Abstract

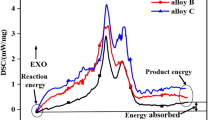

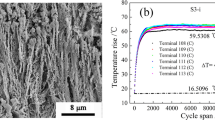

Additive manufacturing (AM) produced Ni-based oxide dispersion-strengthened (ODS) alloy is promising for fabricating intrinsic structural parts under high-temperature operating condition, while little effort has been focused on the oxidation behavior of such alloys by AM. In this study, cyclic oxidation behavior and microstructure of additively manufactured Ni-based ODS alloy were evaluated up to 1100 °C for 2040 thermal cycles. The oxide layer and microstructure were characterized at various thermal cycles using scanning electron microscope (SEM), transmission electron microscope (TEM), and x-ray diffractometer (XRD), respectively. The results showed ultrafine Y-rich particles (<20 nm) in both as-printed and oxidized ODS coupons. In the early oxidation stages, continuous Al2O3 formed underneath oxide mixture of Cr2O3 and NiO with oxide spallation of Cr2O3 and NiO due to the thermal expansion mismatch at later oxidation stages. Uniform oxide dispersion of yttria contributed the stability of Al2O3 layer and thus preserved γ′ phase in the alloy substrate as well as fine grain structure by reducing elemental diffusion and blocking dislocation movement.

Similar content being viewed by others

References

J.S. Benjamin, Dispersion Strengthened Superalloys by Mechanical Alloying, Metall. Trans., 1970, 1(10), p 2943–2951.

S. Weinbruch, A. Anastassiadis, H.M. Ortner, H.P. Martinz, and P. Wilhartitz, On the Mechanism of High-Temperature Oxidation of ODS Superalloys: Significance of Yttrium Depletion Within the Oxide Scales, Oxid. Metals, 1999, 51(1–2), p 111–128.

P.S. Gilman and J.S. Benjamin, Mechanical Alloying, Annu. Rev. Mater. Sci., 1983, 13(1), p 279–300.

H.K.D.H. Bhadeshia, Recrystallisation of Practical Mechanically Alloyed Iron-Base and Nickel-Base Superalloys, Mater. Sci. Eng. A, 1997, 223(1), p 64–77.

M. Durand-Charre, The Microstructure of Superalloys, Routledge, London, 2017.

T.A. Ramanarayanan, M. Raghavan, and R. Petkovic-Luton, The Characteristics of Alumina Scales Formed on Fe-Based Yttria-Dispersed Alloys, J. Electrochem. Soc., 1984, 131(4), p 923–931.

B.A. Pint and K.B. Alexander, Grain Boundary Segregation of Cation Dopants in α-Al2O3 Scales, J. Electrochem. Soc., 1998, 145(6), p 1819–1829.

D. Sun, C. Liang, J. Shang, J. Yin, Y. Song, W. Li, T. Liang, and X. Zhang, Effect of Y2O3 Contents on Oxidation Resistance at 1150°C and Mechanical Properties at Room Temperature of ODS Ni-20Cr-5Al Alloy, Appl. Surf. Sci., 2016, 385, p 587–596.

W.J. Quadakkers, Growth Mechanisms of Oxide Scales on ODS Alloys in the Temperature Range 1000–1100°C, Mater. Corros., 1990, 41(12), p 659–668.

J.P. Buban, K. Matsunaga, J. Chen, N. Shibata, W.Y. Ching, T. Yamamoto, and Y. Ikuhara, Grain Boundary Strengthening in Alumina by Rare Earth Impurities, Science, 2006, 311(5758), p 212–215.

Z. Min, S.N. Parbat, L. Yang, B. Kang, and M.K. Chyu, Fabrication and Characterization of Additive Manufactured Nickel-Based Oxide Dispersion Strengthened Coating Layer for High-Temperature Application, J. Eng. Gas Turbines Power, 2018, 140(6), p 062101.

E. Chia, B.S. Kang, M. Zheng, Y. Li, and M. Chyu, Development of ODS Coating for High Temperature Turbine Components Using DED Additive Manufacturing, in ASME Turbo Expo 2018: Turbomachinery Technical Conference and Exposition (2018)

L.P.H. Jeurgens, W.G. Sloof, F.D. Tichelaar, and E. Mittemeijer, Growth Kinetics and Mechanisms of Aluminum-Oxide Films Formed by Thermal Oxidation of Aluminum, J. Appl. Phys., 2002, 92, p 1649–1656.

G.A. Hope and I.M. Ritchie, Mechanism of Chromium Oxidation, J. Chem. Soc. Faraday Trans. 1 Phys. Chem. Condens. Phases, 1981, 77(11), p 2621–2631.

Y. Zhai, Y. Chen, Y. Zhao, H. Long, X. Li, Q. Deng, H. Lu, X. Yang, G. Yang, W. Li, L. Yang, S. Mao, Z. Zhang, A. Li, and X. Han, Initial Oxidation of Ni-Based Superalloy and Its Dynamic Microscopic Mechanisms: The Interface Junction Initiated Outwards Oxidation, Acta Mater., 2021, 215, p 116991.

B. Ahmad and P. Fox, STEM Analysis of the Transient Oxidation of a Ni-20Cr Alloy at High Temperature, Oxid. Metals, 1999, 52(1), p 113–138.

A. AlGahtani, S. AlMutairi, A.Y. Adesina, and B. AlMangour, Oxidation Performance of Inconel 718 Alloy Fabricated by Directed Energy Deposition, J. Mater. Eng. Perform., 2023. https://doi.org/10.1007/s11665-023-08785-6.

T. Sanviemvongsak, D. Monceau, C. Desgranges, and B. Macquaire, Intergranular Oxidation of Ni-Base Alloy 718 with a Focus on Additive Manufacturing, Corros. Sci., 2020, 170, p 108684.

Y.-J. Kang, S. Yang, Y.-K. Kim, B. AlMangour, and K.-A. Lee, Effect of Post-treatment on the Microstructure and High-Temperature Oxidation Behaviour of Additively Manufactured Inconel 718 Alloy, Corros. Sci., 2019, 158, p 108082.

T. Sanviemvongsak, D. Monceau, M. Madelain, C. Desgranges, J. Smialek, and B. Macquaire, Cyclic Oxidation of Alloy 718 Produced by Additive Manufacturing Compared to a Wrought-718 Alloy, Corros. Sci., 2021, 192, p 109804.

S. Dryepondt, M.M. Kirka, and F.A. List III, Oxidation Behavior of Ni-Based Alloys Fabricated by Additive Manufacturing, NACE CORROSION, NACE, 2019, pp NACE-2019-13558

C. Guo, Z. Yu, C. Liu, X. Li, Q. Zhu, and R. Mark Ward, Effects of Y2O3 Nanoparticles on the High-Temperature Oxidation behavior of IN738LC Manufactured by Laser Powder Bed Fusion, Corros. Sci., 2020, 171, p 108715.

B.S. Kang and C. Ma, Development of ODS Coating for Critical Turbine Components Using DED Additive Manufacturing, in ASME Turbo Expo 2020: Turbomachinery Technical Conference and Exposition, 2020

B.A. Pint, P.F. Tortorelli, and I.G. Wright, Effect of Cycle Frequency on High-Temperature Oxidation Behavior of Alumina-Forming Alloys, Oxid. Metals, 2002, 58(1), p 73–101.

C. Kenel, A. De Luca, S.S. Joglekar, C. Leinenbach, and D.C. Dunand, Evolution of Y2O3 Dispersoids During Laser Powder Bed Fusion of Oxide Dispersion Strengthened Ni-Cr-Al-Ti γ/γ’ Superalloy, Addit. Manuf., 2021, 47, p 102224.

J.R. Rieken, I.E. Anderson, M.J. Kramer, G.R. Odette, E. Stergar, and E. Haney, Reactive Gas Atomization Processing for Fe-Based ODS Alloys, J. Nucl. Mater., 2012, 428(1), p 65–75.

L. Ma, B.S.J. Kang, M.A. Alvin, and C.C. Huang, Characterization of Oxide-Dispersion-Strengthened (ODS) Alloy Powders Processed by Mechano-Chemical-Bonding (MCB) and Balling Milling (BM), Kona Powder Part. J., 2014, 31, p 146–155.

C. Ma, K. Rozman, D. Straub, O. Dogan, S. Parbat, M. Chyu, and B. Kang, Investigation of Microstructure and Mechanical Properties of Additive Manufacturing Fabricated Oxide Dispersion Strengthening (ODS) IN718 Alloys, 2023, pp. 75–83

M. Grandhi, C. Ma, Z. Liu, and B. Kang, Microstructural Characterization and Properties of Laser-DED Built Oxide Dispersion Strengthened SS 316 L, Manuf. Lett., 2022, 33, p 758–764.

S. Ukai and M. Fujiwara, Perspective of ODS Alloys Application in Nuclear Environments, J. Nucl. Mater., 2002, 307–311, p 749–757.

D. Naumenko, B. Pint, and W. Quadakkers, Current Thoughts on Reactive Element Effects in Alumina-Forming Systems. In Memory of John Stringer, Oxid. Metals, 2016, 86, p 1–43.

B. Wahlmann, F. Galgon, A. Stark, S. Gayer, N. Schell, P. Staron, and C. Körner, Growth and Coarsening Kinetics of Gamma Prime Precipitates in CMSX-4 Under Simulated Additive Manufacturing Conditions, Acta Mater., 2019, 180, p 84–96.

C.S. Giggins and F.S. Pettit, Oxidation of Ni-Cr-Al Alloys Between 1000° and 1200°C, J. Electrochem. Soc., 1971, 118(11), p 1782.

V. Guttmann, J.L. Gonzalez-Carrasco, and H. Fattori, Oxidation Behavior of ODS Alloy MA 6000, Oxid. Metals, 1999, 51(1), p 159–180.

Y. Sun, L. Chen, L. Li, and X. Ren, High-Temperature Oxidation Behavior and Mechanism of Inconel 625 Super-Alloy Fabricated by Selective Laser Melting, Opt. Laser Technol., 2020, 132, p 106509.

H. Over and A.P. Seitsonen, Surface Chemistry: Oxidation of Metal Surfaces, Science, 2002, 297(5589), p 2003–2005.

L. Li, L. Luo, J. Ciston, W.A. Saidi, E.A. Stach, J.C. Yang, and G. Zhou, Surface-Step-Induced Oscillatory Oxide Growth, Phys. Rev. Lett., 2014, 113(13), p 136104.

R. Shannon, Revised Effective Ionic Radii and Systematic Studies of Interatomic Distances in Halides and Chalcogenides, Acta Crystallogr. Sect. A, 1976, 32(5), p 751–767.

M.P. Brady, Y. Yamamoto, M.L. Santella, and L.R. Walker, Composition, Microstructure, and Water Vapor Effects on Internal/External Oxidation of Alumina-Forming Austenitic Stainless Steels, Oxid. Metals, 2009, 72(5), p 311.

Y. Yamamoto, M.P. Brady, M.L. Santella, H. Bei, P.J. Maziasz, and B.A. Pint, Overview of Strategies for High-Temperature Creep and Oxidation Resistance of Alumina-Forming Austenitic Stainless Steels, Metall. Mater. Trans. A, 2011, 42(4), p 922–931.

N. Vermaak, A. Mottura, and T.M. Pollock, Cyclic Oxidation of High Temperature Coatings on New γ′-Strengthened Cobalt-Based Alloys, Corros. Sci., 2013, 75, p 300–308.

K.M.N. Prasanna, A.S. Khanna, R. Chandra, and W.J. Quadakkers, Effect of θ-Alumina Formation on the Growth Kinetics of Alumina-Forming Superalloys, Oxid. Metals, 1996, 46(5), p 465–480.

J.A. Haynes, B.A. Pint, W.D. Porter, and I.G. Wright, Comparison of Thermal Expansion and Oxidation Behavior of Various High-Temperature Coating Materials and Superalloys, Mater. High Temp., 2004, 21(2), p 87–94.

B.A. Pint, The Future of Alumina-Forming Alloys: Challenges and Applications for Power Generation, Mater. Sci. Forum, 2011, 696, p 57–62.

G.R. Wallwork and A.Z. Hed, Some Limiting Factors in the Use of Alloys at High Temperatures, Oxid. Metals, 1971, 3(2), p 171–184.

A. Løken, S. Ricote, and S. Wachowski, Thermal and Chemical Expansion in Proton Ceramic Electrolytes and Compatible Electrodes, Crystals, 2018, 8, p 365.

X. Pang, K. Gao, H. Yang, L. Qiao, Y. Wang, and A.A. Volinsky, Interfacial Microstructure of Chromium Oxide Coatings, Adv. Eng. Mater., 2007, 9(7), p 594–599.

C.J. Engberg and E.H. Zehms, Thermal Expansion of Al2O3, BeO, MgO, B4C, SiC, and TiC Above 1000°C, J. Am. Ceram. Soc., 1959, 42(6), p 300–305.

G. Bayer, Thermal Expansion of Oxide Compounds with Spinel Structure, Thermochim. Acta, 1972, 3(6), p 421–426.

A. Petric and H. Ling, Electrical Conductivity and Thermal Expansion of Spinels at Elevated Temperatures, J. Am. Ceram. Soc., 2007, 90, p 1515–1520.

C. Zhu, A. Javed, P. Li, F. Yang, G.Y. Liang, and P. Xiao, A Study of the Microstructure and Oxidation Behavior of Alumina/Yttria-Stabilized Zirconia (Al2O3/YSZ) Thermal Barrier Coatings, Surf. Coat. Technol., 2012, 212, p 214–222.

D. Sun, C. Liang, E. Wang, H. Liu, and X. Zhang, The Oxidation of Four Oxide Dispersion Strengthened Ni-5Al-x Si-0.2Y2O3 (x = 1, 3, 5, 7 wt.%) alloys in air at 1100 °C, Corros. Sci., 2018, 133, p 336–348.

Acknowledgments

The authors express their gratitude for the financial support provided by the United States Department of Energy [Award Number: DE-FE0031277] and the support received from the Instrumentation Seed Program for Innovative Research (InSPIRe) from West Virginia University Research Corporation (WVURC) and WVU Statler College of Engineering and Mineral Resources. The authors also acknowledge the utilization of West Virginia University Shared Research Facilities (SRF). Special thanks are extended to Dr. Qiang Wang and Dr. Marcela Redigolo at WVU SRF for their valuable assistance with XRD and TEM tests, respectively.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, C., Kang, B.S. Oxidation Behavior of Ni-Based Oxide Dispersion-Strengthened Alloy Fabricated by Direct Energy Deposition at 1100 °C. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09449-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09449-9