Abstract

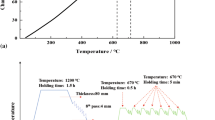

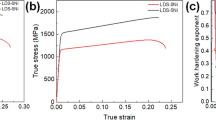

Low density steel is a future hope for automotive industries with high strength–ductility, concerning passenger safety. To investigate the microstructural contributions, an as-cast Fe–0.8C–15Mn–10Al–5Ni wt pct alloy is fabricated by hot rolling, cold rolling, and thereafter annealing at 900 °C. The phase constituents are austenite (γ) as the matrix, B2 as the second phase, and B2 stringer bands originating from heat-treated deformed δ-ferrite in this high-Al-alloyed steel. The work analyzes the effective contribution of intra-granular B2 to yield strength (YS) through precipitation strengthening. The strain-hardening mechanism is rather complex. One group believes that strain incompatibility between softer γ and hard B2 localizes geometrically necessary dislocations at the phase interface for high-strain hardening in this alloy by back stress; whereas, the other considers planar glide with a restricted cross-slip behind the strain-hardening mechanism. The present work successfully resolves the debate by stating that strain hardening is a matrix’s characteristic, dominated by lattice friction stress and dislocation strengthening. The lattice friction of solute-enriched γ-matrix reduces the width of dislocation core merely to an interplanar spacing. Thereby, a difficulty in dislocation movement during tensile deformation results in extraordinary strain hardening for this steel through a constrained planar glide. The static recrystallization and polygonization of heat-treated cold-rolled B2 stringer band induces intergranular micro-cracks, and thereafter its annihilation as a stress concentration site for tensile failure without necking.

Similar content being viewed by others

References

G.S. Cole and A.M. Sherman: Mater. Charact., 1995, vol. 35, pp. 3–9.

G. Frommeyer and U. Brüx: Steel Res. Int., 2006, vol. 77, pp. 627–33.

S. Chen, R. Rana, A. Haldar, and R.K. Ray: Prog. Mater Sci., 2017, vol. 89, pp. 345–91.

M. Sinha, S. Ahad, A.K. Chaudhry, and S. Ghosh: Metall. Mater. Trans. A., 2020, vol. 51A, pp. 809–17.

S.H. Kim, H. Kim, and N.J. Kim: Nature, 2015, vol. 518, pp. 77–79.

I. Gutierrez-Urrutia and D. Raabe: Mater. Sci. Technol., 2014, vol. 30, pp. 1099–1104.

B. Mishra, R. Sarkar, V. Singh, A. Mukhopadhyay, R.T. Mathew, V. Madhu, and M.J.N.V. Prasad: Materialia, 2021, vol. 20, 101198.

H. Kim: Scripta Mater., 2019, vol. 160, pp. 29–32.

G. Park, C.H. Nam, A. Zargaran, and N.J. Kim: Scripta Mater., 2019, vol. 165, pp. 68–72.

B. Laura and D.V. Aken: JOM, 2014, vol. 66, pp. 1770–84.

W. Korter and W. Ton: Arch. Eisenhuettenwes, 1933, vol. 365, p. 7.

J.L. Ham and J.R. Carin: Product. Eng., 1958, vol. 29, p. 51.

U. Prakash, R.A. Buckley, H. Jones, and C.M. Sellars: ISIJ Int., 1991, vol. 31, pp. 111–13.

I. Baker and P.R. Munroe: Int. Mater. Rev., 1997, vol. 42, pp. 181–205.

K. Choi, C.H. Seo, H. Lee, S.K. Kim, J.H. Kwak, K.G. Chin, K.T. Park, and N.J. Kim: Scripta Mater., 2010, vol. 63, pp. 1028–31.

Z.Q. Wu, H. Ding, X.H. An, D. Han, and X.Z. Liao: Mater. Sci. Eng. A, 2015, vol. 639, pp. 187–91.

M. Piston, L. Bartlett, K.R. Limmer, and D.M. Field: Metals, 2020, vol. 10, pp. 1–4.

A. Rahnama, H. Kotadia, and S. Sridhar: Acta Mater., 2017, vol. 132, pp. 627–43.

J.H. Hwang, T.T.T. Trang, O. Lee, G. Park, A. Zargaran, and N.J. Kim: Acta Mater., 2020, vol. 191, pp. 1–2.

A. Rahanama, H. Kotadia, S. Clark, V. Janik, and S. Sridhar: Nat. Sci. Rep., 2018, vol. 8, pp. 1–2.

M.X. Yang, F.P. Yuan, Q.G. Xie, Y.D. Wang, E. Ma, and X.L. Wu: Acta Mater., 2016, vol. 109, pp. 213–22.

B. Mishra, V. Singh, R. Sarkar, A. Mukhopadhyay, K. Gopinath, V. Madhu, and M.J.N.V. Prasad: Mater. Sci. Eng. A, 2022, vol. 842, 143095.

D. Tourret, M.M. Francois, and A.J. Clarke: Comput. Mater. Sci., 2019, vol. 162, pp. 206–27.

B.G. Zhang, X.M. Zhang, and H.T. Liu: Mater. Charact., 2021, vol. 178, 111291.

W. Gąsior, A. Dębski, and Z. Moser: Intermetallics, 2012, vol. 24, pp. 99–105.

C. Colinet, A. Bessoud, and A. Pasturel: J. Phys.: Condens. Matter, 1989, vol. 1, pp. 5837–45.

M.J. Yao, E. Welsch, D. Ponge, S.M.H. Haghighat, S. Sandlöbes, P. Choi, M. Herbig, I. Bleskov, T. Hickel, M. Lipinska-Chwalek, P. Shanthraj, C. Scheu, S. Zaefferer, B. Gault, and D. Raabe: Acta Mater., 2017, vol. 140, pp. 258–73.

D.A. Porter and K.E. Easterling: Phase Transformations in Metals and Alloys, Chapman & Hall, London, 1992.

G.E. Dieter: Mechanical Metallurgy, 3rd ed. Mc Graw-Hill, New York, 1986.

N. Bhowmik, S. Ghosh, S. Mandal, A. Haldar, and P.P. Chattopadhyay: CALPHAD, 2022, vol. 77, 102425.

X.G. Wang, C.H. Liu, B.B. He, C. Jiang, and M.X. Huang: Mater. Sci. Eng. A, 2019, vol. 761, 138050.

B. Sun, Y. Ma, N. Vanderesse, R.S. Varanasi, W. Song, P. Bocher, D. Ponge, and D. Raabe: Acta Mater., 2019, vol. 178, pp. 10–25.

S.D. Antolovich and R.W. Armstrong: Prog. Mater Sci., 2014, vol. 59, pp. 1–60.

B.C. De Cooman, Y. Estrin, and S. Kyu: Acta Mater., 2018, vol. 142, pp. 283–362.

K.M. Rahman, V.A. Vorontsov, and D. Dye: Acta Mater., 2015, vol. 89, pp. 247–57.

S. Hu, Z. Zheng, W. Yang, and H. Yang: Steel Res. Int., 2022, vol. 93, pp. 1–3.

E. Welsch, D. Ponge, S.M.H. Haghighat, S. Sandlöbes, P. Choi, M. Herbig, S. Zaefferer, and D. Raabe: Acta Mater., 2016, vol. 116, pp. 188–99.

I. Gutierrez-Urrutia and D. Raabe: Mater. Sci. Technol. (U.K.), 2014, vol. 30, pp. 1099–104.

P.P. Singh, S. Ghosh, and S. Mula: Mater. Sci. Eng. A, 2022, vol. 859, 144210.

B. Clausen, T. Lorentzen, and T. Leffers: Acta Mater., 1998, vol. 46, pp. 3087–98.

M. Sinha, B. Syed, A. Karmakar, and S. Ghosh: Mater. Sci. Eng. A, 2020, vol. 787, 139519.

M. Calcagnotto, D. Ponge, E. Demir, and D. Raabe: Mater. Sci. Eng. A, 2010, vol. 527, pp. 2738–46.

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, and J.E. Wittig: Acta Mater., 2015, vol. 100, pp. 178–90.

X.L. Liu, Q.Q. Xue, W. Wang, L.L. Zhou, P. Jiang, H.S. Ma, F.P. Yuan, Y.G. Wei, and X.L. Wu: Materialia, 2019, vol. 7, 100376.

O. Bouaziz, S. Allain, and C. Scott: Scripta Mater., 2008, vol. 58, pp. 484–87.

K. Tanaka and T. Mori: Acta Metall., 1970, vol. 18, pp. 931–41.

S. Sarkar, Y. Gao, S. Huang, S. Bhattacharya, S. Patil, and R. Oruganti: Crystals, 2020, vol. 10, p. 306.

Y.Y. Zhao and T.G. Nieh: Intermetallics, 2017, vol. 86, pp. 45–50.

W. Guo, W. Dmowski, J.Y. Noh, P. Rack, P.K. Liaw, and T. Egami: Metall. Mater. Trans. A., 2013, vol. 44A, pp. 1994–97.

C. Lee, Y. Chou, G. Kim, M.C. Gao, K. An, J. Brechtl, C. Zhang, W. Chen, J.D. Poplawsky, G. Song, Y. Ren, Y.C. Chou, and P.K. Liaw: Adv. Mater., 2020, vol. 32, pp. 1–9.

G.E. Nevill: Effect of vibrations on the yield strength of a low carbon steel, Master’s thesis, The RICE Institute, Houstan, TX, 1957.

D. Roylance: The dislocation basis of yield and creep, https://web.mit.edu/course/3/3.11/www/modules/dn.pdf.

G.B. Olson and M. Cohen: Metall. Trans. A, 1976, vol. 7A, pp. 1897–904.

A.K. Patra, C.N. Athreya, S. Mandal, K.C. Hari Kumar, and V. Subramanya Sarma: Mater. Sci. Eng. A, 2021, vol. 810, pp. 140756–57.

J. Nakano and P.J. Jacques: CALPHAD, 2010, vol. 34, pp. 167–75.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck: Metall. Mater. Trans. A, 2009, vol. 40, pp. 3076–90.

P.P. Singh, S. Mula, A. Malakar, and S. Ghosh: Mater. Today Commun., 2022, vol. 31, 103519.

M. Sinha, A. Karmakar, B. Syed, and S. Ghosh: Metall. Mater. Trans. A., 2020, vol. 51A, pp. 3435–46.

T. Imao, S. Hiroshi, T. Tomo, and O. Chiaki: Thermomechanical Processing of High-Strength Low-Alloy Steels, 1st ed. Butterworth, London, 1988.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D. Juul Jensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett: Mater. Sci. Eng. A, 1997, vol. 238, pp. 219–74.

Acknowledgments

The authors are indebted to G. K. Dey, B. Mishra, P. C. Chakraborti and P. P. Chattapadhyay for discussions. The Department of Science and Technology, Government of India is acknowledged for the financial support (File Number CRG/2018/002432).

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhan, S., Rawat, P., Das, S. et al. Origins of Strength, Strain Hardening, and Fracture in B2 Tailored Fe–0.8C–15Mn–10Al–5Ni Wt Pct Austenitic Low Density Steel. Metall Mater Trans A 54, 4080–4099 (2023). https://doi.org/10.1007/s11661-023-07155-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-023-07155-0