Abstract

CrMnFeCoNi high entropy alloy was produced in a shielding gas atmosphere using TIG melting using reverse vacuum system. The produced HEAs were covered with the pack boriding method at 1173 K and 1223 K temperatures and for 2 h, 4 h, 6 h. Boride layer microstructure, XRD and hardness measurements of these samples were examined and Rockwell-C adhesion and corrosion tests were applied. The boride layer has a flat and continuous structure and its thickness ranged from 38 to 115 µm. The sawtooth appearance increased in the coating/matrix transition region depending on the increase in temperature and time. While the uncoated HEA has a face-centered cubic lattice parameter, the surface of the coated HEAs depends on the alloy elements and boron; FeB, Fe2B, NiB, CrB, Co3B, FeNi, FeCo and Fe4Mn phases were detected. By coating the HEAs with boron, the surface hardness was increased by 10 times. According to the Rockwell-C test, the adhesion weakened due to the increase in the coating layer and the hard and brittle boride phases. In the corrosion test, the corrosion rates of boron-coated HEAs decreased compared to the uncoated samples, while the corrosion resistance increased.

Similar content being viewed by others

References

J. Mahaffey, A. Vackel, S. Whetten, M. Melia and A.B. Kustas, Structure Evolution and Corrosion Performance of CoCrFeMnNi High Entropy Alloy Coatings Produced Via Plasma Spray and Cold Spray, J. Therm. Spray Technol., 2022 https://doi.org/10.1007/s11666-022-01373-5

J.W. Yeh, S.J. Lin, T.S. Chin, J.Y. Gan, S.K. Chen, T.T. Shun and S.Y. Chou, Formation of Simple Crystal Structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V Alloys with Multiprincipal Metallic Elements, Metall. Mater. Trans. A, 2004, 35, p 2533–2536.

A. Erdoğan, M.S. Gök and S. Zeytin, Analysis of the High-Temperature Dry Sliding Behavior of CoCrFeNiTi0.5Alx High-Entropy Alloys, Friction., 2020, 8, p 198–207. https://doi.org/10.1007/s40544-019-0278-2

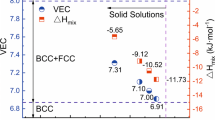

F. Otto, Y. Yang, H. Bei and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61, p 2628–2638. https://doi.org/10.1016/j.actamat.2013.01.042

M.H. Tsai and J.W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2, p 107–123. https://doi.org/10.1080/21663831.2014.912690

Y. Sun, P. Chen, L. Liu, M. Yan, X. Wu, C. Yu and Z. Liu, Local Mechanical Properties of AlxCoCrCuFeNi High Entropy Alloy Characterized Using Nanoindentation, Intermetallics (Barking)., 2018, 93, p 85–88. https://doi.org/10.1016/j.intermet.2017.11.010

I.S. Wani, G.D. Sathiaraj, M.Z. Ahmed, S.R. Reddy and P.P. Bhattacharjee, Evolution of Microstructure and Texture During Thermo-Mechanical Processing of a Two Phase Al0.5CoCrFeMnNi High Entropy Alloy, Mater. Charact., 2016, 118, p 417–424. https://doi.org/10.1016/j.matchar.2016.06.021

İB. Algan Şimşek, M.N. Arık, Ş Talaş and A. Kurt, The Effect of B Addition on the Microstructural and Mechanical Properties of FeNiCoCrCu High Entropy Alloys, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2021, 52, p 1749–1758. https://doi.org/10.1007/s11661-021-06186-9

W.-H. Kao, Y.-L. Su, J.-H. Horng and W.-C. Wu, Mechanical, Tribological and Anti-Corrosion Properties of AlCrNbSiTi High Entropy Coatings with Various Nitrogen Fluxes and Application to Nickel-Based Alloy Milling, Mater. Chem. Phys., 2022, 282, p 125999. https://doi.org/10.1016/j.matchemphys.2022.125999

C. Ji, A. Ma and J. Jiang, Mechanical Properties and Corrosion Behavior of Novel Al-Mg-Zn-Cu-Si Lightweight High Entropy Alloys, J. Alloys Compd., 2022 https://doi.org/10.1016/j.jallcom.2021.163508

Z. Sun, C. Shi, L. Gao, S. Lin and W. Li, Thermal Physical Properties of High Entropy Alloy Al03CoCrFeNi at Elevated Temperatures, J. Alloys Compd., 2022 https://doi.org/10.1016/j.jallcom.2021.163554

L. Huang, Y. Sun, A. Amar, C. Wu, X. Liu, G. Le, X. Wang, J. Wu, K. Li, C. Jiang and J. Li, Microstructure Evolution and Mechanical Properties of AlxCoCrFeNi High-Entropy Alloys by Laser Melting Deposition, Vacuum., 2021 https://doi.org/10.1016/j.vacuum.2020.109875

X. Feng, R. Zheng, Z. Wu, Y. Zhang, Z. Li, X. Tan and H. Xu, Study on a New High-Entropy Alloy Nd20Pr20La20Fe20Co10Al10 with Hard Magnetic Properties, J. Alloys Compd., 2021 https://doi.org/10.1016/j.jallcom.2021.160640

S.K. Bachani, C.J. Wang, B.S. Lou, L.C. Chang and J.W. Lee, Fabrication of TiZrNbTaFeN High-Entropy Alloys Coatings by HiPIMS: Effect of Nitrogen Flow Rate on the Microstructural Development, Mechanical and Tribological Performance, Electrical Properties and Corrosion Characteristics, J. Alloys Compd., 2021 https://doi.org/10.1016/j.jallcom.2021.159605

J. Yang, J. Wu, C.Y. Zhang, S.D. Zhang, B.J. Yang, W. Emori and J.Q. Wang, Effects of Mn on the electrochemical corrosion and passivation behavior of CoFeNiMnCr high-entropy alloy system in H2SO4 solution, J. Alloys Compd., 2020 https://doi.org/10.1016/j.jallcom.2019.152943

S. Öztürk, F. Alptekin, S. Önal, S.E. Sünbül, Ö. Şahin and K. İçin, Effect of Titanium Addition on the Corrosion Behavior of CoCuFeNiMn High Entropy Alloy, J. Alloys Compd., 2022 https://doi.org/10.1016/j.jallcom.2022.163867

J.B. Cheng, X.B. Liang and B.S. Xu, Effect of Nb Addition on the Structure and Mechanical Behaviors of CoCrCuFeNi High-Entropy Alloy Coatings, Surf. Coat Technol., 2014, 240, p 184–190. https://doi.org/10.1016/j.surfcoat.2013.12.053

Q. Zhu, Y. Liu and C. Zhang, Laser Cladding of CoCrFeNi High-Entropy Alloy Coatings: Compositional Homogeneity Towards İmproved Corrosion Resistance, Mater. Lett., 2022, 318, p 132133. https://doi.org/10.1016/j.matlet.2022.132133

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong and D. Zhang, High Temperature wear Performance of Laser-Cladded FeNiCoAlCu High-Entropy Alloy Coating, Appl. Surf. Sci., 2018, 445, p 113–122. https://doi.org/10.1016/j.apsusc.2018.03.135

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang and Y. Wu, Microstructure and Corrosion Properties of CrMnFeCoNi High Entropy Alloy Coating, Appl. Surf. Sci., 2017, 396, p 1420–1426. https://doi.org/10.1016/j.apsusc.2016.11.176

M. Journalmm, Karabaş, E. Mertgenç, Plazma Püskürtme ile Üretilmiş Beyaz ve Gri Al2O3 Kaplamaların Mekanik Özellikleri, J. Mater. Mechatron. A (JournalMM). 2020, 22–28 (2020). http://www.journalmm.com.

E. Mertgenç, Examination of Wear and Rockwell-C adhesion Properties of Nitronic 50 Steel Coated with Pack Boriding Method, Sakarya Univ. J. Sci. 528–537, (2020). https://doi.org/10.16984/saufenbilder.659782.

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada and A.S.M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, J. Therm. Spray Technol., 2020, 29, p 857–893. https://doi.org/10.1007/s11666-020-01047-0

L. Wang, F. Zhang, S. Yan, G. Yu, J. Chen, J. He and F. Yin, Microstructure Evolution and Mechanical Properties of Atmosphere Plasma Sprayed AlCoCrFeNi High-Entropy Alloy Coatings Under Post-Annealing, J. Alloys Compd., 2021 https://doi.org/10.1016/j.jallcom.2021.159607

A. Erdogan and K.M. Doleker, Comparative Study on Dry Sliding Wear and Oxidation Performance of HVOF and Laser Re-Melted Al0.2CrFeNi(Co, Cu) Alloys, Trans. Nonfer. Metals Soc. China (English Edition)., 2021, 31, p 2428–2441. https://doi.org/10.1016/S1003-6326(21)65664-9

L.W. Zhang, J.L. Xu, J. Chen, J. Huang and J.M. Luo, Microstructure and Corrosion Resistance of AlCoCrFeNi High-Entropy Alloy Coating on Sintered NdFeB Magnets Prepared by HVOF Spraying, J. Magn. Magn. Mater., 2022 https://doi.org/10.1016/j.jmmm.2022.169136

A. Günen, Tribocorrosion Behavior of Boronized Co1.19Cr1.86Fe1.30Mn1.39Ni1.05Al0.17B0.04 High Entropy Alloy, Surf. Coat Technol., 2021 https://doi.org/10.1016/j.surfcoat.2021.127426

Y.H. Wu, H.J. Yang, R.P. Guo, X.J. Wang, X.H. Shi, P.K. Liaw and J.W. Qiao, Tribological Behavior of Boronized Al0.1CoCrFeNi High-Entropy Alloys Under Dry and Lubricated Conditions, Wear., 2020 https://doi.org/10.1016/j.wear.2020.203452

A. Günen, Properties and High Temperature Dry Sliding Wear Behavior of Boronized Inconel 718, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2020, 51, p 927–939. https://doi.org/10.1007/s11661-019-05577-3

O.A. Gómez-Vargas, J. Solis-Romero, U. Figueroa-López, M. Ortiz-Domínguez, J. Oseguera-Peña and A. Neville, Boro-nitriding Coating on Pure Iron by Powder-Pack Boriding and Nitriding Processes, Mater. Lett., 2016, 176, p 261–264. https://doi.org/10.1016/j.matlet.2016.04.135

Y. Kayali and S. Taktak, Characterization and Rockwell-C Adhesion Properties of Chromium-Based Borided Steels, J. Adhes. Sci. Technol., 2015, 29, p 2065–2075. https://doi.org/10.1080/01694243.2015.1052617

W. Heinke, A. Leyland, A. Matthews ’, G. Berg, C. Friedrich, E. Broszeit, Evaluation of PVD Nitride Coatings, Using İmpact, Scratch and Rockwell-C Adhesion Tests (1995).

N. Vidakis, A. Antoniadis and N. Bilalis, The VDI 3198 Indentation Test Evaluation of a Reliable Qualitative Control for Layered Compounds, J Mater Process Technol, 2003 https://doi.org/10.1016/S0924-0136(03)00300-5

H. Nakajo and A. Nishimoto, Boronizing of CoCrFeMnNi High-Entropy Alloys Using Spark Plasma Sintering, J. Manuf. Mater. Process., 2022 https://doi.org/10.3390/jmmp6020029

E. Mertgenç and Y. Kayali, Diffusion Kinetics and Boronizing of High Entropy Alloy Produced by TIG Melting Reverse Suction Method, Can. Metall. Q., 2022 https://doi.org/10.1080/00084433.2022.2082203

O. Bican, S.U. Bayça, H. Kuleyin and R. Gümrük, Effect of Boronizing on Operating Stability of Steel AISI 304L under Erosion Impact of Hard Particles, Met. Sci. Heat Treat., 2021, 63, p 156–162. https://doi.org/10.1007/s11041-021-00663-z

Y. Kayali, Y. Akcin, E. Mertgenc and B. Gokce, Investigation of Kinetics of Borided Ductile and Lamellar Graphite Cast Iron, Prot. Met. Phys. Chem. Surf., 2017, 53, p 127–132. https://doi.org/10.1134/S2070205117010105

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, W.S. Cao and U.R. Kattner, An Understanding of High Entropy Alloys from Phase Diagram Calculations, Calphad, 2014, 45, p 1–10. https://doi.org/10.1016/j.calphad.2013.10.006

M. Laurent-Brocq, A. Akhatova, L. Perrière, S. Chebini, X. Sauvage, E. Leroy and Y. Champion, Insights into the Phase Diagram of the CrMnFeCoNi High Entropy Alloy, Acta Mater., 2015, 88, p 355–365. https://doi.org/10.1016/j.actamat.2015.01.068

A. Ostovari Moghaddam, N.A. Shaburova, M.N. Samodurova, A. Abdollahzadeh and E.A. Trofimov, Additive Manufacturing of High Entropy Alloys: A Practical Review, J. Mater. Sci. Technol., 2021, 77, p 131–162. https://doi.org/10.1016/j.jmst.2020.11.029

P. Chen, S. Li, Y. Zhou, M. Yan and M.M. Attallah, Fabricating CoCrFeMnNi High Entropy Alloy via Selective Laser Melting In-Situ Alloying, J. Mater. Sci. Technol., 2020, 43, p 40–43. https://doi.org/10.1016/j.jmst.2020.01.002

M. Ipek, G. Celebi Efe, I. Ozbek, S. Zeytin and C. Bindal, Investigation of Boronizing Kinetics of AISI 51100 Steel, J. Mater. Eng. Perform., 2012, 21, p 733–738. https://doi.org/10.1007/s11665-012-0192-5

S. Cengiz, Effect of Refractory Elements on Boronizing Properties of the CoCrFeNi High Entropy Alloy, Int. J. Refract. Metals Hard Mater., 2021 https://doi.org/10.1016/j.ijrmhm.2020.105418

H. Shahmir, J. He, Z. Lu, M. Kawasaki and T.G. Langdon, Effect of Annealing on Mechanical Properties of a Nanocrystalline CoCrFeNiMn High-Entropy Alloy Processed by High-Pressure Torsion, Mater. Sci. Eng., A, 2016, 676, p 294–303. https://doi.org/10.1016/j.msea.2016.08.118

B. Schuh, F. Mendez-Martin, B. Völker, E.P. George, H. Clemens, R. Pippan and A. Hohenwarter, Mechanical Properties, Microstructure and Thermal Stability of a Nanocrystalline CoCrFeMnNi High-Entropy Alloy After Severe Plastic Deformation, Acta Mater., 2015, 96, p 258–268. https://doi.org/10.1016/j.actamat.2015.06.025

L.L. Xiao, Z.Q. Zheng, S.W. Guo, P. Huang and F. Wang, Ultra-Strong Nanostructured CrMnFeCoNi High Entropy Alloys, Mater. Des., 2020 https://doi.org/10.1016/j.matdes.2020.108895

A. Heczel, M. Kawasaki, J.L. Lábár, J.I. Jang, T.G. Langdon and J. Gubicza, Defect Structure and Hardness in Nanocrystalline CoCrFeMnNi High-Entropy Alloy Processed by High-Pressure Torsion, J. Alloys Compd., 2017, 711, p 143–154. https://doi.org/10.1016/j.jallcom.2017.03.352

X. Liu, H. Yin and Y. Xu, Microstructure, Mechanical and Tribological Properties of Oxide Dispersion Strengthened High-Entropy Alloys, Materials., 2017 https://doi.org/10.3390/ma10111312

M.A. Béjar and E. Moreno, Abrasive Wear Resistance of Boronized Carbon and Low-Alloy Steels, J. Mater. Process Technol., 2006, 173, p 352–358. https://doi.org/10.1016/j.jmatprotec.2005.12.006

A. Bartkowska, A. Pertek, M. Kulka and L. Klimek, Laser Surface Modification of Boronickelized Medium Carbon Steel, Opt. Laser Technol., 2015, 74, p 145–157. https://doi.org/10.1016/j.optlastec.2015.05.014

İ Türkmen, E. Yalamaç and M. Keddam, Investigation of Tribological Behaviour and Diffusion Model of Fe2B Layer Formed by Pack-Boriding on SAE 1020 Steel, Surf. Coat Technol., 2019 https://doi.org/10.1016/j.surfcoat.2019.08.017

A. Günen, M. Keddam, S. Alkan, A. Erdoğan and M. Çetin, Microstructural Characterization, Boriding Kinetics and Tribo-Wear Behavior of Borided Fe-Based A286 Superalloy, Mater. Charact., 2022 https://doi.org/10.1016/j.matchar.2022.111778

M. Carbucicchio, G. Sambogna, Influence of Chromıum on Borıde Coatıngs Produced on Iron Alloys* (1985).

M. Carbucicchio, On the morphology of thermochemically produced Fe=B/Fe interfaces, n.d.

C.M. Brakman, A.W.J. Gommers, E.J. Mittemeijer, Bonding of Fe and Fe-C, Fe-Cr, and Fe-Ni alloys; Boride-layer growth kinetics (2014). http://journals.cambridge.org.

C. Martini, G. Palombarini, G. Poli and D. Prandstraller, Sliding and Abrasive Wear Behaviour of Boride Coatings, Wear, 2004, 256, p 608–613. https://doi.org/10.1016/j.wear.2003.10.003

I. Ozbek, C. Bindal, Mechanical Properties of Boronized AISI W4 Steel (2002).

G.K. Kariofillis, G.E. Kiourtsidis and D.N. Tsipas, Corrosion Behavior of Borided AISI H13 Hot Work Steel, Surf. Coat Technol., 2006, 201, p 19–24. https://doi.org/10.1016/j.surfcoat.2005.10.025

Y. Kayali, A. Büyüksaçiş and Y. Yalçin, Corrosion and wear Behaviors of Boronized AISI 316L Stainless Steel, Met. Mater. Int., 2013, 19, p 1053–1061. https://doi.org/10.1007/s12540-013-5019-x

I. Campos, M. Palomar, A. Amador, R. Ganem and J. Martinez, Evaluation of the Corrosion Resistance of Iron Boride Coatings Obtained by Paste Boriding Process, Surf. Coat Technol., 2006, 201, p 2438–2442. https://doi.org/10.1016/j.surfcoat.2006.04.017

P. Cui, Z. Bao, Y. Liu, F. Zhou, Z. Lai, Y. Zhou and J. Zhu, Corrosion Behavior and Mechanism of Dual Phase Fe1.125Ni1.06CrAl High Entropy Alloy, Corros. Sci., 2022 https://doi.org/10.1016/j.corsci.2022.110276

J. Li, Y. Huang, X. Meng and Y. Xie, A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment, Adv. Eng. Mater., 2019 https://doi.org/10.1002/adem.201900343

A. Parakh, M. Vaidya, N. Kumar, R. Chetty and B.S. Murty, Effect of Crystal Structure and Grain Size on Corrosion Properties of AlCoCrFeNi High Entropy Alloy, J. Alloys Compd., 2021 https://doi.org/10.1016/j.jallcom.2020.158056

S. Sun, H. Liu, J. Hao and H. Yang, Microstructural Evolution and Corrosion Behavior of CoCrFeNiAlxMn(1–x) Dual-Phase High-Entropy Alloy Coatings Prepared by Laser Cladding, J. Alloys Compd., 2021 https://doi.org/10.1016/j.jallcom.2021.161251

Y. Tian, C. Lu, Y. Shen and X. Feng, Microstructure and Corrosion Property of CrMnFeCoNi High Entropy Alloy Coating on Q235 Substrate via Mechanical Alloying Method, Surf. Interfaces., 2019, 15, p 135–140. https://doi.org/10.1016/j.surfin.2019.02.004

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mertgenç, E., Kayalı, Y., Yalçın, M.C. et al. Effect of Boron Coating on Rockwell-C Adhesion and Corrosion Resistance of High Entropy Alloys. J. of Materi Eng and Perform 33, 1194–1201 (2024). https://doi.org/10.1007/s11665-023-08068-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08068-0