Abstract

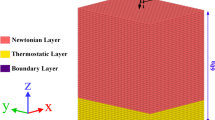

The crystal orientation effect on the mechanical properties and micro-deformation behavior of single-crystal iron (SC Fe) were revealed by molecular dynamics (MD) simulations. The results show that the surviving defects in the SC Fe models are [110] < [100] < [111], and only the vacancy and interstitial atomic clusters are formed in the [111] SC Fe model. Irradiation leads to the increase of elastic modulus owing to the annihilation of irradiation point defects. However, the non-annihilable irradiation clusters reduced the strength. The decrease of yield strain and yield strength of the [111] SC Fe model is significantly higher than those of [110] and [100] SC Fe models, exhibiting worse radiation damage resistance. This is due to the number and types of operation of slip systems in the [110] and [100] SC Fe after irradiation, which is caused by its poor inhibition of [111] crystal orientation on clusters under irradiation, being much lower than those in the [111] SC Fe. The yield strength of SC Fe increases with the increase of the number and length of 1/2 \(\left\langle {111} \right\rangle\) and \(\left\langle {100} \right\rangle\) dislocations, while the plasticity decreases with the increase of the falling gradient of dislocations after yield. The purpose is to provide theoretical guidance for the microstructure design and regulation of radiation-damage-resistant iron-based materials.

Graphical Abstract

Similar content being viewed by others

References

J.S. Lee, J.Y. Park, B.K. Choi, B.G. Hong, K.J. Jung, and Y.H. Jeong, HIP Joining of RAFM/RAFM Steel and Beryllium/RAFM Steel for Fabrication of the ITER TBM First Wall, Met. Mater. Int., 2009, 15, p 465–470.

H.B. Liao, X.Y. Wang, G.P. Yang, Y.J. Feng, P.H. Wang, and K.M. Feng, Recent Progress of R&D Activities on Reduced Activation Ferritic/Martensitic Steel (CLF-1), Fusion Eng. Des., 2019, 147, p 111235.

Q.Y. Huang and FDS Team, Development Status of CLAM Steel for Fusion Application, J. Nucl. Mater., 2014, 455, p 649–654.

V. Khripunov, Secondary Radiation Damage and Gas Production in Plasma Facing Materials under Fusion Neutron Irradiation, Fusion Eng. Des., 2017, 124, p 371–375.

A. Bhattacharya, X. Chen, T. Graening, J.W. Geringer, J. Reed, J. Henry, L. Pilloni, D. Terentyev, A. Puype, T.S. Byun, Y. Katoh, M. Rieth, and S.J. Zinkle, Irradiation Hardening and Ductility Loss of Eurofer97 Steel Variants After Neutron Irradiation to ITER-TBM Relevant Conditions, Fusion Eng. Des., 2021, 173, p 112935.

L. Tan, Y. Yang, and J.T. Busby, Effects of Alloying Elements and Thermomechanical Treatment on 9Cr Reduced Activation Ferritic–Martensitic (RAFM) steels, J. Nucl. Mater., 2013, 442, p S13–S17.

X.C. Li, M.J. Zheng, X.Y. Yang, P.H. Chen, and W.Y. Ding, A Property-Oriented Design Strategy of High-Strength Ductile RAFM Steels Based on Machine Learning, Mater. Sci. Eng., A, 2022, 840, p 142891.

L.S. Wang, P. Li, J.R. Dai, and K.M. Xue, Synergistic Strengthening and Plasticizing of Reduced Activation Ferritic/Martensitic Steel Processed by Sequential Extrusion-Twist-Extrusion, J. Mater. Eng. Perform., 2022, 31, p 3883–3895.

W.B. Liu, Y.Z. Ji, P.K. Tan, C. Zhang, C.H. He, and Z.G. Yang, Microstructure Evolution During Helium Irradiation and Post-irradiation Annealing in a Nanostructured Reduced Activation Steel, J. Nucl. Mater., 2016, 479, p 323–330.

X.J. Jin, S.H. Chen, and L.J. Rong, Microstructure Modification and Mechanical Property Improvement of Reduced Activation Ferritic/Martensitic Steel by Severe Plastic Deformation, Mater. Sci. Eng., A, 2018, 712, p 97–107.

S.H. Chen, X.J. Jin, and L.J. Rong, Improving the Strength and Ductility of Reduced Activation Ferritic/Martensitic Steel by Cold-Swaging and Post-Annealing, Mater. Sci. Eng., A, 2015, 631, p 139–143.

M.R. He, T. Matsumoto, S. Takeda, T. Uchimoto, T. Takagi, H. Miki, H.E. Chen, S.J. Xie, and Z.M. Chen, Nondestructive Evaluation of Plastic Damage in a RAFM Steel Considering the Influence of Loading History, J. Nucl. Mater., 2019, 523, p 248–259.

P.O. Marushchak, N.V. Kret, R.T. Bishchak, and I.M. Kurnat, Influence of Texture and Hydrogenation on the Mechanical Properties and Character of Fracture of Pipe Steel, Mater. Sci., 2019, 55, p 381–385.

J.K. Hwang, Correlation of Strain Path, Texture, Twinning, and Mechanical Properties in Twinning-Induced Plasticity Steel during Wire Drawing, Materials, 2020, 13, p 2250.

K.M. Subramanian, P. Chandramohan, and B. Ravisankar, Influence of Texture on the Mechanical Properties of Hot Rolled Duplex Stainless Steels, Trans. Indian. Inst. Met., 2011, 64, p 519–534.

M. Eddahbi, M.A. Monge, T. Leguey, P. Fernández, and R. Pareja, Texture and Mechanical Properties of EUROFER 97 Steel Processed by ECAP, Mater. Sci. Eng., A, 2011, 528, p 5927–5934.

J.W. Fu, F. Li, J.J. Sun, and Y.C. Wu, Texture, Orientation, and Mechanical Properties of Ti-stabilized Fe-17Cr Ferritic Stainless Steel, Mater. Sci. Eng., A, 2018, 738, p 335–343.

Q.N. Wang, J.W. Wang, J.X. Li, Z. Zhang, and S.X. Mao, Consecutive Crystallographic Reorientations and Superplasticity in Body-Centered Cubic Niobium Nanowires, Sci. Adv., 2018, 4, p 8850.

Q. Yu, M. Legros, and A.M. Minor, In Situ TEM Nanomechanics, MRS Bull., 2015, 40, p 62–70.

H. Wang, D.K. Chen, X.H. An, Y. Zhang, S.J. Sun, Y.Z. Tian, Z.F. Zhang, A.G. Wang, J.Q. Liu, M. Song, S.P. Ringer, T. Zhu, and X.Z. Liao, Deformation-Induced Crystalline-to-Amorphous Phase Transformation in a CrMnFeCoNi High-Entropy Alloy, Sci. Adv., 2021, 7, p 3105.

H.Y. Song, L. Zhang, and M.X. Xiao, Molecular Dynamics Simulation of Effect of Hydrogen Atoms on Crack Propagation Behavior of α-Fe, Phys. Lett. A, 2016, 380, p 4049–4405.

G. Sainath and B.K. Choudhary, Atomistic Simulations on Ductile-Brittle Transition in <111> BCC Fe Nanowires, J. Appl. Phys., 2017, 122, p 095101.

J. Wang, L.M. Yu, Y. Huang, H.J. Li, and Y.C. Liu, Effect of Crystal Orientation and He Density on Crack Propagation Behavior of bcc-Fe, Acta Metall. Sin., 2018, 54, p 47–54.

S. Plimpton, Fast Parallel Algorithms for Short-Range Molecular Dynamics, J. Comput. Phys., 1995, 117, p 1–19.

E. Martínez, D. Schwen, and A. Caro, Helium Segregation to Screw and Edge Dislocations in a-Iron and their Yield Strength, Acta Mater., 2015, 84, p 208–214.

A. Caro, J. Hetherly, A. Stukowski, M. Caro, E. Martinez, S. Srivilliputhur, L.Z. Ruiz, and M. Nastasi, Properties of Helium Bubbles in Fe and FeCr Alloys, J. Nucl. Mater., 2011, 418, p 261–268.

A. Chartier and M.C. Marinica, Rearrangement of Interstitial Defects in alpha-Fe under Extreme Condition, Acta Mater., 2019, 180, p 141–148.

N. Anento and A. Serra, Interaction of a Mobile 112 Grain Boundary with Radiation Induced Defects in α-Fe: Transformation of Defects and Impact on the Shear-Coupled Grain Boundary Migration, Comput. Mater. Sci., 2020, 179, p 109679.

H.G. Xiang, H.T. Li, T. Fu, C. Huang, and X.H. Peng, Formation of Prismatic Loops in AlN and GaN under Nanoindentation, Acta Mater., 2017, 138, p 131–139.

T. Fu, X.H. Peng, Y.B. Zhao, R. Sun, S.Y. Wen, C. Feng, and Z.C. Wang, Molecular Dynamics Simulation of TiN (001) Thin Films Under Indentation, Ceram. Int., 2015, 41, p 14078–14086.

W.G. Hoover, Canonical Dynamics: Equilibrium Phase-Space Distributions, Phys. Rev. A Gener. Phys., 1985, 31, p 1695–1697.

W.G. Hoover, Constant-Pressure Equations of Motion, Phys. Rev. A, 1996, 34, p 2499–2500.

A. Stukowski, Visualization and Analysis of Atomistic Simulation Data with OVITO—The Open Visualization Tool, Model. Simul. Mater. Sci. Eng., 2010, 18, p 015012.

D. Faken and H. Jónsson, Systematic Analysis of Local Atomic Structure Combined with 3D Computer Graphics, Comput. Mater. Sci., 1994, 2, p 279–286.

A. Stukowski and K. Albe, Extracting Dislocations and Non-dislocation Crystal Defects from Atomistic Simulation Data, J. Geophys. Res. Atmos., 2010, 119, p 2131–2145.

X. Huang, J.H. Yi, J. Ding, K. Song, S.Q. Lu, H. Liu, and L.S. Wang, Radiation Damage Behavior and Mechanism in RAFM Steel: Orientation Effect, Vacuum, 2022, 205, p 111445.

C.H. Kai, H. Zang, J.W. Ben, K. Jiang, Z.M. Shi, Y.P. Jia, X.Z. Cao, W. Lü, X.J. Sun, and D.B. Li, Origination and Evolution of Point Defects in AlN Film Annealed at High Temperature, J. Lumin., 2021, 235, p 118032.

P. Li, L.S. Wang, S.L. Yan, M. Meng, Y.F. Zhou, and K.M. Xue, The Role of Non-equilibrium Grain Boundary in Micro-deformation and Failure Mechanisms of Bicrystal Structural Tungsten, Int. J. Refract. Metal Hard Mater., 2021, 94, p 105376.

K.J. Caspersen, A. Lew, M. Ortiz, and E.A. Carter, Importance of Shear in the BCC-to-HCP Transformation in Iron, Phys. Rev. Lett., 2004, 93, p 115501.

A. Parashar and D. Singh, Molecular Dynamics Based Study of an Irradiated Single Crystal Of Niobium, Comput. Mater. Sci., 2017, 131, p 48–54.

Acknowledgments

This work is financially supported by the Scientific Research Foundation of Chongqing University of Technology (01192200552), by Innovative Research Group of Chongqing Municipal Education Commission (CXQT19026), by Chongqing Science and Technology Committee (Nos. CSTC2017JCYJAX0357, cstc2021jcyj-msxmX0010), and by the Science and Technology Research Program of Chongqing Municipal Education Commission (Grant No. KJQN202101117).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, X., Ding, J., Song, K. et al. Crystal Orientation Effect on the Irradiation Mechanical Properties and Deformation Mechanism of α-Fe: Molecular Dynamic Simulations. J. of Materi Eng and Perform 32, 8063–8074 (2023). https://doi.org/10.1007/s11665-022-07730-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07730-3