Abstract

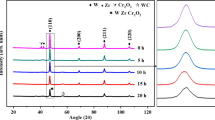

Oxidation behavior at 800°C, 1000°C and 1200°C of nano-Cr2O3 dispersed W-Zr alloys fabricated using mechanical milling followed by conventional sintering at 1500°C in inert atmosphere is discussed. Three different alloys were designated as W-0.5Zr-1Cr2O3 (alloy A), W-0.5Zr-2Cr2O3 (alloy B), and W-1Zr-1Cr2O3 (alloy C) (in wt.%). The application range of W is greatly restricted by oxidation, necessitating the use of suitable alloying and dispersion techniques. Upon exposure to 800°C, alloy A exhibited the highest level of oxidation resistance, whereas alloy B demonstrated superior performance at 1000°C and 1200°C. This enhanced oxidation resistance in alloy B can be attributed to its microstructure, characterized by a fine and uniform distributed Cr2O3-rich and Zr-rich phase. At 800°C, protection against oxidation primarily resulted from improved densification, enhanced adhesion of oxide scale with the matrix phase, and decreased volatilization of WO3. However, at ≥ 1000°C, the development of Cr2WO6 seems to play a vital role. Higher activation energy was also observed in the current alloys compared to pure W, attributed to the combined influence of Cr2O3 and Zr dispersion. This study offers valuable insights into the development of oxidation-resistant alloys through Cr2O3 dispersion, particularly applicable for high-temperature applications.

Similar content being viewed by others

References

E. Lassner and W.D. Schubert, Tungsten Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds (Kluwer Academic, New York, 1999).

Q. Wei, H.T. Zhang, B.E. Schuster, K.T. Ramesh, R.Z. Valiev, L.J. Kecskes, R.J. Dowding, L. Mag-ness, and K. Cho, Acta Mater. 54, 4079 (2006).

A. Patra, Oxide Dispersion Strengthened Refractory Alloys, 1st edn. (CRC Press, Boca Raton, 2022).

J.R. Davis, ASM Specialty Handbook: Heat-Resistant Materials (ASM International, Cleveland, 1999).

F. Klein, T. Wegener, A. Litnovsky, M. Rasinski, X.Y. Tan, J. Gonzalez-Julian, J. Schmitz, M. Bram, J.W. Coenen, and C. Linsmeier, Nucl. Mater. Energy 15, 226 (2018).

A. Litnovsky, T. Wegener, F. Klein, C. Linsmeier, M. Rasinski, A. Kreter, X. Tan, J. Schmitz, Y. Mao, J.W. Coenen, M. Bram, and J. Gonzalez-Julian, Plasma Phys. Control. Fusion 59, 064003 (2017).

A. Hedayat, H. Davilu, and J. Jafari, Loss of coolant accident analyses on tehran research reactor by RELAP5/MOD3.2 code. Prog. Nucl. Energy 49, 511–528 (2007).

T. Wegener, F. Klein, A. Litnovsky, M. Rasinski, J. Brinkmann, F. Koch, and C. Linsmeier, Nucl. Mater. Energy 9, 394 (2016).

A. Calvo, K. Schlueter, E. Tejado, G. Pintsuk, N. Ordás, I. Iturriza, R. Neu, J.Y. Pastor, and C. García-Rosales, Int. J. Refract. Met. Hard Mater. 73, 29 (2018).

J. Das, G. Appa Rao, S.K. Pabi, M. Sankaranarayana, and T.K. Nandy, Int. J. Refract. Met. Hard Mater. 47, 25 (2014).

X.Y. Tan, F. Klein, A. Litnovsky, T. Wegener, J. Schmitz, C. Linsmeier, J.W. Coenen, U. Breuer, M. Rasinski, P. Li, L.M. Luo, and Y.C. Wu, Corros. Sci. 147, 201 (2019).

Y. Itoh, and Y. Ishiwata, JSME Int. J. Ser. A Mech. Mater. Eng. 39, 429 (1996).

S. Telu, R. Mitra, and S.K. Pabi, Metall. Mater. Trans. A 46A, 5909 (2015).

A. Patra, M. Meraj, S. Pal, N. Yedla, and S.K. Karak, Int. J. Refract. Met. Hard Mater. 58, 57 (2016).

V.R. Talekar, A. Patra, S.K. Sahoo, S.K. Karak, and B. Mishra, Int. J. Refract. Met. Hard Mater. 82, 183 (2019).

Z.M. Xie, R. Liu, Q.F. Fang, Y. Zhou, X.P. Wang, and C.S. Liu, J. Nucl. Mater. 444(1–3), 175 (2014).

R. Liu, Z.M. Xie, T. Hao, Y. Zhou, X.P. Wang, Q.F. Fang, and C.S. Liu, J. Nucl. Mater. 451(1–3), 35 (2014).

H. Kurishita, T. Kuwabara, M. Hasegawa, S. Kobayashi, and K. Nakai, J. Nucl. Mater. 343(1–3), 318 (2005).

H. Kurishita, Y. Amano, S. Kobayashi, K. Nakai, H. Arakawa, Y. Hiraoka, T. Takida, K. Takebe, and H. Matsui, J. Nucl. Mater. 367–370, 1453 (2007).

I. Wesemann, W. Spielmann, P. Heel, and A. Hoffmann, Int. J. Refract. Met. Hard Mater. 28, 687 (2010).

B. Das and A. Patra, Mater. Today Proceed. 62, 6055 (2022).

M.A. Yar, S. Wahlberg, H. Bergqvist, H.G. Salem, M. Johnsson, and M. Muhammed, J. Nucl. Mater. 412, 227 (2011).

A. Muñoz, M.A. Monge, B. Savoini, M.E. Rabanal, G. Garces, and R. Pareja, J. Nucl. Mater. 417, 508 (2011).

B. Das, A.R. Khan, and A. Patra, Effect of nano-Cr2O3 dispersed W-Zr alloys by mechanical alloying and pressureless conventional sintering. J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-023-08357-8 (2023).

S. Zhang, R. Li, and Y. Xu, Mater. Res. Express 9, 096510 (2022).

Y. Kim, M.H. Hong, S.H. Lee, E.P. Kim, S. Lee, and J.W. Noh, Met. Mater. Int. 12(3), 245–248 (2006).

S. Samal, High-temperature oxidation of metals, in High Temperature Corrosion, ed. by Z. Ahmad (IntechOpen, 2016), vol. 12, pp. 11–17. https://doi.org/10.5772/63000.

N. Cabrera and N.F. Mott, Theory of the oxidation of metal. Rep. Prog. Phys. 12, 163–184 (1949).

C. Wagner, J. Electrochem. Soc. 99, 369 (1952).

G.C. Wood, Oxid. Met. 2(1), 11 (1970).

D. Yong, High Temperature Oxidation and Corrosion of Metals, first edition, Elsevier Science, 2008 6th August 2008. ISBN: 9780080559414.

G. Tammann and Z. Anorg, Allg. Chem. 111, 78–89 (1920).

A.T. Fromhold, Theory of Metal Oxidation, North Holland Publishing Company, Amsterdam, 1976 Signatur an der Bibliothek der Uni Graz:I 466591.

F. Koch, S. Koppl, and H. Bolt, J. Nucl. Mater. 386–388, 572 (2009).

P. López-Ruiz, N. Ordás, S. Lindig, F. Koch, I. Iturriza, and C. García-Rosales, Phys. Scr. T145, 014018 (2011).

N.B. Pilling and R.E. Bedworth, J. Inst. Met. 29, 529 (1923).

R.F. Speyer. Thermal Analysis of Materials (1st ed.). CRC Press. https://doi.org/10.1201/9781482277425

M.A. Meyers, A. Mishra, and D.J. Benson, Prog. Mater. Sci. 51, 427 (2006).

W.W. Webb, J.T. Norton, and C. Wagner, J. Electrochem. Soc. 103, 107 (1956).

J.B. Berkowitz-Mattuck, A. Buchler, J.L. Engelke, and S.N. Goldstein, J. Chem. Phys. 39, 2722 (1963).

E.A. Gulbransen, Corrosion 26, 19 (1970).

Y.A. Yang, Y. Ma, J.N. Yao, and B.H. Loo, J. Non-Cryst. Solids 272, 71 (2000).

O. Kubaschewski and B.E. Hopkins, J. Less-Common Met. 2, 172 (1960).

M.A. Monge, P. Adeva, A. Muñoz, and P. Pérez, Fusion Eng. Des. 146, 783 (2019).

V. Suman and D. Chaira, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-023-08366-7 (2023).

F. Koch and H. Bolt, Phys. Scr. T128, 100 https://doi.org/10.1088/0031-8949/2007/T128/020 (2007).

S. Samal, High Temp. Corros. https://doi.org/10.5772/63000 (2016).

F.S.P. Neil Birks, and G.H. Meier, High Temperature Oxidation of metals, 2nd edn. (Cambridge University Press, Cambridge, 2000).

V.D. Barth, and G.W.P. Rengstorff, Oxidation of Tungsten, United States (1961).

P. Berthod, Oxid. Met. 64, 235 (2005).

D.J. Young, High Temperature Oxidation and Corrosion of Metals, 2nd edn. (Elsevier, New York, 2016).

M.S. Ansari, V. Chawla, A. Bansal, et al., J. Mater. Eng. Perform. 31, 753 (2022).

S. Telu, R. Mitra, and S.K. Pabi, Int. J. Refract. Met. Hard Mater. 38, 47 (2013).

T.A. Ramanarayanan, R. Ayer, R. Petkovic-Luton, and D.P. Leta, Oxid. Met. 29, 445 (1988).

K.T. Faber and A.G. Evans, Acta Metall. 31, 565 (1983).

D. Ghosh, S. Mukherjee, and S. Das, Surf. Eng. 30, 524 (2014).

H.E. Evans, Int. Mater. Rev. 40, 1 (1995).

S. Telu, A. Patra, M. Sankaranarayana, R. Mitra, and S.K. Pabi, Int. J. Refract. Met. Hard Mater. 36, 191 (2013).

G. Bayer, J. Am. Ceram. Soc. 43, 495 (1960).

T. Ekström and R.J.D. Tilley, Mater. Res. Bull. 10, 1175 (1975).

C.F. Gardinier and L.L.Y. Chang, J. Am. Ceram. Soc. 61, 376 (1978).

K.T. Jacob, J. Mater. Sci. 15, 2167 (1980).

C. Cantalini, J. Eur. Ceram. Soc. 24, 1421 (2004).

W. Kunnmann, S. La Placa, L.M. Corliss, J.M. Hastings, and E. Banks, J. Phys. Chem. Solids 29, 1359 (1968).

W. Liu, C. Ye, L. Xue, W. Zhang, and Y. Yan, Int. J. Refract. Met. Hard Mater. 100, 105631 (2021).

Z.S. Levin and K.T. Hartwig, Mater. Sci. Eng. A 635, 94 (2015).

Acknowledgements

We acknowledge the financial support provided by TEQIP II NIT Rourkela, along with the assistance from FIST-DST for conducting the XRD study.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

Credit author statement: BD: Methodology, Investigation, Formal analysis, Writing, Software, Data Curation, Visualization, Writing- Original draft preparation: VS: Reviewing and Editing: AP: Conceptualization, Methodology, Reviewing and Editing, Supervision.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Das, B., Suman, V. & Patra, A. Comparative Study of Oxidation Behavior of Cr2O3 Dispersed W-Zr Alloys at 800°C, 1000°C and 1200°C Fabricated Using Powder Metallurgy. JOM (2024). https://doi.org/10.1007/s11837-024-06515-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06515-4