Abstract

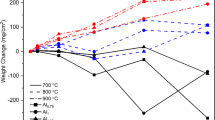

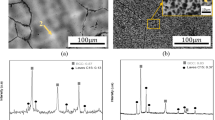

In this study, for the first time, non-isothermal oxidation behavior of the AM Ti-6Al-4V alloy was investigated through TGA-DTA to predict and determine the oxidation mechanism. TGA results were evaluated by both model-free kinetic models and model-fitting methods. The model-fitting kinetic method was applied to predict and determine the reaction mechanism. The obtained results indicate that the reaction is controlled by D2 and D3 models at heating rates of 5 and 10°C/min, respectively. F2 and F1 control the reaction mechanism at heating rates of 20 and 50°C/min, respectively. The results of this study indicate that oxidation kinetics vary with reaction time, allowing us to predict which materials are most favorable to use under certain conditions with respect to oxidation applications.

Similar content being viewed by others

Abbreviations

- A :

-

Pre-exponential factor (s−1)

- E a :

-

Activation energy (kJ/mol)

- k :

-

Reaction-rate constant (s−1)

- R :

-

Universal gas constant (J mol−1 K−1)

- T :

-

Temperature (ºC)

- m :

-

Mass (g)

- α :

-

Fractional conversion degree

- β :

-

Heating rate (ºC/min)

- AM:

-

Additive manufacturing

- DED:

-

Directed energy deposition

- EBM:

-

Electron beam melting

- LPBF:

-

Laser powder bed fusion

- TGA:

-

Thermogravimetric analysis

- DTA:

-

Differential thermal analysis

- FWO:

-

Flynn–Wall–Ozawa

- KAS:

-

Kissinger–Akahira–Sunose

- CR:

-

Coast–Redfern

- OM:

-

Optical microscope

- Ti:

-

Titanium

- g(α):

-

Integrated reaction model

References

J. Dai, J. Zhu, C. Chen, and F. Weng, High Temperature Oxidation Behavior and Research Status of Modifications on Improving High Temperature Oxidation Resistance of Titanium Alloys and Titanium Aluminides: A Review, J. Alloy. Compd., 2016, 685, p 784–798.

K. Gu, H. Zhang, B. Zhao, J. Wang, Y. Zhou, and Z. Li, Effect of Cryogenic Treatment and Aging Treatment on the Tensile Properties and Microstructure of Ti–6Al–4V Alloy, Mater. Sci. Eng. A, 2013, 584, p 170–176.

M. Rahman, Z.G. Wang, and Y.S. Wong, A Review on High-Speed Machining of Titanium Alloys, JSME Int J. Ser. C, 2006, 49(1), p 11–20.

K. Bordji, J.Y. Jouzeau, D. Mainard, E. Payan, P. Netter, K.T. Rie, T. Stucky, and M. Hage-Ali, Cytocompatibility of Ti-6Al-4V and Ti-5Al-2.5Fe Alloys According to Three Surface Treatments, Using Human Fibroblasts and Osteoblasts, Biomaterials, 1996, 17(9), p 929–940.

S. Demirci, T. Dikici, and A.N. Güllüoğlu, Micro/Nanoscale Surface Modification of Ti6Al4V Alloy for Implant Applications, J. Mater. Eng. Perform., 2022, 31(2), p 1503–1511.

O. Schulz, N. Eisenreich, S. Kelzenberg, H. Schuppler, J. Neutz, and E. Kondratenko, Non-isothermal and Isothermal Kinetics of High Temperature Oxidation of Micrometer-Sized Titanium Particles in Air, Thermochim. Acta, 2011, 517(1), p 98–104.

S. Demirci, T. Dikici, and R. Dalmis, Nanoindentation and Corrosion Behavior of Additively Manufactured Ti-6Al-4V Alloy for Biomaterial Applications, J. Mater. Eng. Perform., 2023, 33, p 2133–2145.

C. Veiga, J. Davim, and A. Loureiro, Properties and Applications of Titanium Alloys: A Brief Review, Rev. Adv. Mater. Sci., 2012, 32, p 133–148.

A. Rajabi, A.R. Mashreghi, and S. Hasani, Non-isothermal Kinetic Analysis of High Temperature Oxidation of Ti–6Al–4V Alloy, J. Alloy. Compd., 2020, 815, 151948.

Y. Xiong, S. Zhu, F. Wang, and C. Lee, Effect of Vitreous Enamel Coating on the Oxidation Behavior of Ti6Al4V and TiAl Alloys at High Temperatures, J. Coat. Technol. Res., 2008, 5(1), p 93–98.

M. Peters, J. Hemptenmacher, J. Kumpfert, and C. Leyens, Structure and Properties of Titanium and Titanium Alloys, Titanium and Titanium Alloys: Fundamentals and Applications. C. Leyens, M. Peters Ed., Wiley, 2003, p 1–36

I. González de Arrieta, L. González-Fernández, E. Risueño, T. Echániz, and M.J. Tello, Isothermal Oxidation Kinetics of Nitrided Ti-6Al-4V Studied by Infrared Emissivity, Corros. Sci., 2020, 173, 108723.

C.A.R. Maestro, A.H.S. Bueno, and A.M. de Sousa Malafaia, Cyclic Thermal Oxidation Evaluation to Improve Ti6Al4V Surface in Applications as Biomaterial, J. Mater. Eng. Perform., 2019, 28(8), p 4991–4997.

E. Dong, W. Yu, Q. Cai, L. Cheng, and J. Shi, High-Temperature Oxidation Kinetics and Behavior of Ti–6Al–4V Alloy, Oxid. Met., 2017, 88(5), p 719–732.

H. Guleryuz and H. Cimenoglu, Oxidation of Ti–6Al–4V Alloy, J. Alloy. Compd., 2009, 472(1), p 241–246.

W. Jia, W. Zeng, X. Zhang, Y. Zhou, J. Liu, and Q. Wang, Oxidation Behavior and Effect of Oxidation on Tensile Properties of Ti60 Alloy, J. Mater. Sci., 2011, 46(5), p 1351–1358.

S.J. Qu, S.Q. Tang, A.H. Feng, C. Feng, J. Shen, and D.L. Chen, Microstructural Evolution and High-Temperature Oxidation Mechanisms of a Titanium Aluminide Based Alloy, Acta Mater., 2018, 148, p 300–310.

P. Ouyang, G. Mi, P. Li, L. He, J. Cao, and X. Huang, Non-isothermal Oxidation Behavior and Mechanism of a High Temperature Near-α Titanium Alloy, Materials, 2018, 11(11), p 2141.

G.B. Mi, X.S. Huang, P.J. Li, J.X. Cao, X. Huang, and C.X. Cao, Non-isothermal Oxidation and Ignition Prediction of Ti-Cr Alloys, Trans. Nonferrous Metals Soc. China, 2012, 22(10), p 2409–2415.

P. Majumdar, S.B. Singh, and M. Chakraborty, The Influence of Heat Treatment and Role of Boron on Sliding Wear Behaviour of β-Type Ti–35Nb–7.2Zr–5.7Ta Alloy in Dry Condition and in Simulated Body Fluids, J. Mech. Behav. Biomed. Mater., 2011, 4(3), p 284–297.

M. Kaseem and H.C. Choe, Electrochemical and Bioactive Characteristics of the Porous Surface Formed on Ti-Xnb Alloys Via Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2019, 378, 125027.

Y. Zhang, K. Chu, S. He, B. Wang, W. Zhu, and F. Ren, Fabrication of High Strength, Antibacterial and Biocompatible Ti-5Mo-5Ag Alloy for Medical and Surgical Implant Applications, Mater. Sci. Eng. C, 2020, 106, 110165.

E. Yılmaz, B. Çakıroğlu, A. Gökçe, F. Findik, H.O. Gulsoy, N. Gulsoy, Ö. Mutlu, and M. Özacar, Novel Hydroxyapatite/Graphene Oxide/Collagen Bioactive Composite Coating on Ti16Nb Alloys by Electrodeposition, Mater. Sci. Eng. C, 2019, 101, p 292–305.

Y. Kaynak, A. Gharibi, U. Yılmaz, U. Köklü, and K. Aslantaş, A Comparison of Flood Cooling, Minimum Quantity Lubrication and High Pressure Coolant on Machining and Surface Integrity of Titanium Ti-5553 Alloy, J. Manuf. Process., 2018, 34, p 503–512.

Y. Kaynak and A. Gharibi, Cryogenic Machining of Titanium Ti-5553 Alloy, J. Manuf. Sci. Eng., 2019, 141(4), p 041012.

B. Mueller, Additive Manufacturing Technologies–Rapid Prototyping to Direct Digital Manufacturing, Assem. Autom., 2012 https://doi.org/10.1108/aa.2012.03332baa.010

W.S.W. Harun, N.S. Manam, M.S.I.N. Kamariah, S. Sharif, A.H. Zulkifly, I. Ahmad, and H. Miura, A Review of Powdered Additive Manufacturing Techniques for Ti-6al-4v Biomedical Applications, Powder Technol., 2018, 331, p 74–97.

J. Brezinová, R. Hudák, A. Guzanová, D. Draganovská, G. Ižaríková, and J. Koncz, Direct Metal Laser Sintering of Ti6Al4V for Biomedical Applications: Microstructure, Corros. Prop. Mech. Treat. Implants Metals, 2016, 6(7), p 171.

S. Demirci, T. Dikici, M.M. Tünçay, R. Dalmış, N. Kaya, K. Kanbur, F. Sargın, and A.N. Güllüoğlu, Investigation of Surface-Modified EBM Printed Ti-6Al-4V Alloys for Biomedical Applications, Surf. Interfaces, 2022, 34, 102372.

S. Demirci, R. Dalmış, T. Dikici, M.M. Tünçay, N. Kaya, and A.N. Güllüoğlu, Effect of Surface Modifications of Additively Manufactured Ti-6Al-4V Alloys on Apatite Formation Ability for Biomedical Applications, J. Alloy. Compd., 2021, 887, 161445.

L. Yang, K. Hsu, B. Baughman, D. Godfrey, F. Medina, M. Menon, and S. Wiener, Introduction to Additive Manufacturing, Additive Manufacturing of Metals: The Technology Materials, Design and Productioned. L. Yang, K. Hsu, B. Baughman, D. Godfrey, F. Medina, M. Menon, and, S. Wiener Ed., Springer International Publishing, Cham, 2017, p 1–31

A. Safdar, L.Y. Wei, A. Snis, and Z. Lai, Evaluation of Microstructural Development in Electron Beam Melted Ti-6Al-4V, Mater Charact, 2012, 65, p 8–15.

F. Estupinán-López, C. Orquiz-Muela, C. Gaona-Tiburcio, J. Cabral-Miramontes, R.G. Bautista-Margulis, D. Nieves-Mendoza, E. Maldonado-Bandala, F. Almeraya-Calderón, and A.J. Lopes, Oxidation Kinetics of Ti-6Al-4V Alloys by Conventional and Electron Beam Additive Manufacturing, Materials, 2023, 16(3), p 1187.

A. Fernandez, P. Sette, M. Echegaray, J. Soria, D. Salvatori, G. Mazza, and R. Rodriguez, Clean Recovery of Phenolic Compounds, Pyro-Gasification Thermokinetics, and Bioenergy Potential of Spent Agro-Industrial Bio-Wastes, Biomass Convers. Bioref., 2022, 13, p 12509–12526.

A. Fernandez, A. Saffe, G. Mazza, and R. Rodriguez, Nonisothermal Drying Kinetics of Biomass Fuels by Thermogravimetric Analysis under Oxidative and Inert Atmosphere, Drying Technol., 2017, 35(2), p 163–172.

C.D. Doyle, Estimating Isothermal Life from Thermogravimetric Data, J. Appl. Polym. Sci., 1962, 6(24), p 639–642.

O. Takeo, A New Method of Analyzing Thermogravimetric Data, Bull. Chem. Soc. Jpn, 1965, 38(11), p 1881–1886.

J.H. Flynn and L.A. Wall, A Quick, Direct Method for the Determination of Activation Energy from Thermogravimetric Data, J. Polym. Sci. Part C: Polym. Lett., 1966, 4(5), p 323–328.

J.H. Flynn, The Isoconversional Method for Determination of Energy of Activation at Constant Heating Rates, J. Therm. Anal., 1983, 27(1), p 95–102.

T. Dikici, S. Demirci, M.M. Tünçay, B.K. Yildirim, and N. Kaya, Effect of Heating Rate on Structure, Morphology and Photocatalytic Properties of TiO2 Particles: Thermal Kinetic and Thermodynamic Studies, J. Sol-Gel Sci. Technol., 2021, 97(3), p 622–637.

H.E. Kissinger, Reaction Kinetics in Differential Thermal Analysis, Anal. Chem., 1957, 29(11), p 1702–1706.

S. Demirci, T. Dikici, M.M. Tünçay, and N. Kaya, A Study of Heating Rate Effect on the Photocatalytic Performances of ZnO Powders Prepared by Sol-Gel Route: Their Kinetic and Thermodynamic Studies, Appl. Surf. Sci., 2020, 507, 145083.

M.J. Starink, The Determination of Activation Energy from Linear Heating Rate Experiments: A Comparison of the Accuracy of Isoconversion Methods, Thermochim. Acta, 2003, 404(1), p 163–176.

W. Tang, Y. Liu, H. Zhang, and C. Wang, New Approximate Formula for Arrhenius Temperature Integral, Thermochim. Acta, 2003, 408(1), p 39–43.

A.W. Coats and J.P. Redfern, Kinetic Parameters from Thermogravimetric Data, Nature, 1964, 201(4914), p 68–69.

A.W. Coats and J.P. Redfern, Kinetic Parameters from Thermogravimetric Data. II, J. Polym. Sci. Part B Polym. Lett., 1965, 3(11), p 917–920.

M. Ansariniya, A. Seifoddini, and S. Hasani, (Fe0.9Ni0.1)77Mo5P9C7.5B1.5 Bulk Metallic Glass Matrix Composite Produced by Partial Crystallization: The Non-isothermal Kinetic Analysis, J. Alloys Compd., 2018, 763, p 606–612.

Z. Jaafari, A. Seifoddini, S. Hasani, and P. Rezaei-Shahreza, Kinetic Analysis of Crystallization Process in [(Fe0.9Ni0.1)77Mo5P9C7.5B1.5]100−xCux (x = 0.1 at.%) BMG, J. Therm. Anal. Calorim., 2018, 134(3), p 1565–1574.

V.M. Gorbachev, A Solution of the Exponential Integral in the Non-isothermal Kinetics for Linear Heating, J. Therm. Anal., 1975, 8(2), p 349–350.

P. Rezaei-Shahreza, A. Seifoddini, and S. Hasani, Non-isothermal Kinetic Analysis of Nano-Crystallization Process in (Fe41Co7Cr15Mo14Y2C15)94B6 Amorphous Alloy, Thermochim. Acta, 2017, 652, p 119–125.

A. Brems, J. Baeyens, J. Beerlandt, and R. Dewil, Thermogravimetric Pyrolysis of Waste Polyethylene-Terephthalate and Polystyrene: A Critical Assessment of Kinetics Modelling, Resour. Conserv. Recycl., 2011, 55(8), p 772–781.

Y. Chen and Q. Wang, Thermal Oxidative Degradation Kinetics of Flame-Retarded Polypropylene with intumescent Flame-Retardant Master Batches In Situ Prepared in Twin-Screw Extruder, Polym. Degrad. Stab., 2007, 92(2), p 280–291.

W. Gao, K. Chen, Z. Xiang, F. Yang, J. Zeng, J. Li, R. Yang, G. Rao, and H. Tao, Kinetic Study on Pyrolysis of Tobacco Residues from the Cigarette Industry, Ind. Crops Prod., 2013, 44, p 152–157.

M.S. Masnadi, R. Habibi, J. Kopyscinski, J.M. Hill, X. Bi, C.J. Lim, N. Ellis, and J.R. Grace, Fuel Characterization and Co-Pyrolysis Kinetics of Biomass and Fossil Fuels, Fuel, 2014, 117, p 1204–1214.

T. Takahashi, Y. Minamino, H. Hirasawa, and T. Ouchi, High-Temperature Oxidation and Its Kinetics Study of Ti; Al and Ti; V Alloys in Air, Mater. Trans., 2014, 55(2), p 290–297.

B. Lah, D. Klinar, and B. Likozar, Pyrolysis of Natural, Butadiene, Styrene–Butadiene Rubber and Tyre Components: Modelling Kinetics and Transport Phenomena at Different Heating Rates and Formulations, Chem. Eng. Sci., 2013, 87, p 1–13.

Z. Liang, B. Tang, Y. Gui, and Q. Zhao, High-Temperature Oxidation Behavior of the Ti-6Al-4V Alloy Manufactured by Selective Laser Sintering, JOM, 2019, 71(10), p 3600–3605.

A. Yang, Y. Wu, Y. Duan, M. Peng, S. Zheng, M. Li, and J. Yu, The Effect of Alloying Elements in Ti-5Mo-5V-8Cr-3Al Alloy on Growth Kinetics of TiB Whiskers in Boride Layer, Mater. Des., 2023, 225, 111478.

S. Frangini, A. Mignone, and F. de Riccardis, Various Aspects of the Air Oxidation Behaviour of a Ti6Al4V Alloy at Temperatures in the Range 600–700°C, J. Mater. Sci., 1994, 29(3), p 714–720.

I. Donskoy and A. Kozlov, Thermogravimetric Study of the Kinetics of the Reaction C + CO2 under Pore-Diffusion Control, Energies, 2021, 14(7), p 1886.

C. de Formanoir, S. Michotte, O. Rigo, L. Germain, and S. Godet, Electron Beam Melted Ti–6Al–4V: Microstructure, Texture and Mechanical Behavior of the As-Built and Heat-Treated Material, Mater. Sci. Eng. A, 2016, 652, p 105–119.

X. Tan, Y. Kok, W.Q. Toh, Y.J. Tan, M. Descoins, D. Mangelinck, S.B. Tor, K.F. Leong, and C.K. Chua, Revealing Martensitic Transformation and α/β Interface Evolution in Electron Beam Melting Three-Dimensional-Printed Ti-6Al-4V, Sci. Rep., 2016, 6(1), p 26039.

X. Tan, Y. Kok, Y.J. Tan, G. Vastola, Q.X. Pei, G. Zhang, Y.W. Zhang, S.B. Tor, K.F. Leong, and C.K. Chua, An Experimental and Simulation Study on Build Thickness Dependent Microstructure for Electron Beam Melted Ti–6Al–4V, J. Alloys Compd., 2015, 646, p 303–309.

S. Kumar, T.S.N. Sankara Narayanan, S. Ganesh Sundara Raman, and S.K. Seshadri, Thermal Oxidation of Ti6Al4V Alloy: Microstructural and Electrochemical Characterization, Mater. Chem. Phys., 2010, 119(1), p 337–346.

D. Siva Rama Krishna, Y.L. Brama, and Y. Sun, Thick Rutile Layer on Titanium for Tribological Applications, Tribol. Int., 2007, 40(2), p 329–334.

Y. Luo, W. Chen, M. Tian, and S. Teng, Thermal Oxidation of Ti6Al4V Alloy and Its Biotribological Properties under Serum Lubrication, Tribol. Int., 2015, 89, p 67–71.

Y. Zhang, G.R. Ma, X.C. Zhang, S. Li, and S.T. Tu, Thermal Oxidation of Ti-6Al–4V Alloy and Pure Titanium under External Bending Strain: Experiment and Modelling, Corros. Sci., 2017, 122, p 61–73.

D.A. Porter and K.E. Easterling, Phase Transformations in Metals and Alloys, 3rd ed. Taylor & Francis, 1992.

D.A.H. Hanaor and C.C. Sorrell, Review of the Anatase to Rutile Phase Transformation, J. Mater. Sci., 2011, 46(4), p 855–874.

H.L. Ma, J.Y. Yang, Y. Dai, Y.B. Zhang, B. Lu, and G.H. Ma, Raman Study of Phase Transformation of TiO2 Rutile Single Crystal Irradiated by Infrared Femtosecond Laser, Appl. Surf. Sci., 2007, 253(18), p 7497–7500.

I. Lukačević, S.K. Gupta, P.K. Jha, and D. Kirin, Lattice Dynamics and Raman Spectrum of Rutile TiO2: The Role of Soft Phonon Modes in Pressure Induced Phase Transition, Mater. Chem. Phys., 2012, 137(1), p 282–289.

E.J. Ekoi, A. Gowen, R. Dorrepaal, and D.P. Dowling, Characterisation of Titanium Oxide Layers Using Raman Spectroscopy and Optical Profilometry: Influence of Oxide Properties, Res. Phys., 2019, 12, p 1574–1585.

Acknowledgments

The authors are indebted to Marmara University, Dokuz Eylül University and Katip Çelebi University for infrastructural support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Demirci, S., Kıran Yıldırım, B., Tünçay, M.M. et al. Non-isothermal Kinetic Analysis of High Temperature Oxidation of Additively Manufactured Ti-6Al-4V Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09557-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09557-6