Abstract

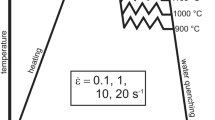

The flow curves of Al-7.8Zn-1.65Mg-2.0Cu (wt.%) alloy in the temperature range of 300-450 °C and strain rate range of 0.01-10 s−1 were obtained by hot compression tests on a Gleeble-3500 isothermal simulator. The effects of deformation heat-induced temperature rising and friction on the flow curves were discussed and the flow curves were corrected to exclude these influences. The constitutive model was constructed and its accuracy was evaluated by the correlation coefficient (R) and average absolute relative error. The values of the corresponding evaluators were determined to be 0.9841 and 6.2346%, respectively. The processing maps were developed and through which the optimal hot working window for this alloy was determined in the range of 380-450 °C and 0.01-0.368 s−1. The microstructure evolution observations revealed that micro-crack and flow localization occurred at 300 °C and 10 s−1 and 400 °C and 10 s−1, which located in the instability region of processing map. With the increasing strain rate, the deformation activation energy decreased, simultaneously, the dislocation multiplication rate accelerated, which resulted in pronounced increasing of LAGBs and HAGBs.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

M.A. Moazam and M. Honarpisheh, Improving the Mechanical Properties and Reducing the Residual Stresses of AA7075 by Combination of Cyclic Close Die Forging and Precipitation Hardening, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2021, 235(3), p 542–549.

F. Chen, H. Qu, W. Wu, J.-H. Zheng, S. Qu, Y. Han, and K. Zheng, A Physical-Based Plane Stress Constitutive Model for High Strength AA7075 under Hot Forming Conditions, Metals, 2021, 11(2), p 314.

L.Z. Xu, L.H. Zhan, Y.Q. Xu, C.H. Liu, and M.H. Huang, Thermomechanical Pretreatment of Al-Zn-Mg-Cu Alloy to Improve Formability and Performance during Creep-Age Forming, J. Mater. Process. Technol., 2021, 293, p 117089.

G.-Z. Quan, J. Liu, A. Mao, B. Liu, and J.-S. Zhang, A Characterization for the Hot Flow Behaviors of As-extruded 7050 Aluminum Alloy, High Temp. Mater. Process. (London), 2015, 34(7), p 643–650.

J. Li, F.G. Li, J. Cai, R.T. Wang, Z.W. Yuan, and F.M. Xue, Flow Behavior Modeling of the 7050 Aluminum Alloy at Elevated Temperatures Considering the Compensation of Strain, Mater. Des., 2012, 42, p 369–377.

Y. Sun, L. Bao, and Y. Duan, Hot Compressive Deformation Behaviour and Constitutive Equations of Mg-Pb-Al-1B-0.4Sc Alloy, Philos. Mag., 2021, 101(22), p 2355–2376.

M. Bambach, I. Sizova, J. Szyndler, J. Bennett, G. Hyatt, J. Cao, T. Papke, and M. Merklein, On the Hot Deformation Behavior of Ti-6Al-4V Made by Additive Manufacturing, J. Mater. Process. Technol., 2021, 288, p 116840.

J. Tang, J.H. Wang, J. Teng, G. Wang, D.F. Fu, H. Zhang, and F.L. Jiang, Effect of Zn Content on the Dynamic Softening of Al-Zn-Mg-Cu Alloys during Hot Compression Deformation, Vacuum, 2021, 184, p 109941.

X.M. Qian, N. Parson, and X.G. Chen, Effects of Mn Addition and Related Mn-Containing Dispersoids on the Hot Deformation Behavior of 6082 Aluminum Alloys, Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process., 2019, 764, p 138253.

J. Li, X. Wu, L. Cao, B. Liao, Y. Wang, and Q. Liu, Hot Deformation and Dynamic Recrystallization in Al-Mg-Si Alloy, Mater. Charact., 2021, 173, p 110976.

A. Rudra, S. Das, and R. Dasgupta, Constitutive Modeling for Hot Deformation Behavior of Al-5083 + SiC Composite, J. Mater. Eng. Perform., 2018, 28(1), p 87–99.

F. Jiang, J. Tang, D. Fu, J. Huang, and H. Zhang, A Correction to the Stress–Strain Curve during Multistage Hot Deformation of 7150 Aluminum Alloy Using Instantaneous Friction Factors, J. Mater. Eng. Perform., 2018, 27(6), p 3083–3090.

H. Xindi, R. Dong, D. Juan, H. Zong, and L. Zhengfeng, Constitutive Behavior and Novel Characterization of Hot Deformation of Al-Zn-Mg-Cu Aluminum Alloy for Lightweight Traffic, Materials Research Express, 2021, 8(1), p 016532.

R.L. Goetz and S.L. Semiatin, The Adiabatic Correction Factor for Deformation Heating during the Uniaxial Compression Test, J. Mater. Eng. Perform., 2001, 10(6), p 710–717.

R. Ebrahimi and A. Najafizadeh, A New Method for Evaluation of Friction in Bulk Metal Forming, J. Mater. Process. Technol., 2004, 152(2), p 136–143.

W. Bao, L. Bao, D. Liu, D. Qu, Z. Kong, M. Peng, and Y. Duan, Constitutive Equations, Processing Maps, and Microstructures of Pb-Mg-Al-B-0.4Y Alloy under Hot Compression, J. Mater. Eng. Perform., 2020, 29(1), p 607–619.

Y. Duan, L. Ma, H. Qi, R. Li, and P. Li, Developed Constitutive Models, Processing Maps and Microstructural Evolution of Pb-Mg-10Al-0.5B Alloy, Mater. Charact., 2017, 129, p 353–366.

Y. Duan, P. Li, L. Ma, and R. Li, Dynamic Recrystallization and Processing Map of Pb-30Mg-9Al-1B Alloy during Hot Compression, Metall. Mater. Trans. A, 2017, 48(7), p 3419–3431.

S. Long, Y.-F. Xia, P. Wang, Y.-T. Zhou, F.-J. Gong-ye, J. Zhou, J.-S. Zhang, and M.-L. Cui, Constitutive Modelling, Dynamic Globularization Behavior and Processing Map for Ti-6Cr-5Mo-5V-4Al Alloy during Hot Deformation, J. Alloy. Compd., 2019, 796, p 65–76.

R.Y. Li, Y.H. Duan, L.S. Ma, and S. Chen, Flow Behavior, Dynamic Recrystallization and Processing Map of Mg-20Pb-1.6Al-0.4B Alloy, J. Mater. Eng. Perform., 2017, 26(5), p 2439–2451.

Z. He, Z. Wang, and P. Lin, A Comparative Study on Arrhenius and Johnson-Cook Constitutive Models for High-Temperature Deformation of Ti2AlNb-Based Alloys, Metals, 2019, 9(2), p 123.

J. Li, F.G. Li, J. Cai, R.T. Wang, Z.W. Yuan, and G.L. Ji, Comparative Investigation on the Modified Zerilli-Armstrong Model and Arrhenius-Type Model to Predict the Elevated-Temperature Flow Behaviour of 7050 Aluminium Alloy, Comput. Mater. Sci., 2013, 71, p 56–65.

D. Samantaray, S. Mandal, and A.K. Bhaduri, A Comparative Study on Johnson Cook, Modified Zerilli-Armstrong and Arrhenius-Type Constitutive Models to Predict Elevated Temperature Flow Behaviour in Modified 9Cr-1Mo Steel, Comput. Mater. Sci., 2009, 47(2), p 568–576.

Y. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and R. Barker, Modeling of Dynamic Material Behavior in Hot Deformation: Forging of Ti-6242, Metall. Trans. A, 1984, 15(10), p 1883–1892.

Y.W. Xiao, Y.C. Lin, Y.Q. Jiang, X.Y. Zhang, G.D. Pang, D. Wang, and K.C. Zhou, A dislocation Density-Based Model and Processing Maps of Ti-55511 Alloy with Bimodal Microstructures during Hot Compression in Alpha Plus Beta Region, Mater. Sci. Eng. A, 2020, 790, p 139692.

B.N. Sahoo and S.K. Panigrahi, Deformation Behavior and Processing Map Development of AZ91 Mg Alloy with and without Addition of Hybrid In-Situ TiC+TiB2 Reinforcement, J. Alloy. Compd., 2019, 776, p 865–882.

Z. Liang, Q. Zhang, L. Niu, and W. Luo, Hot Deformation Behavior and Processing Maps of As-Cast Hypoeutectic Al-Si-Mg Alloy, J. Mater. Eng. Perform., 2019, 28(8), p 4871–4881.

Y.F. Xia, S. Long, T.-Y. Wang, and J. Zhao, A Study at the Workability of Ultra-High Strength Steel Sheet by Processing Maps on the Basis of DMM, High Temp. Mater. Process. (London), 2017, 36(7), p 657–667.

L.-C. Pu, H.-M. Deng, and T.-Q. Zhang, Numerical Simulation of Temperature and Thermal Stress Field in Quenched 7050 Aluminum Alloy Specimen, Spec. Cast. Nonferr. Alloys, 2014, 34(01), p 29–31.

A. Gholamzadeh, and A.K. Taheri, The Prediction of Hot Flow Behavior of Al-6%Mg Alloy, Mech. Res. Commun., 2009, 36(2), p 252–259.

R.W. Evans, and P.J. Scharning, Axisymmetric Compression Test and Hot Working Properties of Alloys, Mater. Sci. Technol., 2001, 17(8), p 995–1004.

V. Singh, C. Mondal, A. Kumar, P.P. Bhattacharjee, and P. Ghosal, High Temperature Compressive Flow Behavior and Associated Microstructural Development in a β-Stabilized High Nb-Containing γ-TiAl Based Alloy, J. Alloy. Compd., 2019, 788, p 573–585.

A. Hajari, M. Morakabati, S.M. Abbasi, and H. Badri, Constitutive Modeling for High-Temperature Flow Behavior of Ti-6242S Alloy, Mater. Sci. Eng. A, 2017, 681, p 103–113.

D. Wu, S. Long, S. Wang, S.-S. Li, and Y.-T. Zhou, Constitutive Modelling with a Novel Two-Step Optimization for an Al-Zn-Mg-Cu Alloy and its Application in FEA, Mater. Res. Exp., 2021, 8(11), p 116511.

L.A. Peterson, M.F. Horstemeyer, T.E. Lacy, and R.D. Moser, Experimental Characterization and Constitutive Modeling of an Aluminum 7085-T711 Alloy under Large Deformations at Varying Strain Rates, Stress States, and Temperatures, Mech. Mater., 2020, 151, p 103602.

C. Zener, and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32.

G.-Z. Quan, J. Pan, and X. Wang, Prediction of the Hot Compressive Deformation Behavior for Superalloy Nimonic 80A by BP-ANN Model, Appl. Sci., 2016, 6(3), p 66.

G.Z. Quan, T. Wang, Y.L. Li, Z.Y. Zhan, and Y.F. Xia, Artificial Neural Network Modeling to Evaluate the Dynamic Flow Stress of 7050 Aluminum Alloy, J. Mater. Eng. Perform., 2016, 25(2), p 553–564.

F. Kang, S. Wei, J. Zhang, E. Wang, D. Fan, and S. Wang, Hot Processing Maps and Microstructural Characteristics of A357 Alloy, J. Mater. Eng. Perform., 2020, 29(11), p 7352–7360.

Acknowledgments

The authors gratefully appreciate Chongqing Science and Technology Commission (cstc2021jcyj-msxmX0653), the Foundation of Science and Technology Project of Chongqing Education Commission (No. KJQN202101515), Research Foundation of Chongqing University of Science and Technology (No. ckrc2020015), Innovation Research Group of Universities in Chongqing (CXQT21030), Chongqing Talent Project (CQYC201905100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Dx., Long, S., Li, Ss. et al. Hot Deformation Behavior of Homogenized Al-7.8Zn-1.65Mg-2.0Cu (wt.%) Alloy. J. of Materi Eng and Perform 32, 3431–3442 (2023). https://doi.org/10.1007/s11665-022-07328-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07328-9