Abstract

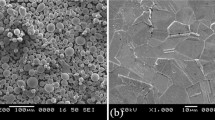

In this paper, microwave joining of Hastelloy C-276 joints is reported using Hastelloy C-276 powder as an interlayer (~ 15 ± 6 µm). Microwave hybrid heating technique was adopted to develop the joints using a graphite susceptor inside a multimode microwave applicator at 900 W power, frequency of 2.45 GHz and 760 s exposure time. The joints were characterized to study the microstructure, hardness, and tensile properties. Microstructural analysis revealed defect and crack-free joints with adequate metallurgical bonding and diffusion between interface layer and base material. Fine cellular (spherical) microstructure and skeleton-like hard carbides were present at the grain boundaries. Formation of intermetallic phases Fe3Ni and Ni3Cr was confirmed by the XRD analysis, whereas hard carbides Mo2C and W2C were identified by EDS analysis. The welded zone possesses 23% higher microhardness than base metal with an average microhardness of 282 HV. The ultimate tensile strength of the joint was estimated 602 ± 22 MPa with 20% of elongation capacity, and the achieved joint efficiency was 82%. Fractography analysis reveals the failure of the joint due to mixed (shear, ductile, and brittle) modes.

Similar content being viewed by others

References

M.S. Srinath, A.K. Sharma, and P. Kumar, A New Approach to Joining of Bulk Copper Using Microwave Energy, Mater. Des., 2011, 32(5), p 2685–2694. https://doi.org/10.1016/j.matdes.2011.01.023

A. Bansal, A.K. Sharma, P. Kumar, and S. Das, Investigation on Microstructure and Mechanical Properties of the Dissimilar Weld Between Mild Steel and Stainless Steel-316 Formed Using Microwave Energy, Proc. Inst. Mech. Eng. B J. Eng. Manuf., 2016, 230(3), p 439–448. https://doi.org/10.1177/0954405414558694

A. Bansal, A.K. Sharma, and S. Das, Metallurgical and Mechanical Characterization of Mild Steel-Mild Steel Joint Formed by Microwave Hybrid Heating Process, Sadhana Acad. Proceed. Eng. Sci., 2013, 38(4), p 679–686. https://doi.org/10.1007/s12046-013-0142-4

D.L. Kamble, R.K. Sahu, and S. Narendranath, Characterization of Inconel 625-SS 304 Weldments Developed by Selective Microwave Hybrid Joining Technique for Promising Applications, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08390-7

V. Kumar and S. Sehgal, Metallurgical and Mechanical Assessment of SS2205/SS304 Joints Fabricated Using Modified Selective Microwave Hybrid Heating-Based Joining, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08605-x

A.K. Sharma and R.R. Mishra, Role of Particle Size in Microwave Processing of Metallic Material Systems, Mater. Sci. Technol. UK, 2018, 34(2), p 123–137. https://doi.org/10.1080/02670836.2017.1412043

M.S. Srinath, A.K. Sharma, and P. Kumar, A Novel Route for Joining of Austenitic Stainless Steel (SS-316) Using Microwave Energy, Proc. Inst. Mech. Eng. B J. Eng. Manuf., 2011, 225(7), p 1083–1091. https://doi.org/10.1177/2041297510393451

A. Bansal, A.K. Sharma, P. Kumar, and S. Das, Characterization of Bulk Stainless Steel Joints Developed Through Microwave Hybrid Heating, Mater Charact, 2014, 91, p 34–41. https://doi.org/10.1016/j.matchar.2014.02.005

A. Bansal, A. Kumar Sharma, S. Das, and P. Kumar, Characterization of Microstructure and Strength of Microwave Welded Inconel 718 Joints at 245 GHz Frequency, Kovove Mater., 2016, 54(1), p 27–35. https://doi.org/10.4149/km-2016-1-27

R.I. Badiger, S. Narendranath, and M.S. Srinath, Joining of Inconel-625 Alloy Through Microwave Hybrid Heating and its Characterization, J. Manuf. Process., 2015, 18, p 117–123. https://doi.org/10.1016/j.jmapro.2015.02.002

R.I. Badiger, S. Narendranath, and M.S. Srinath, Microstructure and Mechanical Properties of Inconel-625 Welded Joint Developed Through Microwave Hybrid Heating, Proc. Inst. Mech. Eng. B J. Eng. Manuf., 2018, 232(14), p 2462–2477. https://doi.org/10.1177/0954405417697350

S. Singh, R. Singh, D. Gupta, and V. Jain, Preliminary Metallurgical and Mechanical Investigations of Microwave Processed Hastelloy Joints, J. Manuf. Sci. E. T. ASME, 2017, 139(6), p 1–5. https://doi.org/10.1115/1.4035370

K. Simant, J. Dutta, and A. Roy, E ff ect of Post-Weld Heat Treatment on the Tensile Strength of Laser Beam Welded Hastelloy C-276 Sheets at di ff Erent Heat Inputs, J. Manuf. Process., 2018, 37(July), p 578–594. https://doi.org/10.1016/j.jmapro.2018.12.019

K.S. Bal, J. Dutta Majumdar, and A. Roy Choudhury, Study on Uni-Axial Tensile Strength Properties of Ytterbium Fiber Laser Welded Hastelloy C-276 Sheet, Opt. Laser Technol., 2018, 108, p 392–403. https://doi.org/10.1016/j.optlastec.2018.07.018

M.D. Barath Kumar and M. Manikandan, Effect of Continuous and Pulsed Current Techniques on Wire-Arc Additive Manufacturing of a Nickel-Based Superalloy, Mater. Lett., 2023 https://doi.org/10.1016/j.matlet.2023.134080

M. Manikandan, N. Arivazhagan, M.N. Rao, and G.M. Reddy, Microstructure and Mechanical Properties of Alloy C-276 Weldments Fabricated by Continuous and Pulsed Current Gas Tungsten Arc Welding Techniques, J. Manuf. Process., 2014, 16(4), p 563–572. https://doi.org/10.1016/j.jmapro.2014.08.002

S. Bezawada and R. Gajjela, Microstructural and Mechanical Characterization of Welded Joints between Stainless Steel and Hastelloy Made Using Pulsed Current Gas Tungsten Arc Welding, J. Mater. Eng. Perform., 2023, 32(3), p 1076–1088. https://doi.org/10.1007/s11665-022-07197-2

D.J. Wu, G.Y. Ma, F.Y. Niu, and D.M. Guo, Pulsed Laser Welding of hastelloy C-276: High-temperature mechanical properties and microstructure, Mater. Manuf. Processes, 2013, 28(5), p 524–528. https://doi.org/10.1080/10426914.2012.736652

K.S. Bal, J. Dutta Majumdar, and A. Roy Choudhury, Study of Variation in Fracture Location of Electron Beam-Welded Hastelloy C-276 Sheets Under Uniaxial Tension, J. Mater. Eng. Perform., 2020, 29(12), p 8370–8394. https://doi.org/10.1007/s11665-020-05266-y

R.R. Mishra and A.K. Sharma, Microwave-Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing, Compos. Part A Appl. Sci. Manuf., 2016, 81, p 78–97. https://doi.org/10.1016/j.compositesa.2015.10.035

K.V. Venkata Nagaraju, S. Kumaran, and T.S. Rao, Optimization of Microwave Processing Parameters on Powder-Metallurgical 316L Stainless Steels, Mater. Manuf. Process., 2022, 37(10), p 1132–1144. https://doi.org/10.1080/10426914.2021.2001512

K.V.V. Nagaraju, S. Kumaran, and T.S. Rao, Microwave-Assisted Hybrid Sintering of 316L Powder Compacts: Microstructure, Mechanical, and Electrochemical Properties, J. Mater. Eng. Perform., 2022, 31(11), p 9555–9572. https://doi.org/10.1007/s11665-022-06948-5

K.V.B. Reddy, G. Venkatesh, and R.R. Mishra, Microwave Joining of SS-316 Plates: A Multi-Physics Simulation Study, J. Manuf. Process., 2023, 98, p 29–41. https://doi.org/10.1016/j.jmapro.2023.04.079

L. Da Silva Ferreira, K. Graf, and A. Scheid, Microstructure and Properties of Nickel-Based C276 Alloy Coatings by PTA on AISI 316L and API 5L X70 Steel Substrates, Mater. Res., 2015, 18(1), p 212–221. https://doi.org/10.1590/1516-1439.332914

S. Zafar and A.K. Sharma, Development and Characterisations of WC-12Co Microwave Clad, Mater Charact, 2014, 96, p 241–248. https://doi.org/10.1016/j.matchar.2014.08.015

A. Bansal, S. Zafar, and A.K. Sharma, Microstructure and Abrasive Wear Performance of Ni-Wc Composite Microwave Clad, J. Mater. Eng. Perform., 2015, 24(10), p 3708–3716. https://doi.org/10.1007/s11665-015-1657-0

S. Singh, D. Gupta, V. Jain, and A.K. Sharma, Microwave Processing of Materials and Applications in Manufacturing Industries: A Review, Mater. Manuf. Processes, 2015, 30(1), p 1–29. https://doi.org/10.1080/10426914.2014.952028

S. Singh, D. Gupta, and V. Jain, Processing of Ni-WC-8Co MMC Casting Through Microwave Melting, Mater. Manuf. Processes, 2018, 33(1), p 26–34. https://doi.org/10.1080/10426914.2017.1291954

A. Das, T. Chowdhury, and S. Tarafder, Ductile Fracture Micro-Mechanisms of High Strength Low Alloy Steels, Mater. Des., 2014, 54, p 100–1009. https://doi.org/10.1016/j.matdes.2013.09.018

A. Das, S. Sivaprasad, M. Tarafder, S.K. Das, and S. Tarafder, Estimation of Damage in High Strength Steels, Appl. Soft Comput. J., 2013, 13(2), p 1033–1041. https://doi.org/10.1016/j.asoc.2012.09.016

A. Das, Effect of Stress State on Fracture Features, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2018, 49(5), p 1425–1432. https://doi.org/10.1007/s11661-018-4516-4

A. F. Liu, Mechanics and Mechanisms of Fracture: an Introduction. ASM International, (2005).

J. L. González-Velázquez, Fractography and Failure Analysis, vol. 24. Springer, (2018).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reddy, K.V.B., Venkatesh, G. & Mishra, R.R. Microstructure and Tensile Properties of Microwave Welded Hastelloy C-276 Joints. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09576-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09576-3