Abstract

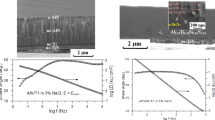

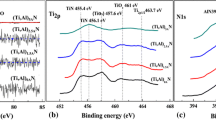

Incorporation of silver particles in nitride coatings has been used to improve the mechanical resistance of steels, but few details are known about the effect of the incorporation of these metals on the electrochemical behavior. In order to evaluate the corrosion resistance and the possible formation of a galvanic couple between the ceramic matrix of TiAlN and the metallic Ag, a TiAlN composite coating doped with four different contents of silver (0.8-25 at.%) was deposited on AISI H11 hot working steel, using the hybrid DCMS/HiPIMS magnetron sputtering technique. The microstructure, topography, elemental chemical, and phase composition of the coatings were determined using SEM/EDS, AFM, XRD, and XPS characterization techniques. The electrochemical behavior was evaluated by electrochemical impedance spectroscopy (EIS) and potentiodynamic polarization. The TiAlN matrix and TiAlN(Ag)-coated samples exhibit higher impedance modulus values than steel substrate, indicating better anticorrosion performance. The anodic current density of the Ag-doped coating increases with the Ag content, suggesting enhanced silver release to the surrounding electrolyte. The TiAlN coating doped with 0.8 at.% silver exhibited the highest corrosion resistance at long immersion times. Finally, it must be noted that all the coatings exhibited corrosion protection to the AISI H11 steel substrate.

Similar content being viewed by others

References

S.D. Jacobsen, R. Hinrichs, I.J.R. Baumvol, G. Castellano and M.A.Z. Vasconcellos, Depth Distribution of Martensite in Plasma Nitrided AISI H13 Steel and its Correlation to Hardness, Surf. Coat. Technol., 2015, 270, p 266–271. https://doi.org/10.1016/j.surfcoat.2015.02.046

G.B. Gaitan, M.G. Botero and M.A. Franco, Deposition and Characterization of Duplex Treated Coating System Applied on Hot Work Steel AISI H13, Rev. Latinoam. Metal. y Mater., 2012, 32, p 218–224.

R.A. Mesquita, M. Kubin and R. Schneider, Tool steels: Properties and performance, CRC Press Taylor & Francis Group, New York, 2017.

Y. Kayali, The Corrosion and Wear Behavior of TiN and TiAlN Coated AISI 316 L Stainless Steel, Physicochem. Probl. Mater. Prot., 2014, 50, p 412–419. https://doi.org/10.1134/S207020511403006X

V.M.C.A. De Oliveira, C. Aguiar, A.M. Vazquez, A.L.M. Robin and M.J.R. Barboza, Corrosion Behavior Analysis of Plasma-Assisted PVD Coated Ti-6Al-4V Alloy in 2 M NaOH Solution, Mater. Res., 2017, 20, p 436–444. https://doi.org/10.1590/1980-5373-MR-2015-0737

V.F.C. Sousa, F.J.G. Da Silva, G.F. Pinto, A. Baptista and R. Alexandre, Characteristics and Wear Mechanisms Of Tialn-Based Coatings for Machining Applications: A Comprehensive Review, Metals (Basel)., 2021, 11, p 1–49. https://doi.org/10.3390/met11020260

D.M. Mattox, Handbook of physical vapor deposition ( PVD ) Processing, Film Formation, Adhesion, Surface, Preparation and contamination control, Noyes Publications, U.S.A, New Jersey, 1998.

K. Sarakinos, J. Alami and S. Konstantinidis, High Power Pulsed Magnetron Sputtering: A Review on Scientific and Engineering State of the Art, Surf. Coat. Technol., 2010, 204, p 1661–1684. https://doi.org/10.1016/j.surfcoat.2009.11.013

B. Gui, H. Zhou, J. Zheng, X. Liu, X. Feng and Y. Zhang, Microstructure and Properties of TiAlCrN Ceramic Coatings Deposited by Hybrid HiPIMS/DC Magnetron Co-Sputtering, Ceram. Int., 2021. https://doi.org/10.1016/j.ceramint.2020.11.175

W. Tillmann, D. Grisales, D. Stangier, I. Ben Jebara, H. Hang, Influence of the Etching Processes on the Adhesion of TiAlN coatings Deposited by DCMS, HiPIMS and Hybrid Techniques on Heat Treated AISI H11. Surf. Coat. Technol., 2019, 378, p 125075

I. Ebrahimzadeh and F. Ashrafizadeh, The Influence of Temperature on the Frictional Behavior of Duplex-Coated Die Steel Rubbing Against Forging Brass, J. Mater. Eng. Perform., 2014 https://doi.org/10.1007/s11665-014-1301-4

K.V. Chauhan and S.K. Rawal, A Review Paper on Tribological and Mechanical Properties of Ternary Nitride Based Coatings, Procedia Technol., 2014, 14, p 430–437. https://doi.org/10.1016/j.protcy.2014.08.055

J.M. Paiva, G. Fox-rabinovich, E.L. Junior, P. Stolf, Y. Seid, A. Id, M.M. Martins, C. Bork and S. Veldhuis, Tribological and Wear Performance of Nanocomposite PVD Hard Coatings Deposited on Aluminum Die Casting Tool, Materials (Basel)., 2018 https://doi.org/10.3390/ma11030358

D. Zheng, S. Zhu and F. Wang, The Influence of TiAIN and enamel Coatings on the Corrosion Behavior of Ti6Al4V Alloy in the Presence of Solid NaCl Deposit and Water Vapor at 450 °C, Surf. Coat. Technol., 2007, 201, p 5889–5864.

M. Zhang, L. Xin, X. Ding, S. Zhu and F. Wang, Effects Ti/TiAlN Composite Multilayer Coatings on Corrosion Resistance of Titanium Alloy in Solid NaCl-H2O-O2 at 600 °C, J. Alloys Compd., 2018, 734, p 307–317. https://doi.org/10.1016/J.JALLCOM.2017.11.035

Q. Cai, S. Li, J. Pu, X. Bai, H. Wang, Z. Cai and X. Wang, Corrosion Resistance and Antifouling Activities of Silver-Doped CrN Coatings Deposited by Magnetron Sputtering, Surf. Coat. Technol., 2018, 354, p 194–202. https://doi.org/10.1016/j.surfcoat.2018.09.006

A.M. Echavarría, J.A. Calderón and G. Gilberto Bejarano, Characterization of the Structure and Electrochemical Behavior of Ag-TaN Nanostructured Composite Coating for Biomedical Applications, Surf Coat. Technol., 2018 https://doi.org/10.1016/j.surfcoat.2018.04.012

X. Liu, J. Kavanagh, A. Matthews and A. Leyland, The Combined Effects of Cu and Ag on the Nanostructure and Mechanical Properties of CrCuAgN PVD Coatings, Surf. Coat. Technol., 2015, 284, p 101–111. https://doi.org/10.1016/J.SURFCOAT.2015.08.070

L. Incerti, A. Rota, S. Valeri, A. Miguel, J.A. García, R.J. Rodríguez and J. Osés, Nanostructured Self-Lubricating CrN-Ag Films Deposited by PVD arc Discharge and Magnetron Sputtering, Vaccum., 2011, 85, p 1108–1113. https://doi.org/10.1016/j.vacuum.2011.01.022

A.M. Echavarría, S. Robledo and G. Gilberto Bejarano, Influence of Ag Nanoparticles on the Mechanical and Tribological Properties and on the Cytotoxic and Bactericidal Effects of TaN(Ag) Coatings, Rev. Metal., 2017 https://doi.org/10.3989/revmetalm.085

A.M. Echavarría and G. Bejarano G., J.M. Meza, Mechanical and Tribological Features of TaN(Ag-Cu) Duplex Nanocomposite Coatings: Their Response to Heat Treatment, Ingeniare, 2017 https://doi.org/10.4067/S0718-33052017000400662

C. Dang, J. Li, Y. Wang, Y. Yang, Y. Wang and J. Chen, Influence of Ag Contents on Structure and Tribological Properties of TiSiN-Ag Nanocomposite Coatings on Ti–6Al–4V, Appl. Surf. Sci., 2017, 394, p 613–624. https://doi.org/10.1016/j.apsusc.2016.10.126

H. Ju, L. Yu, D. Yu, I. Asempah and J. Xu, Microstructure, Mechanical and Tribological Properties of TiN-Ag Films Deposited by Reactive Magnetron Sputtering, Vacuum, 2017, 141, p 82–88. https://doi.org/10.1016/j.vacuum.2017.03.026

L. Yu, H. Zhao and J. Xu, Influence of Silver Content on Structure, Mechanical and Tribological Properties of WCN–Ag Films, Mater. Charact., 2016, 114, p 136–145. https://doi.org/10.1016/j.matchar.2016.02.013

H.D. Mejía, A.M. Echavarría and G. Bejarano G., Influence of Ag-Cu Nanoparticles on the Microstructural and Bactericidal Properties of TiAlN(Ag, Cu) Coatings for Medical Applications Deposited by Direct Current (DC) Magnetron Sputtering, Thin Solid Films, 2019, 687, p 137460. https://doi.org/10.1016/j.tsf.2019.137460

H.D. Mejía V, D. Perea, G. Bejarano G, Development and Characterization of TiAlN(Ag,Cu) Nanocomposite Coatings Deposited by DC Magnetron Sputtering for Tribological Applications. Surf. Coat. Technol. 2020, 381, p 125095

F. Karabudak, R. Yeşildal, E.E. Şüküroğlu, S. Şüküroğlu, H. Zamanlou, N. Dikbaş, F. Bayındır, S. Şen and Y. Totik, An Investigation of Corrosion Resistance and Antibacterial Sensitivity Properties of Nano-Ag-Doped TiO2 Coating and TiO2 Coating Grown on NiTi Alloy with the Micro-Arc Oxidation Process, Arab. J. Sci. Eng., 2017, 42, p 2329–2339. https://doi.org/10.1007/s13369-017-2463-9

E.E. Sukuroglu, Investigation of Antibacterial Susceptibility of Ag-Doped Oxide Coatings onto AZ91 Magnesium Alloy by Microarc Oxidation Method, Adv. Mater. Sci. Eng., 2018, 2018, p 6871241. https://doi.org/10.1155/2018/6871241

G. Greczynski, L. Hultman and M. Odén, X-ray Photoelectron Spectroscopy Studies of Ti1-xAlxN (0 ≤ x ≤ 0.83) High-Temperature Oxidation: The Crucial Role of Al Concentration, Surf. Coat. Technol., 2019, 374, p 923–934. https://doi.org/10.1016/j.surfcoat.2019.06.081

G. Greczynski, J. Jensen, J.E. Greene, I. Petrov and L. Hultman, X-ray Photoelectron Spectroscopy Analyses of the Electronic Structure of Polycrystalline Ti 1–x Al x N Thin Films with 0 ≤ x ≤ 0.96, Surf. Sci. Spectra., 2014, 21, p 35–49. https://doi.org/10.1116/11.20140506

G. Greczynski, J. Lu, M. Johansson, J. Jensen, I. Petrov, J.E. Greene and L. Hultman, Selection of Metal Ion Irradiation for Controlling Ti 1-xAl xN Alloy Growth Via Hybrid HIPIMS/Magnetron Co-Sputtering, Vacuum, 2012, 86, p 1036–1040. https://doi.org/10.1016/j.vacuum.2011.10.027

G. Greczynski, J. Lu, J. Jensen, S. Bolz, W. Kölker, C. Schiffers, O. Lemmer, J.E. Greene and L. Hultman, A Review of Metal-Ion-Flux-Controlled Growth of Metastable TiAlN by HIPIMS/DCMS co-Sputtering, Surf. Coat. Technol., 2014, 257, p 15–25. https://doi.org/10.1016/j.surfcoat.2014.01.055

H. Chandler, V. Flint, R.L. Boring, C. Powers, Heat Treater’s Guide Practices and Procedures for Irons and Steels, ASM Int. (1995)

W. Tillmann, D. Grisales and D. Stangier, Effects of AISI H11 Surface Integrity on the Residual Stresses and Adhesion of TiAlN/Substrate Compounds, Surf. Coat. Technol., 2019, 357, p 466–472. https://doi.org/10.1016/j.surfcoat.2018.10.032

M. Al Bukhaiti, K. Al-hatab, W. Tillmann, F. Hoffmann and T. Sprute, Tribological and Mechanical Properties ofTi/TiAIN/TiAICN Nanoscale Multilayer PVD Coatings Deposited on AISI Hl 1 Hot Work Tool Steel, Appl. Surf. Sci., 2014, 318, p 180–190.

C. Rebholz, H. Ziegele, A. Leyland and A. Matthews, Structure, Mechanical and Tribological Properties of Nitrogen-Containing Chromium Coatings Prepared by Reactive Magnetron Sputtering, Surf. Coat. Technol., 1999, 115, p 222–229. https://doi.org/10.1016/S0257-8972(99)00240-6

G.S. Kim, S.Y. Lee, J.H. Hahn, B.Y. Lee, J.G. Han, J.H. Lee and S.Y. Lee, Effects of the Thickness of Ti Buffer Layer on the Mechanical Properties of TiN Coatings, Surf. Coat. Technol., 2003, 171, p 83–90. https://doi.org/10.1016/S0257-8972(03)00243-3

C. Huang, Deposition of (Ti, Al) N Films on A2 Tool Steel by Reactive r.f. Magnetron Sputtering, Surf. Coat. Technol., 1995, 71, p 259–266.

E. Uhlmann, B. Stawiszynski, C. Leyens, S. Heinze and F. Sammler, Hard Turning of Hot Work and Cold Work Steels with HiPIMS and DCMS TiAlN Coated Carbide Inserts, CIRP Conf. High Perform. Cut., 2016, 46, p 591–594. https://doi.org/10.1016/j.procir.2016.03.231

W. Tillmann, D. Grisales, D. Stangier, I. Ben Jebara and H. Kang, Influence of the Etching Processes on the Adhesion of TiAlN Coatings Deposited by DCMS, HiPIMS and Hybrid Techniques on Heat Treated AISI H11, Surf. Coat. Technol., 2019, 378, p 1–15.

H.D. Mejía V, D. Perea and G. Gilberto Bejarano, Development and Characterization of TiAlN(Ag, Cu) Nanocomposite Coatings Deposited by DC Magnetron Sputtering for Tribological Applications. Surf. Coat. Technol., 2020, 381, p 125095. https://doi.org/10.1016/j.surfcoat.2019.125095.

P.A. Papi, C.P. Mulligan and D. Gall, CrN–Ag Nanocomposite Coatings: Control of Lubricant Transport by Diffusion Barriers, Thin Solid Films, 2012, 524, p 211–217. https://doi.org/10.1016/j.tsf.2012.10.010

S. Calderon Velasco, A. Cavaleiro and S. Carvalho, Functional Properties of Ceramic-Ag Nanocomposite Coatings Produced by Magnetron Sputtering, Prog. Mater. Sci., 2016 https://doi.org/10.1016/j.pmatsci.2016.09.005

Y.N. Kok and P.E. Hovsepian, Resistance of Nanoscale Multilayer C/Cr Coatings Against Environmental Attack, Surf. Coat. Technol., 2006, 201, p 3596–3605. https://doi.org/10.1016/j.surfcoat.2006.08.109

Y. Xin, C. Liu, K. Huo, G. Tang, X. Tian and P.K. Chu, Corrosion Behavior of ZrN/Zr Coated Biomedical AZ91 Magnesium Alloy, Surf. Coat. Technol., 2009, 203, p 2554–2557. https://doi.org/10.1016/j.surfcoat.2009.02.074

S.H. Ahn, J.H. Yoo, J.G. Kim and J.G. Han, On the Corrosion Behavior of Multilayered WC-Ti1-xAlxN Coatings on AISI D2 Steel. Surf. Coat. Technol. 163–64 (n.d.) 611–619. http://cat.inist.fr/?aModele=afficheN&cpsidt=14464939 (accessed June 29, 2016)

D.A. Delisle and J.E. Krzanowski, Surface Morphology and Texture of TiAlN/CrN Multilayer Coatings, Thin Solid Films, 2012, 524, p 100–106. https://doi.org/10.1016/J.TSF.2012.09.073

C.P. Mulligan and D. Gall, CrN–Ag Self-Lubricating Hard Coatings, Surf. Coat. Technol., 2005, 200, p 1495–1500. https://doi.org/10.1016/j.surfcoat.2005.08.063

T. de los Arcos, P. Oelhafen, U. Aebi, A. Hefti, M. Düggelin, D. Mathys, R. Guggenheim, Preparation and Characterization of TiN–Ag Nanocomposite Films, Vacuum, 2002, 67, p 463–470. https://doi.org/10.1016/S0042-207X(02)00232-4

S. Kumar, S.R. Maity and L. Patnaik, Friction and Tribological Behavior of Bare Nitrided, TiAlN and AlCrN Coated MDC-K Hot Work Tool Steel, Ceram. Int., 2020, 46, p 17280–17294. https://doi.org/10.1016/j.ceramint.2020.04.015

O. Comakli, Improved Structural, Mechanical, Corrosion and Tribocorrosion Properties of Ti45Nb Alloys by TiN, TiAlN Monolayers, and TiAlN/TiN Multilayer Ceramics Films, Ceram. Int., 2021, 47, p 4149–4156.

P. Zeman, Structure and Properties of Hard and Superhard Zr – Cu – N Nanocomposite Coatings, Mater. Sci. Eng. A., 2000, 289, p 189–197. https://doi.org/10.1016/S0921-5093(00)00917-5

D. Gall, S. Kodambaka, M.A. Wall, I. Petrov and J.E. Greene, Pathways of Atomistic Processes on TiN(001) and (111) Surfaces During Film Growth: An ab Initio Study, J. Appl. Phys., 2003, 93, p 9086–9094. https://doi.org/10.1063/1.1567797

A. Obrosov, R. Gulyaev, M. Ratzke, A. Volinsky, S. Bolz, M. Naveed and S. Weiß, XPS and AFM Investigations of Ti-Al-N Coatings Fabricated Using DC Magnetron Sputtering at Various Nitrogen Flow Rates and Deposition Temperatures, Metals (Basel)., 2017, 7, p 52. https://doi.org/10.3390/met7020052

R. Ananthakumar, B. Subramanian, A. Kobayashi and M. Jayachandran, Electrochemical Corrosion and Materials Properties of Reactively Sputtered TiN/TiAlN Multilayer Coatings, Ceram. Int., 2012, 38, p 477–485. https://doi.org/10.1016/j.ceramint.2011.07.030

C.F. Almeida Alves, F. Oliveira, I. Carvalho, A.P. Piedade and S. Carvalho, Influence of Albumin on the Tribological Behavior of Ag – Ti (C, N) Thin Films for Orthopedic Implants, Mater. Sci. Eng. C. Mater. Biol. Appl., 2014, 34, p 22–28. https://doi.org/10.1016/j.msec.2013.09.031

H.D. Mejía, A.M. Echavarría, J.A. Calderón and G. Gilberto Bejarano, Microstructural and Electrochemical Properties of TiAlN(Ag, Cu) Nanocomposite Coatings for Medical Applications Deposited by dc Magnetron Sputtering, J. Alloys Compd., 2020, 828, p 154396. https://doi.org/10.1016/J.JALLCOM.2020.154396

L. Cunha, M. Andritschky, L. Rebouta and K. Pischow, Corrosion of CrN and TiAlN Coatings in Chloride-Containing Atmospheres, Surf. Coat. Technol., 1999, 116–119, p 1152–1160. https://doi.org/10.1016/S0257-8972(99)00270-4

A. Amirudin and D. Thieny, Application of Electrochemical Impedance Spectroscopy to Study the Degradation of Polymer-Coated Metals, Prog. Org. Coat., 1995, 26, p 1–28.

D. Quintero, O. Galvis, J.A. Calderón, J.G. Castaño and F. Echeverría, Effect of Electrochemical Parameters on the Formation of Anodic Films on Commercially Pure Titanium by Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2014, 258, p 1223–1231. https://doi.org/10.1016/j.surfcoat.2014.06.058

I.C.P. Margarit-Mattos, EIS and Organic Coatings Performance: Revisiting Some Key Points, Electrochim. Acta. 2020, 354, p 136725

S.N. Akao, M.N. Umata, T.O. Hmi, Thin and Low-Resistivity Tantalum Nitride Diffusion Barrier and Giant-Grain Copper Interconnects for Advanced ULSI Metallization, Jpn. J.Appl. Phys., 1999, 2401 p 4–9

A. Mazare, A. Anghel, C. Surdu-Bob, G. Totea, I. Demetrescu and D. Ionita, Silver Doped Diamond-Like Carbon Antibacterial and Corrosion Resistance Coatings on Titanium, Thin Solid Films, 2018, 657, p 16–23. https://doi.org/10.1016/j.tsf.2018.04.036

T. Yetim, Corrosion Behavior of Ag-doped TiO2 Coatings on Commercially Pure Titanium in Simulated Body Fluid Solution, J. Bionic Eng., 2016, 13, p 397–405. https://doi.org/10.1016/S1672-6529(16)60311-6

T. Wang and Z. J, L. Yan, F. Gao and G. Zhang, Self-Lubricating TiN/MoN and TiAlN/MoN Nano-Multilayer Coatings for Drilling of Austenitic Stainless Steel, Ceram. Int., 2019, 45, p 24248–24253. https://doi.org/10.1016/j.cerarnint.2019.08.136

Acknowledgments

The authors are grateful to Departamento Administrativo de Ciencia, Tecnología e Innovación COLCIENCIAS for the financial support of this work (Contrat.768-2017). The authors also acknowledge the German Research Foundation (DFG) for supporting the development of the TiAlN hybrid coatings within the project Ti 343/34-2 and the German Academic Exchange Service (DAAD) in the scope of the project PPP-PROCOL 57394123.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tillmann, W., Grisales, D., Echavarría, A.M. et al. Effect of Ag Doping on the Microstructure and Electrochemical Response of TiAlN Coatings Deposited by DCMS/HiPIMS Magnetron Sputtering. J. of Materi Eng and Perform 31, 3811–3825 (2022). https://doi.org/10.1007/s11665-021-06467-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06467-9