Abstract

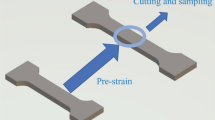

Tribocorrosion behaviors of typical austenitic (ASTM 316), martensitic (ASTM S41500), and ferritic (ASTM S44660) stainless steels were investigated in a 3.5% NaCl solution under cathodic protection conditions, and variations in the microstructures and chemical compositions of worn surfaces were further analyzed. The results showed that the friction coefficient and wear rate of austenitic steels were lower than those of ferritic and martensitic steels in 3.5% NaCl solution with cathodic protection. Additionally, the tribocorrosion properties of ferritic steels were obviously unaffected by load. Wear mechanisms of the three typical stainless steels mainly included abrasive wear at lower loads and plastic deformation at a higher loads. Furthermore, in austenitic steels, variations in microstructure and chemical composition confirmed that a higher load was beneficial to the transformation of austenite to martensite; thus, the hardness and wear resistance were improved. Compared with austenitic steels, the phase compositions of martensitic and ferritic steel were more stable during sliding, and the surface hardness of martensitic steel increased due to the surface phase and microstructure transformations induced by sliding. In addition, the total damage to steel was mainly caused by mechanical wear and the interaction between corrosion and wear. Therefore, ASTM S44660 and 316 were suitable for high-load corrosion-wear environments and low-load corrosion-wear environments, respectively, providing guidance for material selection under practical conditions.

Similar content being viewed by others

References

P.A. Dearnley and G. Aldrichsmith, Corrosion-wear Mechanisms of Hard Coated Austenitic 316L Stainless Steels Wear, 2004, 256, p 491-499.

Y. Sun and R. Bailey, Improvement in Tribocorrosion Behavior of 304 Stainless Steel by Surface Mechanical Attrition Treatment, Surface Coatings Technology., 2014, 253, p 284-291.

Y. Zhang, X. Yin, J. Wang and F. Yan, Influence of Microstructure Evolution on Tribocorrosion of 304SS in Artificial Seawater, Corros. Sci., 2014, 88, p 423-433.

J. Chen, J. Wang, F. Yan, Q. Zhang and Q. Li, Assessing the Corrosion-wear Behaviours of Hastelloy C276 Alloy in Seawater, Lubr. Sci., 2016, 28, p 67-80.

E. Haruman, Y. Sun and M.S. Adenan, A Comparative Study of the Tribocorrosion Behaviour of Low Temperature Nitrided Austenitic and Duplex Stainless Steels in NaCl Solution, Tribol. Int., 2020, 151, art. no. 106412. https://doi.org/10.1016/j.triboint.2020.106412.

X.F. Zhang, J. Wang, H.Y. Fan and D. Pan, Erosion-corrosion Resistance Properties of 316L Austenitic Stainless Steels After Low-temperature Liquid Nitriding, Appl. Surf. Sci., 2018, 440, p 755-762.

B. Zhang, J. Wang, Y. Zhang, G. Han and F. Yan, Comparison of Tribocorrosion Behavior Between 304 Austenitic and 410 Martensitic Stainless Steels in Artificial Seawater, RSC Adv., 2016, 6, p 107933-107941.

G. Han, P. Jiang, J. Wang and F. Yan, Effects of NaCl Concentration on Wear-corrosion Behavior of SAF 2507 Super Duplex Stainless Steel, RSC Adv., 2016, 6, p 111261-111268.

R.P. Gao, E.Y. Liu, Y. Zhang, L.F. Zhu and Z.X. Zeng, Tribocorrosion Behavior of SAF 2205 Duplex Stainless Steel in Artificial Seawater, J. Mater. Eng. Perform., 2019, 28, p 414-422.

Y. Sun and V. Rana, Tribocorrosion Behaviour of AISI 304 Stainless Steel in 0.5M NaCl Solution, Mater. Chem. Phys., 2011, 129, p 138-147.

E.Y. Liu, J.H. Zhang, S. Chen, S.M. Du, H.L. Du, H. Cai and L.L. Wang, High Temperature Negative Wear Behaviour of VN/Ag Composites Induced by Expansive Oxidation Reaction, Ceram. Int., 2021, 47, p 15901-15909.

P. Henry, J. Takadoum and P. Bercot, Depassivation of Some Metals by Sliding Friction, Corros. Sci., 2011, 53, p 320-328.

A. Iwabuchi, T. Sonoda, H. Yashiro and T. Shimizu, Application of Potential Pulse Method to the Corrosion Behavior of the Fresh Surface Formed by Scratching and Sliding in Corrosive Wear, Wear, 1999, 225, p 181-189.

Y. Kayali, A. Büyüksagis, and Y. Yalçin, Corrosion and Wear Behaviors of Boronized AISI 316L Stainless Steel, Metal. Mater. Int., 2013, 19, p 1053-1061.

E.Y. Liu, Y.X. Zhang, L.F. Zhu, Z.X. Zeng and R.P. Gao, Effect of Strain-induced Martensite on the Tribocorrosion of AISI 316L Austenitic Stainless Steel in Seawater, RSC Adv., 2017, 7, p 44923-44932.

R. Pan, R. Ren, X. Zhao and C. Chen, Influence of Microstructure Evolution During the Sliding Wear of CL65 Steel, Wear, 2018, 400-401, p 169-176.

Q. Gao, S.X. Li and Y.S. Su, Investigation on Formation Mechanism of Nano-gradient Structure in Dry Sliding Wear of Martensite Steel, J. Tribol., 2019, 39, p 32-39.

V. Huang, V. Vivier, M.E. Orazem, N. Pébère and B. Tribollet, The Apparent Constant-phase-element Behavior of an Ideally Polarized Blocking Electrode: A Global and Local Impedance Analysis, J. Electrochem. Soc., 2007, 154, p 81-88.

Y. Han and Y. Chen,Electrochemistry Corrosion Behaviors of 316L Stainless Steel in Different Electric Conductivity Seawaters and NaCl Solutions, Material guide., 2012, 26, p 57-60.

S.W. Watson, F.J. Friedersdorf, B.W. Madsen and S.D. Cramer, Methods of Measuring Wear-corrosion Synergism, Wear, 1995, 181-183, p 476-484.

Z. Yu, M.H. Chen, F.J. Li, S.L. Zhu and F.H. Wang, Synergistic Effect of Corrosion and Wear of the 316 Stainless Steel in Molten Zinc Alloy at 460 °C, Corros. Sci., 2020, 165, art. no. 108411. https://doi.org/10.1016/j.corsci.2019.108411.

M. Hua, X.C. Wei and J. Li, Friction and Wear Behavior of SUS 304 Austenitic Stainless Steel Against Al2O3 Ceramic Ball Under Relative High Load, Wear, 2008, 265, p 799-810.

Q.S. Luo, J.B. Li, Q.T. Yan, W.B. Li, Y.B. Gao, M. Kitchen, L. Bowen, N. Farmilo and Y.T. Ding, Sliding Wear of Medium-carbon Bainitic/martensitic/austenitic Steel Treated by Short-term Low-temperature Austempering, Wear., 2021, art. no. 203732. https://doi.org/10.1016/j.wear.2021.203732.

K. Yang, H.Y. Gou, B. Zhang, R. Huang, H. Li, M.M. Lu, X.Y. Zhang and J.W. Zhang, Microstructures and Fracture Features of Cold-rolled Low Carbon Steel Sheet After Annealing and Mechanical Stress Concurrently Loaded, Materials Science and Engineering A-structural Materials Properties Microstructure and Processing., 2009, 502, p 126-130.

R. Ueji, N. Tsuji, Y. Minamino and Y. Koizumi, Ultragrain Refinement of Plain Low Carbon Steel by Cold-rolling and Annealing of Martensite, Acta Mater., 2002, 50, p 4177-4189.

Y.Y. Chen, J.Q. Sun, Q.K. He, F. Ma, Y.J. Cao, X. Gao, S.T. Zhang and K. Xie, Improvement in Dry-sliding Wear Properties and Corrosion Resistance of AISI 304 Steel with Low Temperature Gaseous Nitriding, International Journal of Materials Engineering Innovation., 2018, 9, p 218.

Acknowledgments

The authors acknowledge the financial supports by the Shaanxi Provincial Key Research and Development Program (Grant Nos. 2021SF-469 & 2020GY-115), National Natural Science Foundation of China (Grant No. 51705415) and Foundation of Key Laboratory of Marine Materials and Related Technologies, CAS (Grant No. 2018K01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, Z., Liu, E., Du, S. et al. Tribocorrosion Behavior of Typical Austenitic, Martensitic, and Ferritic Stainless Steels in 3.5% NaCl Solution. J. of Materi Eng and Perform 30, 6284–6296 (2021). https://doi.org/10.1007/s11665-021-05846-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05846-6