, Mater. High Temp., 2012, 29(3), p 219-228

A.U. Syed, T. Hussain, J.E. Oakey, and N.J. Simms, Fireside Corrosion of Superheater Materials in Oxy-Fired Power Plants, Eurocorr (Stockholm), 2011, p 1062-1078

A.U. Syed, N.J. Simms, and J.E. Oakey, Fireside Corrosion of Superheaters: Effects of Air and Oxy-Firing of Coal and Biomass, Fuel, 2012, 101, p 62-73

S. Paul and M. Harvey, Corrosion Testing of Ni Alloy HVOF Coatings in High Temperature Environments for Biomass Applications, J. Therm. Spray Technol. doi:10.1007/s11666-012-9820-8

N. Bala, H. Singh, and S. Prakash, High Temperature Corrosion Behavior of Cold Spray Ni-20Cr Coating on Boiler Steel in Molten Salt Environment at 900 °C, J. Therm. Spray Technol., 2010, 19(1), p 110-118

N. Bala, H. Singh, S. Prakash, and J. Karthikeyan, Investigations on the Behavior of HVOF and Cold Sprayed Ni-20Cr Coating on T22 Boiler Steel in Actual Boiler Environment, J. Therm. Spray Technol., 2012, 21(1), p 144-158

J.R. Davis, Handbook of Thermal Spray Technology, TSS/ASM International, Materials Park, OH, 2004

D. Zhang, S.J. Harris, and D.G. McCartney, Microstructure Formation and Corrosion Behaviour in HVOF-Sprayed Inconel 625 Coatings, Mater. Sci. Eng. A, 2003, 344(1-2), p 45-56

T.S. Sidhu, S. Prakash, and R.D. Agrawal, Studies on the Properties of High-Velocity Oxy-Fuel Thermal Spray Coatings for Higher Temperature Applications, Mater. Sci., 2005, 41(6), p 805-823

H. Edris, D. McCartney, and A. Sturgeon, Microstructural Characterization of High Velocity Oxy-Fuel Sprayed Coatings of Inconel 625, J. Mater. Sci., 1997, 32(4), p 863-872

N.J. Simms and A.T. Fry, Modelling Fireside Corrosion of Heat Exchangers in Co-fired Pulverised Fuel Power Systems, Materials for Advanced Power Engineering, J. Lecomte-Beckers and M. Carton, Ed., Forschungszentrum Jülich GmbH, 2010

Draft Code of Practice for Discontinuous Corrosion Testing in High Temperature Gaseous Atmospheres, EC Project SMT3-CT95-2001, TESTCORR, ERA Technology, UK, 2000

Corrosion of Metals and Alloys—Methods for Metallographic Examination of Samples After Exposure to High Temperature Corrosive Environments, Draft ISO Standard. ISO/TC 156 NWI 5092005, 2006

S.R.J. Saunders, Guidelines for Methods of Testing and Research in High Temperature Corrosion, H.J. Grabke and D.B. Meadowcroft, Ed., The Institute of Metals, 1995, p 85

K. Natesan and J.H. Park, Fireside and Steamside Corrosion of Alloys for USC Plants, Int. J. Hydrogen Energy, 2007, 32(16), p 3689-3697

E. Raask, Mineral Impurities in Coal Combustion, Hemisphere Publishing Corporation, Washington, DC, 1985

J.R. Nicholls, N.J. Simms, and A. Encinas-Oropesa, Modelling Hot Corrosion in Industrial Gas Turbines, Mater. High Temp., 2007, 24(3), p 149-192

T. Hussain, D.G. McCartney, P.H. Shipway, and T. Marrocco, Corrosion Behavior of Cold Sprayed Titanium Coatings and Free Standing Deposits, J. Therm. Spray Technol., 2011, 20(1-2), p 260-274

V. Higuera, F.J. Belzunce, A. Carriles, and S. Poveda, Influence of the Thermal-Spray Procedure on the Properties of a Nickel-Chromium Coating, J. Mater. Sci., 2002, 37(3), p 649-654

F. Azarmi, T.W. Coyle, and J. Mostaghimi, Optimization of Atmospheric Plasma Spray Process Parameters Using a Design of Experiment for Alloy 625 Coatings, J. Therm. Spray Technol., 2008, 17(1), p 144-155

F.H. Yuan, Z.X. Chen, Z.W. Huang, Z.G. Wang, and S.J. Zhu, Oxidation Behavior of Thermal Barrier Coatings with HVOF and Detonation-Sprayed NiCrAlY Bondcoats, Corros. Sci., 2008, 50(6), p 1608-1617

J.R. Nicholls and P. Hancock, Analysis of Oxidation and Hot Corrosion Data—A Statistical Approach, International Corrosion Conference Series, NACE, San Diego, CA, 1983, p 198-210

N. Birks and G.H. Meier, Introduction to High Temperature Oxidation of Metals, Edward Arnold, London, 1983

D. Young, High Temperature Oxidation and Corrosion of Metals, Elsevier, Amsterdam, 2008

T. Sundararajan, S. Kuroda, and F. Abe, Effect of Thermal Spray on the Microstructure and Adhesive Strength of High-Velocity Oxy-Fuel-Sprayed Ni-Cr Coatings on 9Cr-1Mo Steel, Metall. Mater. Trans. A, 2004, 35(10), p 3187-3199

Acknowledgments

The authors acknowledge the supports from the ASPECT project, which is a Technology Strategy Board (TSB)-funded project, and especially thank the following companies: Doosan Babcock, E.ON, the National Physical Laboratory, Sulzer Metco, Monitor Coatings, and RWE npower, for their valuable contributions to the project. The authors would also like to thank Dr Johannes Rauch from Sulzer Metco WOKA GmbH for his kind cooperation during this project.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hussain, T., Dudziak, T., Simms, N.J. et al. Fireside Corrosion Behavior of HVOF and Plasma-Sprayed Coatings in Advanced Coal/Biomass Co-Fired Power Plants. J Therm Spray Tech 22, 797–807 (2013). https://doi.org/10.1007/s11666-013-9887-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9887-x