Abstract

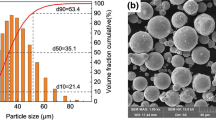

Silver coating in its jewelry application needs to resist tarnishing as well as wear. The corrosion and tribological behavior of pulse reverse current (PRC) and the addition of SiC 45-60 nm-size nanoparticles in the Ag-Ge coating on copper substrate were investigated. The contact angle, open circuit potential and electrochemical polarization in ammonium sulfide and artificial sweat media and thioacetamide corrosion were studied. Moreover, the pin-on-disc method and microhardness were used to assess the wear behavior of the coatings. FE-scanning electron microscopy equipped with energy dispersive spectroscopy and x-ray diffraction patterns were used. During reverse time in PRC process, the already reduced hydrogen on cathode surface was released and resulted in fine-grained microstructure, reduction of internal defects and smooth surface, which in turn improved the corrosion resistance of the coating. PRC together with nano-SiC changed the coating behavior from super-hydrophilic to hydrophobicity. Corrosion analysis showed that PRC sample possessed the best resistance to corrosion in both ammonium sulfide as well as artificial sweat. Although SiC addition reduced the corrosion resistance, still was much higher than that of direct current sample. Analyses of the wear behavior of the deposited film showed that samples containing SiC nanoparticles obtained superior wear resistance than samples without SiC. The dominant wear mechanism in both DC and PRC coatings was the delamination mechanism, whereas the wear mechanism in the coatings contained 4 and 8 g SiC in electrolyte was the adhesive wear mechanism.

Similar content being viewed by others

References

D. Zhang and Y. Tang, Enhancing Light Reflective Properties on ITO Glass by Plasmonic Effect of Silver Nanoparticles, Results Phys., 2017, 7, p 2874–2877. https://doi.org/10.1016/j.rinp.2017.07.067

K. Mijnendonckx, N. Leys, J. Mahillon, S. Silver, and R. Van Houdt, Antimicrobial Silver: Uses, Toxicity and Potential for Resistance, Biometals, 2013, 26(4), p 609–621. https://doi.org/10.1007/s10534-013-9645-z

R. Wiesinger, I. Martina, C. Kleber, and M. Schreiner, Influence of Relative Humidity and Ozone on Atmospheric Silver Corrosion, Corros Sci., 2013, 77, p 69–76. https://doi.org/10.1016/j.corsci.2013.07.028

F. Alimohammadi, M.P. Gashti, A. Shamei, and A. Kiumarsi, Deposition of Silver Nanoparticles on Carbon Nanotube by Chemical Reduction Method: Evaluation of Surface, Thermal and Optical Properties, Superlattices Microstruct., 2012, 52(1), p 50–62. https://doi.org/10.1016/j.spmi.2012.04.015

H. Zhang and X. Xue, The Research Progress on Corrosion and Protection of Silver Alloy, SN Appl. Sci., 2019, 1, p 464. https://doi.org/10.1007/s42452-019-0495-3

J. Ortíz-Corona and F.J. Rodriguez-Gómez, Role of Copper in Tarnishing Process of Silver Alloys in Sulphide Media, Trans. Nonferrous Met. Soc. China., 2019, 29, p 2646.

A. Cusma, M. Sebastiani, D.D. Felicis, A. Basso, and E. Bemporad, Study on the Correlation between Microstructure Corrosion and Wear Resistance of Ag-Cu-Ge Alloys, Coatings, 2015, 5, p 78–94. https://doi.org/10.3390/coatings5010078

Gamon J.P, Silver ternary alloy, US20070009375A1, 2004.

Gamon J.P, Silver alloys, investment casting using the alloys and casting grain, GB2561376A, 2017.

S.I. Ghazanlou, S. Ahmadiyeh, and R. Yavari, Investigation of Pulse Electrodeposited Ni-Co/SiO2 Nanocomposite Coating, Surf. Eng., 2017, 33(5), p 337–47. https://doi.org/10.1080/02670844.2016.1275484

V. Kalaivani and C. Shanthi, Pulse Reverse Plating of Silver on Silver Alloy, Prot. Met. Phys. Chem. Surfaces., 2018, 54(4), p 668–672. https://doi.org/10.1134/S2070205118040202

S. Jayapoorani, K.V. Malini, and K.U. Prakash, Comparison of Technology- DC Plating, Pulse Plating and Pulse Reverse Plating on Printed Circuit Board, Solid State Technol., 2021, 64(1), p 1928–1933.

S. Imanian Ghazanlou, A.H.S. Farhood, S. Hosouli, S. Ahmadiyeh, and A. Rasooli, Pulse and Direct Electrodeposition of Ni-Co/micro and Nanosized SiO2 Particles, Mater. Manuf. Process., 2018, 33(10), p 1067–1079. https://doi.org/10.1080/10426914.2017.1364748

J.P.G. Farr, Future Pulse Plating of Silver, Trans. Inst. Met. Finish., 2008, 86(5), p 275–279. https://doi.org/10.1179/174591908X345031

Y.K. Sun, A. Chamaani, and G. Zangari, Electrodeposition of Ag-Pd Alloy at Ru Substrate from Simple Acidic Nitrate Bath, J. Electrochem. Soc., 2020, 167, p 062506. https://doi.org/10.1149/1945-7111/ab7d41

M. Thirumoorthy and K. Ramesh, Characteristics of Pulse Electrodeposited AgGaS2 Thin Films for Photovoltaic Application, Mater Today Proc., 2021 https://doi.org/10.1016/j.matpr.2021.03.410

V. Kumar Sharma, N. Kukreja, and K. Mausam, Application of Pulse Plating Technique to Improve Hardness, Mater Today Proc., 2021, 45, p 3449–3451. https://doi.org/10.1016/j.matpr.2020.12.934

A. Sharma, C.H. Chung, and B. Ahn, Pulse Co-Deposition of Tin-Silver Alloy from Citric Acid Plating Bath for Microelectronic Applications, Mater. Res. Exp., 2019, 6(11), p 1165. https://doi.org/10.1088/2053-1591/ab512d

C. Başaran and I. Karakaya, Effects of Pulse Electroplating Parameters on Return Loss (S11) and Surface Roughness of Silver Coatings, ECS, 2019 https://doi.org/10.1149/osf.io/4ugvc

C. Başaran, Effects of Pulse Parameters on Surface Properties of Silver Coatings on Copper Substrates [dissertaion], Natural and Applied Sciences of Middle East Technical University, Ankara, 2019.

P. Leisner, C. Zanella, I. Belov, C. Edström, G. Sandulache, and W.E.G. Hansal, Control of Silver Throwing Power by Pulse Reverse Electroplating, Trans. Inst. Met. Finish., 2017, 95(1), p 25–30. https://doi.org/10.1080/00202967.2017.1260895

M. Lakatos-Varsányi, M. Furko, and T. Pozman, Electrochemical Impedance Spectroscopy Study on Silver Coated Metallic Implants, Electrochim. Acta, 2011, 56(23), p 7787–7795. https://doi.org/10.1016/j.electacta.2011.01.072

C. Shanthi, S. Barathan, R. Jaiswal, and R.M. Arunachalam, Study of Surface Morphology in DC and Pulse Plating of Silver Alloy, Indian J. Eng. Mater. Sci., 2009, 16(2), p 128–132.

C. Shanthi, S. Barathan, R. Jaiswal, R.M. Arunachalam, and S. Mohan, The Effect of Pulse Parameters in Electro Deposition of Silver Alloy, Mater Lett., 2008, 62(30), p 4519–4521. https://doi.org/10.1016/j.matlet.2008.08.032

Y. Fu, M. Hou, H. Xu, Z. Hou, P. Ming, Z. Shao et al., Ag-polytetrafluoroethylene Composite Coating on Stainless Steel as Bipolar Plate of Proton Exchange Membrane Fuel Cell, J. Power Sources., 2008, 182(2), p 580–584. https://doi.org/10.1016/j.matlet.2008.08.032

V. Srimaneepong, D. Rokaya, P. Thunyakitpisal, J. Qin, and K. Saengkiettiyut, Corrosion Resistance of Graphene oxide/Silver Coatings on Ni-Ti alloy and Expression of IL-6 and IL-8 in Human Oral Fibroblasts, Sci. Rep., 2020, 10, p 3247. https://doi.org/10.1038/s41598-020-60070-x

I.L.P.M. Kharmachi a, bDhouibi aBerçot bRezrazi, Pulse Plating as an Alternative Approach to Improve Ni-Co Alloys Properties Coated from a Bath with a Low Nickel Content, J. Mater. Environ. Sci., 2016, 7(5), p 1670–1684.

O.R. Monteiro, S. Murugesan, and V. Khabashesku, Electroplated Ni-B Films and Ni-B Metal Matrix Diamond Nanocomposite Coatings, Surf. Coat. Technol., 2015, 272, p 291–297. https://doi.org/10.1016/j.surfcoat.2015.03.049

S. Ahmadiyeh, A. Rasooli, and M.G. Hosseini, Ni-B/SiC Nanocomposite Coating Obtained by Pulse Plating and Evaluation of its Electrochemistry and Mechanical Properties, Surf Eng., 2019, 35(10), p 861–872. https://doi.org/10.1080/02670844.2018.1498823

S. Singh, M. Sribalaji, N.P. Wasekar, S. Joshi, G. Sundararajan, R. Singh et al., Microstructural, Phase Evolution and Corrosion Properties of Silicon Carbide Reinforced Pulse Electrodeposited Nickel-Tungsten Composite Coatings, Appl. Surf. Sci., 2016, 364, p 264–272. https://doi.org/10.1016/j.apsusc.2015.12.179

Y. Yang and Y.F. Cheng, Fabrication of Ni-Co-SiC Composite Coatings by Pulse Electrodeposition - Effects of Duty Cycle and Pulse Frequency, Surf Coat. Technol., 2013, 216, p 282–288. https://doi.org/10.1016/j.surfcoat.2012.11.059

S. Jayapoorani, D.K. Ghosh, Effect of pulse reverse plating using silver on printed circuit boards, International Conference & Workshop on Recent Trends in Technology, International Conference & Workshop on Recent Trends in Technology, (TCET) 2012: 25–27.

O.L. Bersirova and V.S. Kublanovskii, Corrosion Properties of Electrodeposited Thin Coatings of Polycrystalline Silver, Mater Sci., 2012, 48(2), p 197–202. https://doi.org/10.1007/s11003-012-9491-0

P. Bulkin, S. Gaiaschi, P. Chapon, D. Daineka, and N. Kundikova, Protective Coatings for Front Surface Silver Mirrors by Atomic Layer Deposition, Opt. Exp., 2020, 28, p 15753. https://doi.org/10.1364/OE.388546

M. Kawamura, T. Kiba, Y. Abe, K.H. Kim, and H. Murotani, Metal Nanolayer Deposited Highly Stable Ag Thin Films and Their Optical Properties, IOP Conf Series: Journal of Physics: Conf Series, 2018, 987, p 012002.

A.E. Marquardt, E.M. Breitung, T. Drayman-Weisser, G. Gates, and R.J. Phaneuf, Protecting Silver Cultural Heritage Objects with Atomic Layer Deposited Corrosion Barriers, Herit Sci, 2015, 3, p 37.

W. Bahmani, A. Zakeri, and A. Sabour Rouh Aghdam, Microstructural Analysis and Surface Studies on Ag-Ge Alloy Coatings Prepared by Electrodeposition Technique, J. Mater. Sci., 2021, 56, p 6427–6447.

A. Sharma, S. Bhattacharya, S. Das et al., A Study on the Effect of Pulse Electrodeposition Parameters on the Morphology of Pure tin Coatings, Metall. Mater. Sci., 2014, 45(10), p 4610–4622.

R.S. Prasannakumar, K. Bhakyaraj, V.I. Chukwuike, S. Mohan, and R.C. Barik, An Investigation of the Effect of Pulse Electrochemical Deposition Parameters on Morphology, Hardness and Corrosion Behaviour in the Marine Atmosphere, Surf. Eng., 2019, 35(12), p 1–12. https://doi.org/10.1080/02670844.2019.1609289

Q. Shen, H. Li, H. Lin, L. Li, W. Li, and Q. Song, Simultaneously Improving the Mechanical Strength and Electromagnetic Interference Shielding of Carbon/Carbon Composites by Electrophoretic Deposition of SiC Nanowires, J. Mater. Chem. C, 2018, 22, p 5888–5899.

V.S. Protsenko and F.I. Danilov, Kinetic Model of Composite Coatings Electrodeposition Assuming Irreversible Adsorption of Dispersed Particles on a Growing Metal Substrate, J. Electroanal. Chem., 2022, 918, p 116463.

J.P. Franey, M. Hill, G.W. Kammlott, and T.E. Graedel, The Corrosion of Silver by Atmospheric Sulfurous Gases, , Corros Sci., 1985, 25(2), p 133–143. https://doi.org/10.1016/0010-938X(85)90104-0

U. Baig, M.A. Gondal, M.A. Dastageer, A.B. Khalil, and S.M. Zubair, Photo-Catalytic Deactivation of Hazardous Sulfate Reducing Bacteria Using Palladium Nanoparticles Decorated Silicon Carbide: A Comparative Study with pure Silicon carbide Nanoparticles, J. Photochem. Photobiol. B Biol., 2018 https://doi.org/10.1016/j.jphotobiol.2018.08.010

S. Goriparti, E. Miele, A. Scarpellini, S. Marras, M. Prato, A. Ansaldo et al., Germanium Nanocrystals-MWCNTs Composites as Anode Materials for Lithium Ion Batteries, ECS Trans., 2014, 62(1), p 19–24. https://doi.org/10.1149/06201.0019ecst

J. Umashankari, D. Inbakandan, T.T. Ajithkumar, and T. Balasubramanian, Mangrove Plant, Rhizophora mucronata (Lamk, 1804) Mediated One Pot Green Synthesis of Silver Nanoparticles and Its Antibacterial Activity Against Aquatic Pathogens, Aquat. Biosyst., 2012, 8(1), p 1–7. https://doi.org/10.1186/2046-9063-8-11

U. Holzwarth and N. Gibson, The Scherrer Equation Versus the ‘Debye–Scherrer Equation, Nat. Nanotechnol., 2011, 6, p 534.

J. Fahim, H. Ghayour, S.M.M. Hadavi, and S.A. Hassanzadeh Tabrizi, Fabrication of Superhydrophobic Al5083 Aluminum Alloy for Marine Applications, Prot. Metals Phys. Chem. Surfaces, 2018, 54(5), p 899–908.

E. Murat Baba, C. Elif Cansoy, and E. OzkanZayim, Investigation of Wettability and Optical Properties of Superhydrophobic Polystyrene-SiO2 Composite Surfaces, Prog. Org. Coat., 2016, 99, p 378–385.

Y. Qing, C. Yang, N. Yu, Y. Shang, Y. Sun, L. Wang, and C. Liu, Superhydrophobic TiO2/polyvinylidene Fluoride Composite Surface with Reversible Wettability Switching and Corrosion Resistance, Chem. Eng. J., 2016, 290, p 37–44.

L. Benea, V. Dragan, B. Tribollet, Electrochemical corrosion properties of SiC/Ni nano-composite coatings in 0.5M NaCl. The Annals of “Dunarea De Jos” university of Galati. Metallurgy and Materials Science. 2010.

P. Calandra, M. Cioni, V.L. Parola, and T.D. Caro, Alkylphosphates as Low-Cost Inhibitors in Silver Tarnishing, Atti Accad. Pelorit. Pericol. Cl Sci. Fis. Mat. Nat., 2019, 97, p 131.

L. Paussa, L. Guzman, E. Marin, N. Isomaki, and L. Fedrizzi, Protection of Silver Surfaces Against Tarnishing by Means of Alumina/titania-nanolayers, Surf. Coat. Technol., 2011, 206, p 976–980.

Y. Huo, S.W. Fu, Y.L. Chen, and C. Lee, A Reaction Study of Sulfur Vapor with Silver and Silver–Indium Solid Solution as a Tarnishing Test Method, J. Mater. Sci.: Mater. Electron., 2016, 27, p 10382–10392.

Y.B. Amor, E. Sutter, H. Takenouti et al., Electrochemical Study of the Tarnish Layer of Silver Deposited on Glass, Electrochim. Acta, 2014, 131, p 89–95. https://doi.org/10.1016/j.electacta.2013.12.011

S. Yazdani, R. Tima, and F. Mahboubi, Investigation of Wear Behavior of as-Plated and Plasma-Nitrided Ni-B-CNT Electroless Having Different CNTs Concentration, Appl. Surf. Sci., 2018, 457, p 942–955. https://doi.org/10.1016/j.apsusc.2018.07.020

Y. Zhou, F.Q. Xie, X.Q. Wu, W.D. Zhao, and X. Chen, A Novel Plating Apparatus for Electrodeposition of Ni-SiC Composite Coatings Using Circulating-Solution co-Deposition Technique, J. Alloys Compd., 2017, 699, p 366–377. https://doi.org/10.1016/j.jallcom.2016.12.331

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Javadian, H.R., Hadavi, S.M.M. & Gholampour, M. Corrosion Resistance and Tribological Behavior of Ag-Ge/Nano-SiC Coatings Prepared by Pulse Electrodeposition. J. of Materi Eng and Perform 32, 10191–10203 (2023). https://doi.org/10.1007/s11665-023-07850-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07850-4