Abstract

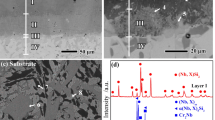

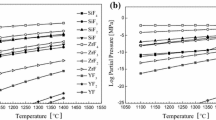

The needs for thermal and propulsive efficiency in equipment operating at high temperatures together with stricter environmental legislation are some of the factors driving the search for materials that can withstand harsh operating conditions. Available high-temperature materials, such as Ni-based superalloys, have already reached their maximum performance limits as they are used in applications where they operate close to their solidus temperature. The development of materials for demanding industrial applications is therefore essential. While the properties of niobium-silicon alloys are attractive for high-temperature applications due to the higher temperature capability, there are challenges to be addressed regarding the workability of these alloys. The high melting temperature and low toughness of Nb silicides challenge conventional manufacturing processes such as forging and milling. The Plasma Transferred Arc is the only arc technique that allows to use powders and powder mixtures as feedstock. The arc technique provides higher power efficiency compared to laser-based processes, allowing to manufacture larger components more competitively. This study assesses the fabricability of niobium silicides multilayers by in situ synthesis during the deposition of powder mixtures by plasma transferred arc. Because of the high solubility limit of oxygen in niobium, the investigation also assessed the impact of oxygen content during processing of a Nb + 37 wt.%Si powder mixture in air and argon environments. Powder Plasma Transferred Arc successfully processed the Nb silicide multilayer from a powder mixture. Although changes in the deposition environment required adjustments in the processing parameters, these did not compromise in situ synthesis of NbSi2 and Nb5Si3. The microstructure of the multilayers was affected by the availability of oxygen, and the multilayer processed in argon had superior oxidation behavior.

Similar content being viewed by others

References

P. Tsakiropoulos, Alloys for Application at Ultra-High Temperatures: Nb-Silicide In Situ Composites: Challenges, Breakthroughs and Opportunities, Prog. Mater. Sci., 2020 https://doi.org/10.1016/j.pmatsci.2020.100714

M. Sankar, R.G. Baligidad, D.V.V. Satyanarayana and A.A. Gokhale, Effect of Internal Oxidation on the Microstructure and Mechanical Properties of C-103 Alloy, Mater. Sci. Eng. A, 2013, 574, p 104–112. https://doi.org/10.1016/j.msea.2013.02.057

S. Kashyap and K. Chattopadhyay, Synthesis and Phase Evolution in Nb/Si Multilayers Obtained by Sequential Laser Ablation, Thin Solid Films, 2013, 531, p 312–319. https://doi.org/10.1016/j.tsf.2013.01.052

E.P. Cardozo, G.R. Pardal, S. Ríos et al., Additive Techniques to Refurbish Ni Based Components, Soldage Insp, 2019 https://doi.org/10.1590/0104-9224/SI24.03

B.V. Shchetanov, D.V. Graschenkov, I.U. Efimochkin et al., Investigation of a High-Temperature Nb-Based Composite Material Mechanically Doped with Si, Inorg. Mater. Appl. Res., 2019, 10, p 1033–1038. https://doi.org/10.1134/S2075113319050290

S. Mathieu, S. Knittel, P. Berthod et al., On the Oxidation Mechanism of Niobium-Base In Situ Composites, Corros. Sci., 2012, 60, p 181–192. https://doi.org/10.1016/j.corsci.2012.03.037

T.B. Massalski, H. Okamoto, P.R. Subramanian and L. Kacprzak, Binary Alloy Phase Diagrams, 2nd ed., ASM International, 1990, ISBN 978-0-87170-403-0.

B.P. Bewlay, M.R. Jackson, J. Zhao and P.R. Subramanian, A Review of Very-High-Temperature Nb-Silicide-Based Composites, Metall. Mater. Trans., 2003, 34A, p 2043–2052. https://doi.org/10.1007/s11661-003-0269-8

G.F. Menegotto and A.S.C.M. d’Oliveira, The Influence of Si on NbAl Coatings, Surf. Coat. Technol., 2017, 325, p 338–345. https://doi.org/10.1016/j.surfcoat.2017.06.069

C.T. Rios, S. Milenkovic, P.L. Ferrandini and R. Caram, Directional Solidification, Microstructure and Properties of the Al3Nb-Nb2Al Eutectic, J. Cryst. Growth, 2005, 275, p 153–158. https://doi.org/10.1016/j.jcrysgro.2004.10.100

Y. Guo, L. Jia, B. Kong et al., Heat Treatment Induced Phase Transition and Microstructural Evolution in Electron Beam Surface Melted Nb-Si Based Alloys, Appl. Surf. Sci., 2017, 423, p 417–420. https://doi.org/10.1016/j.apsusc.2017.05.248

W. Long, J. Yao and Z. Fu, Effects of Al Addition on the Microstructure and Properties of Nb/Nb5Si3 In Situ Composites Fabricated Via Spark Plasma Sintering, J. Wuhan Univ. Technol. Sci. Ed., 2014, 29, p 1036–1038. https://doi.org/10.1007/s11595-014-1039-8

N.R. Philips, M. Carl and N.J. Cunningham, New Opportunities in Refractory Alloys, Metall. Mater. Trans. A., 2020 https://doi.org/10.1007/s11661-020-05803-3

L. Su, L. Jia, Y. Feng et al., Microstructure and Room-Temperature Fracture Toughness of Directionally Solidified Nb-Si-Ti-Cr-Al-Hf Alloy, Mater. Sci. Eng. A, 2013, 560, p 672–677. https://doi.org/10.1016/j.msea.2012.10.011

V.A. Surkov, Methods of Producing Intermetallic Composites: A Review, Russ Eng Res, 2019, 39, p 31–36. https://doi.org/10.3103/S1068798X19010222

T. Griemsmann, A. Abel, C. Hoff et al., Laser-Based Powder Bed Fusion of Niobium with Different Build-Up Rates, Int. J. Adv. Manuf. Technol., 2021, 114, p 305–317. https://doi.org/10.1007/s00170-021-06645-y

C.A. Terrazas, J. Mireles, S.M. Gaytan et al., Fabrication and Characterization of High-Purity Niobium Using Electron Beam Melting Additive Manufacturing Technology, Int. J. Adv. Manuf. Technol., 2016, 84, p 1115–1126. https://doi.org/10.1007/s00170-015-7767-x

A. Allen, A.C. Douglas, L.M. Feitosa et al., Solidification of Niobium-Silicide-Based Alloys During Laser Additive Manufacturing Process, IOP Conf. Ser. Mater. Sci. Eng., 2019, 529, p 012006. https://doi.org/10.1088/1757-899X/529/1/012006

W. Liu, H.P. Xiong, N. Li et al., Microstructure Characteristics and Mechanical Properties of Nb-17Si-23Ti Ternary Alloys Fabricated by In Situ Reaction Laser Melting Deposition, Acta Metall. Sin. (Engl. Lett.), 2018, 31, p 362–370. https://doi.org/10.1007/s40195-017-0619-y

T. Murakami, S. Sasaki, K. Ichikawa and A. Kitahara, Microstructure, Mechanical Properties and Oxidation Behavior of Nb-Si-Al and Nb-Si-N Powder Compacts Prepared by Spark Plasma Sintering, Intermetallics, 2001, 9, p 621–627.

C. Brunetti, G. Pintaude and D`Oliveira ASCM, The Influence of Fe Content on the Mechanical Properties of NiAl Coatings Processed In-Situ, J. Mater. Eng. Perform., 2014, 23, p 3934–3040.

A. Gatto, E. Bassoli and M. Fornari, Plasma Transferred Arc Deposition of powdered High Performanced Alloys: Process Parameters Optimisation as a Function of Alloy and Geometrical Configuration, Surf. Coat. Technol., 2004, 187, p 265–271.

A.E. Yaedu and D`Oliveira ASCM, Cobalt Based Alloy PTA Hardfacing on Different Substrate Steels, Mater. Sci. Technol., 2005, 21, p 459–466.

I. Papadimitriou, C. Utton, A. Scott and P. Tsakiropoulos, Ab Initio Study of the Intermetallics in Nb-Si Binary System, Intermetallics, 2014, 54, p 125–132. https://doi.org/10.1016/j.intermet.2014.05.020

F. Zhang, L.T. Zhang, A.D. Shan and J.S. Wu, In Situ Observations of the Pest Oxidation Process of NbSi2 at 1023 K, Scr. Mater., 2005, 53, p 653–656. https://doi.org/10.1016/j.scriptamat.2005.05.023

A.K. Sinha, H.J. Levinstein and T.E. Smith, Thermal Stresses and Cracking Resistance of Dielectric Films (SiN, Si3N4, and SiO2) on Si Substrates, J. Appl. Phys., 2008, 2423, p 2–6.

M.D. Novak, Microstructure Development and High-Temperature Oxidation of Silicide Coatings for Refractory Niobium Alloys, University of California, Santa Barbara, 2010.

W.Y. Kim, H. Tanaka, A. Kasama and S. Hanada, Microstructure and Room Temperature Fracture Toughness of Nbss /Nb5Si3 In Situ Composites, Intermetallics, 2001, 9, p 827–834. https://doi.org/10.1016/S0966-9795(01)00072-3

J.H. Schneibel, C.J. Rawn, T.R. Watkins and E.A. Payzant, Thermal Expansion Anisotropy of Ternary Molybdenum Silicides Based on Mo5Si3, Phys. Rev. B Condens. Matter Mater. Phys., 2002, 65, p 1–5. https://doi.org/10.1103/PhysRevB.65.134112

M.L. Rossi, V. Ponomarev and A. Scotti, Heat Exchange and Voltage Drop in Welding Arc Column, IEEE Trans. Plasma Sci., 2016, 44, p 2446–2454. https://doi.org/10.1109/TPS.2016.2606628

Pitman SH, Tsakiropoulos P (1995) Study of the Microstructure and Oxidation of NbSi2 Base Alloys. In: Materials Research Society Symposium, pp. 1321–1326

Lin C-H (2008) Oxidation (of Silicon). In: Encyclopedia of Microfluidics and Nanofluidics, vol. 1584. https://doi.org/10.1007/978-3-642-27758-0_1145-2

Bach D (2009) EELS Investigations of Stoichiometric Niobium Oxides and Niobium-based Capacitors. Thesis 204

F. Zhang, L.T. Zhang, A.D. Shan and J.S. Wu, Microstructural Effect on Oxidation Kinetics of NbSi2 at 1023 K, J. Alloys. Compd., 2006, 422, p 308–312. https://doi.org/10.1016/j.jallcom.2005.12.015

Acknowledgments

The authors gratefully acknowledge the financial support provided by CAPES and CNPq and wish to thank CBMM for supplying the niobium powders and substrate.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cardozo, E.P., D’Oliveira, A.S.C.M. Niobium Silicide Multilayers Processed by In Situ Synthesis During Deposition of Powder Mixtures. J. of Materi Eng and Perform 31, 3998–4005 (2022). https://doi.org/10.1007/s11665-021-06460-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06460-2