Abstract

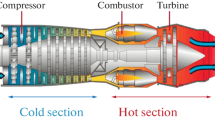

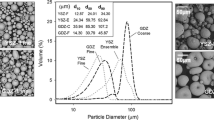

Environmental regulations governing heavy-duty diesel engines (HDDE) have become more stringent, mandating them to ensure a lower environmental and human health impact, with improved efficiency in terms of emissions and fuel economy. The focus of most of the researches is on advancement in thermodynamic cycles and maximum heat utilization techniques. Thermal barrier coating (TBCs) is one of the most efficient methods of increasing energy efficiency through effective utilization of heat by insulating the turbine and combustor engine components. The primary focus of this work, is on the effective material behaviour of TBCs on HDDE components in terms of mechanical, tribological and thermal characterization. Inlet and exhaust valve substrates were coated with Gadolinium Zirconate (GZ) with and without bond coat (NiCr) with a thickness of 100 and 150 µm respectively using the plasma spray technique. Reciprocative wear, thermal conductivity and expansion behavior of uncoated and coated substrates were carried out as per the ASTM Standards. The results indicated a reduction in co-efficient of friction in GZ/NiCr substrate by 15 and 3% in comparison with uncoated and GZ coated substrate respectively. Furthermore, the mean expansion value of GZ/NiCr substrate was 10.04% lower than the GZ coated substrate, substantiating the reduction in micro-crack formation as a result of combating the CTE mismatch between substrate and coating. Among the samples, GZ/NiCr substrate showed a maximum reduction in thermal conductivity accounting to 8 to 11%. These findings elaborate the capability of TBCs towards improving wear resistance and sustaining high temperature thermal exposure of combustion chamber components in HDDE.

Similar content being viewed by others

References

G. Latz, O. Erlandsson, T. Skåre, A. Contet, S. Andersson, and K. Munch, Performance Analysis of a Reciprocating Piston Expander and a Plate Type Exhaust Gas Recirculation Boiler in a Water-Based Rankine Cycle for Heat Recovery from a Heavy Duty Diesel Engine, Energies, 2016 https://doi.org/10.3390/en9070495

O. Delgado, F. Rodriguez, and R. Muncrief, Fuel efficiency technology in european heavy-duty vehicles: baseline and potential for the 2020–2030 timeframe. Int. Counc. Clean Transp. 1–3 (2017). Available: www.theicct.org

J. O’connor et al., Optimization of an Advanced Combustion Strategy Towards 55% BTE for the Volvo SuperTruck Program, Int. J. Engines, 2017, 10(3), p 1217–1227. https://doi.org/10.2307/26285123

R. Ghasemi and H. Vakilifard, Plasma-Sprayed Nanostructured YSZ Thermal Barrier Coatings: Thermal Insulation Capability and Adhesion Strength, Ceram. Int., 2017, 43(12), p 8556–8563. https://doi.org/10.1016/j.ceramint.2017.03.074

B. Bernard et al., Thermal Insulation Properties of YSZ Coatings: Suspension Plasma Spraying (SPS) Versus Electron Beam Physical Vapor Deposition (EB-PVD) and Atmospheric Plasma Spraying (APS), Surf. Coat. Technol., 2017, 318, p 122–128. https://doi.org/10.1016/j.surfcoat.2016.06.010

H.J. Rätzer-Scheibe and U. Schulz, The Effects of Heat Treatment and Gas Atmosphere on the Thermal Conductivity of APS and EB-PVD PYSZ Thermal Barrier Coatings, Surf. Coat. Technol., 2007, 201(18), p 7880–7888. https://doi.org/10.1016/j.surfcoat.2007.03.028

P. Song, D. Naumenko, R. Vassen, L. Singheiser, and W.J. Quadakkers, Effect of Oxygen Content in NiCoCrAlY Bondcoat on the Lifetimes of EB-PVD and APS Thermal Barrier Coatings, Surf. Coat. Technol., 2013, 221, p 207–213. https://doi.org/10.1016/j.surfcoat.2013.01.054

M. Movchan and Y. Rudoy, Composition, Structure and Properties of Gradient Thermal Barrier Coatings (TBCs) Produced by Electron Beam Physical Vapor Deposition (EB-PVD), Mater. Des., 1998, 19(5–6), p 253–258. https://doi.org/10.1016/s0261-3069(98)00020-x

R. Velusamy et al., Effect of Single Layer Thin Film Thermal Barrier Coatings on Mechanical, Thermal and Tribological Characterization of Cast Iron (GJL 300), SAE Tech. Pap., 2021, 17323(2021), p 1–7. https://doi.org/10.4271/2021-28-0285

L. Łatka, Thermal Barrier Coatings Manufactured by Suspension Plasma Spraying - A Review, Adv. Mater. Sci., 2018, 18(3), p 95–117. https://doi.org/10.1515/adms-2017-0044

V. Bolleddu, V. Racherla, and P.P. Bandyopadhyay, Characterization of Air Plasma-Sprayed Yttria-Stabilized Zirconia Coatings Deposited with Nitrogen, Int. J. Adv. Manuf. Technol., 2017, 90(9–12), p 3437–3449. https://doi.org/10.1007/s00170-016-9613-1

V.K. Domakonda, P. Devendra Reddy, and S. Farooq, Effect of Lanthanum Zirconate Thermal Barrier Coating on the Performance and Emissions of a Diesel Engine Using Biodiesel, IOP Conf. Ser. Mater. Sci. Eng., 2019 https://doi.org/10.1088/1757-899X/577/1/012174

S. Kossman et al., Sliding Wear Response of Nanostructured YSZ Suspension Plasma-Sprayed Coating, J. Therm. Spray Technol., 2014, 23(8), p 1350–1361. https://doi.org/10.1007/s11666-014-0146-6

R.H.J. Hannink, P.M. Kelly, and B.C. Muddle, Transformation Toughening in Zirconia-Containing Ceramics, J. Am. Ceram. Soc., 2000, 83(3), p 461–487. https://doi.org/10.1111/j.1151-2916.2000.tb01221.x

C. Piconi and G. Maccauro, Zirconia as a Ceramic Biomaterial, Biomaterials, 1999, 20(1), p 1–25. https://doi.org/10.1016/S0142-9612(98)00010-6

H. Fang, W. Wang, J. Huang, Y. Li, and D. Ye, Corrosion Behavior and Thermos-Physical Properties of a Promising Yb2O3 and Y2O3 Co-stabilized ZrO2 Ceramic for Thermal Barrier Coatings Subject to Calcium-Magnesium-Aluminum-Silicate (CMAS) Deposition: Experiments and First-Principles Calculation, Corros. Sci., 2021, 182(September 2020), p 109230. https://doi.org/10.1016/j.corsci.2020.109230

T. Yang et al., Preparation and Thermophysical Properties of CeO2-Gd2O3 Costabilized Zirconia Thermal Barrier Coating, J. Therm. Spray Technol., 2020, 29(1–2), p 115–124. https://doi.org/10.1007/s11666-019-00971-0

R.A. Miller, Thermal Barrier Coatings for Aircraft Engines: History and Directions, J. Therm. Spray Technol., 1997, 6(1), p 35–42. https://doi.org/10.1007/BF02646310

R.L. Jones, R.F. Reidy, and D. Mess, Scandia, Yttria-Stabilized Zirconia for Thermal Barrier Coatings, Surf. Coat. Technol., 1996, 82(1–2), p 70–76. https://doi.org/10.1016/0257-8972(95)02646-0

J. Kim, Effect of Ta205, Nb205, and Hf02 Alloying on the Transformability of Y20s-Stabilized Tetragonal Z r 0 2 Due, J. Am. Cerom. Soc., 1990, 73(1), p 115–120.

D. Zhu and R.A. Miller, Sintering and Creep Behavior of Plasma-Sprayed Zirconia- and Hafnia-Based Thermal Barrier Coatings, Surf. Coat. Technol., 1998, 108–109(1–3), p 114–120. https://doi.org/10.1016/S0257-8972(98)00669-0

F.M. Pitek and C.G. Levi, Opportunities for TBCs in the ZrO2-YO1.5-TaO2.5 System, Surf. Coat. Technol., 2007, 201(12), p 6044–6050. https://doi.org/10.1016/j.surfcoat.2006.11.011

M. Gell, J. Wang, R. Kumar, J. Roth, C. Jiang, and E.H. Jordan, Higher Temperature Thermal Barrier Coatings with the Combined Use of Yttrium Aluminum Garnet and the Solution Precursor Plasma Spray Process, J. Therm. Spray Technol., 2018, 27(4), p 543–555. https://doi.org/10.1007/s11666-018-0701-7

H. Fang, W. Wang, J. Huang, and D. Ye, Investigation of CMAS Resistance of Sacrificial Plasma-Sprayed Mullite-YSZ Protective Layer on 8YSZ Thermal Barrier Coating, Corros. Sci., 2020, 173(130), p 108764. https://doi.org/10.1016/j.corsci.2020.108764

J.B. Huang et al., Improve Durability of Plasma-Splayed Thermal Barrier Coatings by Decreasing Sintering-Induced Stiffening in Ceramic Coatings, J. Eur. Ceram. Soc., 2020, 40(4), p 1433–1442. https://doi.org/10.1016/j.jeurceramsoc.2019.11.074

S. Sivakumar, K. Praveen, G. Shanmugavelayutham, S. Yugeswaran, and J. Mostaghimi, Thermo-Physical Behavior of Atmospheric Plasma Sprayed High Porosity Lanthanum Zirconate Coatings, Surf. Coat. Technol., 2017, 326, p 173–182. https://doi.org/10.1016/j.surfcoat.2017.07.054

S.M. Naga et al., Effect of La2Zr2O7 Coat on the Hot Corrosion of Multi-layer Thermal Barrier Coatings, Mater. Des., 2016, 102, p 1–7. https://doi.org/10.1016/j.matdes.2016.03.133

J. Zhang, X. Guo, Y.G. Jung, L. Li, and J. Knapp, Lanthanum Zirconate Based Thermal Barrier Coatings: A Review, Surf. Coat. Technol., 2017, 323, p 18–29. https://doi.org/10.1016/j.surfcoat.2016.10.019

S. Sivakumar, G. Shanmugavelayutham, S. Yugeswaran, and J. Mostaghimi, Influence of Water Vapour on Structural and thermal conductivity of post-heat treated plasma sprayed LZ and YSZ coatings, J. Alloys Compd., 2018, 740, p 212–221. https://doi.org/10.1016/j.jallcom.2018.01.056

Z. Xu et al., Double-Ceramic-Layer Thermal Barrier Coatings of La2Zr2O7/YSZ Deposited by Electron Beam-Physical Vapor Deposition, J. Alloys Compd., 2009, 473(1–2), p 509–515. https://doi.org/10.1016/j.jallcom.2008.06.064

Z. Shen, L. He, Z. Xu, R. Mu, and G. Huang, Rare Earth Oxides Stabilized La2Zr2O7 TBCs: EB-PVD, Thermal Conductivity and Thermal Cycling Life, Surf. Coat. Technol., 2019, 357(July 2018), p 427–432. https://doi.org/10.1016/j.surfcoat.2018.10.045

R. Velusamy et al., Tribological and Thermal Characterization of Electron Beam Physical Vapor Deposited Single Layer Thin Film for TBC Application, Surf. Topogr. Metrol. Prop., 2021, 9(2), p 25043. https://doi.org/10.1088/2051-672X/ac0c61

L. Wang, J.I. Eldridge, and S.M. Guo, Thermal Radiation Properties of Plasma-Sprayed Gd2Zr 2O7 Thermal Barrier Coatings, Scr. Mater., 2013, 69(9), p 674–677. https://doi.org/10.1016/j.scriptamat.2013.07.026

J.A. Krogstad et al., Phase Stability of t′-zirconia-Based Thermal Barrier Coatings: Mechanistic Insights, J. Am. Ceram. Soc., 2011, 94(SUPPL. 1), p s168–s177. https://doi.org/10.1111/j.1551-2916.2011.04531.x

Y. Feng, T.S. Dong, B.G. Fu, G.L. Li, Q. Liu, and R. Wang, Thermal Shock Resistance of Double-Layer Thermal Barrier Coatings, J. Mater. Res., 2020, 35(20), p 2808–2816. https://doi.org/10.1557/jmr.2020.228

Z. Yang, W. Wang, S. Deng, H. Fang, T. Yang, and L. Wang, Thermal Shock Behavior and Particle Erosion Resistance of Toughened GZ Coatings Prepared by Atmospheric Plasma Spraying, Coatings, 2021 https://doi.org/10.3390/coatings11121477

S. Mahade, A. Jahagirdar, X.H. Li, B. Kjellman, S. Björklund, and N. Markocsan, Tailoring Microstructure of Double-Layered Thermal Barrier Coatings Deposited by Suspension Plasma Spray for Enhanced Durability, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127704

K.M. Doleker and A.C. Karaoglanli, Comparison of Oxidation Behavior of YSZ and Gd2Zr2O7 Thermal Barrier Coatings (TBCs), Surf. Coat. Technol., 2017, 318, p 198–207. https://doi.org/10.1016/j.surfcoat.2016.12.078

M. GuvenGok and G. Goller, Production and Characterisation of GZ/CYSZ Alternative Thermal Barrier Coatings with Multilayered and Functionally Graded Designs, J. Eur. Ceram. Soc., 2016, 36(7), p 1755–1764. https://doi.org/10.1016/j.jeurceramsoc.2016.01.036

P. Carpio, M.D. Salvador, A. Borrell, and E. Sánchez, Thermal Behaviour of Multilayer and Functionally-Graded YSZ/Gd2Zr2O7 Coatings, Ceram. Int., 2017, 43(5), p 4048–4054. https://doi.org/10.1016/j.ceramint.2016.11.178

T. Mokhena, M. Mochane, M. Tshwafo, L. Linganiso, O. Thekisoe, and S. Songca, We are IntechOpen, the World’s Leading Publisher of Open Access Books Built by Scientists, for Scientists TOP 1%. (Intech, 2016), pp. 225–240, [Online]. Available: https://www.intechopen.com/books/advanced-biometric-technologies/liveness-detection-in-biometrics

J. Zucchetto, P. Myers, J. Johnson, and D. Miller, An Assessment of the Performance and Requirements for ‘Adiabatic’ Engines, Science, 1988, 240(4856), p 1157–1162. https://doi.org/10.1126/science.240.4856.1157

R. Kamo and W. Bryzik, Adiabatic Turbocompound Engine Performance Prediction, SAE Tech. Pap., 1978, 87, p 213–223. https://doi.org/10.4271/780068

M. Panțuru, D. Chicet, Ș Lupescu, B. Istrate, and C. Munteanu, Applications of Ceramic Coatings as TBCs on the Internal Combustion Engine Valves, Appl. Math. Mech. Eng., 2018, 61(I), p 137–142.

V. Guruprakash, N. Harivignesh, G. Karthick, and N. Bose, Thermal Barrier Coating on I.C Engine Cylinder Liner, Arch. Mater. Sci. Eng., 2016, 81(1), p 37–41. https://doi.org/10.5604/18972764.1229626

I. Taymaz, The Effect of Thermal Barrier Coatings on Diesel Engine Performance, Surf. Coat. Technol., 2007, 201(9–11), p 5249–5252. https://doi.org/10.1016/j.surfcoat.2006.07.123

V. Garud et al., Performance and CombustionCharacteristics of Thermal Barrier Coated (YSZ) Low Heat Rejection Diesel Engine, Mater. Today Proc., 2017, 4(2), p 188–194. https://doi.org/10.1016/j.matpr.2017.01.012

A. Thibblin, S. Kianzad, S. Jonsson, and U. Olofsson, Running-in Behaviour of Thermal Barrier Coatings in the Combustion Chamber of a Diesel Engine, Proc. Inst. Mech. Eng. Part D J. Automob. Eng., 2020, 234(1), p 172–182. https://doi.org/10.1177/0954407019841173

S.B. Patond, S.A. Chaple, P.N. Shrirao, and P.I. Shaikh, Comparative Study of Performance and Combustion Characteristics of Conventional and Low Heat Rejection (Mullite Coated) Diesel Engines, IOP Conf. Ser. Mater. Sci. Eng., 2013 https://doi.org/10.1088/1757-899X/46/1/012008

Y. Paik, C.R. Sahu, K.K. Pandey, S.K. Barik, S. Murugan, and D. Debasish, Effect of Thermal Barrier Coating on Performance and Emissions of a di Diesel Engine, SAE Tech. Pap., 2020 https://doi.org/10.13140/RG.2.2.16856.52481

P.V. Elumalai, K. Annamalai, and B. Dhinesh, Effects of Thermal Barrier Coating on the Performance, Combustion and Emission of DI Diesel Engine Powered by Biofuel Oil–Water Emulsion, J. Therm. Anal. Calorim., 2019, 137(2), p 593–605. https://doi.org/10.1007/s10973-018-7948-6

N. Ramasamy, M.A. Kalam, M. Varman, and Y.H. Teoh, Effect of Thermal Barrier Coating on the Performance and Emissions of Diesel Engine Operated with Conventional Diesel and Palm Oil Biodiesel, Coatings, 2021, 11(6), p 1–14. https://doi.org/10.3390/coatings11060692

A. Rohini, and S. Prema, A Review on Thermal Barrier Coating for Diesel Engine and Its Characteristics Studies, J. Phys. Conf. Ser., 2020 https://doi.org/10.1088/1742-6596/1473/1/012039

E.A. Majeed, H.K. Rashid, and M.K. Hussain, Review of Ceramic Materials that Used as a Thermal Barrier in Diesel Engine Pistons, J. Phys. Conf. Ser., 1973, 1, p 2021. https://doi.org/10.1088/1742-6596/1973/1/012125

V. Karthickeyan, Effect of Thermal Barrier Coating on Performance and Emission Characteristics of Kapok Oil Methyl Ester in Diesel Engine, Aust. J. Mech. Eng., 2020, 18(3), p 467–480. https://doi.org/10.1080/14484846.2018.1546450

A.M. Kalinkin, V.Y. Vinogradov, and E.V. Kalinkina, Solid-State Synthesis of Nanocrystalline Gadolinium Zirconate Using Mechanical Activation, Inorg. Mater., 2021, 57(2), p 178–185. https://doi.org/10.1134/S0020168521020072

X. Zhong et al., Improvement in Thermal Shock Resistance of Gadolinium Zirconate Coating by Addition of Nanostructured Yttria Partially-Stabilized Zirconia, Ceram. Int., 2015, 41(6), p 7318–7324. https://doi.org/10.1016/j.ceramint.2015.02.027

D. Zhou et al., Thermal Cycling Performances of Multilayered Yttria-Stabilized Zirconia/Gadolinium Zirconate Thermal Barrier Coatings, J. Am. Ceram. Soc., 2020, 103(3), p 2048–2061. https://doi.org/10.1111/jace.16862

N. Krishnamurthy, M.S. Prashanthareddy, H.P. Raju, and H.S. Manohar, A Study of Parameters Affecting Wear Resistance of Alumina and Yttria Stabilized Zirconia Composite Coatings on Al-6061 Substrate, ISRN Ceram., 2012, 2012, p 1–13. https://doi.org/10.5402/2012/585892

Z. Shen, G. Liu, Z. Liu, L. He, R. Mu, and L. Wang, Dy Doped Gd2Zr2O7 Thermal Barrier Coatings: Thermal Expansion Coefficient, Microstructure and Failure Mechanism, Appl. Surf. Sci. Adv., 2021, 6, p 100174. https://doi.org/10.1016/j.apsadv.2021.100174

C. Wang, L. Guo, Y. Zhang, X. Zhao, and F. Ye, Enhanced Thermal Expansion and Fracture Toughness of Sc2O3-Doped Gd2Zr2O7 Ceramics, Ceram. Int., 2015, 41(9), p 10730–10735. https://doi.org/10.1016/j.ceramint.2015.05.008

R.S. Lima, A. Kucuk, and C.C. Berndt, Bimodal Distribution of Mechanical Properties on Plasma Sprayed Nanostructured Partially Stabilized Zirconia, Mater. Sci. Eng. A, 2002, 327(2), p 224–232. https://doi.org/10.1016/S0921-5093(01)01530-1

P. Carpio et al., Microstructure and Indentation Mechanical Properties of YSZ Nanostructured Coatings Obtained by Suspension Plasma Spraying, Surf. Coat. Technol., 2013, 220, p 237–243. https://doi.org/10.1016/j.surfcoat.2012.09.047

N. Krishnamurthy, M.S. Murali, B. Venkataraman, and P.G. Mukunda, Characterization and Solid Particle Erosion Behavior of Plasma Sprayed Alumina and Calcia-Stabilized Zirconia Coatings on Al-6061 Substrate, Wear, 2012, 274–275, p 15–27. https://doi.org/10.1016/j.wear.2011.08.003

J. Salguero, J.M. Vazquez-Martinez, I. Del Sol, and M. Batista, Application of Pin-On-Disc Techniques for the Study of Tribological Interferences in the Dry Machining of A92024–T3 (Al-Cu) Alloys, Materials (Basel), 2018, 11(7), p 1–11. https://doi.org/10.3390/ma11071236

P.M. Jadhav and N.S. KumarReddy, Wear Behavior of Carbide Tool Coated with Yttria-Stabilized Zirconia Nano Particles, IOP Conf. Ser. Mater. Sci. Eng, 2018 https://doi.org/10.1088/1757-899X/346/1/012007

A.D. Sarkar, Friction and Wear, Woodhead Publishing Limited, Cambridge, 1980. https://doi.org/10.2324/gomu.72.186

B.J. Briscoe and S.K. Sinha, Tribological Applications of Polymers and Their Composites - Past, Present and Future Prospects, Second. Elsevier, 2013. https://doi.org/10.1016/B978-0-444-59455-6.00001-5

Q. Luo, Tribofilms in Solid Lubricants, Encycl. Tribol., 2013 https://doi.org/10.1007/978-0-387-92897-5_1252

T.P. Mollart, J. Haupt, R. Gilmore, and W. Gissler, Tribological Behaviour of Homogeneous Ti-B-N, Ti-B-N-C and TiN/h-BN/TiB2 Multilayer Coatings, Surf. Coat. Technol., 1996, 86–87(1), p 231–236. https://doi.org/10.1016/S0257-8972(96)02950-7

S. Chinnusamy, V. Ramasamy, S. Venkatajalapathy, G.V. Kaliyannan, and S.K. Palaniappan, Experimental Investigation on the Effect of Ceramic Coating on the Wear Resistance of Al6061 Substrate, J. Mater. Res. Technol., 2019, 8(6), p 6125–6133. https://doi.org/10.1016/j.jmrt.2019.10.007

A. Günen, Micro-Abrasion Wear Behavior of Thermal-Spray-Coated Steel Tooth Drill Bits, Acta Phys. Pol. A, 2016, 130(1), p 217–222. https://doi.org/10.12693/APhysPolA.130.217

R. Gheisari and A.A. Polycarpou, Three-Body Abrasive Wear of Hard Coatings: Effects of Hardness and Roughness, Thin Solid Films, 2018, 666(May), p 66–75. https://doi.org/10.1016/j.tsf.2018.07.052

M.M. Stack and M.T. Mathew, Mapping the Micro-abrasion Resistance of WC/Co Based Coatings in Aqueous Conditions, Surf. Coat. Technol., 2004, 183(2–3), p 337–346. https://doi.org/10.1016/j.surfcoat.2003.09.061

V. Viswanathan, G. Dwivedi, and S. Sampath, Multilayer, Multimaterial Thermal Barrier Coating Systems: Design, Synthesis, and Performance Assessment, J. Am. Ceram. Soc., 2015, 98(6), p 1769–1777. https://doi.org/10.1111/jace.13563

S. Mahade, N. Curry, S. Björklund, N. Markocsan, and S. Joshi, Durability of Gadolinium Zirconate/YSZ Double-Layered Thermal Barrier Coatings Under Different Thermal Cyclic Test Conditions, Materials (Basel), 2019 https://doi.org/10.3390/ma12142238

C. Vorkötter, D.E. Mack, D. Zhou, O. Guillon, and R. Vaßen, Effect of Low-CTE Oxide-Dispersion-Strengthened Bond Coats on Columnar-Structured YSZ Coatings, Coatings, 2022, 12(3), p 1–11. https://doi.org/10.3390/coatings12030396

R. Vassen, H. Kassner, A. Stuke, D.E. Mack, M.O. Jarligo, and D. Stöver, Functionally Graded Thermal Barrier Coatings with Improved Reflectivity and High-Temperature Capability, Mater. Sci. Forum, 2010, 631–632, p 73–78. https://doi.org/10.4028/www.scientific.net/MSF.631-632.73

R. Vaßen, D.E. Mack, M. Tandler, Y.J. Sohn, D. Sebold, and O. Guillon, Unique Performance of Thermal Barrier Coatings Made of Yttria-Stabilized Zirconia at Extreme Temperatures (>1500°C), J. Am. Ceram. Soc., 2021, 104(1), p 463–471. https://doi.org/10.1111/jace.17452

J.P. Martins, H. Yu, Y. Chen, G. Brewster, R. McIntyre, and P. Xiao, Effect of Bond Coat Topography on the Fracture Mechanics and Lifetime of Air-Plasma Sprayed Thermal Barrier Coatings, Surf. Coat. Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127447

E.J. Gildersleeve, V. Viswanathan, M.J. Lance, J.A. Haynes, B.A. Pint, and S. Sampath, Role of Bond Coat Processing Methods on the Durability of Plasma Sprayed Thermal Barrier Systems, Surf. Coat. Technol., 2019, 375, p 782–792. https://doi.org/10.1016/j.surfcoat.2019.07.065

S. Mahade, N. Curry, S. Björklund, N. Markocsan, and P. Nylén, Thermal Conductivity and Thermal Cyclic Fatigue of Multilayered Gd2Zr2O7/YSZ Thermal Barrier Coatings Processed by Suspension Plasma Spray, Surf. Coat. Technol., 2015, 283, p 329–336. https://doi.org/10.1016/j.surfcoat.2015.11.009

B. Guerreiro, R.S. Lima, N. Curry, M. Leitner, and K. Körner, The Influence of Plasma Composition in the Thermal Cyclic Performance of Yttria-Stabilized Zirconia (8YSZ) Thermal Barrier Coatings (TBCs), J. Therm. Spray Technol., 2021, 30(1–2), p 59–68. https://doi.org/10.1007/s11666-021-01153-7

J.R. Nicholls, K.J. Lawson, A. Johnstone, and D.S. Rickerby, Methods to Reduce the Thermal Conductivity of EB-PVD TBCs, Surf. Coat. Technol., 2002, 151–152, p 383–391. https://doi.org/10.1016/S0257-8972(01)01651-6

P.K. Schelling and S.R. Phillpot, Mechanism of Thermal Transport in Zirconia and Yttria-Stabilized Zirconia by Molecular-Dynamics Simulation, J. Am. Ceram. Soc., 2001, 84(3–12), p 2997–3007. https://doi.org/10.1111/j.1151-2916.2001.tb01127.x

P.G. Klemens, Theory of Thermal Conduction in Thin Ceramic Films, Int. J. Thermophys., 2001, 22(1), p 265–275. https://doi.org/10.1023/A:1006776107140

K.W. Schlichting, N.P. Padture, and P.G. Klemens, Thermal Conductivity of Dense and Porous Yttria-Stabilized Zirconia, J. Mater. Sci., 2001, 36(12), p 3003–3010. https://doi.org/10.1023/A:1017970924312

Acknowledgments

The author would like to express his sincere thanks to Scientists Dr. Dhanalakshmi Sathiskumar, Dr. Vishwanathan, Mr. Kumaraswamy, and Mr. Vamsi Krishna from CVRDE-DRDO, Avadi, Chennai, Tamilnadu for supporting the overall research activities. The authors would also like to thank Dr. Natarajan Venkat, Ex-Director and Scientist ‘G’, RIC-DRDO for providing the permission to utilize Multi-Functional Tribometer (MFT-5000, USA) and also Mr. Naveen Kumar for helping to carry out the tribology test. Further, I thank Dr. G Sakthinathan and Dr. R Vignesh for their expertise and assistance in analyzing the characterization study of ceramic coated substrates.

Funding

This research was supported by the Defence Research and Development Organization (DRDO).—Combat Vehicles Research and Development Establishment (CVRDe), India and Research Innovation Centre (RIC), IITM Research Park, Chennai [Grant No: ERIP/ER/201807001/M/01/1746].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Velusamy, R., Babu, A.S., Swaminathan, M.R. et al. Evaluation of Mechanical, Tribological, and Thermal Characterization of GZ TBCs for Heavy Duty Diesel Engine Application. J. of Materi Eng and Perform 33, 2736–2750 (2024). https://doi.org/10.1007/s11665-023-08164-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08164-1