Abstract

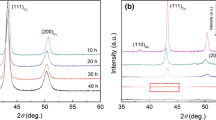

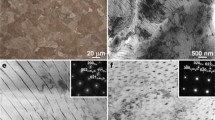

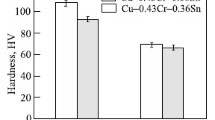

Although nanostructure offers several advantages in improving the performance for Cu alloys prepared by mechanical alloying, the excellent properties have not been obtained to date primarily due to a single strengthening method or the Fe contamination introduced by the stainless steel grinding tank and balls. Herein, we added Cr to regulate the milling process and control the content of Fe doped into the Cu matrix. And the effects of Cr on the morphology, crystallite size, lattice strain and properties of Cu were studied. The results showed that adding an appropriate amount of Cr could prevent more Fe from being doped into the alloy matrix. When the Cr content was lower than 0.2 wt.%, the work hardening could be accelerated, so that the Cu alloys had smaller crystallite size, greater internal strain and higher tensile strength. But with continuous increase in Cr content, the crystallite sizes of the alloys began to increase again. Nevertheless, the nanostructured Cu alloys with particle size less than 10 nm were still obtained. In conclusion, by appropriately adjusting the Cr content, we demonstrated an improvement in the properties of the Cu alloys. The optimum properties were achieved by Cu-0.2 wt.% Cr with tensile strength of 517 MPa, ductility of 7.28% and electrical conductivity of 73.37% IACS. And the study provided a new idea for overcoming the Fe contamination in the metal matrix, and further improving high-performance Cu alloys through the combination of fine-grain strengthening and alloy strengthening.

Similar content being viewed by others

References

L. Chai, Z. Zhou, Z. Xiao, J. Tu, Y. Wang, and W. Huang, Evolution of Surface Microstructure of Cu-50Cr Alloy Treated by High Current Pulsed Electron Beam, Sci. China Technol. Sci., 2015, 58(3), p 462–469.

J.R. Davis, Copper and Copper Alloys, Corr. Metal/Environ. React., 2001, 3(2), p 527–602.

W. Wang, J. Zhu, N. Qin, Y. Zhang, S. Li, Z. Xiao, Q. Lei, and Z. Li, Effects of Minor Rare Earths on the Microstructure and Properties of Cu-Cr-Zr Alloy, J. Alloys Compd., 2020, 847, 155762.

M.T. Dehaqani and G.H. Akbari, Effect of Milling Parameters and Cr Content on Morphology and Solubility of Nanostructured Cu–Cr Solid Solutions, Trans. Indian Inst. Met., 2014, 67(3), p 385–391.

X. Liu, L. Zhuang, and Y. Zhao, Microstructure and Mechanical Properties of Ultrafine-Grained Copper by Accumulative Roll Bonding and Subsequent Annealing, Mater. Basel, Switzerland, 2020, 13(22), p 5171. (in eng)

W. Zeng, J. Xie, D. Zhou, Z. Fu, D. Zhang, and E.J. Lavernia, Bulk Cu-NbC Nanocomposites with High Strength and High Electrical Conductivity, J. Alloys Compd., 2018, 745, p 55–62.

A.S. Prosviryakov, SiC Content Effect on the Properties of Cu–SiC Composites Produced by Mechanical Alloying, J. Alloys Compd., 2015, 632, p 707–710.

J. Li, J. Ni, B. Huang, J. Chen, Z. Xu, S. Liao, C. Wang, and W. Luo, Long-Term Ball Milling and Hot Pressing of in-situ Nanoscale Tungsten Carbides Reinforced Copper Composite and Its Characterization, Mater. Charact., 2019, 152, p 134–140.

L. Peng, H. Xie, G. Huang, Y. Li, X. Yin, X. Feng, X. Mi, and Z. Yang, The Phase Transformation and Its Effects on Properties of a Cu−0.12 wt.% Zr alloy, Mater. Sci. Eng. A, 2015, 633, p 28–34.

G.H. Akbari and M. Taghian Dehaqani, Nanostructure Cu–Cr Alloy with High Dissolved Cr Contents Obtained by Mechanical Alloying Process, Powder Metal., 2011, 54(1), p 19–23.

D. Roy, M.A. Atwater, K. Youssef, J.C. Ledford, R.O. Scattergood, and C.C. Koch, Studies on Thermal Stability, Mechanical and Electrical Properties of Nano Crystalline Cu99.5Zr05 Alloy, J Alloys Compd, 2013, 558, p 44–49.

J. Schiøtz and K.W. Jacobsen, A Maximum in the Strength of Nanocrystalline Copper, Science, 2003, 301(5638), p 1357–1359.

C.J. Shen, Z.W. Zhu, and D. Zhu, A Bulk of Uniform Nanocrystalline Copper with Superior Comprehensive Mechanical Properties Electroformed in an Ultra-low Sulfate Concentration Bath without Additives, Mater. Scie. Eng. A, 704(Supplement C), 238-245 (2017)

A. Habibi, M. Ketabchi, and M. Eskandarzadeh, Nano-grained Pure Copper with High-Strength and High-Conductivity Produced by Equal Channel Angular Rolling Process, J. Mater Process Technol., 2011, 211(6), p 1085–1090.

L. Lu, Y. Shen, X. Chen, L. Qian, and K. Lu, Ultrahigh Strength and High Electrical Conductivity in Copper, 304(5669), 422-426 (2004)

R.M. Babaheydari, S.O. Mirabootalebi, and G.H. Akbari, Investigation on Mechanical and Electrical Properties of Cu-Ti Nanocomposite Produced by Mechanical Alloying, Int. J. Eng. 33(9), 1759-1765 (2020) (in en)

R. Mirahmadi Babaheydari, S.O. Mirabootalebi, and G.H. Akbari Fakhrabadi, Effect of Alloying Elements on Hardness and Electrical Conductivity of CU Nanocomposites Prepared by Mechanical Alloying, IUST, 18(1), 1–11 (2021)

L.N. Rajeshkumar and K.S. Amirthagadeswaran, Variations in the Properties of Copper-Alumina Nanocomposites Synthesized by Mechanical Alloying, Mater. Technol., 2019, 53(1), p 57–63.

P.K. Prajapati and D. Chaira, Fabrication and Characterization of Cu–B4C Metal Matrix Composite by Powder Metallurgy: Effect of B4C on Microstructure, Mechanical Properties and Electrical Conductivity, Trans. Indian Inst. Metals, 2019, 72(3), p 673–684.

D.A. Aksenov, R.N. Asfandiyarov, G.I. Raab, E.I. Fakhretdinova, and M.A. Shishkunova, Influence of the Chromium Content in Low-Alloyed Cu-Cr Alloys on the Structural Changes, Phase Trans. Proper. Equal-Channel Ang. Pressing, Metals, 11(11), 14, 1795, (2021) (in English)

K. Rodak, Cu-Cr and Cu-Fe Alloys Processed by New Severe Plastic Deformation: Microstructure and Properties, ed., 2017

C. Gao, M. Yao, C. Shuai, S. Peng, and Y. Deng, Nano-SiC Reinforced Zn Biocomposites Prepared via Laser Melting: Microstructure, Mechanical Properties and Biodegradability, J. Mater. Sci. Technol., 2019, 35(11), p 2608–2617.

A. Fathy, A. Wagih, and A. Abu-Oqail, Effect of ZrO2 Content on Properties of Cu-ZrO2 Nanocomposites Synthesized by Optimized High Energy Ball Milling, Ceram Int, 45, (2018)

C. Suryanarayana, Mechanical Alloying and Milling, Prog. Mater. Sci., 2001, 46(1), p 1–184.

D. Maurice and T.H. Courtney, Modeling of Mechanical Alloying: Part II. Development of Computational Modeling Programs, Metal. Mater. Trans. A, 1995, 26(9), p 2431–2435.

A. Kumar, K. Jayasankar, M. Debata, and A. Mandal, Mechanical Alloying and Properties of Immiscible Cu-20 wt.% Mo Alloy. J. Alloys Comp., 647, 1040-1047 (2015)

J. Zhou, D. Zhu, L. Tang, X. Jiang, S. Chen, X. Peng, and C. Hu, Microstructure and Properties of Powder Metallurgy Cu-1%Cr-0.65%Zr Alloy Prepared by Hot Pressing, Vacuum, 131, 156-163 (2016)

K.R. Ramkumar, S. Sivasankaran, and A.S. Alaboodi, Effect of Alumina Content on Microstructures, Mechanical, Wear and Machining Behavior of Cu-10Zn Nanocomposite Prepared by Mechanical Alloying and Hot-Pressing, J. Alloy. Compd., 2017, 709, p 129–141.

A. Torabi, R.M. Babaheydari, G.H. Akbari, and S.O. Mirabootalebi, Optimizing of Micro-hardness of Nanostructured Cu–Cr Solid Solution Produced by Mechanical Alloying Using ANN and Genetic algorithm, SN Appl. Sci., 2020, 2(11), p 1919.

A. Khajesarvi and G.H. Akbari, Synthesis and Structural Characterization of Nanocrystalline Ni50Al50—xMoxintermetallic Compound Prepared by Mechanical Alloying, Russian J. Non-Ferrous Metals, 2017, 58(4), p 411–417.

J. Arasteh and G.H. Akbari, Microstructural Evolution During High-energy Mechanical Alloying of Immiscible Zr–Cr Alloy, J. Mater. Res., 2020, 35(14), p 1825–1836.

C.F. Sun, Y.C. Guo, Z. Yang, J.P. Li, S.Q. Xi, Z.Q. Jie, and T. Xu, Microstructurally Stable Nanocomposite WTaMoNb/Cu Prepared by Mechanical Alloying and Hot Pressing Sintering, Mater Lett. 306, 4, 130894, (2022) (in English)

M. Azimi and G.H. Akbari, Development of Nano-structure Cu–Zr Alloys by the Mechanical Alloying Process, J. Alloys Compd., 2011, 509(1), p 27–32.

V. Nguyen-Hoang and N.T.H. Oanh, Microstructure and Electrical Property of Ex-Situ and In-Situ Copper Titanium Carbide Nanocomposites, Metals, 2020, 10, p 735.

J. Zhuang, Y. Liu, Z. Cao, and Y. Li, The Influence of Technological Process on Dry Sliding Wear Behaviour of Titanium Carbide Reinforcement Copper Matrix Composites, Mater. Trans., 2010, 51, p 2311–2317.

J. Zou, D.-P. Lu, Q.-F. Fu, K.-M. Liu, and J. Jiang, Microstructure and Properties of Cu–Fe Deformation Processed in-situ Composite, Vacuum, 2019, 167, p 54–58.

G. Shi, X. Chen, H. Jiang, Z. Wang, H. Tang, and Y. Fan, Strengthening Mechanisms of Fe Nanoparticles for Single Crystal Cu–Fe Alloy, Mater. Sci. Eng., A, 2015, 636, p 43–47.

H. Gao, J. Wang, D. Shu, and B. Sun, Microstructure and Properties of Cu–11Fe–6Ag in situ Composite after Thermo-mechanical Treatments, J. Alloy. Compd., 2007, 438(1), p 268–273.

P. Qi, X. Liang, Y. Tong, Y. Chen, and Z.J.R.M.M. Zhang, Engineering, Effect of Milling Time on Preparation of NbMoTaW High Entropy Alloy Powder by Mechanical Alloying, Rare Metal Mater. Eng., (2019)

P.J.M.S. Xiao, E.o.P. Metallargy, Influence of Milling Rate and Process control Agents on Mechanically Alloying of Ti-26% Cr, Rare Metal Mater. Eng. (2002)

F. Wang, Y. Li, K. Wakoh, Y. Koizumi, and A. Chiba, Cu–Ti–C Alloy with High Strength and High Electrical Conductivity Prepared by Two-Step Ball-Milling Processes, Mater. Des., 2014, 61, p 70–74.

Q.-Y. Dong, L.-N. Shen, M.-P. Wang, Y.-L. Jia, Z. Li, F. Cao, and C. Chen, Microstructure and Properties of Cu–23Fe–003P Alloy During Thermomechanical Treatments, Trans. Nonferrous Metals Soc. China, 2015, 25(5), p 1551–1558.

Q. Dong, L. Shen, F. Cao, Y. Jia, K. Liao, and M. Wang, Effect of Thermomechanical Processing on the Microstructure and Properties of a Cu-Fe-P Alloy, J. Mater. Eng. Perform., 2015, 24(4), p 1531–1539.

S. Papaefthymiou, M. Bouzouni, and E. Gavalas, Theoretical Study of Particle Dissolution during Homogenization in Cu–Fe–P Alloy, 8(6), 455 (2018)

H. Cao, J.Y. Min, S.D. Wu, A.P. Xian, and J.K. Shang, Pinning of Grain Boundaries by Second Phase Particles in Equal-Channel Angularly Pressed Cu–Fe–P alloy, Mater. Sci. Eng. A, 2006, 431(1), p 86–91.

L. Han, J. Liu, H. Tang, X. Ma, and W. Zhao, Preparation and Properties of Ultra-Fine-Grained and Nanostructured Copper Alloy with the Addition of P, Mater. Chem. Phys., 2019, 221, p 322–331.

R.E. Smallman and R.J. Bishop, Preface, Modern Physical Metallurgy and Materials Engineering (Sixth Edition)ed., R.E. Smallman, R.J. Bishop, Eds., Butterworth-Heinemann, 1999, p x

Q. Fang, Z. Kang, Y. Gan, and Y. Long, Microstructures and Mechanical Properties of Spark Plasma Sintered Cu–Cr Composites Prepared by Mechanical Milling and Alloying, Mater. Des., 2015, 88, p 8–15.

I. Lahiri and S. Bhargava, Compaction and Sintering Response of Mechanically Alloyed Cu–Cr Powder, Powder Technol., 2009, 189(3), p 433–438.

S. Cui and I.-H. Jung, Thermodynamic Modeling of the Cu-Fe-Cr and Cu-Fe-Mn Systems, Calphad, 2017, 56, p 241–259.

Q. Fang and Z. Kang, An Investigation on Morphology and Structure of Cu–Cr Alloy Powders Prepared by Mechanical Milling and Alloying, Powder Technol., 2015, 270, p 104–111.

L. Shan, X. Wang, and Y. Wang, Extension of Solid Solubility and Structural Evolution in Nano-Structured Cu-Cr Solid Solution Induced by High-Energy Milling, 13(23), 5532 (2020).

H. Fernee, J. Nairn, and A. Atrens, Precipitation Hardening of Cu-Fe-Cr Alloys Part I Mechanical and Electrical Properties, J. Mater. Sci., 2001, 36(11), p 2711–2719.

G.H. Akbari and M.T. Dehaqani, Behavior of CU-CR Powder Mixtures during Mechanical Alloying, Int. J. Eng. Trans. B, 2010, 23, p 69–76.

F.L. Zhang, C.Y. Wang, and M. Zhu, Nanostructured WC/Co Composite Powder Prepared by High Energy Ball Milling, Scripta Mater., 2003, 49(11), p 1123–1128.

J. Eckert, J.C. Holzer, C.E. Krill, and W.L. Johnson, Structural and Thermodynamic Properties of nanocrystalline fcc metals Prepared by Mechanical Attrition, J. Mater. Res., 1992, 7(7), p 1751–1761.

S. Patra, Gouthama, and K. Mondal, Densification Behavior of Mechanically Milled Cu–8at% Cr Alloy and Its Mechanical and Electrical Properties, Progress Nat. Sci. Mater. Int. 24(6), 608–622 (2014)

S. Safi and G.H. Akbari, Evaluation of Synthesizing Nano Particles in Copper Matrix by Mechanical Alloying of Cu-1% Al and Copper Oxide %J, J. Adv. Mater. Eng., 2017, 36(1), p 71–85.

I. Börner and J. Eckert, Structural Properties and Compositional Dependence of Grain Size in Heavily Mechanically Deformed Nanophase NiAl, Mater. Sci. Forum, 1996, 225–227, p 377–382.

C. Aguilar, V.D.P. Martinez, J.M. Palacios, S. Ordoñez, and O. Pavez, A thermodynamic approach to energy storage on mechanical alloying of the Cu–Cr system, Scripta Mater., 2007, 57(3), p 213–216.

Y. Jin, K. Adachi, T. Takeuchi, and H.G. Suzuki, Correlation Between the Electrical Conductivity and Aging Treatment for a Cu-15 wt.% Cr Alloy Composite Formed in-situ, Mater. Lett., 1997, 32(5), p 307–311.

L. Lu, M.O. Lai, and S. Zhang, Diffusion in Mechanical Alloying, J. Mater Process Technol, 1997, 67(1), p 100–104.

L. Lu, M.O. Lai, and S. Zhang, Evolution and Characterization of a Ni3Al Intermetallic Compound During Mechanical Alloying, Mater. Des., 1994, 15(2), p 79–86.

G. Veltl, B. Scholz, and H.D. Kunze, Amorphization of Cu–Ta Alloys by Mechanical Alloying, Mater. Sci. Eng. A, 1991, 134, p 1410–1413.

A.R. Yavari, P.J. Desré, and T. Benameur, Mechanically Driven Alloying of Immiscible Elements, Phys. Rev. Lett, 1992, 68(14), p 2235–2238.

M. Vaezi, S. Ghassemi, and A. Shokuhfar, The Effect of Impact Energy on the Formation of Nanocrystalline Powders in Cu50% Fe Immiscible Alloy Systems, Mater. Sci.—Poland, 26, (2008)

N. Ravishankar, T.A. Abinandanan, and K. Chattopadhyay, Application of Effective Potential Formalism to Mechanical Alloying in Ag–Cu and Cu–Fe Systems, Mater. Sci. Eng. A, 2001, 304–306, p 413–417.

A. Orecchini, F. Sacchetti, C. Petrillo, P. Postorino, A. Congeduti, C. Giorgetti, F. Baudelet, and G. Mazzone, Magnetic States of Iron in Metastable fcc Fe–Cu Alloys, J. Alloys Compd., 2006, 424(1), p 27–32.

L. Han, J. Liu, H. Tang, X. Ma, and W. Zhao, Investigation on the Properties of Nanostructured Cu Alloy Prepared by Mechanical Milling and Reactive Hot-Pressing, J. Alloys Compd., 2018, 742, p 284–289.

F. Wang, Y. Li, X. Wang, Y. Koizumi, Y. Kenta, and A. Chiba, In-situ Fabrication and Characterization of ultrafine structured Cu–TiC Composites with High Strength and High Conductivity by Mechanical Milling, J. Alloys Compd., 2016, 657, p 122–132.

N. Simos, Z. Kotsina, E. Dooryhee, Z. Zhong, H. Zhong, F. Camino, E. Quaranta, N. Charitonidis, A. Bertarelli, S. Redaelli, L. Snead, and D. Sprouster, 200 MeV Proton Irradiation of the Oxide-Dispersion-Strengthened Copper Alloy (GlidCop-Al15), J. Nucl. Mater., 2019, 516, p 360–372.

M. Ziemnicka-Sylwester, The Cu Matrix Cermets Remarkably Strengthened by TiB2 “in situ” Synthesized via Self-Propagating High Temperature Synthesis, Mater. Des., 2014, 53, p 758–765.

Acknowledgments

This work was supported by the Funds for Creative Research Groups of China (Grant No. 21521092) and the National Natural Science Foundation of China (Grant No. 52071311).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Han, L., Liu, J., Tang, H. et al. Effect of Cr Addition on the Milling Process and Properties of Nanostructured Cu Alloys Prepared by Mechanical Alloying. J. of Materi Eng and Perform 31, 9947–9961 (2022). https://doi.org/10.1007/s11665-022-06991-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06991-2