Abstract

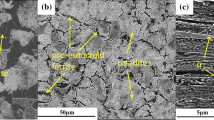

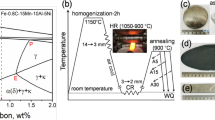

A comprehensive analysis and characterization of granular structure (GS) and granular bainite (GB) were conducted in a low-carbon alloy steel with the objective to elucidate the mechanisms that contributed to strength–ductility combination. Ferrite + martensite–austenite (M-A) islands were observed in both GS and GB, but a transformation mechanism produced a variation in the matrix and in the M-A size, distribution and morphology. The differences in the matrix and M-A islands were carefully studied by electron backscatter diffraction. Furthermore, tensile tests were interrupted at different strains to study the microstructure evolution during tensile straining and mechanical properties determined from samples tensile strained to fracture. It was observed that the specimen with GB exhibited higher tensile strength, ductility and strain hardening compared to GS. Dislocation strengthening of GB was more apparent than GS. The higher volume fraction and uniform distribution of M-A islands also contributed to the higher strength of GB. The improvement in ductility may partly be attributed to the sub-structural refinement. An increased presence of geometrically necessary dislocations array in GB also simultaneously enhanced strength and ductility. During deformation, GB exhibited a more uniform local strain distribution compared to GS because of superior plastic ability of M-A islands. Based on the experimental results and analysis, we propose models describing the different failure mechanism in GS and GB.

Similar content being viewed by others

References

L. Habraken, Proceedings of the Fourth International Conference on Electron Microscopy, Springer, Berlin, 1958.

L. Habraken, Bainitic Transformation of Steels, Rev. Metall., 1956, 53(12), p 930.

H.K.D.H. Bhadeshia, Bainite in Steels: Theory and Practice, CRC Press, 2019.

F. Hongsheng, B.A.I. Bingzhe, Z. Xiuhua et al., Morphology and Phase Transformation of Granular Bainite and Granular Structure, Acta Metall. Sin., 1986, 22(4), p 5–142.

M. Zhang and M. Kang, Strengthening-Toughening Mechanism of Granular Bainite and Granular Structure of Low-Carbon Low-Alloy Steel, Kang T’ieh/Iron Steel (Peking), 1993, 28(9), p 51–55.

Z.X. Qiao, Y.C. Liu, L.M. Yu et al., Formation Mechanism of Granular Bainite in a 30CrNi3MoV Steel, J. Alloy. Compd., 2009, 475(1–2), p 560–564.

F.S. Lepera, Improved Etching Technique for the Determination of Percent Martensite in High-Strength Dual-Phase Steels, Metallography, 1979, 12(3), p 263–268.

X. Luo, X. Chen, T. Wang et al., Effect of Morphologies of Martensite–Austenite Constituents on Impact Toughness in Intercritically Reheated Coarse-Grained Heat-Affected Zone of HSLA Steel, Mater. Sci. Eng. A, 2018, 710, p 192–199.

Y. Li and T.N. Baker, Effect of Morphology of Martensite–Austenite Phase on Fracture of Weld Heat Affected Zone in Vanadium and Niobium Microalloyed Steels, Mater. Sci. Technol., 2010, 26(9), p 1029–1040.

H. Bhadeshia, Martensite and Bainite in Steels: Transformation Mechanism & Mechanical Properties, J. Phys. IV, 1997, 7(C5), p C5-367-C5-376.

X. Li, A. Ramazani, U. Prahl et al., Quantification of Complex-Phase Steel Microstructure by Using Combined EBSD and EPMA Measurements, Mater. Charact., 2018, 142, p 179–186.

M. Calcagnotto, Y. Adachi, D. Ponge et al., Deformation and Fracture Mechanisms in Fine-and Ultrafine-Grained Ferrite/Martensite Dual-Phase Steels and the Effect of Aging, Acta Mater., 2011, 59(2), p 658–670.

J.M. Moyer and G.S. Ansell, The Volume Expansion Accompanying the Martensite Transformation in Iron-Carbon Alloys, Metall. Trans. A, 1975, 6(9), p 1785.

D.L. Bourell and A. Rizk, Influence of Martensite Transformation Strain on the Ductility of Dual-Phase Steels, Acta Metall., 1983, 31(4), p 609–617.

J. Kadkhodapour, A. Butz and S.Z. Rad, Mechanisms of Void Formation During Tensile Testing in a Commercial, Dual-Phase Steel, Acta Mater., 2011, 59(7), p 2575–2588.

N.K. Patel, M.G. Walunj and B.R. Kumar, Importance of Martensite Spatial Distribution at Large Volume Fractions in Imparting Ductility in High-Strength Dual-Phase Steel, J. Mater. Eng. Perform., 2019, 28(3), p 1391–1401.

C. Ren, W.J. Dan, Y.S. Xu et al., Strain-Hardening Model of Dual-Phase Steel With Geometrically Necessary Dislocations, J. Eng. Mater. Technol., 2018, 140(3), p 031009.

P. Shi, W. Ren, T. Zheng et al., Enhanced Strength–Ductility Synergy in Ultrafine-Grained Eutectic High-Entropy Alloys by inheriting microstructural lamellae, Nat. Commun., 2019, 10(1), p 1–8.

X. Wu, M. Yang, F. Yuan et al., Heterogeneous Lamella Structure Unites Ultrafine-Grain Strength With Coarse-Grain Ductility, Proc. Natl. Acad. Sci., 2015, 112(47), p 14501–14505.

Y. Liu, Y. Cao, Q. Mao et al., Critical Microstructures and Defects in Heterostructured Materials and Their Effects on Mechanical Properties, Acta Mater., 2020, 189, p 129–144.

N. Huda, Y. Wang, L. Li et al., Effect of Martensite-Austenite (MA) Distribution on Mechanical Properties of Inter-Critical Reheated Coarse Grain Heat Affected Zone in X80 linepipe steEl, Mater. Sci. Eng. A, 2019, 765, p 138301.

J. Lian, Z. Jiang and J. Liu, Theoretical Model for the Tensile Work Hardening Behaviour of Dual-Phase Steel, Mater. Sci. Eng. A, 1991, 147(1), p 55–65.

Acknowledgments

The authors at NEU acknowledge support from the National Key R&D Program of China (Grant No. 2016YFB0300701) and the National Natural Science Foundation of China (Grant No. 51674081). The authors at NEU are grateful to Professor R.D.K. Misra for his willingness to collaborate in this study and for meaningful discussion.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No conflict of interest exits in the submission of this manuscript, and manuscript is approved by all authors for publication. I would like to declare on behalf of my co-authors that the work described is original research and has not been published previously, and is not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, X.N., Tian, Y., Ye, Q.B. et al. The Significant Impact of the Characteristics of Granular Structure and Granular Bainite on the Mechanisms Contributing to Strength–Ductility Combination. J. of Materi Eng and Perform 30, 7479–7487 (2021). https://doi.org/10.1007/s11665-021-05887-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05887-x