Abstract

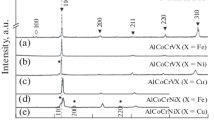

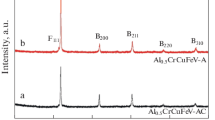

Two 3d transition metal high-entropy alloys (3d TM HEAs), AlFeNiVCu and AlFeNiVTi, were suction cast under identical conditions into a cylinder copper mould for investigating the compositional dependence of phase components, microstructures, and compressive properties. The phase components of the AlFeNiVCu were composed of a BCC FeV-rich dendritic phase, a netlike FCC Cu-rich interdendritic phase, and a uniformly distributed B2 AlNi-rich phase, when Cu substituted by Ti the phase components transformed to two BCC solid solution phases of the AlFeNiVTi. Moreover, an outstanding synergy in strength and ductility (ultimate compressive strength: 1936 MPa, plastic strain: 10.0%) was acquired for the AlFeNiVCu, which was sharply contrast with the typically brittle behaviour at the ultimate strength of 108 MPa for the alloy AlFeNiVTi. The distinctions of phase components and morphology were analysed to uncover the conflict in mechanical performance by Cu and Ti mutual substitution in AlFeNiV-base alloys.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also form part of an ongoing study.

References

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6:299–303

Cantor B, Chang ITH, Knight P, Vincent AJB (2004) Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A 375–377:213–218. https://doi.org/10.1016/j.msea.2003.10.257

Yoshida S, Ikeuchi T, Bhattacharjee T, Bai Y, Shibata A, Tsuji N (2019) Effect of elemental combination on friction stress and Hall-Petch relationship in face-centered cubic high/medium entropy alloys. Acta Mater 171:201–215. https://doi.org/10.1016/j.actamat.2019.04.017

Miracle DB, Senkov ON (2017) A critical review of high entropy alloys and related concepts. Acta Mater 122:448–511. https://doi.org/10.1016/j.actamat.2016.08.081

Tsai MH, Yeh JW (2014) High-entropy alloys: a critical review. Mater Res Lett 2(3):107–123. https://doi.org/10.1080/21663831.2014.912690

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP (2014) Microstructures and properties of high-entropy alloys. Prog Mater Sci 61:1–93. https://doi.org/10.1016/j.pmatsci.2013.10.001

Yi J, Tang S, Xu M, Yang L, Wang L, Zeng L (2020) A novel Al0.5CrCuNiV 3d transition metal high-entropy alloy: phase analysis, microstructure and compressive properties. J Alloy Compd. https://doi.org/10.1016/j.jallcom.2020.156466

Miracle D, Miller J, Senkov O, Woodward C, Uchic M, Tiley J (2014) Exploration and development of high entropy alloys for structural applications. Entropy 16(1):494–525. https://doi.org/10.3390/e16010494

Yeh JW, Chen SK, Gan JY, Lin SJ, Chin TS, Shun TT, Tsau CH, Chang SY (2004) Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall Mater Trans A 35A:2533–2536

Tong CJ, Chen MR, Chen SK, Yeh JW, Shun TT, Lin SJ, Chang SY (2004) Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A 36A:1263–1271

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP (2014) Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater 62:105–113. https://doi.org/10.1016/j.actamat.2013.09.037

Zhuang YX, Liu WJ, Xing PF, Wang F, He JC (2012) Effect of Co element on microstructure and mechanical properties of FeCoxNiCuAl alloys. Acta Metall Sin 25:124–130

Wang X, Xie H, Jia L, Lu ZL (2012) Effect of Ti, Al and Cu addition on structural evolution and phase constitution of FeCoNi system equimolar alloys. Mater Sci Forum 724:335–338

Li BS, Wang YP, Ren MX, Yang C, Fu HZ (2008) Effects of Mn, Ti and V on the microstructure and properties of AlCrFeCoNiCu high entropy alloy. Mater Sci Eng A 498(1–2):482–486. https://doi.org/10.1016/j.msea.2008.08.025

Zhang K, Fu Z (2012) Effects of annealing treatment on phase composition and microstructure of CoCrFeNiTiAlx high-entropy alloys. Intermetallics 22:24–32. https://doi.org/10.1016/j.intermet.2011.10.010

Stepanov ND, Shaysultanov DG, Salishchev GA, Tikhonovsky MA, Oleynik EE, Tortika AS, Senkov ON (2015) Effect of V content on microstructure and mechanical properties of the CoCrFeMnNiVx high entropy alloys. J Alloy Compd 628:170–185. https://doi.org/10.1016/j.jallcom.2014.12.157

Kang B, Lee J, Ryu HJ, Hong SH (2018) Ultra-high strength WNbMoTaV high-entropy alloys with fine grain structure fabricated by powder metallurgical process. Mater Sci Eng A 712:616–624. https://doi.org/10.1016/j.msea.2017.12.021

Chen MR, Lin SJ, Yeh JW, Chen SK, Huang YS, Chuang MH (2006) Effect of vanadium addition on the microstructure, hardness, and wear resistance of Al0.5CoCrCuFeNi high-entropy alloy. Metall Mater Trans A 37A:1363–1369

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK (2008) Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater 10(6):534–538. https://doi.org/10.1002/adem.200700240

Guo S, Ng C, Lu J, Liu CT (2011) Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys. J Appl Phys 109(10):103505. https://doi.org/10.1063/1.3587228

Hsu US, Hung UD, Yeh JW, Chen SK, Huang YS, Yang CC (2007) Alloying behavior of iron, gold and silver in AlCoCrCuNi-based equimolar high-entropy alloys. Mater Sci Eng A 460–461:403–408. https://doi.org/10.1016/j.msea.2007.01.122

Singh S, Wanderka N, Murty BS, Glatzel U, Banhart J (2011) Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater 59(1):182–190. https://doi.org/10.1016/j.actamat.2010.09.023

Zhu JM, Zhang HF, Fu HM, Wang AM, Li H, Hu ZQ (2010) Microstructures and compressive properties of multicomponent AlCoCrCuFeNiMox alloys. J Alloy Compd 497(1–2):52–56. https://doi.org/10.1016/j.jallcom.2010.03.074

Chen H-Y, Tsai C-W, Tung C-C, Yeh J-W, Shun T-T, Yang C-C, Chen S-K (2006) Effect of the substitution of Co by Mn in Al-Cr-Cu-Fe-Co-Ni high-entropy alloys. Annales de Chimie Science des Matériaux 31(6):685–698. https://doi.org/10.3166/acsm.31.685-698

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and Its application to characterization of the main alloying element. Mater Trans 46:2817–2829

Guo S, Ng C, Liu CT (2013) Anomalous solidification microstructures in Co-free AlxCrCuFeNi2 high-entropy alloys. J Alloy Compd 557:77–81. https://doi.org/10.1016/j.jallcom.2013.01.007

Acknowledgements

Financial support from the Natural Science Foundation of China (Grant No. 51801124), Natural Science Foundation of Jiangsu Province (Grant No. BK20181047) and Natural Science Research of Jiangsu Higher Education Institutions (Grant No. 18KJB430012) is gratefully acknowledged.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by JY, LY, MX, LW and LL. The first draft of the manuscript was written by JY, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, J., Yang, L., Xu, M. et al. Influence of mutual substitution between Cu and Ti on phase components, microstructures, and compressive properties of AlFeNiV–Cu/Ti alloys. J Mater Sci 56, 11448–11455 (2021). https://doi.org/10.1007/s10853-021-06016-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06016-8