Abstract

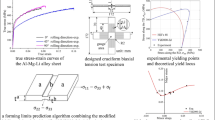

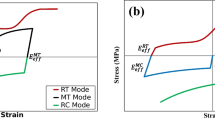

Strong initial and induced anisotropies, observed in the deformation of Mg alloys, have restricted their industrial applications. The initial anisotropic behavior is caused by the initial texture of Mg sheets which are fabricated by successive rolling operations. This behavior could be well described by appropriate yield criteria. However, the texture evolution inside the material induces the distortion of the yield surface, which has strong effects on the hardening and damage evolution. Classical isotropic and kinematic hardening could not precisely describe the induced anisotropic hardening. Therefore, distortional hardening, describing the shape alteration of the yield surface, should be considered in modeling the mechanical behaviors of Mg alloy sheets. In this study, a plasticity model fully coupled with isotropic damage for Mg alloys is proposed, and the constitutive equations are formulated within the thermodynamic framework using state variables. The current constitutive model could accurately reproduce the stress–strain evolution under tension, shear and compression for Mg alloy AZ31. In addition, both of the initial anisotropic yield surface and the subsequent distorted yield surface are captured correctly, and the failure under combined loading path is well predicted by the proposed model.

Similar content being viewed by others

References

Banabic, D.: Advances in plastic anisotropy and forming limits in sheet metal Forming. J. Manuf. Sci. Eng. 138(9), 1–9 (2016)

Wang, Q., Bertolini, R., Bruschi, S., et al.: Anisotropic fracture behavior of AZ31 magnesium alloy sheets as a function of the stress state and temperature. Int. J. Mech. Sci. 163, 105–146 (2019)

Li, Z., Yang, H., Liu, J.: Comparative study on yield behavior and non-associated yield criteria of AZ31B and ZK61 M magnesium alloys. Mater. Sci. Eng. A 759, 329–345 (2019)

Yi, S., Bohlen, J., Heinemann, F., et al.: Mechanical anisotropy and deep drawing behaviour of AZ31 and ZE10 magnesium alloy sheets. Acta Mater. 58(2), 592–605 (2010)

Habib, S.A., Khan, A.S., Gnäupel-Herold, T., et al.: Anisotropy, tension-compression asymmetry and texture evolution of a rare-earth-containing magnesium alloy sheet, ZEK100, at different strain rates and temperatures: Experiments and modeling. Int. J. Plast. 95, 163–190 (2017)

Steglich, D., Tian, X., Besson, J.: Mechanism-based modelling of plastic deformation in magnesium alloys. Eur. J. Mech. A Solids 55, 289–303 (2016)

Zhang, K., Badreddine, H., Saanouni, K.: Thermodynamically-consistent constitutive modeling of hardening asymmetry including isotropic ductile damage for Mg alloys. Eur. J. Mech. A Solids 73, 169–180 (2019)

Khan, A.S., Pandey, A., Stoughton, T.: Evolution of subsequent yield surfaces and elastic constants with finite plastic deformation. Part III: Yield surface in tension–tension stress space (Al 6061–T 6511 and annealed 1100 Al). Int. J. Plast. 26(10), 1432–1441 (2010)

Shi, B., Peng, Y., Yang, C., et al.: Loading path dependent distortional hardening of Mg alloys: experimental investigation and constitutive modeling. Int. J. Plast. 90, 76–95 (2017)

Tuninetti, V., Gilles, G., Flores, P., et al.: Impact of distortional hardening and the strength differential effect on the prediction of large deformation behavior of the Ti6Al4V alloy. Meccanica 54, 1823–1840 (2019)

Saanouni, K.: Damage mechanics in metal forming: advanced modeling and numerical simulation. Wiley, New York (2012)

Saanouni, K., Chaboche, J.: Computational damage mechanics. Application to metal forming. Numerical and Computational Methods in Comprehensive Structural Integrity 3, 321–376 (2003)

Shi, B., Mosler, J.: On the macroscopic description of yield surface evolution by means of distortional hardening models: Application to magnesium. Int. J. Plast. 44, 1–22 (2013)

Yang, Y., Balan, T.: Prediction of the yield surface evolution and some apparent non-normality effects after abrupt strain-path change using classical plasticity. Int. J. Plast. 119, 331–343 (2019)

Teodosiu, C., Hu, Z.: Microstructure in the continuum modelling of plastic anisotropy. In: Nineteenth Riso International Symposium on Materials Science (1998)

Feigenbaum, H.P., Dafalias, Y.F.: Directional distortional hardening in metal plasticity within thermodynamics. Int. J. Solids Struct. 44(22–23), 7526–7542 (2007)

François, M.: A plasticity model with yield surface distortion for non proportional loading. Int. J. Plast. 17(5), 703–717 (2001)

Barlat, F., Ha, J., Grácio, J.J., et al.: Extension of homogeneous anisotropic hardening model to cross-loading with latent effects. Int. J. Plast. 46, 130–142 (2013)

Zhang, W., Zhuang, X., Zhang, Y., et al.: An enhanced François distortional yield model: theoretical framework and experimental validation. Int. J. Plast. 127, 102643 (2019)

Msolli, S., Badreddine, H., Labergere, C., et al.: Experimental characterization and numerical prediction of ductile damage in forming of AA1050-O sheets. Int. J. Mech. Sci. 99, 262–273 (2015)

Wang, X., Sun, B., Li, Z.: Damage-induced material softening and its effect on seismic performance of steel structures. Sci. China Technol. Sci. 59(10), 1559–1572 (2016)

Bai, Q., Mohamed, M., Shi, Z., et al.: Application of a continuum damage mechanics (CDM)-based model for predicting formability of warm formed aluminium alloy. Int. J. Adv. Manuf. Technol. 88(9–12), 3437–3446 (2016)

Shen, X., Mroz, Z., Xu, B.: Constitutive theory of plasticity coupled with orthotropic damage for geomaterials. Appl. Math. Mech. 22(9), 1028–1034 (2001)

Badreddine, H., Yue, Z.M., Saanouni, K.: Modeling of the induced plastic anisotropy fully coupled with ductile damage under finite strains. Int. J. Solids Struct. 108, 49–62 (2017)

Yue, Z., Badreddine, H., Saanouni, K., et al.: Numerical simulation of sheet metal blanking based on fully coupled elastoplasticity-damage constitutive equations accounting for yield surface distortion-induced anisotropy. Int. J. Damage Mech. 26(7), 1061–1079 (2016)

Yue, Z.M., Chu, X.R., Gao, J.: Numerical simulation of incremental sheet forming with considering yield surface distortion. Int. J. Adv. Manuf. Technol. 92(5–8), 1761–1768 (2017)

Zhang, K., Badreddine, H., Saanouni, K.: Thermomechanical modeling of distortional hardening fully coupled with ductile damage under non-proportional loading paths. Int. J. Solids Struct. 144, 123–136 (2018)

Fassin, M., Eggersmann, R., Wulfinghoff, S., et al.: Efficient algorithmic incorporation of tension compression asymmetry into an anisotropic damage model. Comput. Methods Appl. Mech. Eng. 354, 932–962 (2019)

Lemaitre, J., Chaboche, J.-L.: Mech. Solid Mater. Cambridge University Press, Cambridge (1994)

Zhang, K., Badreddine, H., Saanouni, K.: Ductile fracture prediction using enhanced CDM model with Lode angle-dependency for titanium alloy Ti–Al–4V at room temperature. J. Mater. Process. Technol. 277, 116462 (2020)

Yue, Z.M., Badreddine, H., Saanouni, K., et al.: Experimental and numerical studies of AL7020 formability under orthogonal loading paths with considering yield surface distortion. Int. J. Mech. Sci. 123, 151–161 (2017)

Khan, A.S., Pandey, A., Gnäupel-Herold, T., et al.: Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int. J. Plast. 27(5), 688–706 (2011)

Acknowledgements

The first author appreciates the finical support from Fundamental Research Funds for the Central Universities (20CX06023A) and Qingdao Postdoctoral Applied Research Program (QD20190014). The second author acknowledges the financial support from Shandong Provincial Natural Science Foundation (ZR2019BEM012). Thanks are due to Prof. Z. Yue and Dr. S. Wang (SDU, China) for their help of performing the experiments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, K., Li, H. & Liu, J. Effect of yield surface distortion on the failure prediction of Mg alloy sheets. Arch Appl Mech 91, 151–167 (2021). https://doi.org/10.1007/s00419-020-01760-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00419-020-01760-w