Abstract

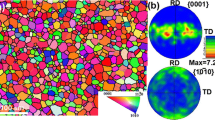

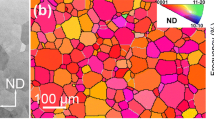

The Ti–20Zr–6.5Al–4V (T20Z, wt%) alloy surface was treated by the process of laser surface nitriding. The evolution of microstructures and microhardness has been investigated by changing the laser power parameter from 120 to 240 W. All laser-treated T20Z samples show two regions with distinctly different microstructural features, as compared with the untreated substrate: dense TiN dendrites and (α + β) − Ti (remelting zone, RMZ), nanoscale α laths doped with part of β phase (heat-affected zone, HAZ). The formation of TiN dendrites can be analyzed by a series of complex reactions during the process of melting and solidification. The increase in laser power results in the increase in content of TiN dendrite which is mainly due to the increase in energy input. In HAZ, the self-quenching effect leads to the formation of nanoscale α laths and the residue of β phase. Microhardness profile of different regions was measured from the surface to the interior, and the highest microhardness was obtained (~ HV 916.8) in the RMZ, as the laser power was set to 240 W. In the present study, we explained various microstructural characteristics induced by laser surface nitriding treatment.

Graphic abstract

Similar content being viewed by others

References

Li W, Liu J, Zhou Y, Li S, Wen S, Wei Q, Yan C, Shi Y. Effect of laser scanning speed on a Ti–45Al–2Cr–5Nb alloy processed by selective laser melting: microstructure, phase and mechanical properties. J Alloy Compd. 2016;688:626.

Yang Y, Chen RR, Fang HZ, Guo JJ, Ding HS, Su YQ, Fu HZ. Improving microstructure and mechanical properties of alloy Ti43Al5Nb0.1B by addition of Fe. Rare Met. 2019;38(11):1024.

MacLeod SG, Tegner BE, Cynn H, Evans WJ, Proctor JE, McMahon MI, Ackland GJ. Experimental and theoretical study of Ti–6Al–4V to 220 GPa. Phys Rev B. 2012;85(22):224202.

Boyer RR, Briggs RD. The use of β titanium alloys in the aerospace industry. J Mater Eng Perform. 2005;14(6):681.

Akahori T, Niinomi M, Fukui H, Ogawa M, Toda H. Improvement in fatigue characteristics of newly developed beta type titanium alloy for biomedical applications by thermo-mechanical treatments. Mater Sci Eng, C. 2005;25(3):248.

Ikeda M, Komatsu SY, Sowa I, Niinomi M. Aging behavior of the Ti–29Nb–13Ta–4.6Zr new beta alloy for medical implants. Metall Mater Trans. 2002;33(3):487.

Vaithilingam J, Goodridge RD, Hague RJ, Christie SD, Edmondson S. The effect of laser remelting on the surface chemistry of Ti6Al4 V components fabricated by selective laser melting. J Mater Process Technol. 2016;232:1.

Meier H, Haberland C. Experimental studies on selective laser melting of metallic parts. Materialwiss Werkstofftech. 2008;39(9):665.

Jin L, Zhou HB, Huang ZZ, Zhang T, Zhi X. Preparing and anticorrosion properties of Fe and Al based amorphous coatings. Rare Met. 2018;38(6):283.

Wang Y, Qian Z, Li XY, Tandon KN. Sliding wear properties of TiAl alloys with/without TiN coatings. Surf Coat Technol. 1997;91(1–2):37.

Rodriguez D, Gil FJ, Planell JA. Wear resistance of the nitrogen diffusion hardening of the Ti–6Al–4 V alloy. J Biomech. 1998;1001(31):49.

Proskurovsky DI, Rotshtein VP, Ozur GE, Ivanov YF, Markov AB. Physical foundations for surface treatment of materials with low energy, high current electron beams. Surf Coat Technol. 2000;125(1–3):49.

Zhang XD, Hao SZ, Li XN, Dong C, Grosdidier T. Surface modification of pure titanium by pulsed electron beam. Appl Surf Sci. 2011;257(13):5899.

Sathish S, Geetha M, Pandey ND, Richard C, Asokamani R. Studies on the corrosion and wear behavior of the laser nitrided biomedical titanium and its alloys. Mater Sci Eng, C. 2010;30(3):376.

Yao Y, Li X, Wang YY, Zhao W, Li G, Liu RP. Microstructural evolution and mechanical properties of Ti–Zr beta titanium alloy after laser surface remelting. J Alloy Compd. 2014;583:43.

Chai L, Chen B, Wang S, Guo N, Huang C, Zhou Z, Huang W. Microstructural changes of Zr702 induced by pulsed laser surface treatment. Appl Surf Sci. 2016;364:61.

dos Reis AG, Reis DAP, de Moura Neto C, Barboza MJR, Oñoro J. Creep behavior and surface characterization of a laser surface nitrided Ti–6Al–4V alloy. Mater Sci Eng, A. 2013;577:48.

Mahamood RM, Akinlabi ET, Akinlabi S. Laser power and scanning speed influence on the mechanical property of laser metal deposited titanium-alloy. Lasers Manuf Mat Process. 2015;2(1):43.

Dahotre SN, Vora HD, Pavani K, Banerjee R. An integrated experimental and computational approach to laser surface nitriding of Ti–6Al–4V. Appl Surf Sci. 2013;271:141.

da Silva Briguente N, Aparecida L, Oñoro J. The influence of laser nitriding on creep behavior of Ti–4Al–4V alloy with widmanstätten microstructure. Metals. 2019;9(2):236.

Katahira K, Tanida Y, Takesue S. Rapid surface nitridin of titanium alloy by a nanosecond fiber laser under atmospheric conditions. CIRP Ann. 2018;67(1):563.

Mridha S, Baker TN. Effects of nitrogen gas flow rates on the microstructure and properties of laser-nitrided IMI318 titanium alloy (Ti–4V–6Al). J Mater Process Technol. 1998;77(1–3):115.

Jing R, Liang SX, Liu CY, Ma MZ, Zhang XY, Liu RP. Structure and mechanical properties of Ti–6Al–4V alloy after zirconium addition. Mater Sci Eng, A. 2012;552:295.

Jing R, Liang SX, Liu CY, Ma MZ, Liu RP. Effect of the annealing temperature on the microstructural evolution and mechanical properties of TiZrAlV alloy. Mater Des. 2013;52:981.

Liang SX, Yin LX, Liu XY, Jing R, Zhou YK, Ma MZ, Liu RP. Effects of annealing treatments on microstructure and mechanical properties of the Zr345Ti35Al33V alloy. Mater Sci Eng, A. 2013;582:374.

Zhang B, Zhang X, Zhang XY, Jia YZ, Ma MZ, Liu RP, Jing Q. Effects of microstructure on the mechanical properties of a high-strength Ti20Zr6.5Al4V alloy. J Alloy Compd. 2018;735:2133.

Haghighi SE, Liu YJ, Cao GH, Zhang LC. Influence of Nb on the β/α” martensitic phase transformation and properties of the newly designed Ti–Fe–Nb alloys. Mater Sci Eng, C. 2016;60:503.

Jiang XJ, Jing R, Liu CY, Ma MZ, Liu RP. Structure and mechanical properties of TiZr binary alloy after Al addition. Mater Sci Eng, A. 2013;586:301.

Dong HC, Feng ZH, Ma MZ, Zhang XY, Liu RP. Optimization of phase composition and mechanical properties in Zr alloys by micro-alloying. Mater Lett. 2017;202:25.

Balla VK, Soderlind J, Bose S, Bandyopadhyay A. Microstructure, mechanical and wear properties of laser surface melted Ti6Al4V alloy. J Mech Behav Biomed Mater. 2014;32:335.

Chikarakara E, Naher S, Brabazon D. High speed laser surface modification of Ti–6Al–4V. Surf Coat Technol. 2012;206(14):3223.

Singh R, Kurella A, Dahotre NB. Laser surface modification of Ti–6Al–4V: wear and corrosion characterization in simulated biofluid. J Biomater Appl. 2006;21(1):49.

Chen Z, Liu Y, Wu H, Zhang W, Guo W, Tang H, Liu N. Microstructures and wear properties of surface treated Ti–36Nb–2Ta–3Zr–0.35O alloy by electron beam melting (EBM). Appl Surf Sci. 2015;357:2347.

Juechter V, Scharowsky T, Singer RF, Körner C. Processing window and evaporation phenomena for Ti–6Al–4V produced by selective electron beam melting. Acta Mater. 2014;76:252.

Gustmann T, Schwab H, Kühn U, Pauly S. Selective laser remelting of an additively manufactured Cu–Al–Ni–Mn shape-memory alloy. Mater Des. 2018;153:129.

Abboud JH. Effect of processing parameters on titanium nitrided surface layers produced by laser gas nitriding. Surf Coat Technol. 2013;214:19.

Labudovic M, Kovacevic R, Kmecko I, Khan TI, Blecic D, Blecic Z. Mechanism of surface modification of the Ti–6Al–4V alloy using a gas tungsten arc heat source. Metall Mater Trans A. 1999;30(6):1597.

Abboud JH, Fidel AF, Benyounis KY. Surface nitriding of Ti–6Al–4V alloy with a high power CO2 laser. Opt Laser Technol. 2008;40(2):405.

Shi D, Winslow D. Accuracy of a volume fraction measurement using areal image analysis. J Test Eval. 1991;19(3):210–3.

Wanying L, Yuanhua L, Yuhai C, Taihe S, Singh A. Effect of different heat treatments on microstructure and mechanical properties of Ti6Al4V titanium alloy. Rare Met Mater Eng. 2017;46(3):634.

Li H, Zhao Z, Guo H, Yao Z, Ning Y, Miao X, Ge M. Effect of initial alpha lamellar thickness on deformation behavior of a near-α high-temperature alloy during thermomechanical processing. Mater Sci Eng, A. 2017;682:345.

Draper CW, Mazzoldi P. Laser Surface Treatment of Metals. Dordrecht: Springer; 2012. 213.

Acknowledgements

This study was financially supported by the Youth Top Talents Research Project of Hebei Provincial Education Department China (No. BJ2018052), the Natural Science Foundation of Hebei Province of China (Nos. E2019208205 and E2018208126), the National Natural Science Foundation of China (No. 51701064), the Science and Technology on Plasma Dynamics Laboratory Fund Project (No. 614220206021806), the Key Research and Development Program of Hebei Province (No. 19211016D) and the Open Foundation of State Key Laboratory of Metastable Materials Science and Technology (Nos. 201804 and 201812).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Feng, ZH., Sun, XY., Han, PB. et al. Microstructure and microhardness of a novel TiZrAlV alloy by laser gas nitriding at different laser powers. Rare Met. 39, 270–278 (2020). https://doi.org/10.1007/s12598-019-01362-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01362-8