Abstract

Solute and precipitate effects on static recrystallization (SRX) and grain growth were examined by systematically varying Zn content and substituting Ce for Zn in ZK60 alloys. Thermal treatments after extrusion and cold rolling were performed, and SRX was observed to initiate at shear bands and grain boundaries of primarily non-basal grains in all as-rolled samples. Increased precipitate and solute content decreased grain growth kinetics. Basal grains were found to grow preferentially during grain growth.

Similar content being viewed by others

References

D. Letzig, J. Swiostek, J. Bohlen, P.A. Beaven, and K.U. Kainer, Wrought Magnesium Alloys for Structural Applications, Mater. Sci. Technol., 2008, 24(8), p 991–996.

M. Easton, A. Beer, M. Barnett, C. Davies, G. Dunlop, Y. Durandet, S. Blacket, T. Hilditch, and P. Beggs, Magnesium Alloy Applications in Automotive Structures, JOM, 2008, 60(11), p 57–62.

N. Stanford and M.R. Barnett, The Origin of “Rare Earth” Texture Development in Extruded Mg-Based Alloys and Its Effect on Tensile Ductility, Mater. Sci. Eng. A, 2008, 496(1–2), p 399–408.

H. Yu, Y.M. Kim, B.S. You, H.S. Yu, and S.H. Park, Effects of Cerium Addition on the Microstructure, Mechanical Properties and Hot Workability of ZK60 Alloy, Mater. Sci. Eng. A, 2013, 559, p 798–807.

E.P. Silva, R.H. Buzolin, F. Marques, F. Soldera, U. Alfaro, and H.C. Pinto, Effect of Ce-Base Mischmetal Addition on the Microstructure and Mechanical Properties of Hot-Rolled ZK60 Alloy, J. Magnes. Alloys, 2020 https://doi.org/10.1016/j.jma.2020.09.018

J.J. Bhattacharyya, S.R. Agnew, and G. Muralidharan, Texture Enhancement during Grain Growth of Magnesium Alloy AZ31B, Acta Mater., 2015, 86, p 80–94.

M.T. Pérez-Prado and O.A. Ruano, Texture Evolution during Annealing of Magnesium AZ31 Alloy, Scr. Mater., 2002, 46(2), p 149–155.

J.A. Chapman and D.U. Wilson, Room-Temperature Ductility of Fine-Grain Magnesium, J. Inst. Met., 1962, 91(1), p 39.

T. Al-Samman and X. Li, Sheet Texture Modification in Magnesium-Based Alloys by Selective Rare Earth Alloying, Mater. Sci. Eng. A, 2011, 528(10), p 3809–3822.

J. Bohlen, M.R. Nürnberg, J.W. Senn, D. Letzig, and S.R. Agnew, The Texture and Anisotropy of Magnesium-Zinc-Rare Earth Alloy Sheets, Acta Mater., 2007, 55(6), p 2101–2112.

S. Wang, S.B. Kang, and J. Cho, Effect of Hot Compression and Annealing on Microstructure Evolution of ZK60 Magnesium Alloys, J. Mater. Sci., 2009, 44(20), p 5475–5484.

J.-F. Nie, Precipitation and Hardening in Magnesium Alloys, Metall. Mater. Trans. A, 2012, 43(11), p 3891–3939.

X. Gao, S.M. He, X.Q. Zeng, L.M. Peng, W.J. Ding, and J.F. Nie, Microstructure Evolution in a Mg-15Gd-0.5Zr (wt.%) Alloy during Isothermal Aging at 250 °C, Mater. Sci. Eng. A, 2006, 431(1–2), p 322–327.

J.P. Hadorn, K. Hantzsche, S. Yi, J. Bohlen, D. Letzig, and S.R. Agnew, Effects of Solute and Second-Phase Particles on the Texture of Nd-Containing Mg Alloys, Metall. Mater. Trans. A, 2012, 43(4), p 1363–1375.

E.A. Ball and P.B. Prangnell, Tensile-Compressive Yield Asymmetries in High Strength Wrought Magnesium Alloys, Scr. Metall. Mater., 1994, 31(2), p 111–116.

J.E. Burke and D. Turnbull, Recrystallization and Grain Growth, Prog. Met. Phys., 1952, 3, p 220–292.

X. Fang, D. Yi, W. Luo, B. Wang, X. Zhang, and F. Zheng, Effects of Yttrium on Recrystallization and Grain Growth of Mg-4.9Zn-0.7Zr Alloy, J. Rare Earths, 2008, 26(3), p 392–397.

A. Sheikhani, Y. Palizdar, M. Soltan Ali Nezhad, S. Najafi, and H. Torkamani, The Effect of Ce Addition (up to 3%) and Extrusion Ratio on the Microstructure and Tensile Properties of ZK60 Mg Alloy, Mater. Res. Express, 2019, 6(8), p 086594.

R. Agarwal, S.G. Fries, H.L. Lukas, G. Petzow, E. Sommer, T.G. Chart, and G. Effenberg, Assessment of the Mg-Zn System, Int. J. Mater. Res., 1992, 83(4), p 216–223.

J.J. Park and L.L. Wyman, Phase Relationships in Magnesium Alloys. Period Covered: December 1954 to August 1957. National Bureau of Standards, Washington, D.C., 1957, https://www.osti.gov/biblio/4312291. Accessed 16 December 2022.

R. Pei, Y. Zou, D. Wei, and T. Al-Samman, Grain Boundary Co-Segregation in Magnesium Alloys with Multiple Substitutional Elements, Acta Mater., 2021, 208, 116749.

Acknowledgments

The authors acknowledge support by the Center for Advanced Non-Ferrous Structural Alloys (CANFSA), a National Science Foundation Industry/University Cooperative Research Center (I/UCRC) (Award No. 1624836) at the Colorado School of Mines. Mag Specialties, Inc. supplied and designed all alloys evaluated during the project duration.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Magnesium. The issue was organized by Prof. C. (Ravi) Ravindran, Dr. Raja Roy, Mr. Payam Emadi, and Mr. Bernoulli Andilab, Ryerson University.

Appendix

Appendix

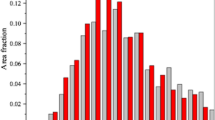

See Figures 1, 2, 3, 4, 5 and 6.

See Tables 1,

and 3.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Storey, G.K., Eres-Castellanos, A., Peterson, N. et al. Solute and Precipitate Effects on Static Recrystallization and Grain Growth Kinetics of Ce-Containing Mg Alloys. J. of Materi Eng and Perform 32, 2543–2551 (2023). https://doi.org/10.1007/s11665-023-07977-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07977-4