Abstract

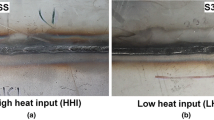

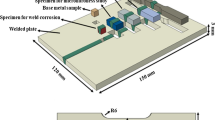

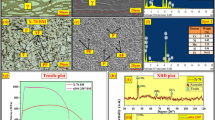

In this study, a Ni-reduced austenitic stainless TRIP/TWIP steel with < 5 vol.% δ-ferrite was investigated before and after plasma arc welding and gas tungsten arc welding. The 4-mm-thick hot-rolled sheet was produced as hot-rolled heavy plate on an industrial scale and manufactured as longitudinally welded pipes without filler metal. Microstructural characterization was done using light optical microscope and scanning electron microscope with electron backscatter diffraction (EBSD). The microstructure consisted of non-recrystallized austenite with a small amount of δ-ferrite. The welds exhibited skeletal and lacy δ-ferrite morphologies. ε-martensite and α´-martensite were found in the weld seam after pipe expansion. Further, the mechanical properties were evaluated using tensile test. The results showed a tensile strength of 823 MPa with a uniform elongation of 69% at room temperature. The change of hardness in the weld seam was studied for welded pipe, welded expanded pipe and welded, post-weld heat-treated (PWHT) pipe with Vickers hardness testing. The lowest hardness was achieved after PWHT. The corrosion resistance tests were conducted in chloride containing environment. The results showed that the susceptibility to pitting corrosion increased with the degree of deformation. Furthermore, the weld metal and heat-affected zone exhibited local attack whereas the base metal seemed unaffected.

Similar content being viewed by others

Data Availability

The raw/process data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

P. Behjati, A. Kermanpur, and A. Najafizadeh, Influence of Nitrogen Alloying on Properties of Fe-18Cr-12Mn-XN Austenitic Stainless Steels, Mater. Sci. Eng. A, 2013, 588, p 43–48.

K.H. Tseng and C.Y. Hsu, Performance of Activated TIG Process in Austenitic Stainless Steel Welds, J. Mater. Process. Technol, 2011, 211(3), p 503–512. https://doi.org/10.1016/j.jmatprotec.2010.11.003

W. Chuaiphan and L. Srijaroenpramong, Optimization of TIG Welding Parameter in Dissimilar Joints of Low Nickel Stainless Steel AISI 205 and AISI 216, J. Manuf. Process., 2020, 58(July), p 163–178. https://doi.org/10.1016/j.jmapro.2020.07.052

W. Chuaiphan and L. Srijaroenpramong, Heat Input and Shielding Gas Effects on the Microstructure, Mechanical Properties and Pitting Corrosion of Alternative Low Cost Stainless Steel Grade 202, Results Mater., 2020, 7(April), p 100111. https://doi.org/10.1016/j.rinma.2020.100111

T.D. Anderson, M.J. Perricone, J.N. DuPont, and A.R. Marder, The Influence of Molybdenum on Stainless Steel Weld Microstructures, Weld. J., 2007, 86, p 281-s-292-s.

M. Sabzi, S.H. MousaviAnijdan, A.R. Eivani, N. Park, and H.R. Jafarian, The Effect of Pulse Current Changes in PCGTAW on Microstructural Evolution, Drastic Improvement in Mechanical Properties, and Fracture Mode of Dissimilar Welded Joint of AISI 316L-AISI 310S Stainless Steels, Mater. Sci. Eng. A, 2021, 823(July), p 141700. https://doi.org/10.1016/j.msea.2021.141700

R.W. Revie, Uhlig´s Corrosion Handbook, Phys. Rev. E, 3rd edn, (Wiley) (2011), http://www.ainfo.inia.uy/digital/bitstream/item/7130/1/LUZARDO-BUIATRIA-2017.pdf

A. Golchinvafa, S.H. Mousavi Anijdan, M. Sabzi, and M. Sadeghi, The Effect of Natural Inhibitor Concentration of Fumaria Officinalis and Temperature on Corrosion Protection Mechanism in API X80 Pipeline Steel in 1 M H2SO4 Solution, Int. J. Press. Vessel. Pip., 2020, 188, p 104241. https://doi.org/10.1016/j.ijpvp.2020.104241

M. Sabzi, A.H. Jozani, F. Zeidvandi, M. Sadeghi, and S.M. Dezfuli, Effect of 2-Mercaptobenzothiazole Concentration on Sour-Corrosion Behavior of API X60 Pipeline Steel: Electrochemical Parameters and Adsorption Mechanism, Int. J. Miner. Metall. Mater., 2022, 29(2), p 271–282.

C. Lemaitre, A. Abdel Moneim, R. Djoudjou, B. Baroux, and G. Beranger, A Statistical Study of the Role of Molybdenum in the Pitting Resistance of Stainless Steels, Corros. Sci., 1993, 34(11), p 1913–1922.

R.F.A. Jargelius-Pettersson, Electrochemical Investigation of the Influence of Nitrogen Alloying on Pitting Corrosion of Austenitic Stainless Steels, Corros. Sci., 1999, 41(8), p 1639–1664.

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, 1st ed. Wiley, New Jersey, 2005.

B. Mateša, I. Samardžić, and M. Dunder, The Influence of the Heat Treatment on Delta Ferrite Transformation in Austenitic Stainless Steel Welds, Metalurgija, 2012, 51(2), p 229–232.

DIN 50125, Prüfung Metallischer Werkstoffe-Zugproben. Deutsch. Insti.für Norm. (2022)

M. Hauser, M. Wendler, A. Weiß, O. Volkova, and J. Mola, On the Critical Driving Force for Deformation-Induced α′-Martensite Formation in Austenitic Cr–Mn–Ni Steels, Adv. Eng. Mater., 2019, 21(5), p 1–6.

M. Hauser, M. Wendler, A. Weiß, and J. Mola, Quantification of Deformation-Induced α’-Martensite Content in Fe-19Cr-3Mn-4Ni-0.15C-0.17N Austenitic Stainless Steel by in-Situ Magnetic Measurements, in 8th European Stainless Steel and Duplex Stainless Steel Conference 2015 (2015), p 19–26

DIN EN ISO 643, Stahl - Mikrophotographische Bestimmung der erkennbaren Korngröße. Deutsch. Inst. für Norm. (2020)

DIN EN ISO 9015-1, Zerstörende Prüfung von Schweißverbindungen an metallischen Werkstoffen - Härteprüfung - Teil 1: Härteprüfung für Lichtbogenschweißverbindungen. Deutsch. Inst. für Norm. (2011)

G. Stein and J. Menzel, Nitrogen Alloyed Steels—a New Generation of Materials with Extraordinary Properties, Int. J. Mater. Prod. Technol., 1995, 10(3–6), p 290–302.

F. Lecroisey and A. Pineau, Martensitic Transformations Induced by Plastic Deformation in the Fe-Ni-Cr-C System, Metall. Trans., 1972, 3(2), p 391–400.

C. Quitzke, C. Schröder, C. Ullrich, M. Mandel, L. Krüger, O. Volkova, and M. Wendler, Evaluation of Strain-Induced Martensite Formation and Mechanical Properties in N-Alloyed Austenitic Stainless Steels by in Situ Tensile Tests, Mater. Sci. Eng. A, 2021, 808(February), p 140930.

S. Marich and R. Player, Sulfide Inclusions in Iron, Metall. Trans., 1970, 1(7), p 1853–1857.

M. Nabeel, M. Alba, and N. Dogan, Influence of Al and n Content and Cooling Rate on the Characteristics of Complex Mns Inclusions in AHSS, Crystals, 2020, 10(11), p 1–14.

S. Kozuh, M. Gojic, and L. Kose, Mechanical Properties and Microstructure of Austenitic Stainless Steel after Welding and Post-Weld Heat Treatment, Kov. Mater., 2009, 47(4), p 253–262.

S.A. David, S.S. Babu, and J.M. Vitek, Welding: Solidification and Microstructure, J Miner. Met Mater Soc, 2003, 55(6), p 14–20.

C. Quitzke, C. Schröder, M. Mande, L. Krüger, O. Volkova, and M. Wendler, Solidification of Plasma TIG-welded N-alloyed Austenitic CrMnNi Stainless Steel, Weld World, 2022 https://doi.org/10.1007/s40194-022-01353-x

S. Kou, Welding Metallurgy, 3rd ed. Wiley, New Jersey, 2021.

A. Kromm and T. Kannengießer, Influence of Local Weld Deformation on the Solidification Cracking Susceptibility of a Fully Austenitic Stainless Steel, in Hot Cracking Phenomena in Welds II, 1th edn, eds by T. Böllinghaus, H. Herold, C.E. Cross, and J.C. Lippold (Springer, Berlin, Heidelberg, 2008) p. 127–146

B. Zakaria, H. Soumia, and J. Vincent, Effect of Heat Treatment on the Microstructural Evolution in Weld Region of 304L Pipeline Steel, J. Therm. Eng., 2016, 2(6), p 1017–1022.

A. Rodrigues and A. Loureiro, Effect of Cooling Rate on the Microstructure and Hardness of Austenitic Stainless Steel Welds, Mater. Sci. Forum, 2004, 455–456, p 312–316.

T. Wegrzyn, Delta Ferrite in Stainless Steel Weld Metals, Weld. Int., 1992, 6(9), p 690–694.

A. Das, S. Sivaprasad, M. Ghosh, P.C. Chakraborti, and S. Tarafder, Morphologies and Characteristics of Deformation Induced Martensite During Tensile Deformation of 304 LN Stainless Steel, Mater. Sci. Eng. A., 2008, 486(1–2), p 283–286.

G.B. Olson and M. Cohen, Kinetics of Strain-Induced Martensitic Nucleation, Metall. Trans. A, 1975, 6A, p 791–795.

H. Vashishtha, R.V. Taiwade, S. Sharma, and A.P. Patil, Effect of Welding Processes on Microstructural and Mechanical Properties of Dissimilar Weldments between Conventional Austenitic and High Nitrogen Austenitic Stainless Steels, J. Manuf. Process. Soc. Manuf. Eng., 2018, 2017(25), p 49–59. https://doi.org/10.1016/j.jmapro.2016.10.008

J.F. Breedis, Influence of Dislocation Substructure on the Martensitic Transformation in Stainless Steel, Acta Metall., 1965, 13(3), p 239–250.

N. Saenarjhan, J.H. Kang, and S.J. Kim, Effects of Carbon and Nitrogen on Austenite Stability and Tensile Deformation Behavior of 15Cr-15Mn-4Ni Based Austenitic Stainless Steels, Mater. Sci. Eng. A., 2018, 2019(742), p 608–616. https://doi.org/10.1016/j.msea.2018.11.048

A. Kovalev, M. Wendler, A. Jahn, A. Weiß, and H. Biermann, Thermodynamic-Mechanical Modeling of Strain-Induced α′- Martensite Formation in Austenitic Cr-Mn-Ni As-Cast Steel, Adv. Eng. Mater., 2013, 15(7), p 609–617.

I. Chattoraj, A.K. Bhattamishra, S. Jana, S.K. Das, S.P. Chakraborty, and P.K. De, The Association of Potentiokinetic Reactivation and Electrochemical Pitting Tests on a Nitrogen Bearing 19 Cr-17 Mn Steel with Its Thermal History, Corros. Sci., 1996, 38(6), p 957–969.

P. Schmuki and H. Böhni, Metastable Pitting and Semiconductive Properties of Passive Films, J. Electrochem. Soc., 1992, 139(7), p 1908–1913.

U. Kamachi Mudali, P. Shankar, S. Ningshen, R.K. Dayal, H.S. Khatak, and B. Raj, On the Pitting Corrosion Resistance of Nitrogen Alloyed Cold Worked Austenitic Stainless Steels, Corros. Sci., 2002, 44(10), p 2183–2198.

L. Peguet, B. Malki, and B. Baroux, Influence of Cold Working on the Pitting Corrosion Resistance of Stainless Steels, Corros. Sci., 2007, 49(4), p 1933–1948.

E.M. Gutman, G. Solovioff, and D. Eliezer, The Mechanochemical Behavior of Type 316L Stainless Steel, Corros. Sci., 1996, 38(7), p 1141–1145.

B.I. Kolodii, Theoretical Investigation of the Interaction of a Deformed Metal with a Corrosion Medium, Mater. Sci., 2000, 36(6), p 884–891.

E.M. Gutman, Mechanochemistry of Solid Surfaces, World Scientific Publishing Company, Hackensack, 1994.

B.T. Lu, Z.K. Chen, J.L. Luo, B.M. Patchett, and Z.H. Xu, Pitting and Stress Corrosion Cracking Behavior in Welded Austenitic Stainless Steel, Electrochim. Acta, 2005, 50(6), p 1391–1403.

M. Dadfar, M.H. Fathi, F. Karimzadeh, M.R. Dadfar, and A. Saatchi, Effect of TIG Welding on Corrosion Behavior of 316L Stainless Steel, Mater. Lett., 2007, 61(11–12), p 2343–2346.

M.A. Baker and J.E. Castle, The Initiation of Pitting Corrosion at MnS Inclusions, Corros. Sci., 1993, 34(4), p 667–682.

E.M.F. de Souza Silva, G.S. da Fonseca, and E.A. Ferreira, Microstructural and Selective Dissolution Analysis of 316L Austenitic Stainless Steel, J. Mater. Res. Technol., 2021, 15, p 4317–4329.

Y. Cui and C.D. Lundin, Austenite-Preferential Corrosion Attack in 316 Austenitic Stainless Steel Weld Metals, Mater. Des., 2007, 28(1), p 324–328.

P.E. Manning, C.E. Lyman, and D.J. Duquette, A STEM Examination of the Localized Corrosion Behavior of a Duplex Stainless Steel, Corrosion, 1980, 36(5), p 246–251.

Acknowledgments

The authors thank the German Research Foundation (DFG) for the financial support of this work. This work was carried out within the framework of the Collaborative Research Center 799 (grant number 54473466), transfer project T5. The authors thank Dr.-Ing. Michael Hauser from Institute of Iron and Steel Technology, TU Bergakademie Freiberg for the thermodynamic calculations with the Thermo-Calc software. The authors thank also Dipl.-Ing. Frank Hoffmann from Institute of Metal Forming, TU Bergakademie Freiberg for hot rolling the bars.

Author information

Authors and Affiliations

Contributions

CQ and CH contributed to investigation, visualization and writing—original draft. CS contributed to conceptualization, methodology and writing—review. CS contributed to investigation, formal analysis, visualization and writing—review. BA contributed to investigation and writing—review. SH contributed to validation, writing—review and project administration. MM contributed to writing—review and validation. LK contributed to validation, project administration and writing—review. OV contributed to validation, writing—review and project administration. MW contributed to writing—review, supervision, validation and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Quitzke, C., Hempel, C., Schröder, C. et al. Manufacturing and Characterization of Plasma Gas Tungsten Arc-Welded Pipes Made of a Ni-Reduced Austenitic Stainless CrMnNi Steel. J. of Materi Eng and Perform 32, 7915–7927 (2023). https://doi.org/10.1007/s11665-022-07676-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07676-6