Abstract

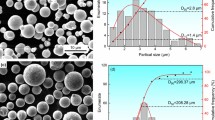

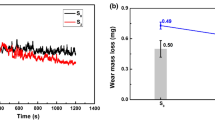

The present study emphasizes the development aspects of modular die setup to perform pressure-assisted sintering of recently developed Mg3Zn1Ca15Nb in a tubular heating furnace. The customized die setup was built in such a way that it could apply an arbitrary amount of pressure to the green compact of Mg3Zn1Ca15Nb. Subsequently, the pressurized sample was sintered in a tube furnace. Additionally, to validate the efficacy of the experimental setup, the mechanical and anti-corrosion properties of Mg3Zn1Ca15Nb were compared with samples sintered without utilizing the developed experimental setup. It was found that the less compacted sample sintered with spring load showed significant improvement in the mechanical and corrosion properties. However, only a marginal improvement in these properties was obtained for the highly compacted samples sintered with spring load. The application of spring load during sintering resulted in a highly dense product due to the formation of strong intermetallic bonding between the powder particles, which led to improved mechanical and anti-corrosion properties. After the sintering, it was noticed that the spring had lost its flexibility, which may have caused a reduction in the applied pressure. The application of pressure on the sample during sintering resulted in finer microstructure and reduction in porosity than the sample sintered without any pressure. As confirmed by XRD analysis, no phase constituents were found in the sintered Mg3Zn1Ca15Nb.

Similar content being viewed by others

References

T. Kim, C.W. See, X. Li et al., Orthopedic Implants and Devices for Bone Fractures and Defects: Past, Present and Perspective, Eng. Regen., 2020, 1, pp. 6–18

M. Navarro, A. Michiardi, O. Castaño et al., Biomaterials in Orthopaedics, J. R. Soc. Interface, 2008, 5, pp. 1137–1158

H. Windhagen et al., Biodegradable Magnesium-Based Screw Clinically Equivalent to Titanium Screw in Hallux Valgus Surgery: Short Term Results of the First Prospective, Randomized, Controlled Clinical Pilot Study, Biomed. Eng. Online, 2013, 62, pp. 1–10

C. Janning, E. Willbold, C. Vogt et al., Magnesium Hydroxide Temporarily Enhancing Osteoblast acTivity and Decreasing the Osteoclast Number in Peri-Implant Bone Remodelling, Acta Biomater., 2010, 6, pp. 1861–1868

D. Persaud-Sharma and A. McGoron, Biodegradable Magnesium Alloys: A Review of Material Development and Applications, J. Biomim. Biomater. Tissue Eng., 2012, 12, pp. 25–39

S.-J.L. Kang, Sintering: Densification, Grain Growth and Microstructure, Elsevier, Amsterdam, 2004

A. Kumar and P.M. Pandey, Study of the Influence of Microwave Sintering Parameters on the Mechanical Behaviour of Magnesium-Based Metal Matrix Composite, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., 2021, 235, pp. 2416–2425

F. Witte, N. Hort, C. Vogt et al., Degradable Biomaterials Based on Magnesium Corrosion, Curr. Opin. Solid State Mater. Sci., 2008, 12, pp. 63–72

F. Mordike, Magnesium Technology Metallurgy, Design Data, Applications. 2006. Epub ahead of print 2006. DOI: https://doi.org/10.1145/3132847.3132886

C.C. Ng, M.M. Savalani, H.C. Man et al., Layer Manufacturing of Magnesium and its Alloy Structures for Future Applications, Virtual Phys. Prototyp., 2010, 5, pp. 13–19

A. Kumar and P.M. Pandey, Development of Mg Based Biomaterial with Improved Mechanical and degradation Properties Using Powder Metallurgy, J. Magnes. Alloy, 2020, 8, pp. 883–898

A. Kumar and P. Pandey, Statistical Modelling of Mechanical Properties and Bio-Corrosion Behaviour of Mg3Zn1Ca15Nb Fabricated Using Microwave Sintering, J. Alloys Compd., 2020, 854, pp. 156211

A. Kumar and P.M. Pandey, Effect of Ultrasonic Assisted Sintering on Mechanical Properties and Degradation Behaviour of Mg15Nb3Zn1Ca Biomaterial, J. Magnes. Alloy, 2021, 9, pp. 1989–2008

M. Bram, A.M. Laptev, T.P. Mishra et al., Application of Electric Current-Assisted Sintering Techniques for the Processing of Advanced Materials, Adv. Eng. Mater., 2020, 22, pp. 2000051

A. Vahid, P. Hodgson, and Y. Li, Reinforced Magnesium Composites by Metallic Particles for Biomedical Applications, Mater. Sci. Eng. A, 2017, 685, pp. 349–357

ASTM B962–15, Standard Test Methods for Density of Compacted or Sintered Powder Metallurgy ( PM ) Products Using Archimedes ’ Principle. ASTM Int 2016, pp. 1–7

ISO 13314:2011(E), Mechanical testing of metals-Ductility testing-Compression test for porous and cellular metals. 2011

H.T. Tadashi Kokubo, How useful is SBF in predicting in vivo bone bioactivity?

D.K. Pathak and P.M. Pandey, An Experimental Investigation of the Fabrication of Biodegradable Zinc—Hydroxyapatite Composite Material Using Microwave Sintering, Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., 2020, 234, pp. 1–18

J.D.B. De Mello, R. Binder, A.N. Klein, and I.M. Hutchings, Effect of Compaction Pressure and Powder Grade on the Microstructure , Hardness and surface Topography of Steam Oxidized Sintered Iron. In: Steels and Materials for Power Plants. 2020, pp. 248–254

R. Srivastava and M. Dixit, Effect of Compaction Pressure on Microstructure, Density and Hardness of COPPER Prepared by Powder Metallurgy Route, IOP Conf. Ser. Mater. Sci. Eng., 2018, 377, pp. 012209

M. Güden, E. Çelik, A. Hizal et al., Effects of Compaction Pressure and Particle Shape on the Porosity and Compression Mechanical Properties of Sintered Ti6Al4V Powder Compacts for Hard Tissue Implantation, J. Biomed. Mater. Res. Part B Appl. Biomater., 2008, 85, pp. 547–555

A. Du, Y. Yang, Y. Qin et al., Effects of Heating Rate and Sintering Temperature on 316 L stainless Steel Powders Sintered Under Multiphysical Field Coupling, Mater. Manuf. Process., 2013, 28, pp. 66–71

C. Padmavathi, A. Upadhyaya, and D. Agrawal, Effect of Microwave and Conventional Heating on Sintering Behavior and Properties of Al-Mg-Si-Cu Alloy, Mater. Chem. Phys., 2011, 130, pp. 449–457

X. Zhang, G. Ruiz, M. Tarifa et al., Production of Aluminium Matrix Composite Components Using Conventional PM Technology, Mater. (Basel), 2017, 10, pp. 292–301

X. Xiong, H.C. Sheng, J. Chen et al., Effects of Sintering Pressure and Temperature on Microstructure and Tribological Characteristic of Cu-based Aircraft Brake Material, Trans. Nonferrous Met. Soc. China, 2007, 17, pp. 669–675

K.H.W. Seah and X. Chen, A Comparison of Sintered Between the Corrosion and Unsintered Porous Behaviour Titanium, Corros. Sci., 1995, 37, pp. 1333–1340

G. Xie, F. Qin, S. Zhu et al., Intermetallics Corrosion Behaviour of Porous Ni-Free Ti-Based Bulk Metallic Glass Produced by Spark Plasma Sintering in Hanks ’ Solution, Intermetallics, 2014, 44, pp. 55–59

F. Aydin, Y. Sun, and T.M. Emre, Influence of TiC Content on Mechanical, Wear and Corrosion Properties of Hot-Pressed AZ91/TiC Composites, J. Compos. Mater., 2020, 54, pp. 141–152

Acknowledgments

The research work was financially supported by a grant from the Department of Science and Technology (DST)-Science and Engineering Research Board (SERB), New Delhi, India (Grant reference no. EMR/2017/001550) for the project titled “Design and development of biodegradable metal implants for orthopaedic and cardiovascular applications” for carrying out this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential competing financial interests with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Pandey, P.M. Investigations into Mechanical and Corrosion Properties of Mg-Based Biomaterial Sintered Using a Customized Die Setup Coupled with a Tube Furnace. J. of Materi Eng and Perform 32, 8174–8184 (2023). https://doi.org/10.1007/s11665-022-07720-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07720-5