Abstract

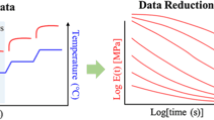

Viscoelastic materials exhibit a variable mechanical behavior generally investigated through Dynamic Mechanical Analysis (DMA). Such kind of test is carried out on standardized specimens, which have to be specifically produced or extracted from the component to be characterized, causing its destruction. This work, taking advantage of an innovative non-invasive testing procedure, based on an instrumented evaluation of indentation, aims to experimentally study the viscoelastic properties changes in polymer compounds, caused by exposure to UV rays. The analysis has been executed on two different polymer compounds designed for tire tread. An extensive use of UV radiation is performed to generate changes in rubber compound properties, but as concerns tire compounds application, there are only a few studies in literature and the same can be stated regarding the monitoring of properties over time using non-destructive procedures. In order to evaluate the viscoelastic properties variation, a proper test bench has been developed employing an UV lamp coupled with an innovative testing device. A test campaign has been carried out on the different tire compound specimens, tested in different conditions in terms of exposure time, exposure face and after various time ranges from the exposition. The tested compound samples exhibit a different chemical composition in terms of polymer blend ratio. The overall results highlight: the ability of the proposed technique to measure the variation in the mechanical behavior of the materials induced by exposure to UV rays and significant variations in viscoelastic properties induced on the compounds as a function of the time of exposure to UV rays and of the chemical composition.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

In the vehicle dynamics field, the investigation of the tire tread compounds viscoelastic properties is fundamental to understand the tire-road interaction phenomena. The knowledge of such properties allows to obtain useful information about the mechanical behavior of tire tread and how its response changes over time. Thanks to such information, it is possible to deeply investigate the phenomena that cause time variations of the viscoelastic response, such as progressive wear or specific chemical and physical modifications of the polymer. In this context, it is well known that polymeric materials, especially those containing double bonds and designed to be used for outdoor applications, are particularly affected by oxygen and/or UV radiation. In many cases, the combined action of these external agents is mainly responsible for the so-called photo-oxidative degradation. The UV radiation effects have been extensively investigated in literature, and it has been observed that there are various mechanisms involved in the photodegradation processes of polymers and elastomers: from the polymeric chains scission, to their crosslinking, due to free radicals generation in presence of air, resulting in a deterioration of the mechanical properties, such as stiffening and toughness reduction (Ref 1,2,3,4,5,6,7). In some applications, in which elastomers are used in cementitious matrices, these UV-induce changes in their behavior and surface finishing can be positively adopted to enhance matrix performance (Ref 8, 9). On the other hand, despite the presence of a correlation between nano-mechanical and chemical variations induced by the photo-oxidation of a vulcanized styrene-butadiene rubber specimen (Ref 10), there are no specific works focused on the correlative study between viscoelastic and chemical properties variations of tires induced by the UV. Having this information available allows an in-depth description of the viscoelastic response of the tire tread compound and, consequently, a better prediction of its performance. As a matter of fact, there is a strong link between viscoelastic properties and grip generation mechanisms that affect both tire performance and road safety (Ref 11, 12). However, even if the experimental evaluation of rubber tire’s viscoelastic behavior is necessarily required to perform a detailed analysis of the contact mechanics, the compound characterization is not always easy to be carried out, or it can become a source of further issues. For example, in motorsport applications, or in the field of quality control for tire manufacturing processes, the needed adoption of standard destructive procedures, such as the DMA methodology, makes the tire then unusable. The adoption of non-invasive testing procedures allows to perform the mechanical characterization of a component a theoretically unlimited number of times. This gives the possibility to analyze the effects of the external stresses or of the environmental conditions on the viscoelastic properties of the tires’ tread, monitoring the state during their entire lifecycle. For this reason, an innovative non-destructive methodology, known as VESevo (Viscoelasticity Evaluation System evolved) (Ref 13), has been adopted for the experimental study of the variations in viscoelastic properties.

The non-invasive nature of the technique allows to pursue the aim of the present research: the investigation of the viscoelasticity variations of the tire tread polymers’ compound caused by exposure to UV rays, as it could significantly influence vehicle safety.

The analysis has been executed on two tire tread compounds with different chemical compositions in terms of polymer blend ratio. The UV rays effects have been investigated on both compounds varying several parameters, such as exposure time, exposure face and time from the exposition. The paper is organized as follows: in Sect. 1, the principles of viscoelasticity and friction phenomena have been described. Subsequently, in Sect. 2, the innovative non-destructive procedure for viscoelastic properties evaluation is presented. Section 3 is focused on the experimental set-up adopted for the test campaign, whereas Sect. 4 shows the most significant results obtained.

2 Viscoelastic Behavior and Grip Generation Mechanisms

Pneumatic tires tread can be considered as a viscoelastic material due to its styrene-butadiene rubber (SBR) composition which offers high adhesion thanks to its peculiar mechanical behavior, described as a combination of purely elastic and viscous response to solicitations (Ref 14, 15). Typically, the viscoelastic properties of the polymeric materials are investigated with dynamic experiments imposing a sinusoidal oscillating input in terms of strain (or stress) and measuring the resulting response (Ref 16, 17). For viscoelastic materials, a signal shift between input and output occurs with a phase angle between 0 and 90°, as shown in Fig. 1(a). The input solicitation and the output response are related to each other by a transfer function which contains all the information on the physical properties of the sample. This peculiar function, known as complex dynamic modulus, is defined as follows:

where \(E^{\prime}\left( \omega \right)\) is related to energy storage mechanisms, whereas \(E^{\prime\prime}\left( \omega \right)\) describes completely irreversible processes which are not recoverable when external loads are removed. For these reasons, they are called Storage Modulus and Loss Modulus, respectively (Ref 18,19,20,21,22,23). The ratio between these two dynamic functions is equal to:

and is defined as Loss Factor, that is a measure of the polymeric material’s attitude to dissipate energy in a loading–unloading cycle, as in Fig. 1(b). These viscoelastic properties play an important role in the two mechanisms of grip generation which take place at rubber-road interface (Ref 11, 24,25,26), as shown in Fig. 2:

Main mechanisms of grip generation in tire-road interactions (Ref 27).

-

The first mechanism, known as road roughness effect, involves the hysteretic nature of the rubber tire that causes its asymmetrical deformation generating a tangential force in opposite direction to the slippage speed. This results in a hysteretic grip generation;

-

The second one is molecular adhesion which involves the polymeric chains’ ability to resist to deformation thanks to their viscous properties, generating friction.

From these considerations, it is noticeable how evident is a the link between vehicle performance and safety and the tire tread viscoelastic behavior.

3 Non-Destructive Viscoelasticity Evaluation

The viscoelastic analysis of tire tread compounds can be carried out with different testing methods. They can be destructive or non-destructive tests, depending on the capability to perform the analysis without damaging the tire sample itself. Among these characterization techniques, the Dynamic Mechanical Analysis is one of the most known. However, the complex and bulky equipment related to this technology implies that it can be carried out only in particular and controlled environments, such as laboratories. In addition, DMA cannot be always applied for tread characterization because the tire must necessarily be destroyed in order to extract a specimen with specific dimensions required by the standardized testing procedures. In this scenario, recent studies have been conducted in order to develop different methodologies for non-destructive characterization of polymers (Ref 28, 29). In this regard, VESevo technology has been proven to be a valid alternative to conventional destructive characterization methods (Ref 13). More in detail, in (Ref 28), it has been demonstrated that the results obtained with the proposed testing procedure show the same relative ranking between the compounds obtained by the DMA, both for the storage modulus and the loss tangent. Developed by the Vehicle Dynamics Research Group of the Industrial Engineering Department at the University of Naples “Federico II”, VESevo is capable of characterizing tire tread compound viscoelastic properties, their variations due to cooling/heating thermal cycles and to monitor their time-evolution. VESevo has been designed to characterize compound viscoelasticity directly on tires, performing tests both in laboratory and on track. As shown in Fig. 3(a), VESevo device houses a rod-spring mechanism which consists of a steel rod with a semi-spherical indenter and a spring element. A suitable zero-friction guide allows the steel rod to slide with a negligible damping and to bounce freely once it hits the sample surface. A specifically developed semi-automatic drop system is implemented to ensure that the rod motion starts always from the same initial position, thereby guaranteeing a high measurement repeatability. During each test, the rod displacement is measured by means of an optical laser sensor with high resolution and frequency response, whereas a compact size IR pyrometer is used for the real-time measurement of the tread surface temperature. A proper acquisition unit, illustrated in Fig. 3(b), is connected to VESevo device to record and store acquisitions in real-time. A typical raw signal of the displacement curve obtained during a single acquisition is shown in Fig. 4 for a specific measured temperature. The displacement curve exhibits three different phases which are essential for the evaluation of several physical magnitudes related to the viscoelastic behavior. The first phase is represented by the monotonically decreasing curve section, which reflects the free fall of the steel rod followed by the sinking of the indenter, corresponding to the minimum point of the acquisition curve. In the second phase, the rod reaches the maximum point of the curve after the first indentation as a result of its interaction with the tread surface. The last phase is characterized by a stabilized rod displacement value corresponding to the indenter-sample contact when the rebound phenomenon is completely extinct. In order to investigate the temperature dependence of the compound viscoelastic response, the displacement curves are acquired over the entire operating temperature range. Typically, the VESevo test session is carried out using the following standard testing procedure:

-

About 30 acquisitions at ambient temperature;

-

Cooling down to about −20 °C employing a climatic cell, a freezing spray or any other method capable to keep the temperature low and stable and then, performing VESevo acquisitions during the natural heating process up to ambient temperature;

-

Forced heating up to 100 °C through a thermal blanket or a professional heating gun and then, carrying out acquisitions down to ambient temperature.

In Fig. 5, it is clearly highlighted how the temperature strongly affects the rod-sample interaction and, consequently, the rebound phenomenon, both in terms of the amplitude and of the bounces number, reflecting the viscoelastic response variation: At low temperatures, high energy dissipation occurs and the material behaves as a glassy solid; when the compound is heated up to about 100 °C, on the other side, a progressive decrease in the energy dissipation is observed with a resulting increase in rebounds number, with an evident highlight of the rubbery behavior. Here, it is worth noting that the first phase of rod free fall is not dependent on the sample’s temperature; thus, the impact velocity of the rod is always the same in all the tested temperature range generating, in turn, the same material excitation.

From the rod displacement raw signals, it is possible to evaluate the viscoelastic properties. Particularly, the Loss Factor can be defined with the following mathematical relationship obtained by modeling the dynamic response of the steel rod with a second-order damped mass-spring system (Ref 30):

where \(\omega_{s}\) is the frequency of the damped motion of the rod on the viscoelastic surface, while \(K_{c}\) and \(\sigma_{c}\) represent the equivalent contact stiffness and damping coefficient, respectively. It is worth noting that as described in (Ref 28), since we referred to the damped motion of the rod, the frequency value \(\omega_{s}\) depends on the temperature of the specimen in a single acquisition. The lower the temperature, the shorter the contact duration; contrary, increasing the temperature, the compound behaves as a pure viscous solid and the indentation phase will be longer

4 Experimental Set-Up

The polymeric materials degradation, induced by the UV radiation exposure, and the relative changes of their mechanical properties have been investigated by setting up a proper test bench for the viscoelasticity characterization of different polymer compounds designed to be used as tire treads. Notice that all the tests have been conducted on tire tread flat samples, with the same testing procedure described in Sect. 2 and in the same environmental conditions. Thus, there are no-influences of typical tires parameters such as inflation pressure. The polymeric samples, provided by a compounds manufacturer, are SBR/BR rubber blends. In more detail, two polymeric compounds, denoted as Compound A and B, have been selected in the shape of 10 × 10 cm square slabs with different blend ratios. For each slab, four zones of measurement have been characterized with VESevo device before the UV treatment in order to verify the homogeneity of their properties. After this check, each compound has been divided into three square-shaped subsamples, as summarized in Table 1:

-

First subsample has been chosen as reference material, and it has not been interested by any irradiation treatment;

-

Second and third subsamples, instead, have been subjected to a UV exposure cycle.

Particularly, two different exposure times have been chosen to investigate viscoelastic properties variations and the compounds’ susceptibility to UV rays as the blend ratio changes. The UV irradiation has been performed following the ISO standard for the UV exposure (Ref 31): All subsamples under analysis have been irradiated in dry conditions with the same irradiation intensity, regardless of the exposure time. In addition, no external stress is applied to the specimens during the UV exposure treatment. The test bench mainly consists of:

-

UV rays source: a Scangrip UV-Gun showed in Fig. 6(a), which houses a UV lamp capable of emitting ultraviolet radiation with a UV peak at 395-400 nm;

-

A horizontal worktable on which the UV-Gun is placed and a vertical surface on which the polymer subsamples to be exposed are fixed.

In order to obtain the right irradiance and a proper curing area such as to guarantee uniform irradiation of all polymer subsamples at the same time, the UV curing lamp is positioned at a distance of 56 cm from the specimens. An external IR pyrometer, Fig. 6(b), has been used for the real-time monitoring of the specimens temperature, to verify that eventual significant thermal heating did not occur during the UV exposure cycle. After the irradiation treatment, VESevo has been employed. Three tests have been carried out for each subsample with the aim of having a statistically representative measurement set of the viscoelastic characterization outputs. The overall results shown in the following section represent the average of such three tests.

5 Result Analysis

In order to measure only the UV-induced viscoelastic changes, it is important to ensure that the virgin polymer compounds do not exhibit intrinsic time variations in their mechanical behavior, due to early aging phenomena. To this end, all subsamples have been tested with the VESevo device before the UV treatment in two separate test sessions, at a distance of two months from each other. The single test session involves two sub-sessions consisting of two consecutive days of testing carried out in the same week. The resulting VESevo curves confirmed that the specimens exhibit long-term stability of the viscoelastic properties. In addition, VESevo characterization has shown that the two selected compounds exhibit different viscoelastic responses as the blend ratio changes, as shown in Fig. 7. Particularly, both the Loss Factor peak and the corresponding temperature decrease with the rise of Butadiene Rubber content. Conversely, there are no evident differences at higher temperatures. After this preliminary analysis, UV irradiation has been carried out. During the UV exposure cycle, an increase in the subsamples surface temperature of about 10 °C has been measured by the external IR pyrometer. To understand if the UV irradiation is able to propagate inside the material causing modifications in the viscoelastic response, only one face of the polymeric subsamples has been exposed to UV rays. After one hour from the exposure cycle, the treated side of the specimens has been tested with the VESevo device following the standard testing procedure. The same test has been carried out after 24 h on both sides of the slabs in order to verify if the effects of the UV curing treatment on the viscoelastic properties change over this time period. The results of Compound A are shown in Fig. 8. For this compound, an exposure time of 10 min leads to a slight decrease in the Loss Factor peak after 1 h and a more marked reduction after 24 h; both sides are affected by the same hardening phenomenon. On the other hand, an exposure time of 30 min causes a slight decrease in Loss Factor only for the cured side tested after 1 h, while in all other cases, an evident increase in the Loss Factor peak values has been observed. The same viscoelastic analysis has been performed on Compound B (Fig. 9). It shows different viscoelastic responses as a function of the exposure time. Particularly, with an exposure duration of 10 min, the following trends are observed:

-

A slight reduction in the Loss Factor values at low temperatures after one hour from the UV rays treatment compared to the unexposed reference material although this effect does not appear on the cured side;

-

Tests carried out 24 h after the UV radiation show a slight reduction in the Loss Factor on both sides of the compound under analysis.

An exposure duration of 30 min seems to have no effect on the Loss Factor curves of both sides of the compound tested after one hour. After 24 h, an increase in the Loss Factor peak value on the unexposed side has been observed. The overall results highlight that the UV curing treatment affects not only the surface properties but also the viscoelastic response of the polymer compound in the bulk. The most significant variations are observed at low temperatures, close to the Loss Factor peak, especially after 24 h from the treatment. In addition, Compound A seems to be more susceptible to UV radiations as viscoelastic curves suggest.

6 Conclusions

In this work, the investigation of the viscoelastic properties variations of polymeric materials induced by UV irradiation has been performed. The viscoelasticity characterization has been carried out on different polymer compounds by means of a non-destructive testing device, known as VESevo. The output curves obtained with the VESevo technology clearly highlight different viscoelastic responses of the compounds as a function of the exposure time and blend ratio. The compound with a higher content of SBR seems to have a greater susceptibility to the UV treatment, especially for higher exposure times. In general, both sides of each sample exhibit noticeable variations proving that the UV radiation exposure affects both surface and bulk properties. Interesting future developments might include:

-

A correlation study between the UV-induced viscoelastic properties variations measured by the VESevo technology, and chemical-physical properties measured with appropriate instrumentation;

-

Investigation of the UV radiation effects directly on the tires evaluating how the UV-induced changes in viscoelastic properties affect the grip performance of the pneumatic tires.

-

Thanks to the proposed methodology, new research scenarios could be opened, investigating how the tires aging due to their exposure to the natural UV Ray affects the viscoelastic properties. This may help to define strategies to check their stability to improve vehicle safety.

References

J.F. Rabek, Photodegradation of Polymers: Physical Characteristics and Applications, Springer, Cham, 2012.

M.G. Aboelkheir, R.D.T Filho, and F.G Souza Jr, Study on Vulcanized Rubber Degradation after Exposure to Ultraviolet Irradiation (2019).

J.A. Bousquet and J.P. Fouassier, Photo-Oxidation of Elastomers. A Fundamental Approach Based on the Study of a Series of Photo-Sensitive Elastomeric Systems: A Review, Polym. Degrad. Stab., 1987, 18(2), p 163–185.

C. Adam, J. Lacoste, and J. Lemaire, Photo-Oxidation of Elastomeric Materials: Part II—Photo-Oxidation of Styrene-Butadiene Copolymer, Polym. Degrad. Stab., 1989, 26(3), p 269–284.

M. Nowakowska, Photo-Oxidation of Styrene-Butadiene Copolymer: Importance of a Copolymer-Oxygen Collision Complex, Polym. Photochem., 1985, 6(4), p 303–318.

D. Ruch, C. Becker, A. Riche, S. Etienne, and J. Bour, Photooxidation of Dyed Styrene-Butadiene and Natural Rubbers, Polym. Sci. Ser. A, 2008, 50(6), p 716–720.

M. Piton and A. Rivaton, Photo-Oxidation of ABS at Long Wavelengths (λ> 300 nm), Polym. Degrad. Stab., 1997, 55(2), p 147–157.

A. Alawais and R.P. West, Ultra-Violet and Chemical Treatment of Crumb Rubber Aggregate in a Sustainable Concrete Mix, J. Struct. Integr. Maint., 2019, 4(3), p 144–152.

G. Ossola and A. Wojcik, UV Modification of Tire Rubber for Use in Cementitious Composites, Cement Concr. Compos., 2014, 52, p 34–41.

G. Mertz, F. Hassouna, P. Leclère, A. Dahoun, V. Toniazzo, and D. Ruch, Correlation Between (Nano)-Mechanical and Chemical Changes Occurring during Photo-Oxidation of Filled Vulcanised Styrene Butadiene Rubber (SBR), Polym. Degrad. Stab., 2012, 97(11), p 2195–2201.

A. Genovese, F. Carputo, M. Ciavarella, F. Farroni, A. Papangelo, and A. Sakhnevych, Analysis of Multiscale Theories for Viscoelastic Rubber Friction, in Conference of the Italian Association of Theoretical and Applied Mechanics, (Springer, Cham, 2019), p. 1125–1135

Y. Wang, J. Hu, F.A. Wang, H. Dong, Y. Yan, Y. Ren, and G. Yin, Tire Road Friction Coefficient Estimation: Review and Research Perspectives, Chin. J. Mech. Eng., 2022, 35(1), p 1–11.

F. Farroni, A. Genovese, A. Maiorano, A. Sakhnevych, and F. Timpone, Development of An Innovative Instrument for Non-Destructive Viscoelasticity Characterization: VESevo, in The International Conference of IFToMM Italy, (Springer, Cham, 2020), p. 804–812

R. Lakes and R.S. Lakes, Viscoelastic Materials, Cambridge University Press, Cambridge, 2009.

J. Sweeney and I.M. Ward, Mechanical properties of solid polymers, Wiley, Hoboken, NJ, 2012.

K.P. Menard and N.R. Menard, Dynamic Mechanical Analysis, CRC Press, Boca Raton, 2020.

K.S. Cho, Theory of Linear Viscoelasticity. In Viscoelasticity of Polymers, Springer, Dordrecht, 2016.

R. Christensen, Theory of Viscoelasticity: An Introduction, Elsevier, Amsterdam, 2012.

N.W. Tschoegl, The Phenomenological Theory of Linear Viscoelastic Behavior: An Introduction, Springer, Cham, 2012.

J.D. Ferry, Viscoelastic Properties of Polymers, Wiley, Hoboken, NJ, 1980.

M.T. Shaw and W.J. MacKnight, Introduction to polymer viscoelasticity, Wiley, Hoboken, NJ, 2005.

H.F. Brinson and L.C. Brinson, Polymer Engineering Science and Viscoelasticity. An Introduction, Springer, New York, NY, 2008.

J.E. Mark, B. Erman, and M. Roland, The science and technology of rubber, Academic press, Cambridge, 2013.

K.A. Grosch, The Relation Between the Friction and Visco-Elastic Properties of Rubber, Proc. R Soc. Lond. Ser. A, 1963, 274(1356), p 21–39.

B.N. Persson, Rubber Friction: Role of the Flash Temperature, J. Phys. Condens. Matter, 2006, 18(32), p 7789.

M. Klüppel and G. Heinrich, Rubber Friction on Self-Affine Road Tracks, Rubber Chem. Technol., 2000, 73(4), p 578–606.

M. Acosta, S. Kanarachos, and M. Blundell, Road Friction Virtual Sensing: A Review of Estimation Techniques with Emphasis on Low Excitation Approaches, Appl. Sci., 2017, 7(12), p 1230.

A. Genovese, A. Maiorano, and R. Russo, A Novel Methodology for Non-Destructive Characterization of Polymers’ Viscoelastic Properties, Int. J. Appl. Mech., 2022, 14(3), p 2250017.

A. Genovese and S.R. Pastore, A Novel Nondestructive Procedure for Tire Tread Viscoelastic Characterization, Tire Sci. Technol., 2022, 50(1), p 61–77.

A. Genovese and S.R. Pastore, Development of a Portable Instrument for Non-Destructive Characterization of the Polymers Viscoelastic Properties, Mech. Syst. Signal Process., 2021, 150, p 107259.

ISO 4892–3, Plastics-Methods of Exposure to Laboratory Light Sources-Part 3: Fluorescent UV Lamps, ISO, Geneva, 2016.

Funding

Open access funding provided by Università degli Studi di Napoli Federico II within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the 4th International Symposium on Dynamic Response and Failure of Composite Materials (Draf2022) held June 21-25, 2022, on the Island of Ischia, Italy. It has been expanded from the original presentation. The issue was organized by Valentina Lopresto, Ilaria Papa, Antonello Astarita, and Michele Guida of the University of Naples Federico II.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Farroni, F., Sakhnevych, A., Timpone, F. et al. Ultraviolet Light Radiation Effects on Viscoelastic Property Variation in Polymers. J. of Materi Eng and Perform 32, 3896–3904 (2023). https://doi.org/10.1007/s11665-023-08180-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08180-1