Abstract

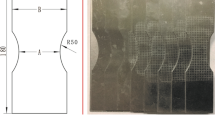

For the Al-Mg-Li alloy sheet with significant anisotropy, the uniaxial and cruciform biaxial tension tests and the Nakazima test are firstly performed to systematically determine the mechanical properties (including strength coefficient, strain hardening exponent, normal anisotropy coefficient, experimental yielding points and forming limits) of this sheet. Afterward, the widely used Hill’s 48 and Yld2000-2d yield criteria are, respectively, identified to describe the yield locus of this sheet and compared with the experimental yielding points. Comparison shows that the identified Yld2000-2d yield function provides a better description of the yield locus for the Al-Mg-Li alloy sheet. Finally, the forming limits of this sheet are predicted by the modified M-K (Marciniak–Kuczyński) model with the Yld2000-2d yield criterion identified in this work. The results show that the predicted forming limits correspond well with the experimental ones within the whole range of strain paths.

Graphical Abstract

Similar content being viewed by others

Abbreviations

- rb :

-

Biaxial anisotropy coefficient

- α 1~α 8, m:

-

Parameters in the Yld2000-2d yield function

- α b :

-

Equi-biaxial yielding stress

- \(\bar{\sigma }\) :

-

Equivalent stress

- f 0, f :

-

Initial and instant thickness imperfection coefficients in M-K model

- α k , γ k, η k :

-

Simplified notations (k=a or b) for calculation in M-K model

- ω 1 k , ω 2 k, ω 3 k :

-

Simplified notations (k=a or b) for calculation in M-K model

References

H. Xiao, Z. Lu, K. Zhang, S. Jiang and C. Shi,Achieving Outstanding Combination of Strength and Ductility of the Al-Mg-Li Alloy by Cold Rolling Combined with Electropulsing Assisted Treatment, Mater. Des, 2020, 186, p 108279.

A.A. El-Aty, Y. Xu, S. Zhang, Y. Ma and D. Chen, Experimental Investigation of Tensile Properties and Anisotropy Of 1420, 8090 and 2060 Al-Li Alloys Sheet Undergoing Different Strain Rates and Fibre Orientation: a Comparative Study, Procedia Eng., 2017, 207, p 13–18.

Y. Jin and H. Yu, Superior Mechanical Properties and Microstructual Evolution of 2195–T6 Al-Li Alloys at a High Strain Rate, Mater. Sci. Eng. A, 2021, 816, p 141314.

R.J. Rioja and R.H. Graham, Al-Li Alloys Find Their Niche, Adv. Mater. Process., 1992, 141, p 23–26.

A. Deschamps, C. Sigli, T. Mourey, F. de Geuser, W. Lefebvre and B. Davo, Experimental and Modelling Assessment of Precipitation Kinetics in an Al-Li-Mg alloy, Acta Mater., 2012, 60(9), p 1917–1928.

L.B. Khokhlatova, N.I. Kolobnev, M.S. Oglodkov and E.D. Mikhaylov, Aluminum-Lithium Alloys for Aircraft Building, Metallurgist, 2012, 56, p 336–341.

R.J. Rioja and J. Liu, The Evolution of Al-Li Base Products for Aerospace and Space Applications, Metall. Mater. Trans. A, 2012, 43, p 3325–3337.

S.H. Choi and F. Barlat, Prediction of Macroscopic Anisotropy in Rolled Aluminum-Lithium Sheet, Scripta Mater., 1999, 41, p 981–987.

S.Y. Betsofen, V.V. Antipov and M.I. Knyazev, Al-Cu-Li and Al-Mg-Li Alloys: Phase Composition, Texture, and Anisotropy of Mechanical Properties (Review), Russ. Metall. (Metally), 2016, 4, p 326–341.

A.A. El-Aty, Y. Xu, X. Guo, S. Zhang, Y. Ma and D. Chen, Strengthening Mechanisms, Deformation Behavior, and Anisotropic Mechanical Properties of Al-Li alloys: A Review, J. Adv. Res., 2018, 10, p 49–67.

T.Z. Zhao, L. Jin, Y. Xu and S.H. Zhang, Anisotropic Yielding Stress of 2198 Al-Li Alloy Sheet and Mechanisms, Mat. Sci. Eng. A, 2020, 771, p 138572.

C. Cheng, M. Wan, X.D. Wu, Z.Y. Cai, R. Zhao and B. Meng, Effect of Yield Criteria on the Formability Prediction of Dual-Phase Steel Sheets, Int. J. Mech. Sci., 2017, 133, p 28–41.

R.P.R. Cardoso and O.B. Adetoro, A Generalisation of the Hill’s Quadratic Yield Function for Planar Plastic Anisotropy to Consider Loading Direction, Int. J. Mech. Sci., 2017, 128–129, p 253–268.

L. Wang and T.C. Lee, The Effect of Yield Criteria on the Forming Limit Curve Prediction and the Deep Drawing Process Simulation, Int. J. Mach. Tool. Manu., 2006, 46, p 988–995.

D. Banabic, Advances in Plastic Anisotropy and Forming Limits in Sheet Metal Forming, J. Manuf. Sci. Eng., 2016, 138, p 090901.

Y. Lou and J.W. Yoon, Anisotropic Yield Function Based on Stress Invariants for BCC and FCC Metals and its Extension to Ductile Fracture Criterion, Int. J. Plast., 2018, 101, p 125–155.

R. Hill, A Theory of the Yielding and Plastic Flow of Anisotropic Metals, Proc. Royal Soc. Lond. (Series A), 1948, 193, p 281–297.

S. Panich, F. Barlat, V. Uthaisangsuk, S. Suranuntchai and S. Jirathearanat, Experimental and Theoretical Formability Analysis Using Strain and Stress Based Forming Limit Diagram for Advanced High Strength Steels, Mater. Des., 2013, 51, p 756–766.

P.A. Eggertsen and K. Mattiasson, On Constitutive Modeling for Springback Analysis, Int. J. Mech. Sci., 2010, 52, p 804–818.

H.B. Campos, M.C. Butuc, J.J. Grácio, J.E. Rocha and J.M.F. Duarte, Theorical and Experimental Determination of the Forming Limit Diagram for the AISI 304 Stainless Steel, J. Mater. Process. Technol., 2006, 179, p 56–60.

Y. Yan, H. Wang and Q. Li, The Inverse Parameter Identification of Hill 48 Yield Criterion and its Verification in Press Bending and Roll Forming Process Simulations, J. Manuf. Process., 2015, 20, p 46–53.

Q. Hu, L. Zhang, Q. Ouyang, X. Li, X. Zhu and J. Chen, Prediction of Forming Limits for Anisotropic Materials with Nonlinear Strain Paths by an Instability Approach, Int. J. Plast., 2018, 103, p 143–167.

N. Park, H. Huh, S.J. Lim, Y. Lou, Y.S. Kang and M.H. Seo, Fracture-Based Forming Limit Criteria for Anisotropic Materials in Sheet Metal Forming, Int. J. Plast., 2017, 96, p 1–35.

F. Barlat, J.C. Brem, J.W. Yoon, K. Chung, R.E. Dick, D.J. Lege, F. Pourboghrat, S.H. Choi and E. Chu, Plane Stress Yield Function for Aluminum Alloy Sheets-Part 1: Theory, Int. J. Plast., 2003, 19, p 1297–1319.

E.H. Lee, T.B. Stoughton and J.W. Yoon, Kinematic Hardening Model Considering Directional Hardening Response, Int. J. Plast., 2018, 110, p 145–165.

C. Butcher, F. Khameneh, A. Abedini, D. Connolly and S. Kurukuri, On the Experimental Characterization of Sheet Metal Formability and the Consistent Calibration of the MK Model for Biaxial Stretching in Plane Stress, J. Mater. Process. Technol, 2021, 287, p 116887.

C.P. Dick and Y.P. Korkolis, Anisotropy of Thin-Walled Tubes by a New Method of Combined Tension and Shear Loading, Int. J. Plast., 2015, 71, p 87–112.

T. Kuwabara, T. Mori, M. Asano, T. Hakoyama and F. Barlat, Material Modeling of 6016-O and 6016–T4 Aluminum Alloy Sheets and Application to Hole Expansion Forming Simulation, Int. J. Plast., 2017, 93, p 164–186.

J.J. Kim, Q.T. Pham and Y.S. Kim, Thinning Prediction of Hole-Expansion Test for Dp980 Sheet Based on A Non-Associated Flow Rule, Int. J. Mech. Sci., 2021, 191, p 106067.

H. Zhang, M. Diehl, F. Roters and D. Raabe, A Virtual Laboratory Using High Resolution Crystal Plasticity Simulations to Determine the Initial Yield Surface for Sheet Metal Forming Operations, Int. J. Plast., 2016, 80, p 111–138.

D. Kim, H. Kim, J.H. Kim, M.G. Lee, K.J. Kim, F. Barlat, Y. Lee and K. Chung, Modeling of Forming Limit for Multilayer Sheets Based on Strain-Rate Potentials, Int. J. Plast., 2015, 75, p 63–99.

Y. Wang, A. Sha, X. Li, C. Jia and W. Hao, Experimental Study on the Forming Limit of GH605 Superalloy Sheet Using Digital Image Correlation, J. Mater. Eng. Perform., 2021, 30, p 1420–1429.

H.W. Swift, Plastic Instability Under Plane Stress, J. Mech. Phys. Solids, 1952, 1, p 1–18.

R. Hill, On Discontinuous Plastic States, with Special Reference to Localized Necking in Thin Sheets, J. Mech. Phys. Solids, 1952, 1, p 19–30.

N. Manopulo, P. Hora, P. Peters, M. Gorji and F. Barlat, An Extended Modified Maximum Force Criterion for the Prediction of Localized Necking under Non-Proportional Loading, Int. J. Plast., 2015, 75, p 189–203.

Z. Marciniak and K. Kuczyński, Limit Strains in the Processes of Stretch-Forming Sheet Metal, Int. J. Mech. Sci., 1967, 9, p 609–620.

X. Li, Y. Chen, L. Lang and R. Xiao, A Modified M-K Method for Accurate Prediction of FLC of Aluminum Alloy, Metals, 2021, 11, p 394.

M. Nurcheshmeh and D.E. Green, Prediction of Forming Limit Curves for Nonlinear Loading Paths Using Quadratic and Non-Quadratic Yield Criteria and Variable Imperfection Factor, Mater. Des., 2016, 91, p 248–255.

C. Wang, Y. Yi, S. Huang, F. Dong, H. He, K. Huang and Y. Jia, Experimental and Theoretical Investigation on the Forming Limit of 2024-O Aluminum Alloy Sheet at Cryogenic Temperatures, Met. Mater. Int., 2021 https://doi.org/10.1007/s12540-020-00922-3

A.S. Khan and M. Baig, Anisotropic Responses, Constitutive Modeling and the Effects of Strain-Rate and Temperature on the Formability of an Aluminum Alloy, Int. J. Plast., 2011, 27, p 522–538.

P. Dasappa, K. Inal and R. Mishra, The Effects of Anisotropic Yield Functions and Their Material Parameters on Prediction of Forming Limit Diagrams, Int. J. Solids Struct., 2012, 49, p 3528–3550.

S.M. Mirfalah-Nasiri, A. Basti and R. Hashemi, Forming Limit Curves Analysis of Aluminum Alloy Considering the Through-Thickness Normal Stress, Anisotropic Yield Functions and Strain Rate, Int. J. Mech. Sci., 2016, 117, p 93–101.

S.M. Mirfalah-Nasiri, A. Basti, R. Hashemi and A. Darvizeh, Effects of Normal and Through-Thickness Shear Stresses on the Forming Limit Curves of AA3104-H19 Using Advanced Yield Criteria, Int. J. Mech. Sci., 2018, 137, p 15–23.

Q. Hu, X. Li and J. Chen, Forming Limit Evaluation by Considering Through-Thickness Normal Stress: Theory and Modeling, Int. J. Mech. Sci., 2019, 155, p 187–196.

K.V. Jata, A.K. Hopkins and R.J. Rioja, The Anisotropy and Texture of Al-Li Alloys, Mater. Sci. Forum., 1996, 217–222, p 647–652.

T. Kuwabara, S. Ikeda and K. Kuroda, Measurement and Analysis of Differential Work Hardening in Cold-Rolled Steel Sheet Under Biaxial Tension, J. Mater. Process. Technol., 1998, 80–81, p 517–523.

Y. Wang, C. Zhang, Y. Yang, G. Wang, G. Zhao and L. Chen, The Identification of Improved Johnson-Cook Constitutive Model in a Wide Range of Temperature and its Application In Predicting FLCs of Al-Mg-Li Sheet, J. Mater. Res. Technol., 2020, 9, p 3782–3795.

Y. Wang, C. Zhang, Y. Yang, S. Fan, G. Wang, G. Zhao and L. Chen, The Integration of Through-Thickness Normal Stress and Friction Stress in the M-K Model to Improve the Accuracy of Predicted FLCs, Int. J. Plast., 2019, 120, p 147–163.

Acknowledgment

The authors would like to acknowledge the financial support from National Natural Science Foundation of China (51975330, 51735008) and Key Research and Development Program of Shandong Province (2019JZZY010360). The authors also gratefully acknowledge the beneficial help from Prof. Min Wan and Prof. Xiangdong Wu in Beihang University for providing the support of cruciform biaxial test.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, Y., Zhang, C., Wang, Y. et al. An Investigation on the Anisotropic Plastic Behavior and Forming Limits of an Al-Mg-Li Alloy Sheet. J. of Materi Eng and Perform 30, 8224–8234 (2021). https://doi.org/10.1007/s11665-021-05981-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05981-0