Abstract

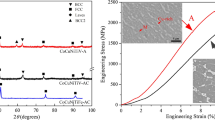

Similar atom substitution in 3d transition metal high entropy alloys (HEAs) were employed via Cr, Fe, and Cu equimolarly incorporated into CoNiTiV-base alloy, by which its effects on phase components, microstructures, and mechanical properties were intensively investigated. Results show that phase components of CoNiTiVCr and CoNiTiVFe alloys belong to a single-phase BCC solid solution. In addition to the BCC phase, FCC phase emerges into the CoNiTiVCu alloy as well, which has been confirmed being Cu-rich phase, implying that it might be originated form the ease of Cu segregation. In the mechanical view, the alloys with single-BCC phases are obviously stronger than the multiphase alloy. The yield strengths of CoNiTiVCr, CoNiTiVFe, and CoNiTiVCu HEAs are 1764, 2730, and 1674 MPa, respectively. Furthermore, the CoNiTiVFe alloy also possesses the most promising plasticity of ε \(\approx\) 6.8% due to its relatively uniform composition distribution. As comparison, the Ni-rich dendritic and Cu-rich intergranular phase in the Cr- and Cu-containing HEAs, respectively, take the responsibility for their extremely low plasticity.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303.

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218.

L.J. Zhang, K. Guo, H. Tang, M.D. Zhang, J.T. Fan, P. Cui, Y.M. Ma, P.F. Yu, and G. Li, The Microstructure and Mechanical Properties of Novel Al-Cr-Fe-Mn-Ni High-Entropy Alloys with Trimodal Distributions of Coherent B2 Precipitates, Mater. Sci. Eng. A, 2019, 757, p 160–171.

X. Jin, J. Bi, L. Zhang, Y. Zhou, X. Du, Y. Liang, and B. Li, A New CrFeNi2Al Eutectic High Entropy Alloy System with Excellent Mechanical Properties, J. Alloys Compd., 2019, 770, p 655–661.

C. Li, J.C. Li, M. Zhao, and Q. Jiang, Effect of Alloying Elements on Microstructure and Properties of Multiprincipal Elements High-Entropy Alloys, J. Alloys Compd., 2009, 475(1–2), p 752–757.

J. Pan, T. Dai, T. Lu, X. Ni, J. Dai, and M. Li, Microstructure and Mechanical Properties of Nb25Mo25Ta25W25 and Ti8Nb23Mo23Ta23W23 high Entropy Alloys Prepared by Mechanical Alloying and Spark Plasma Sintering, Mater. Sci. Eng. A, 2018, 738, p 362–366.

S.E. Sünbül, K. Için, F.Z. Şeren, Ö. Şahin, D.D. Çakil, R. Sezer, and S. Öztürk, Determination of Structural, Tribological, Isothermal Oxidation and Corrosion Properties of Al-Co-Cr-Fe-Ni-Ti-Cu High-Entropy Alloy. Vacuum 187, 110072 (2021)

X. Qiu, Microstructure, Hardness and Corrosion Resistance of Al2CoCrCuFeNiTix High-Entropy Alloy Coatings Prepared by Rapid Solidification, J. Alloys Compd., 2018, 735, p 359–364.

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle, Oxidation Behavior of a Refractory NbCrMo0.5Ta0.5TiZr Alloy, J. Mater. Sci., 2012, 47(18), p 6522–6534.

M.G. Poletti, G. Fiore, F. Gili, D. Mangherini, and L. Battezzati, Development of a New High Entropy Alloy for Wear Resistance: FeCoCrNiW0.3 and FeCoCrNiW0.3+ 5 at.% of C, Mater. Des., 2017, 115, p 247–254.

Y.P. Wang, B.S. Li, M.X. Ren, C. Yang, and H.Z. Fu, Microstructure and Compressive Properties of AlCrFeCoNi High Entropy Alloy, Mater. Sci. Eng. A, 2008, 491(1–2), p 154–158.

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy, J. Alloys Compd., 2011, 509(20), p 6043–6048.

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, and X.D. Hui, Phase Composition and Solid Solution Strengthening Effect in TiZrNbMoV High-Entropy Alloys, Mater. Des., 2015, 83, p 651–660.

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen, Microstructure and Compressive Properties of Multicomponent Alx(TiVCrMnFeCoNiCu)100–x High-Entropy Alloys, Mater. Sci. Eng. A, 2007, 454–455, p 260–265.

J. Yi, L. Wang, L. Zeng, M. Xu, L. Yang, and S. Tang, Excellent Strength-Ductility Synergy in a Novel Single-Phase Equiatomic CoFeNiTiV High Entropy Alloy, Int. J. Refract. Met. Hard Mater., 2021, 95, p 105416.

J. Yi, L. Yang, M. Xu, L. Wang, L. Liu, and L. Zeng, Investigation of a Novel CuFeNiTiV High Entropy Alloy on Phase Component, Microstructure and Mechanical Properties, J. Alloys Compd., 2021, 874, p 159985.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10(6), p 534–538.

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-Component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238.

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Prog. Nat. Sci. Mater., 2011, 21(6), p 433–446.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of Valence Electron Concentration on Stability of fcc or bcc Phase in High Entropy Alloys, J. Appl. Phys., 2011, 109(10), p 103505.

S. Sheikh, S. Shafeie, Q. Hu, J. Ahlström, C. Persson, J. Veselý, J. Zýka, U. Klement, and S. Guo, Alloy design for intrinsically ductile refractory high-entropy alloys, J. Appl. Phys., 2016, 120(16), p 164902.

R. Chen, G. Qin, H. Zheng, L. Wang, Y. Su, Y. Chiu, H. Ding, J. Guo, and H. Fu, Composition Design of High Entropy Alloys Using the Valence Electron Concentration to Balance Strength and Ductility, Acta Mater., 2018, 144, p 129–137.

Y.L. Chou, J.W. Yeh, and H.C. Shih, The Effect of Molybdenum on the Corrosion Behaviour of the High-Entropy Alloys Co1.5CrFeNi1.5Ti0.5Mox in Aqueous Environments, Corros. Sci., 2010, 52(8), p 2571–2581.

S.G. Ma and Y. Zhang, Effect of Nb Addition on the Microstructure and Properties of AlCoCrFeNi High-Entropy Alloy, Mater. Sci. Eng. A, 2012, 532, p 480–486.

Z. Sun, X. Tan, C. Wang, M. Descoins, D. Mangelinck, S.B. Tor, E.A. Jägle, S. Zaefferer, and D. Raabe, Reducing Hot Tearing by Grain Boundary Segregation Engineering in Additive Manufacturing: Example of an AlxCoCrFeNi High-Entropy Alloy, Acta Mater., 2021, 204, p 116505.

X. Hao, H. Dong, Y. Xia, and P. Li, Microstructure and Mechanical Properties of Laser Welded TC4 Titanium Alloy/304 Stainless Steel Joint with (CoCrFeNi)100-xCux High-Entropy Alloy Interlayer, J. Alloys Compd., 2019, 803, p 649–657.

H. Zheng, R. Chen, G. Qin, X. Li, Y. Su, H. Ding, J. Guo, and H. Fu, Microstructure Evolution, Cu Segregation and Tensile Properties of CoCrFeNiCu High Entropy Alloy During Directional Solidification, J. Mater. Sci. Technol., 2020, 38, p 19–27.

Z. Xu, Z. Li, Y. Tong, W. Zhang, and Z. Wu, Microstructural and Mechanical Behavior of a CoCrFeNiCu4 Non-Equiatomic High Entropy Alloy, J. Mater. Sci. Technol., 2021, 60, p 35–43.

Y. Chen, Z. Xu, M. Wang, Y. Li, C. Wu, and Y. Yang, A Single-Phase V0.5Nb0.5ZrTi Refractory High-Entropy Alloy with Outstanding Tensile Properties, Mater. Sci. Eng. A, 2020, 792, p 139774.

X. Yan and Y. Zhang, A Body-Centered Cubic Zr50Ti35Nb15 Medium-Entropy Alloy with Unique Properties, Scr. Mater., 2020, 178, p 329–333.

Q. Ding, Y. Zhang, X. Chen, X. Fu, D. Chen, S. Chen, L. Gu, F. Wei, H. Bei, Y. Gao, M. Wen, J. Li, Z. Zhang, T. Zhu, R.O. Ritchie, and Q. Yu, Tuning Element Distribution, Structure and Properties by Composition in High-Entropy Alloys, Nature, 2019, 574(10), p 223–227.

K. Liu, Y. Li, and J. Wang, Vacuum Diffusion Bonding TC4 to Ni80Cr20: Interfacial Microstructure, Segregation, Cracking and Properties, Vacuum, 2018, 158, p 218–222.

K.B. Zhang, Z.Y. Fu, J.Y. Zhang, W.M. Wang, H. Wang, Y.C. Wang, Q.J. Zhang, and J. Shi, Microstructure and Mechanical Properties of CoCrFeNiTiAlx High-Entropy Alloys, Mater. Sci. Eng. A, 2009, 508(1–2), p 214–219.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19(5), p 698–706.

É. Fazakas, V. Zadorozhnyy, L.K. Varga, A. Inoue, D.V. Louzguine-Luzgin, F. Tian, and L. Vitos, Experimental and Theoretical Study of Ti20Zr20Hf20Nb20X20 (X=V or Cr) Refractory High-Entropy Alloys, Int. J. Refract. Met. Hard Mater., 2014, 47, p 131–138.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George, and R.O. Ritchie, A Fracture-Resistant High-Entropy Alloy for Cryogenic Applications, Science, 2014, 345(6201), p 1153–1158.

X. Yang, Y. Zhang, and P.K. Liaw, Microstructure and Compressive Properties of NbTiVTaAlx High Entropy Alloys, Procedia Eng., 2012, 36, p 292–298.

N.D. Stepanov, N.Y. Yurchenko, D.V. Skibin, M.A. Tikhonovsky, and G.A. Salishchev, Structure and Mechanical Properties of the AlCrxNbTiV (x = 0, 0.5, 1, 1.5) High Entropy Alloys, J. Alloys Compd., 2015, 652, p 266–280.

O.N. Senkov, S.V. Senkova, D.B. Miracle, and C. Woodward, Mechanical Properties of Low-Density, Refractory Multi-Principal Element Alloys of the Cr-Nb-Ti-V-Zr System, Mater. Sci. Eng. A, 2013, 565, p 51–62.

Acknowledgments

Financial supports from Changzhou Science and Technology Bureau (No. CJ20210065, CQ20210086) and Jiangsu Province of China Innovation and Entrepreneurship Program “Doctor of Innovation and Entrepreneurship” are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, M., Lu, L., Wang, L. et al. Influence of Cr, Fe, or Cu 3d Transition Metals on Phase Components, Microstructures, and Mechanical Properties of CoNiTiV-Base High Entropy Alloys. J. of Materi Eng and Perform 32, 4500–4507 (2023). https://doi.org/10.1007/s11665-022-07425-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07425-9