Abstract

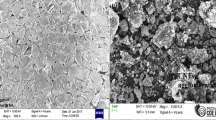

FeAl intermetallic matrix composites reinforced by ceramic particles such as titanium carbide have attracted much attention in recent years. In this study, shrouded plasma spraying with nitrogen as a protective gas was employed to deposit FeAl/TiC composite coatings. Fe-35Al powder and Fe-35Al/TiC composite powders containing 35 and 45 vol.% TiC prepared by mechanical alloying were used as feedstock powders. The microstructures of the ball-milled powders and the as-sprayed coatings were characterized by scanning electron microscopy and x-ray diffraction. The mean coefficients of thermal expansion (CTEs) of FeAl and FeAl/TiC were measured. The results showed that dense FeAl and FeAl/TiC coatings with low oxide inclusions were deposited by shrouded plasma spraying. The mean CTEs measured in the present study were reasonably consistent with those calculated based on the formula. As a result, the mean CTE of FeAl-based composite coating can be properly controlled by adjusting TiC content in the composite coating to match with those of different substrate materials.

Similar content being viewed by others

References

J.M. Guilemany, C.R.C. Lima, N. Cinca, and J.R. Miguel, Studies of Fe-40Al Coatings Obtained by High Velocity Oxy-Fuel, Surf. Coat. Technol., 2006, 201, p 2072-2079

T.C. Totemeier, R.N. Wright, and W.D. Swank, Mechanical and Physical Properties of High-Velocity Oxy-Fuel-Sprayed Iron Aluminide Coatings, Metall. Mater. Trans. A, 2003, 34(10), p 2223-2231

B.S. Xu, Z.X. Zhu, S.N. Ma, W. Zhang, and W.M. Liu, Sliding Wear Behavior of Fe-Al and Fe-Al/WC Coatings Prepared by High Velocity Arc Spraying, Wear, 2004, 257(11), p 1089-1095

J.M. Guilemany, N. Cinca, J. Fernández, and S. Sampath, Erosion, Abrasive, and Friction Wear Behavior of Iron Aluminide Coatings Sprayed by HVOF, J. Therm. Spray Technol., 2008, 17(5-6), p 762-773

S.C. Deevi, V.K. Sikka, and C.T. Liu, Processing, Properties, and Applications of Nickel and Iron Aluminides, Prog. Mater Sci., 1997, 42(1-4), p 177-192

N.S. Stoloff, Iron Aluminides: Present Status and Future Prospects, Mater. Sci. Eng. A, 1998, 258(1-2), p 1-14

S.C. Deevi and V.K. Sikka, Nickel and Iron Aluminides: An Overview on Properties, Processing, and Applications, Intermetallics, 1996, 4(5), p 357-375

A.C. Lilly, S.C. Deevi, and Z.P. Gibbs, Electrical Properties of Iron Aluminides, Mater. Sci. Eng. A, 1998, 258(1-2), p 42-49

M. Kass, C.R. Brooks, D. Falcon, and D. Basak, The Formation of Defects in Fe-Al Alloys: Electrical Resistivity and Specific Heat Measurements, Intermetallics, 2002, 10(10), p 951-966

J.M. Guilemany, N. Cinca, S. Dosta, and I.G. Cano, FeAl and NbAl3 Intermetallic-HVOF Coatings: Structure and Properties, J. Therm. Spray Technol., 2009, 18(4), p 536-545

J.M. Guilemany, N. Cinca, S. Dosta, and C.R.C. Lima, High-Temperature Oxidation of Fe40Al Coatings Obtained by HVOF Thermal Spray, Intermetallics, 2007, 15(10), p 1384-1394

N. Babu, R. Balasubramaniam, and A. Ghosh, High-Temperature Oxidation of Fe3Al-Based Iron Aluminides in Oxygen, Corros. Sci., 2001, 43(12), p 2239-2254

N. Masahashi, S. Watanabe, and S. Hanada, Microstructure and Oxidation Behavior of Low Pressure Plasma Sprayed Iron Aluminides, ISIJ Int., 2001, 41(9), p 1010-1017

P.F. Tortorelli and K. Natesan, Critical Factors Affecting the High-Temperature Corrosion Performance of Iron Aluminides, Mater. Sci. Eng. A, 1998, 258(1-2), p 115-125

P.F. Tortorelli and J.H. DeVan, Behavior of Iron Aluminides in Oxidizing and Oxidizing/Sulfidizing Environments, Mater. Sci. Eng. A, 1992, 153(1-2), p 573-577

J.H. DeVan and P.F. Tortorelli, The Oxidation-Sulfidation Behavior of Iron Alloys Containing 16-40 at% aluminium, Corros. Sci., 1993, 35(5-8), p 1065-1071

P.C. Patnaik and W.W. Smeltzer, Sulfidation Properties of Fe-Al Alloys (6-28 a/o Al) at 1173 K in Sulfur Vapor at P = 1.45 × 10−3 Pa, J. Electrochem. Soc., 1985, 132(5), p 1226-1232

C.T. Liu, E.P. George, P.J. Maziasz, and J.H. Schneibel, Recent Advances in B2 Iron Aluminide Alloys: Deformation, Fracture and Alloy Design, Mater. Sci. Eng. A, 1998, 258(1-2), p 84-98

P. Fan, E. Riddle, Z.Z. Fang, and H.Y. Sohn, Iron Aluminide Coatings by an In-Situ Reaction Process, Surf. Coat. Technol., 2008, 202(24), p 6090-6094

F.J. Pérez, M.P. Hierro, J.A. Trilleros, M.C. Carpintero, L. Sánchez, J.M. Brossard, and F.J. Bolívar, Iron Aluminide Coatings on Ferritic Steels by CVD-FBR Technology, Intermetallics, 2006, 14(7), p 811-817

L. Sánchez, F.J. Bolívar, M.P. Hierro, J.A. Trilleros, and F.J. Pérez, Effect of Reactive Gaseous Mixture and Time on the Growth Rate and Composition of Aluminium Diffusion Coating by CVD-FBR on 12Cr-Ferritic Steel, Surf. Coat. Technol., 2007, 201(18), p 7626-7634

P. Moine, O. Popoola, J.P. Villain, Junqua, S. Pimbert, J. Delafond, and J. Grilhe, Tribological Behavior of Some Alloys After Surface Modification Using Ion Beam Techniques, Surf. Coat. Technol., 1987, 33, p 479-486

Z.Y. Liu, W. Gao, and F.H. Wang, Oxidation Behaviour of FeAl Intermetallic Coatings Produced by Magnetron Sputter Deposition, Scr. Mater., 1998, 39(11), p 1497-1502

N.H. Heo, M.T. Kim, J.H. Shin, and C.Y. Kim, Simultaneous Chromizing and Aluminizing Using Chromium Oxide and Aluminum: (II) on Austenitic Stainless Steel, Surf. Coat. Technol., 2000, 124(1), p 39-43

Z.D. Xiang and P.K. Datta, Relationship Between Pack Chemistry and Aluminide Coating Formation for Low-Temperature Aluminisation of Alloy Steels, Acta Mater., 2006, 54(17), p 4453-4463

G. Benamati, P. Buttol, A. Casagrande, and C. Fazio, Effects of Heat Treatment and Cooling Rate on Microstructural and Mechanical Characteristics of Aluminide Coatings on MANET Steel, J. Nucl. Mater., 1996, 230(3), p 214-218

G. Ji, O. Elkedim, and T. Grosdidier, Deposition and Corrosion Resistance of HVOF Sprayed Nanocrystalline Iron Aluminide Coatings, Surf. Coat. Technol., 2005, 190(2-3), p 406-416

T. Grosdidier, G. Ji, and N. Bozzolo, Hardness, Thermal Stability and Yttrium Distribution in Nanostructured Deposits Obtained by Thermal Spraying from Milled-Y2O3 Reinforced-or Atomized FeAl Powders, Intermetallics, 2006, 14(7), p 715-721

G. Ji, J.P. Morniroli, and T. Grosdidier, Nanostructures in Thermal Spray Coatings, Scr. Mater., 2003, 48(12), p 1599-1604

T.C. Totemeier, R.N. Wright, and W.D. Swank, FeAl and Mo-Si-B Intermetallic Coatings Prepared by Thermal Spraying, Intermetallics, 2004, 12(12), p 1335-1344

B.V. Reddy and S.C. Deevi, Thermophysical Properties of FeAl (Fe-40 at.% Al), Intermetallics, 2000, 8(12), p 1369-1376

Y.G. Zhang, Y.F. Han, G.L. Chen, J.T. Guo, X.J. Wan, and D. Feng, Intermetallic Structural Materials, National Defense Industry Press, Beijing, 2001 (in Chinese)

B. David and W.K. Craig, Properties and Selection: Stainless Steels, Tool Materials and Special-Purpose Metals, American Society for Metals, OH, 1980

H.O. Pierson, Handbook of Refractory Carbides and Nitrides: Properties, Characteristics, Processing and Applications, Noyes Publications, New Jersey, 1996

S. Kumar, V. Selvarajan, P.V.A. Padmanabhan, and K.P. Sreekumar, Characterization and Comparison Between APS Coatings Prepared from Ball Milled and Plasma Processed Nickel-Aluminium Powders, Mater. Sci. Eng. A, 2008, 486(1-2), p 287-294

G. Ji, T. Grosdidier, H.L. Liao, J.P. Morniroli, and C. Coddet, Spray Forming Thick Nanostructured and Microstructured FeAl Deposits, Intermetallics, 2005, 13(6), p 596-607

R.J. Li, Ceramics-Metal Composite Materials, Metallurgical Industry Press, Beijing, 2004 (in Chinese)

W.D. Porter and P.J. Maziasz, Thermal Expansion Data on Several Iron- and Nickel-Aluminide Alloys, Scr. Metall. Mater., 1993, 29(8), p 1043-1048

J.B. Wachtman and D.G. Lam, Young’s Modulus of Various Refractory Materials as a Function of Temperature, J. Am. Ceram. Soc., 1959, 42(5), p 254-260

S.C. Deevi and R.W. Swindeman, Yielding, Hardening and Creep Behavior of Iron Aluminides, Mater. Sci. Eng. A, 1998, 258(1-2), p 203-210

Acknowledgment

The present work is supported by the National Science Fund for Distinguished Young Scholars of China (No. 50725101).

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is an invited paper selected from presentations at the 2011 International Thermal Spray Conference and has been expanded from the original presentation. It is simultaneously published in Thermal Spray 2011: Proceedings of the International Thermal Spray Conference, Hamburg, Germany, September 27-29, 2011, Basil R. Marple, Arvind Agarwal, Margaret M. Hyland, Yuk-Chiu Lau, Chang-Jiu Li, Rogerio S. Lima, and André McDonald, Ed., ASM International, Materials Park, OH, 2011.

Rights and permissions

About this article

Cite this article

Tian, LH., Li, CX., Li, CJ. et al. Effect of Dispersed TiC Content on the Microstructure and Thermal Expansion Behavior of Shrouded-Plasma-Sprayed FeAl/TiC Composite Coatings. J Therm Spray Tech 21, 689–694 (2012). https://doi.org/10.1007/s11666-012-9767-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-012-9767-9