Abstract

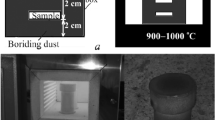

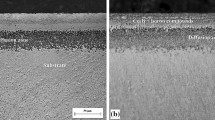

Silicide-free boride layers were grown on Inconel 718 Ni-based superalloy surface at 850 °C, 950 °C, and 1050 °C for 2, 4, 6 hour by the powder pack-boronizing process using nano-sized B4C powders. The coatings were examined using optical microscopy, scanning electron microscopy, energy dispersive spectroscopy, X-ray diffractometry, 3D profilometry, and microhardness measurements. Wear experiments were carried out on untreated and boronized Inconel 718 using a ball-on-disk tribometer under dry sliding conditions at temperatures of 25 °C, 400 °C, and 750 °C. An increase in boronizing temperature and duration increased the thickness and hardness of the obtained boride layers, which resulted in low coefficient of friction values and decreased wear rates. Scanning electron microscopy images of the worn surfaces revealed two-body abrasion as the effective wear mechanism in the untreated samples, and three-body abrasion assisted by microcracking and spalling as the dominant wear mechanism in the boronized samples. A transition from mild to severe wear occurred in the untreated samples, while wear rates remained low in the boronized samples up to 750 °C. In conclusion, boronized Inconel 718 was capable of sustaining its boride layers under 5 N for 1800 m at wear-test temperatures up to 750 °C.

Similar content being viewed by others

References

H. Zhang, C. Li, Q. Guo, Z. Ma, Y. Huang, H. Li, Y. Liu: Mat. Sci. Eng. A-Struct., 2018, vol. 722, pp. 136-146. https://doi.org/10.1016/j.msea.2018.02.093.

A. Thomas, M. El-Wahabi, J.M. Cabrera, J. M. Prado: J. Mater. Process. Tech., 2006, vol. 177, pp. 469-472. https://doi.org/10.1016/j.jmatprotec.2006.04.072.

S. Kumar, G.S. Rao, K. Chattopadhyay, G.S. Mahobia, N.C.S. Srinivas, V. Singh: Mater. Design., 2014, vol. 62, pp. 76-82. https://doi.org/10.1016/j.matdes.2014.04.084.

A.D. Sharma, A.K. Sharma, N. Thakur: J. Alloy. Compd., 2014, vol. 597, pp. 175-180. https://doi.org/10.1016/j.jallcom.2014.02.011.

M.M. Ma, Z.M. Wang, X.Y. Zeng: Mater. Charact., 2015, vol. 106, pp. 420-427. https://doi.org/10.1016/j.matchar.2015.06.027.

T. Kurzynowski, I. Smolina, K. Kobiela, B. Kuźnicka, E. Chlebus: Mater. Design., 2017, vol. 132, pp. 349-359. https://doi.org/10.1016/j.matdes.2017.07.024.

H. Dinc, A. Motellabzadeh, M. Baydogan, H. Cimenoglu: Acad. J. Sci., 2013, vol. 2 (2), pp. 385-389.

A. Günen, E. Kanca, H. Çakir, M. S. Karakaş, M. S. Gök, Y. Küçük, M. Demir: Surf. Coat. Tech., 2017, vol. 311, pp. 374-382. https://doi.org/10.1016/j.surfcoat.2016.12.097.

A. Günen and E. Kanca: Materia, 2017, vol. 22, 2. https://doi.org/10.1590/s1517-707620170002.0161.

M. Aghaie-Khafri and M. Mohamadpour Nazar Abady: JOM, 2012, vol. 64 (6), pp. 694-701. https://doi.org/10.1007/s11837-012

A. Günen, E. Kanca, M. S. Karakaş, V. Koç, M. S. Gök, Y. Kanca, M. Demir: Surf. Coat. Tech., 2018, vol. 348, pp. 130-141. https://doi.org/10.1016/j.surfcoat.2018.04.071.

T. Arai, The thermo-reactive deposition and diffusion process for coating steels to improve wear resistance. In Thermochemical Surface Engineering of Steels (2015) pp. 703-735, https://doi.org/10.1533/9780857096524.5.703

F. Czerwinski, Thermochemical treatment of metals. In Heat Treatment-Conventional and Novel Applications. InTech. (2012) https://doi.org/10.5772/51566.

Xu XL, Yu ZW, Cui LY (2019) Mater. Charact. https://doi.org/10.1016/j.matchar.2019.109798

H.J. Hunger and G. Trute, Succesful boronizing of nickel based alloys. Mater. Sci. Forum, 1994, vols. 163-165, pp. 341-348.

W. Muhammad, K. Hussain, A. Tauqir, A. Ulhaq, A.Q. Khan: Metall. Mater. Trans. A, 1999, vol. 30A, pp. 670-674. https://doi.org/10.1007/s11661-999-0059-z

D. W. Deng, C. G. Wang, Q. Q. Liu, T. T. Niu: Nonferr. Metal Soc., 2015, vol. 25(2), pp. 437-443. https://doi.org/10.1016/s1003-6326(15)63621-4.

A. Günen and E. Kanca: Pamukkale University. J. Eng. Sci., 2017, vol. 23(4), pp. 411-416. doi: 10.5505/pajes.2017.56689.

R. S. Petrova, N. Suwattananont, V. Samardzic: J. Mater. Eng. Perform., 2008, vol. 17(3), pp. 340-345. https://doi.org/10.1007/s11665-008-9228-2

I. Campos-Silva, A. D. Contla-Pacheco, A. Ruiz-Rios, J. Martínez-Trinidad, G. Rodríguez-Castro, A. Meneses-Amador, W.D. Wong-Angel: Surf. Coat. Tech., 2018, vol. 349, pp. 917-927. https://doi.org/10.1016/j.surfcoat.2018.05.086.

K. M. Doleker, O. Odabas, Y. Ozgurluk, K. Asgarov, & A. C. Karaoglanli, Mater. Res. Exp., 2019. doi.org/10.1088/2053-1591/ab26d8.

S. Kumar, B. Satapathy, D. Pradhan, G. S. Mahobia, Mater. Res. Exp.,, 2019, vol. 6.8. https://doi.org/10.1088/2053-1591/ab1dc7.

K. Feng, Y. Chen, P. Deng, Y. Li, H. Zhao, F. Lu, R. Li, & Z. Li, . J. of Mater.Process. Techn., 2017, 243, 82-91. https://doi.org/10.1016/j.jmatprotec.2016.12.001.

Y. Birol, Wear, 2010, 269, 664-671

O. Azouani, M. Keddam, A. Brahimi, A. Sehisseh, J. Min. Metall. Sect. B 2015, 51(1), 49–54.

A. Günen, M. Ulutan, M. S. Gok, B. Kurt, N. Orhan: J. Balk. Tribol. Assoc., 2014, vol. 20(3), pp. 362-379.

O. Ozdemir, M.A. Omar, M. Usta, S. Zeytin, C. Bindal, A.H. Ucisik: Vacuum, 2008, vol. 83(1), pp. 175-179. https://doi.org/10.1016/j.vacuum.2008.03.026.

M. S. Karakaş, A. Günen, E. Kanca, E. Yilmaz: Arch. Metall. Mater., 2018, vol. 63(1), pp. 159-165. https://doi.org/10.24425/118923.

Thirugnanasambantham KG, Raju R, Sankaramoorthy T, Velmurugan P, Kannagi A, Chaitanya M, Reddy K, Chary VS, Mustafa MA, Chandra V (2018) Cogent Eng https://doi.org/10.1080/23311916.2018.1501864.

H. L. Du, P. K. Datta, I. A. Inman, R. Geurts, C. Kubel: Mat. Sci. Eng. A, 2003, vol. 357, pp. 412-422. https://doi.org/10.1016/s0921-5093(03)00258-2.

M. S. Gök, Y. Küçük, A. Erdoğan, M. Öge, E. Kanca, A. Günen, Surf. Coat. Tech. 328 (2017) 54-62 https://doi.org/10.1016/j.surfcoat.2017.08.008.

C. Zimmerman: Boriding (Boronizing) of Metals, ASM Handbook, Heat Treating, 4A, 2013, pp. 709–724. https://doi.org/10.31399/asm.hb.v04a.a0005772.

J.C.A. Batista, A. Matthews, C. Godoy: Surf. Coat. Tech., 2001, vol. 142-144, pp. 1137-1143. https://doi.org/10.1016/s0257-8972(01)01189-6.

B. Kurt, Y. Küçük, M.S. Gök: Tribol. T., 2014, vol. 57(2), pp. 345-352.

A. Günen, B. Kurt, P. Milner, M.S. Gök: Int. J. Ref. Met. Hard Mater. (2019) 81, 333-344

A. Pauschitz, M. Roy, F. Franek: Tribol. Int., 2008, 41(7), pp. 584–602. https://doi.org/10.1016/j.triboint.2007.10.003.

B.L. Strahin, D.D. Shreeram, G.L. Doll: JOM., 2017 69 (7), pp. 1160–1164. https://doi.org/10.1007/s11837-017-2370-2.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted April 19, 2019.

Rights and permissions

About this article

Cite this article

Günen, A. Properties and High Temperature Dry Sliding Wear Behavior of Boronized Inconel 718. Metall Mater Trans A 51, 927–939 (2020). https://doi.org/10.1007/s11661-019-05577-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05577-3