Abstract

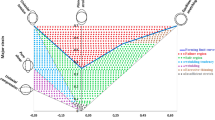

Based on the BBC2005 yield criterion, a material model that accounts for the deformation anisotropy of sheet metals is developed, named the BBC2005-different work hardening (BBC05-DWH) yield criterion. In contrast to the standard formulation, in this model the material parameters depend on the equivalent plastic strain. To evaluate the different material models, uniaxial and biaxial tensile tests and hydraulic bulging tests are carried out on a 5182-O aluminum alloy produced by Kobelco. The results show that predictions based on the developed material model are more accurate than predictions based on three other yield criteria that use different material parameter identification methods (Hill48-r, Hill48-σ, Barlat89-r, Barlat89-σ and BBC2005 yield criteria). The developed material model is also used to modify the hardening curve produced by the hydraulic bulging test. In the process of extrapolating the hardening curve in the reference direction, the influences of different yield criteria, material parameter identification methods and different work hardening behavior on the equivalent stress are discussed.

Similar content being viewed by others

Data Availability

All data are presented within the manuscript.

Code Availability

Not applicable.

References

D. Banabic, F. Barlat, O. Cazacu, and T. Kuwabara, Advances in Anisotropy of Plastic Behaviour and Formability of Sheet Metals. Int. J. Mater. Form. 2020, 13, p 749-787

S.H. Zhang, S.F. Chen, Y. Ma, H.W. Song, and M. Chen, Developments of New Sheet Metal Forming Technology and Theory in China. Acta Metall. Sin. Engl. Lett. 2015, 28, p 1452-1470

M. Sigvant, K. Mattiasson, H. Vegter and P. Thilderkvist, A Viscous Pressure Bulge Test for the Determination of a Plastic Hardening Curve and Equibiaxial Material Data, Int. J. Mater. Form., 2009, 2, p 235–242.

F.F. Zhang, J. Chen, J.S. Chen, J. Lu, G. Liu and S.J. Yuan, Overview on Constitutive Modeling for Hydroforming with the Existence of Through-Thickness Normal Stress, J. Mater. Process. Technol., 2012, 212, p 2228–2237.

G. Gutscher, H.C. Wu, G. Ngaile and T. Altan, Determination of Flow Stress for Sheet Metal Forming Using the Viscous Pressure Bulge (VPB) Test, J. Mater. Process. Technol., 2004, 146, p 1–7.

L.M. Smith, C. Wanintrudal, W. Yang and S. Jiang, A New Experimental Approach for Obtaining Diffuse-Strain Flow Stress Curves, J. Mater. Process. Technol., 2009, 209, p 3830–3839.

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. R. Soc. London., 1948, 193, p 281–297.

A. Nasser, A. Yadav, P. Pathak and T. Altan, Determination of the flow stress of five AHSS sheet materials (DP 600, DP 780, DP 780-CR, DP 780-HY and TRIP 780) using the uniaxial tensile and the biaxial Viscous Pressure Bulge (VPB) tests, J. Mater. Process. Technol., 2010, 210, p 429–436.

R. Hill, Constitutive Modelling of Orthotropic Plasticity in Sheet Metals, J. Mech. Phys. Solids, 1990, 38, p 405–417.

J. Mulder, H. Vegter, H. Aretz, S. Keller and A.H. van den Boogaard, Accurate Determination of Flow Curves Using the Bulge Test with Optical Measuring Systems, J. Mater. Process. Technol., 2015, 226, p 169–187.

S. Suttner and M. Merklein, Experimental and Numerical Investigation of a Strain Rate Controlled Hydraulic Bulge Test of Sheet Metal, J. Mater. Process. Technol., 2016, 235, p 121–133.

H. Alharthi, S. Hazra, A. Alghamdi, D. Banabic and R. Dashwood, Determination of the Yield Loci of Four Sheet Materials (AA6111-T4, AC600, DX54D+Z, and H220BD+Z) by Using Uniaxial Tensile and Hydraulic Bulge Tests, Int. J. Adv. Manuf. Technol., 2018, 98, p 1307–1319.

V. Prakash, D.R. Kumar, A. Horn, H. Hagenah and M. Merklein, Modeling Material Behavior of AA5083 Aluminum Alloy Sheet Using Biaxial Tensile Tests and Its Application in Numerical Simulation of Deep Drawing, Int. J. Adv. Manuf. Technol., 2019, 106, p 1133–1148.

R. Hill, S.S. Hecker and M.G. Stout, An Investigation of Plastic Flow and Differential Work Hardening in Orthotropic Brass Tubes Under Fluid Pressure and Axial Load, Int. J. Solids Struct., 1994, 31, p 2999–3021.

M.S. Aydin, J. Gerlach, L. Kessler and A.E. Tekkaya, Yield Locus Evolution and Constitutive Parameter Identification Using Plane Strain Tension and Tensile Tests, J. Mater. Process. Technol., 2011, 211, p 1957–1964.

M. Ishiki, T. Kuwabara and Y. Hayashida, Measurement and Analysis of Differential Work Hardening Behavior of Pure Titanium Sheet Using Spline Function, Int. J. Mater. Form., 2009, 4, p 193–204.

T. Kuwabara, T. Mori, M. Asano, T. Hakoyama and F. Barlat, Material Modeling of 6016-O and 6016–T4 Aluminum Alloy Sheets and Application to Hole Expansion Forming Simulation, Int. J. Plast., 2017, 93, p 164–186.

M.O. Andar, T. Kuwabara, and D. Steglich, Material Modeling of AZ31 Mg Sheet Considering Variation of r-Values and Asymmetry of the Yield Locus. Mater. Sci. Eng. 2012, A 549, p 82-92

J.W. Yoon, F. Barlat, R.E. Dick, K. Chung and T.J. Kang, Plane Stress Yield Function for Aluminum Alloy Sheets-Part II: FE Formulation and Its Implementation, Int. J. Plast., 2004, 20, p 495–522.

H. Aretz, A Simple Isotropic-Distortional Hardening Model and Its Application in Elastic-Plastic Analysis of Localized Necking in Orthotropic Sheet Metals, Int. J. Plast., 2008, 24, p 1457–1480.

H.B. Wang, M. Wan, X.D. Wu and Y. Yan, The Equivalent Plastic Strain-Dependent Yld 2000–2d Yield Function and the Experimental Verification, Comput. Mater. Sci., 2009, 47, p 12–22.

P. Peters, N. Manopulo, C. Lange and P. Hora, A Strain Rate Dependent Anisotropic Hardening Model and Its Validation Through Deep Drawing Experiments, Int. J. Mater. Form., 2014, 7, p 447–457.

J.H. Yoon, O. Cazacu, J.W. Yoon and R.E. Dick, Earing Predictions for Strongly Textured Aluminum Sheets, Int. J. Mech. Sci., 2010, 52, p 1563–1578.

T. Kuwabara, Advances in Experiments on Metal Sheets and Tubes in Support of Constitutive Modeling and Forming Simulations, Int. J. Plast., 2007, 23, p 385–419.

D. Banabic, F. Barlat, O. Cazacu and T. Kuwabara, Advances in Anisotropy and Formability, Int. J. Mater. Form., 2010, 3, p 165–189.

Y. Hou, J.Y. Min, T.B. Stoughton, J.P. Lin, J.E. Carsley, and B.E. Carlson, A Non-quadratic Pressure-Sensitive Constitutive Model Under Non-associated Flow Rule With Anisotropic Hardening: Modeling and Validation. Int. J. Plast., 2020, 135, p 102808

J.Y. Min, J.E. Carsley, J.P. Lin, Y.Y. Wen and B. Kuhlenkotter, A Non-quadratic Constitutive Model Under Nonassociated Flow Rule of Sheet Metals with Anisotropic Hardening: Modeling and Experimental Validation, Int. J. Mech. Sci., 2016, 119, p 343–359.

H.B. Wang, Y. Yan, F. Han and M. Wan, Experimental and Theoretical Investigations of the Forming Limit of 5754O Aluminum Alloy Sheet Under Different Combined Loading Paths, Int. J. Mech. Sci., 2017, 133, p 147–166.

F. Barlat and K. Lian, Plastic Behavior and Stretchability of Sheet Metals. Part I: A Yield Function for Orthotropic Sheets Under Plane Stress Conditions. Int. J. Plast., 1989, 5, p 51-66

J. Pilthammar, D. Banabic, and M. Sigvant, BBC05 with Non-integer Exponent and Ambiguities in Nakajima Yield Surface Calibration. Int. J. Mater. Form., 2020, 3

G.M. Han, C.G. Tian, C.Y. Cui, Z.Q. Hu, and X.F. Sun, Portevin–Le Chatelier Effect in Nimonic 263 Superalloy. Acta Metall. Sin. (Engl. Lett.)., 2015, 28, p 542-549

H. Halim, D.S. Wilkinson and M. Niewczas, The Portevin-Le Chatelier (PLC) Effect and Shear Band Formation in an AA5754 alloy, Acta Mater., 2007, 55, p 4151–4160.

J.Y. Min, T.B. Stoughton J.E. Carsley, B.E. Carlson J.P. Lin, and X.L. Gao, Accurate Characterization of Biaxial Stress-Strain Response of Sheet Metal from Bulge Testing. Int. J. Plast., 2017, 94, p 192-213

D. Steglich, Y. Jeong, M.O. Andar and T. Kuwabara, Biaxial Deformation Behaviour of AZ31 Magnesium Alloy: Crystal-Plasticity-Based Prediction and Experimental Validation, Int. J. Solids Struct., 2012, 49, p 3551–3561.

S.B. Lin and J.L. Ding, A Modified form of Hill’s Orientationdashdependent Yield Criterion for Orthotropic Sheet Metals, J. Mech. Phys. Solids, 1996, 44, p 1739–1764.

J.H. Lian, F.H. Shen, X.X. Jia, D.C. Ahn, D.C. Chae, S. Munstermann and W. Bleck, An Evolving Non-associated Hill48 Plasticity Model Accounting for Anisotropic Hardening and r-Value Evolution and Its Application to Forming Limit Prediction, Int. J. Solids Struct., 2018, 151, p 20–44.

T. Kuwabara and F. Sugawara, Multiaxial Tube Expansion Test Method for Measurement of Sheet Metal Deformation Behavior Under Biaxial Tension for a Large Strain Range, Int. J. Plast., 2013, 45, p 103–118.

T. Hakoyama and T. Kuwabara, Forming Limit Analyses of Cold Rolled IF Steel Sheet Using Differential Work Hardening Model, Procedia Eng., 2014, 81, p 1246–1251.

S. Kaya, T. Altan, P. Groche and C. Klopsch, Determination of the Flow Stress of Magnesium AZ31-O Sheet at Elevated Temperatures Using the Hydraulic Bulge Test, Int. J. Mach. Tools Manuf., 2008, 48, p 550–557.

K.M. Zhao, L.M. Wang, Y. Chang and J.W. Yan, Identification of Post-Necking Stress-Strain Curve for Sheet Metals by Inverse Method, Mech. Mater., 2016, 92, p 107–118.

J.H. Kim, A. Serpantié, F. Barlat, F. Pierron and M.G. Lee, Characterization of the Post-Necking Strain Hardening Behavior Using the Virtual Fields Method, Int. J. Solids Struct., 2013, 50, p 3829–3842.

Acknowledgment

The authors thank the Press Shop and TWA Laboratory of BMW Brilliance Automotive Ltd. for their support and help with the experiments.

Funding

This study was funded by the Promotion China Ph.D. Program of BMW Brilliance Automotive Ltd.

Author information

Authors and Affiliations

Contributions

KD contributed to conceptualization, formal analysis, validation and writing original draft. SH was involved in supervision and funding acquisition. HW performed review and editing. FY and LP performed project administration. HH contributed to investigation and methodology. WZ was involved in methodology and writing—review and editing. XY performed writing—review and editing, and supervision.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Ethics Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, K., Huang, S., Wang, H. et al. Effect of Different Yield Criteria and Material Parameter Identification Methods on the Description Accuracy of the Anisotropic Behavior of 5182-O Aluminum Alloy. J. of Materi Eng and Perform 31, 1077–1095 (2022). https://doi.org/10.1007/s11665-021-06295-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06295-x