Abstract

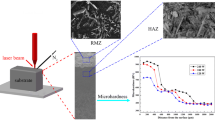

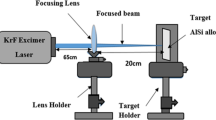

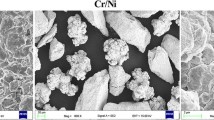

Multiple treatment of engineering surfaces can provide improved surface properties that cannot be obtained by a single surface treatment. Consequently, this study investigates the effects of laser melting on the microstructures of plasma nitrided Ti-6Al-4V alloy. The study consists of two parts. In the first part, governing equations pertinent to the laser melting process are developed, and temperature variation across the melted zone is predicted. In the second, an experiment is conducted to nitride the surface of the alloy through plasma nitriding process and to melt the plasma nitrided and the untreated alloy surfaces with a CO2 laser beam. The resulting metallurgical changes are examined using x-ray diffraction (XRD), bdenergy-dispersive spectrometry (EDS), and scanning electron microscopy (SEM) techniques. It is shown that three distinct nitride layers are formed in the vicinity of the alloy surface prior to the laser melting process, and that after the melting process nitrided species are depleted while cellular and dendritic structures are formed. In addition, the structure consisting of transformed β containing coarse and fine acicular α is observed in the melted regions.

Similar content being viewed by others

References

A. Gicquel, N. Laidani, P. Saillard, and I. Amauroux, Plasma and Nitrides: Application to the Nitriding of Titanium, Pure Appl. Chem., Vol 62 (No. 9), 1990, p 1743–1750

M. Zlatanovic, T. Gredic, N. Popovic, and Z. Bogdanov, Matching of TiN Coating Structures by Plasma Nitriding of Substrates, Vacuum, Vol 44 (No. 2), 1993, p 83–88

A. Muche and M. Braun, Requisite Parameters for Optimal Wear Performance of Nitrogen Implanted Titanium and Ti-6A1-4V, Surf. Coat. Technol, Vol 50, 1992, p 135–139

N. Laidani, J. Perriere, D. Lincot, A. Gicquel, and J. Amauroux, Nitriding of Bulk Titanium and Thin Titanium Films in a NH3 Low Pressure Plasma, Appl. Surf. sci., Vol 36, 1989, p 520–529

B.L. Mordike, State of the Art of Surface Engineering with High Energy Beams, Key. Eng. Mater., Vol 46,47,1990, p 13–26

T. Bell, M.H. Sohi, J.R. Betz, and A. Bloyce, Energy Beams in Second Generation Surface Engineering of Aluminum and Titanium Alloys Key Eng. Mater., Vol 46,47,1990, p 69–84

R. Zenker and U. Zenker, Combined Heat Treatment of Steel: Nitrocementation and Laser Treatment, Phys. Met. Metallogr., Vol 66 (No. 6), 1968, p 97–105

I. Sawchyn and C.W. Draper, AES and RBS Analysis of Laser Mixed Cr and Ni Multilayer Films on Cu Alloys, Appl. Surf. sci., Vol 18 (No. 1–2), 1984, p 86–105

B.S. Yilbas, A.Z. Sahin, and R. Davier, Laser Heating Mechanism Including Evaporation Process Initiating Laser Drilling, Int. J. Mech. Tools Manufact., Vol 35 (No. 7), 1995, p 1047–1062

B.S. Yilbas and A.Z. Al-Garni, Some Aspects of Laser Heating of Engineering Materials, J. Laser Appl., Vol 8, 1996, p 197–204

J. Folhers, D.R.F. West, and W.M. Steen, Laser Surface Melting and Alloying of Titanium, Laser Surface Treatment of Metals, Vol 6,1986, p 451–460

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Mohammed, M.A., Hashmi, M.S.J. & Yilbas, B.S. A study into effects of CO2 laser melting of nitrided Ti-6Al-4V alloy. J. of Materi Eng and Perform 6, 642–648 (1997). https://doi.org/10.1007/s11665-997-0058-4

Issue Date:

DOI: https://doi.org/10.1007/s11665-997-0058-4