Abstract

Thin coatings AlN, AlTiN, and AlTiSiN were deposited by pulsed magnetron sputtering. High-speed steel T1, structural carbon steel 1017, and hard alloy HG30 were used as substrates. The magnetron current, nitrogen content in the gas mixture, and bias voltage on the substrate were changed to obtain nanostructured and amorphous coating layers with different elemental compositions. The microstructure, defects, and elemental composition of the coatings were investigated on an Ultra 55 field emission electron microscope with an EDX microanalysis system. Voltammetry and impedance spectroscopy was performed on coated samples in 3% NaCl solution. The corrosion behavior of the coatings was characterized by the corrosion current density icorr and the polarization resistance Rp (at the corrosion potential). The research shows that the investigated coatings (except for AlN) are electrochemically active, and corrosion processes occur not only on the substrate in the discontinuities of the coating but also on the coating surface. The corrosion current density for AlN and AlTiSiN coatings on a T1 substrate is about 0.1 μA cm−2. The paper discusses factors influencing the corrosion behavior of the coatings under study.

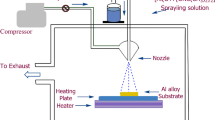

Graphical Abstract

Similar content being viewed by others

References

A.V. Pshyk, L.E. Coy, L. Yate, K. Załęski, G. Nowaczyk, A.D. Pogrebnjak and S. Jurga, Combined Reactive/Non-Reactive DC Magnetron Sputtering of High Temperature Composite AlN-TiB2-TiSi2, Mater. Des., 2016, 94, p 230–239. https://doi.org/10.1016/j.matdes.2015.12.174

S. Das, S. Guha, R. Ghadai and B. Prasad Swain, A Comparative Analysis Over Different Properties of TiN TiAlN and TiAlSiN Thin Film Coatings Grown in Nitrogen Gas Atmosphere, Mater. Chem. Phys., 2021, 258, p 123866. https://doi.org/10.1016/j.matchemphys.2020.123866

C. Besleaga, V. Dumitru, L.M. Trinca, A.-C. Popa, C.-C. Negrila, Ł Kołodziejczyk, C.-R. Luculescu, G.-C. Ionescu, R.-G. Ripeanu, A. Vladescu and G.E. Stan, Mechanical, Corrosion and Biological Properties of Room-Temperature Sputtered Aluminum Nitride Films with Dissimilar Nanostructure, Nanomaterials, 2017, 7(11), p 394. https://doi.org/10.3390/nano7110394

H. Savaloni, R. Karami, H.S. Bahari and F. Abdi, Influence of N+ Implantation on Structure, Morphology and Corrosion Behaviour of Al in NaCl Solution, Chin. Phys. B, 2020, 29(5), p 058102. https://doi.org/10.1088/1674-1056/ab7d97

J.F. Marco, A.C. Agudelo, J.R. Gancedo, M.A. Auger, O. Sánchez and J.M. Albella, Corrosion Behaviour of AlN and TiAlN Coatings on Iron, Surf. Interf. Anal., 2006, 38(4), p 243–247. https://doi.org/10.1002/sia.2165

Z. Wu, Z. Cheng, H. Zhang, Z. Xu, Y. Wang and F. Zhou, Electrochemical and Tribological Properties of CrAlN, TiAlN, and CrTiN Coatings in Water-Based Cutting Fluid, J. Mater. Eng. Perform., 2029, 20, p 2153–2163. https://doi.org/10.1007/s11665-020-04772-3

A. A. Matei, I. Pencea, M. Branzei, D. E. Trancă, G. Ţepeş, C. E. Sfăt, E. Ciovica Coman, A. I. Gherghilescu and G. A. Stanciu, Corrosion Resistance Appraisal of TiN, TiCN and TiAlN Coatings Deposited by CAE-PVD Method on WC–Co Cutting Tools Exposed to Artificial Sea Water, Appl. Surf. Sci., 2015, 358, p 572–578. https://doi.org/10.1016/j.apsusc.2015.08.041

L. Zhang, Y. Chen, Y. P. Feng, S. Chen, Q. L. Wan and J. F. Zhu, Electrochemical Characterization of AlTiN, AlCrN and AlCrSiWN Coatings, Int. J. Refract. Hard Met., 2015, 53, p 68–73. https://doi.org/10.1016/j.ijrmhm.2015.03.018

X.-Z. Ding, A.L.K. Tan, X.T. Zeng, C. Wang, T. Yue and C.Q. Sun, Corrosion Resistance of CrAlN and TiAlN Coatings Deposited by Lateral Rotating Cathode arc, Thin Solid Films, 2008, 516(16), p 5716–5720. https://doi.org/10.1016/j.tsf.2007.07.069

G. Wang, Z. Xie, T. Chen, Z. Chen, X. Song, X. Gao, X. Yu and H. Song, Electrochemical Behavior of TiAlSiN Hard Coatings Synthesized by a Multi-Plasma Immersion Ion Implantation and Deposition Technique, Thin Solid Films, 2015, 584, p 222–227. https://doi.org/10.1016/j.tsf.2015.02.027

M. Chen, F. Cai, W. Chen, Q. Wang and S. Zhang, Influence of Vacuum Annealing on Structures and Properties of AlTiSiN Coatings with Corrosion Resistance, Surf. Coat. Tech., 2017, 312, p 25–31. https://doi.org/10.1016/j.surfcoat.2016.08.006

J. Hahn, M.A. Abro, X. Xiao and D.B. Lee, Corrosion of Multilayered TiAlSiN Films at 800–1000 °C in N2/01% H2S gas, Met. Mater. Int., 2021, 27(9), p 3260–3268. https://doi.org/10.1007/s12540-020-00665-1

A.L. Кameneva, The influence of TiN, ZrN and TixZr1-xN layers of anti-friction multi-layer coatings on corrosion resistance of hard alloy in sodium hydroxide solution, Res. J. Pharm. Biol. Chem. Sci., 2015, 6(1), p 1381-1391, https://www.scopus.com/record/display.uri?eid=2-s2.0-84921496093&origin=resultslist&sort=plf-f, 2021. Accessed 20 December 2021

A.L. Кameneva, V.I. Кichigin, T.O. Soshina, V.V. Karmanov, Using Ti1-xAlxN coating to enhance corrosion resistance of tool steel in sodium chloride solution. Res. J. Pharm., Biol. Chem. Sci. 2014;5(5):1148-1156, https://www.scopus.com/record/display.uri?eid=2-s2.0-84907156621&origin=resultslist&sort=plf-f, 2021. Accessed 20 December 2021

A.L. Kameneva and V.I. Kichigin, Corrosion, Wear, and Friction Behavior of a Number of Multilayer Two-, Three- and Multicomponent Nitride Coatings on Different Substrates, Depending on the Phase and Elemental Composition Gradient, Appl. Surf. Sci., 2019, 489, p 165–174. https://doi.org/10.1016/j.apsusc.2019.05.331

A.L. Kameneva, V.I. Kichigin, N.V. Lobov and N.V. Kameneva, Data on the Effect of Structure, Elemental and Phase Composition Gradient of Nitride Multilayer Coatings on Corrosion Protection of Different Substrates in 3% NaCl and 5% NaOH Solutions, Data in Brief, 2019, 27, p 796. https://doi.org/10.1016/j.dib.2019.104796

A.L. Кameneva, V.V. Karmanov, I.V. Dombrovsky, Physical and mechanical properties of Ti1-xAlxN thin films prepared by different ion-plasma methods, Res. J. Pharm., Biol. Chem. Sci. 2014;5(6):762-771, https://www.scopus.com/record/display.uri?eid=2-s2.0-84911106998&origin=resultslist&sort=plf-f, 2021. Accessed 20 December 2021.

V.N. Antsiferov and A.L. Кameneva, Experimental Study of the Structure of Multicomponent Nanostructured Coatings on the Basis of Ti-Zr-N Alloys Formed by Ionic Plasma Methods, Russ. J. of Non-ferr. met., 2007, 48(6), p 485–499. https://doi.org/10.3103/S1067821207060211

A.L. Кameneva, L.N. Guselnikova and T.O. Soshina, Establishing the Relationship Between Substrate Bias Voltage and Formation Process of Single Component Ion-Plasma’s Thin Film Based on TiN by Electric-Arc Evaporation, e-J. Surf. Sci. Nanotech., 2011, 9, p 34–39. https://doi.org/10.1380/ejssnt.2011.34

A.L. Kameneva, The Influence of Aluminum on the Texture, Microstructure, Physical, Mechanical and Tribological Properties of Ti1-xAlxN Thin Films. Res. J. of Pharm. Biol. Chem. Sci., 2014, 5(6), p 965-975, https://www.scopus.com/record/display.uri?eid=2-s2.0-84911097451&origin=resultslist&sort=plf-f, 2021. Accessed 20 December 2021.

A. Kameneva, N. Antonova, M. Pesin, V. Makarov, S. Nikitin, and N. Bublik, Structural and Phase Transformations Control in Ti and Al Cathode Materials, WC-Co Substrate, and Ti1-xAlxN Coating to Improve Their Physico-Mechanical and Wear Properties, Int. J. Refract. Hard Met., 2022, 102, No. 105726, https://www.sciencedirect.com/science/article/pii/S0263436821002584, 2021. Accessed 20 December 2021.

V.V. Bannikov, A.R. Beketov, M.V. Baranov, A.A. Elagin, V.S. Kudyakova and R.A. Shishkin, Electronic Structure and Magnetic Properties of Doped Al1–xTixN (x = 0.03, 0.25) Compositions Based on Cubic Aluminum Nitride from ab Initio Simulation Data, Phys. Solid State, 2016, 58(5), p 924–932. https://doi.org/10.1134/s106378341605005x

V. Mortet, M. Nesladek, K. Haenen, A. Morel, M. D’Olieslaeger and M. Vanecek, Physical Properties of Polycrystalline Aluminium Nitride Films Deposited by Magnetron Sputtering, Diam. Relat. Mater., 2004, 13(4–8), p 1120–1124. https://doi.org/10.1016/j.diamond.2003.10.082

C. Liu, Q. Bi, A. Leyland and A. Matthews, An Electrochemical Impedance Spectroscopy Study of the Corrosion Behaviour of PVD Coated Steels in 0.5 N NaCl Aqueous Solution: Part I Establishment of Equivalent Circuits for EIS Data Modelling, Corros. Sci., 2003, 45(6), p 1243–1256. https://doi.org/10.1016/S0010-938X(02)00213-5

C. Liu, Q. Bi, A. Leyland and A. Matthews, An Electrochemical Impedance Spectroscopy Study of the Corrosion Behaviour of PVD Coated Steels in 0.5 N NaCl Aqueous Solution: Part II EIS Interpretation of Corrosion Behavior, Corros. Sci., 2003, 45(6), p 1257–1273. https://doi.org/10.1016/S0010-938X(02)00214-7

V.K.W. Grips, H.C. Barshilia, V.E.Selvi, Kalavati, and K.S. Rajam, Electrochemical Behavior of Single Layer CrN, TiN, TiAlN Coatings and Nanolayered TiAlN/CrN Multilayer Coatings Prepared by Reactive Direct Current Magnetron sputtering, Thin Solid Films, 2006, 514(1-2), p 204-211, doi.org/ https://doi.org/10.1016/j.tsf.2006.03.008

V.M.C.A. de Oliveira, C. Aguiara, A.M. Vazqueza, A.L.M. Robina and M.J.R. Barboza, Corrosion Behavior Analysis of Plasma-Assisted PVD Coated Ti-6Al-4V Alloy in 2 M NaOH Solution, Mater. Res., 2017, 20(2), p 436–444. https://doi.org/10.1590/1980-5373-MR-2015-0737

Y. Goldberg, In Properties of Advanced Semiconductor Materials GaN, AlN, InN, BN, SiC, SiGe. Eds. M.E. Levinshtein, S.L. Rumyantsev, M.S. Shur, Wiley ,New York, 2001, 31-47

W. Lengauer, Transition Metal Carbides, Nitrides, and Carbonitrides, Handbook of Ceramic Hard Mater., 2000, 7, p 202. https://doi.org/10.1002/9783527618217.ch7

M.E. Orazem and B. Tribollet, Electrochemical Impedance Spectroscopy, Wiley, Hoboken, NJ, 2008.

S. Buteau, D.C. Dahn and J.R. Dahn, Explicit Conversion Between Different Equivalent Circuit Models for Electrochemical Impedance Analysis of Lithium-Ion Cells, J. Electrochem. Soc., 2018, 165(2), p A228–A234. https://doi.org/10.1149/2.0841802jes

Funding

The results were obtained within the framework of the State task of the Ministry of Science and Higher Education of the Russian Federation (Project No. FSNM-2020-0026).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper. The authors declare the following financial interests/personal relationships which may be considered as potential competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kameneva, A., Kichigin, V. & Bublik, N. Structure and Electrochemical Behavior of AlN, AlTiN, and AlTiSiN Physical Vapor Deposition Coatings in 3% NaCl Solution. J. of Materi Eng and Perform 31, 10402–10411 (2022). https://doi.org/10.1007/s11665-022-07030-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07030-w