Abstract

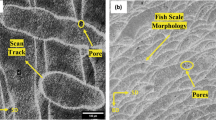

Additive manufacturing (AM) has emerged as an outstanding technique for obtaining complex geometries and custom parts, without the material loss of conventional subtractive manufacturing processes. In this work, AISI 316L stainless steel specimens were fabricated by laser powder bed fusion (L-PBF), and its microstructure was characterized by several techniques. Tensile tests with in situ x-ray diffraction (XRD) measurements were performed using synchrotron radiation. Stress–strain curves and diffractograms were obtained for the as-printed AM 316L, annealed AM 316L and conventional/rolled 316L samples for comparison. The results indicated lower ductility for the AM samples when compared to the sheet. This can be a result of the remaining porosity associated with the AM process. The annealing of the AM samples led to a reduction of the residual stress and an improvement of ductility without significant loss on the ultimate tensile strength. In situ XRD data indicated that AM samples did not undergo phase transformation during straining, maintaining a fully austenitic microstructure and preventing a transformation-induced plasticity (TRIP) effect. On the other hand, in the rolled sample, peaks of α′-martensite were identified. Electron backscattered diffraction (EBSD) measurements indicated that a random texture was achieved by the parameters and scanning strategy used. The results indicate that process parameters must be carefully chosen in order to avoid porosity, and excessive residual stresses, features that directly affect the mechanical behavior of the material.

Similar content being viewed by others

References

D. Herzog, V. Seyda, E. Wycisk and C. Emmelmann, Additive Manufacturing of Metals, Acta Mater., 2016, 117, p 371–392. https://doi.org/10.1016/j.actamat.2016.07.019

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De and W. Zhang, Additive Manufacturing of Metallic Components – Process, Structure and Properties, Prog. Mater. Sci., 2018, 92, p 112–224.

A. Adeyemi, E.T. Akinlabi and R.M. Mahamood, Powder Bed Based Laser Additive Manufacturing Process of Stainless Steel: A Review, Mater. Today Proc., 2018, 5(9), p 18510–18517. https://doi.org/10.1016/j.matpr.2018.06.193

C.Y. Yap, C.K. Chua, Z.L. Dong, Z.H. Liu, D.Q. Zhang, L.E. Loh and S.L. Sing, Review of Selective Laser Melting: Materials and Applications, Appl. Phys. Rev., 2015 https://doi.org/10.1063/1.4935926

Z. Dong, Y. Liu, W. Wen, J. Ge and J. Liang, Effect of Hatch Spacing on Melt Pool and As-Built Quality during Selective Laser Melting of Stainless Steel: Modeling and Experimental Approaches, Materials (Basel), 2018, 12(1), p 50.

J.A. Cherry, H.M. Davies, S. Mehmood, N.P. Lavery, S.G.R. Brown and J. Sienz, Investigation into the Effect of Process Parameters on Microstructural and Physical Properties of 316L Stainless Steel Parts by Selective Laser Melting, Int. J. Adv. Manuf. Technol., 2014, 76(5–8), p 869–879.

K.G. Prashanth, S. Scudino, H.J. Klauss, K.B. Surreddi, L. Löber, Z. Wang, A.K. Chaubey, U. Kühn and J. Eckert, Microstructure and Mechanical Properties of Al-12Si Produced by Selective Laser Melting: Effect of Heat Treatment, Mater. Sci. Eng. A, 2014, 590, p 153–160. https://doi.org/10.1016/j.msea.2013.10.023

H. Zhang, H. Zhu, T. Qi, Z. Hu and X. Zeng, Selective Laser Melting of High Strength Al-Cu-Mg Alloys: Processing, Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2016, 656, p 47–54. https://doi.org/10.1016/j.msea.2015.12.101

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck and J.P. Kruth, A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V, Acta Mater., 2010, 58(9), p 3303–3312. https://doi.org/10.1016/j.actamat.2010.02.004

F. Hengsbach, P. Koppa, K. Duschik, M.J. Holzweissig, M. Burns, J. Nellesen, W. Tillmann, T. Tröster, K.P. Hoyer and M. Schaper, Duplex Stainless Steel Fabricated by Selective Laser Melting - Microstructural and Mechanical Properties, Mater. Des., 2017, 133, p 136–142. https://doi.org/10.1016/j.matdes.2017.07.046

K. Davidson and S. Singamneni, Selective Laser Melting of Duplex Stainless Steel Powders: An Investigation, Mater. Manuf. Process., 2016, 31(12), p 1543–1555.

H. Yu, J. Yang, J. Yin, Z. Wang and X. Zeng, Comparison on Mechanical Anisotropies of Selective Laser Melted Ti-6Al-4V Alloy and 304 Stainless Steel, Mater. Sci. Eng. A, 2017, 695(April), p 92–100. https://doi.org/10.1016/j.msea.2017.04.031

K. Abd-Elghany and D.L. Bourell, Property Evaluation of 304L Stainless Steel Fabricated by Selective Laser Melting, Rapid Prototyp. J., 2012, 18(5), p 420–428.

B. Zhang, L. Dembinski and C. Coddet, The Study of the Laser Parameters and Environment Variables Effect on Mechanical Properties of High Compact Parts Elaborated by Selective Laser Melting 316L Powder, Mater. Sci. Eng. A, 2013, 584, p 21–31. https://doi.org/10.1016/j.msea.2013.06.055

A. Röttger, K. Geenen, M. Windmann, F. Binner and W. Theisen, Comparison of Microstructure and Mechanical Properties of 316 L Austenitic Steel Processed by Selective Laser Melting with Hot-Isostatic Pressed and Cast Material, Mater. Sci. Eng. A, 2016, 678(April), p 365–376. https://doi.org/10.1016/j.msea.2016.10.012

O.O. Salman, C. Gammer, A.K. Chaubey, J. Eckert and S. Scudino, Effect of Heat Treatment on Microstructure and Mechanical Properties of 316L Steel Synthesized by Selective Laser Melting, Mater. Sci. Eng. A, 2018, 2019(748), p 205–212. https://doi.org/10.1016/j.msea.2019.01.110

Y. Zhong, L. Liu, S. Wikman, D. Cui and Z. Shen, Intragranular Cellular Segregation Network Structure Strengthening 316L Stainless Steel Prepared by Selective Laser Melting, J. Nucl. Mater., 2016, 470, p 170–178. https://doi.org/10.1016/j.jnucmat.2015.12.034

D. Kong, X. Ni, C. Dong, L. Zhang, C. Man, J. Yao, K. Xiao and X. Li, Heat Treatment Effect on the Microstructure and Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting for Proton Exchange Membrane Fuel Cells, Electrochim. Acta, 2018, 276, p 293–303. https://doi.org/10.1016/j.electacta.2018.04.188

K. Saeidi, X. Gao, F. Lofaj, L. Kvetková and Z.J. Shen, Transformation of Austenite to Duplex Austenite-Ferrite Assembly in Annealed Stainless Steel 316L Consolidated by Laser Melting, J. Alloys Compd., 2015, 633, p 463–469. https://doi.org/10.1016/j.jallcom.2015.01.249

O. Fergani, A. Bratli Wold, F. Berto, V. Brotan and M. Bambach, Study of the Effect of Heat Treatment on Fatigue Crack Growth Behaviour of 316L Stainless Steel Produced by Selective Laser Melting, Fatigue Fract. Eng. Mater. Struct., 2018, 41(5), p 1102–1119. https://doi.org/10.1111/ffe.12755

F. Khodabakhshi, M.H. Farshidianfar, A.P. Gerlich, M. Nosko, V. Trembo and A. Khajepour, Effects of Laser Additive Manufacturing on Microstructure and Crystallographic Texture of Austenitic and Martensitic Stainless Steels, Addit. Manuf., 2019, 2020, p 31.

S. Takajo, D.W. Brown, B. Clausen, G.T. Gray, C.M. Knapp, D.T. Martinez, C.P. Trujillo and S.C. Vogel, Spatially Resolved Texture and Microstructure Evolution of Additively Manufactured and Gas Gun Deformed 304L Stainless Steel Investigated by Neutron Diffraction and Electron Backscatter Diffraction, Powder Diffr., 2018, 33(2), p 141–146.

H. Choo, K. Sham, J. Bohling, A. Ngo, X. Xiao, Y. Ren, P.J. Depond, M.J. Matthews and E. Garlea, Effect of Laser Power on Defect, Texture, and Microstructure of a Laser Powder Bed Fusion Processed 316L Stainless Steel, Mater. Des., 2019, 164, p 107534. https://doi.org/10.1016/j.matdes.2018.12.006

T. Arai, G. M. Baker, C. E. Bates, and B. A. Becherer, “Heat Treating,” 1st ed., ASM International, 1991.

B. Beausir and J.-J. Fundenberger, “Analysis Tools for Electron and X-Ray Diffraction, ATEX - Software,” (Université de Lorraine - Metz), 2017, www.atex-software.eu.

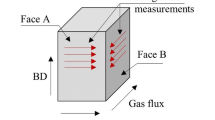

G. Faria, L. Wu, T. Alonso, A. Isaac, J. Piton, R. Neuenschwander, and A.J. Ramirez, In-Situ Studies with Photons, Neutrons and Electrons Scattering II, In-situ Stud. with Photons, Neutrons Electrons Scatt. II, 2014.

G.A. Faria, Exploring Metallic Materials Behavior Through In Situ Crystallographic Studies, 2014, p 129.

M.T. Izumi, J.J.H. Quintero, M.R. Crivoi, M.Y. Maeda, R.S. Namur, D.J. Marcolino, O. de Aguiar and M. Cintho, In Situ X-Ray Diffraction Analysis of Face-Centered Cubic Metals Deformed at Room and Cryogenic Temperatures, J. Mater. Eng. Perf., 2019, 28(8), p 4658–4666. https://doi.org/10.1007/s11665-019-04226-5

M.R. Crivoi, J.J. Hoyos, M.T. Izumi, D.J.M. de Aguiar, R.S. Namur, A.L. Terasawa and O.M. Cintho, In Situ Analysis of Cryogenic Strain of AISI 316L Stainless Steel Using Synchrotron Radiation, Cryogenics (Guildf), Elsevier, 2019, 2020(105), p 103020. https://doi.org/10.1016/j.cryogenics.2019.103020

B.D. Cullity and S.R. Stock, Elements of X-Ray Diffraction, 3rd ed. Person Education Limited, London, 2014.

P.H.F. Oliveira, D.C.C. Magalhães, M.T. Izumi, O.M. Cintho, A.M. Kliauga and V.L. Sordi, A Evolution of Dislocation and Stacking-Fault Densities for a Cu-0 7Cr-0. 07Zr Alloy during Cryogenic Tensile Test: An in-Situ Synchrotron X-Ray Diffraction Analysis, Mater. Sci. Eng. A, 2021, 813, p 141154.

P. Thirathipviwat, G. Song, J. Bednarcik, U. Kühn, T. Gemming, K. Nielsch and J. Han, Progress in Natural Science: Materials International Compositional Complexity Dependence of Dislocation Density and Mechanical Properties in High Entropy Alloy Systems, Prog. Nat. Sci. Mater. Int., 2020, 30(4), p 545–551. https://doi.org/10.1016/j.pnsc.2020.07.002

Y.L. Gong, C.E. Wen, X.X. Wu, S.Y. Ren, L.P. Cheng and X.K. Zhu, A The influence of Strain Rate, Deformation Temperature and Stacking Fault Energy on the Mechanical Properties of Cu Alloys, Mater. Sci. Eng., 2013, 583, p 199–204.

G. Ribárik and T. Ungár, Characterization of the Microstructure in Random and Textured Polycrystals and Single Crystals by Diffraction Line Profile Analysis, Mater. Sci. Eng. A, 2010, 528, p 112–121.

I.R. Souza Filho, M.J.R. Sandim, D. Ponge, H.R.Z. Sandim and D. Raabe, Strain Hardening Mechanisms during Cold Rolling of a High-Mn Steel: Interplay between Submicron Defects and Microtexture, Mater. Sci. Eng. A, 2019, 754, p 636–649.

T. Ungár, I. Dragomir, Á. Révész and A. Borbély, The Contrast Factors of Dislocations in Cubic Crystals: The Dislocation Model of Strain Anisotropy in Practice, J. Appl. Crystallogr., 1999, 32(5), p 992–1002.

P. Bian, J. Shi, Y. Liu and Y. Xie, Influence of Laser Power and Scanning Strategy on Residual Stress Distribution in Additively Manufactured 316L Steel, Opt. Laser Technol., 2019, 2020(132), p 106477. https://doi.org/10.1016/j.optlastec.2020.106477

I.R.S. Filho, K.D. Zilnyk, M.J.R. Sandim, R.E. Bolmaro and H.R.Z. Sandim, Strain Partitioning and Texture Evolution during Cold Rolling of AISI 201 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2017, 702(July), p 161–172. https://doi.org/10.1016/j.msea.2017.07.010

H.D. Carlton, A. Haboub, G.F. Gallegos, D.Y. Parkinson and A.A. MacDowell, Damage Evolution and Failure Mechanisms in Additively Manufactured Stainless Steel, Mater. Sci. Eng. A, 2016, 651, p 406–414. https://doi.org/10.1016/j.msea.2015.10.073

Z. Sun, X. Tan, S.B. Tor and C.K. Chua, Simultaneously Enhanced Strength and Ductility for 3D-Printed Stainless Steel 316L by Selective Laser Melting, NPG Asia Mater., 2018, 10(4), p 127–136. https://doi.org/10.1038/s41427-018-0018-5

Z. Sun, X. Tan, S.B. Tor and W.Y. Yeong, Selective Laser Melting of Stainless Steel 316L with Low Porosity and High Build Rates, Mater. Des., 2016, 104, p 197–204. https://doi.org/10.1016/j.matdes.2016.05.035

M.J. Sohrabi, M. Naghizadeh and H. Mirzadeh, Deformation-Induced Martensite in Austenitic Stainless Steels: A Review, Arch. Civ. Mech. Eng., 2020, 20(4), p 1–24.

M. Meyers and K. Chawla, Mechanical Behavior of Materials, 2nd ed. Cambridge University Press, New York, 2009.

KRAUSS, G. Steels - Processing, Structure, and Performance. ASM International, 2005.

M. Soleimani, A. Kalhor and H. Mirzadeh, Transformation-Induced Plasticity (TRIP) in Advanced Steels: A Review, Mater. Sci. Eng. A, 2020, 795, p 140023. https://doi.org/10.1016/j.msea.2020.140023

Q. Chao, V. Cruz, S. Thomas, N. Birbilis, P. Collins, A. Taylor, P.D. Hodgson and D. Fabijanic, On the Enhanced Corrosion Resistance of a Selective Laser Melted Austenitic Stainless Steel, Scr. Mater., 2017, 141, p 94–98. https://doi.org/10.1016/j.scriptamat.2017.07.037

N.S. Al-Mamun, K. Mairaj Deen, W. Haider, E. Asselin and I. Shabib, Corrosion Behavior and Biocompatibility of Additively Manufactured 316L Stainless Steel in a Physiological Environment: The Effect of Citrate Ions, Addit. Manuf., 2020, 34, p 101237. https://doi.org/10.1016/j.addma.2020.101237

L. Shoji Aota, P. Bajaj, K.D. Zilnyk, E.A. Jagle, D. Ponge, H.R.Z. Sandim and D. Raabe, Recrystallization Kinetics, Mechanisms, and Topology in Alloys Processed by Laser Powder-Bed Fusion: AISI 316L Stainless Steel as Example, Materialia, 2021 https://doi.org/10.1016/j.mtla.2021.101236

O. Gokcekaya, T. Ishimoto, S. Hibino and J. Yasutomi, Acta Materialia Unique Crystallographic Texture Formation in Inconel 718 by Laser Powder b e d Fusion and Its Effect on Mechanical Anisotropy, Acta Mater., 2021, 212, p 116876. https://doi.org/10.1016/j.actamat.2021.116876

M.J.R. Sandim, V. Mauro, S.S.M. Tavares, K.D. Zilnyk and H.R.Z. Sandim, Journal of Magnetism and Magnetic Materials Magnetic Properties and Microstructural Characterization of Cold-Rolled and Annealed 317L Austenitic Stainless Steel, J. Magn. Magn. Mater., 2021, 539, p 168336. https://doi.org/10.1016/j.jmmm.2021.168336

S.Y. Kim, H.S. Kwon and H.S. Kim, Effect of Delta Ferrite on Corrosion Resistance of Type 316L Stainless Steel in Acidic Chloride Solution by Micro-Droplet Cell, Solid State Phenom., 2007, 126, p 1533–1536. https://doi.org/10.4028/www.scientific.net/SSP.124-126.1533

J.W. Elmer and S.M. Allen, Microstructural Development during Solidification of Stainless Steel Alloys, Metall. Trans. A, 1989, 20(October), p 2117.

L.F.K. Unti, L.S. Aota, A.L. Jardini, A.P. Tschiptschin and D. Zilnyk, Materials Characterization Microstructural Characterization of 15–5PH Stainless Steel Processed by Laser Powder-Bed Fusion, Mater. Charact., 2021, 181(September), p 111485.

X. Wang, J.A. Muñiz-Lerma, O. Sánchez-Mata, M.A. Shandiz and M. Brochu, Microstructure and Mechanical Properties of Stainless Steel 316L Vertical Struts Manufactured by Laser Powder Bed Fusion Process, Mater. Sci. Eng. A, 2018, 736, p 27–40. https://doi.org/10.1016/j.msea.2018.08.069

Y. Kok, X.P. Tan, P. Wang, M.L.S. Nai, N.H. Loh, E. Liu and S.B. Tor, Anisotropy and Heterogeneity of Microstructure and Mechanical Properties in Metal Additive Manufacturing: A Critical Review, Mater. Des., 2018, 139, p 565–586. https://doi.org/10.1016/j.matdes.2017.11.021

F. Yan, W. Xiong and E.J. Faierson, Grain Structure Control of Additively Manufactured Metallic Materials, Materials (Basel), 2017, 10(11), p 1260.

Z.G. Zhu, Q.B. Nguyen, F.L. Ng, X.H. An, X.Z. Liao, P.K. Liaw, S.M.L. Nai and J. Wei, Hierarchical Microstructure and Strengthening Mechanisms of a CoCrFeNiMn High Entropy Alloy Additively Manufactured by Selective Laser Melting, Scr. Mater., 2018, 154, p 20–24.

Y.J. Yin, J.Q. Sun, J. Guo, X.F. Kan and D.C. Yang, Mechanism of High Yield Strength and Yield Ratio of 316 L Stainless Steel by Additive Manufacturing, Mater. Sci. Eng. A, 2018, 2019(744), p 773–777. https://doi.org/10.1016/j.msea.2018.12.092

M. Naghizadeh and H. Mirzadeh, Microstructural Evolutions During Reversion Annealing of Cold-Rolled AISI 316 Austenitic Stainless Steel, Metall. Mater. Trans. A, 2018, 49(6), p 2248–2256. https://doi.org/10.1007/s11661-018-4583-6

M.J. Sohrabi, H. Mirzadeh and C. Dehghanian, Significance of Martensite Reversion and Austenite Stability to the Mechanical Properties and Transformation-Induced Plasticity Effect of Austenitic Stainless Steels, J. Mater. Eng. Perform., 2020, 29(5), p 3233–3242. https://doi.org/10.1007/s11665-020-04798-7

S. Kheiri, H. Mirzadeh and M. Naghizadeh, Tailoring the Microstructure and Mechanical Properties of AISI 316L Austenitic Stainless Steel via Cold Rolling and Reversion Annealing, Mater. Sci. Eng. A, 2019, 759(March), p 90–96. https://doi.org/10.1016/j.msea.2019.05.028

Acknowledgments

The authors acknowledge LNNano/LNLS/CNPEM for technical support and infrastructure used in Proposals 20180252 and 20190101, Department of Materials Science and Engineering at Ohio State University (OSU) for the infrastructure used, GE Additive for the machine donation, CAPES (Coordination for the Improvement of Higher Education Personnel) and São Paulo Research Foundation (FAPESP, grant #2019/06679-1) for financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Appendices

Appendix

Applied Corrections of the Diffraction Profiles, and the Procedure for Calculating Phase Fractions (Direct Comparison Method)

The corrected angle position (Δ(2θ)) and corrected intensity (I(2θ)) must be calculated because the diffraction surface moves in a normal direction to the surface plane during the tensile test. The values of (Δ(2θ)) and (I(2θ)) can be calculated by Eq 1 and 2 (Ref 27,28,29).

where 2θobs is the observed angle, t is the sample thickness, ω is the beam incident angle, ε is the sample’s strain, g is the distance between the detector center and the irradiated region of the sample, I(2θ) is the corrected integrated intensity, Iobs(2θ) is the observed integrated intensity, and θ is the corrected angle of the diffraction beam.

The direct comparison method is appropriated for calculating the phases fractions of polyphasic, polycrystalline samples (Ref 30). According to this method, the volumetric phase fraction phase Vi is related to the integrated intensity as follows in Eq 3., K and Rihkl are calculated from Eq 4 and 5, respectively.

where Iihkl is the integrated intensity from the diffracted beam for the hkl plane related to an i phase, K is the instrumental factor, Rihkl is the scattering factor, Vi is the volumetric fraction of phase i, v is the unit cell volume, F is the structure factor for the hkl reflection plane, p is the multiplicity factor, \({\text{e}}^{\text{-2m}}\) is the temperature factor, λ is the wavelength of the incident beam, μ is the linear absorption coefficient, A is the section area transversal to the incident beam, I0 is the intensity of the incident beam, r is the radius of the diffractometer, and e and m are electron charge and mass, respectively.

However, as the experiments were carried in a synchrotron source beam, the diffraction plane is vertical and there is no intensity lost due to the polarization factor (Ref 26, 27). Thus, the polarization factor can be considered as 1. The polarization factor (P) is given in Eq 6 (Ref 30).

This way, the volumetric fraction of phases austenite and α′ martensite can be calculated by Eq 3. with the simplification of the polarization factor.

Rights and permissions

About this article

Cite this article

Starck, L.F., Zilnyk, K.D., Senra, A.L.T. et al. In Situ x-ray Diffraction Study of the Deformation of an AISI 316L Stainless Steel Produced by Laser Powder Bed Fusion. J. of Materi Eng and Perform 31, 8013–8026 (2022). https://doi.org/10.1007/s11665-022-06851-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06851-z