Abstract

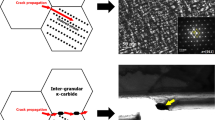

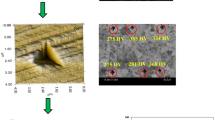

In order to elucidate the relationship between red hardness/toughness and tungsten content, strong carbide-forming element tungsten was added to a 5 wt.% Cr medium carbon steel (Cr5) in melting. After normalization and forging, the vacuum gas-quenched experimental steels were tempered at 560 and 600 °C for 10-40 h, respectively. Rockwell hardness and un-notched impact energy were evaluated. It was revealed that the precipitation phases play a critical role in the mechanical properties of the steels. The tungsten element effectively improved the red hardness of the steel by 6.3-15.8% when tempering at 600 °C for 10-40 h, while the corresponding impact toughness holds at the same level, about 250J, as Cr5 steel. Through observations by scanning electron microscopy (SEM) and transmission electron microscopy (TEM), mesoscales carbides were found with a structure of (Fe, Cr, W, Mo, V)6C. It was deduced that tungsten element acts a positive role in inhibiting the coarseness of secondary M6C-type carbides and impeding the formation of M23C6 and M7C3, and thus enhances the thermal stability of Cr5W steel at elevated temperature. Furthermore, the tempering stability prediction model was constructed to predict the red hardness of tungsten-containing Cr5W steel.

Similar content being viewed by others

References

Q.C. Jiang, X.M. Zhao, F. Qiu, T.N. Ma and Q.L. Zhao, The Relationship Between Oxidation and Thermal Fatigue of Martensitic Hot-Work Die Steels, Acta Metall. Sin., 2018, 31(07), p 1–7.

M. Umino, T. Sera, K. Kondo, Y. Okada and H. Tubakino, Effect of Silicon Content on Tempered Hardness, High Temperature Strength and Toughness of Hot Working Tool Steels, Tetsu to Hagane, 2003, 89(6), p 673–679.

D. Delagnes, P. Lamesle, M.H. Mathon, N. Mebarki and C. Levaillant, Influence of Silicon Content on the Precipitation of Secondary Carbides and Fatigue Properties of a 5%Cr Tempered Martensitic Steel, Mater. Sci. Eng. A, 2005, 394(1–2), p 435–444.

M. Zhang, S. Xing, Q. Xin, L. Xiao and J. Gou, Abnormal Failure Analysis of H13 Punches in Steel Squeeze Casting Process, J. Iron Steel Res. Int., 2008, 15(3), p 47–51.

M. Tolcha, H. Altenbach and G. Tibba, Modeling Fatigue Crack and Spalling for Rolling Die Under Hot Milling, Fatigue. Fract. Eng. M., 2019, 42(12), p 2611–2624.

Q. Xiang, Effect of Alloying Elements on Tempering Resistance of Hot-Work Die Steel, Heat Treat., 2018, 33(01), p 21–23. (in Chinese)

J. Zhou, D.S. Ma, H.X. Chi, Z.Z. Chen and X.Y. Li, Microstructure and Properties of Hot Working Die Steel H13MOD, Iron Steel Res. Int., 2013, 09, p 120–128.

E.A. Smol’nikov and L.M. Orestova, Red Hardness of High-Speed Steels, Met. Sci. Heat Treat., 1975, 17(6), p 467–470.

T.S. Li, F.M. Wang, C.R. Li, G.Q. Zhang and Q.Y. Meng, Carbide Evolution in High Molybdenum Nb-Microalloyed H13 Steel during Annealing Process, J. Iron Steel Res. Int., 2015, 022(4), p 330–336.

J.Z. Lu, J. Cao, H.F. Lu, L.Y. Zhang and K.Y. Luo, Wear Properties and Microstructural Analyses of Fe-Based Coatings with Various WC Contents on H13 Die Steel by Laser Cladding, Surf. Coat. Tech., 2019, 369, p 228–237.

R.A. Mesquita, C.A. Barbosa, E.V. Morales and H.J. Kestenbach, Effect of Silicon on Carbide Precipitation after Tempering of H11 Hot Work Steels, Metall. Trans. A, 2011, 42(2), p 461–472.

Q. Zhou, X. Wu, N. Shi, J. Li and N. Min, Microstructure Evolution and Kinetic Analysis of DM Hot-Work Die Steels During Tempering, Mater. Sci. Eng. A, 2011, 528(18), p 5696–5700.

Y.J. Shi, X.C. Wu, J.W. Li and M. Na, Tempering stability of Fe-Cr-Mo-W-V Hot Forging Die Steels, Int. J Min. Met. Mater., 2017, 10, p 73–85.

H.F. Fischmeister, S. Karagöz and H.O. Andrén, Acta, An Atom Probe Study of Secondary Hardening in High Speed Steels, Metall Sin-Engl., 1988, 36(4), p 817–825.

A. Mazilkin, M.M. Abramova, N.A. Enikeev, I.V. Lomakin, R.Z. Valiev, Yu. Ivanisenko, C. Kübel, A. Etienne, X. Sauvage and B. Radiguet, The Effect of Tungsten on Microstructure and MECHANICAL PERFORMANCE of an ultrafine Fe-Cr Steel, Mater. Lett., 2018, 227, p 292–295.

C.Y. Zhu, N.N. Shi, P.P. Zuo, N. Min and X.C. Wu, Effect of Mn and W on Thermal Stability of 4Cr2Mo2W2V Die Steel, Trans. Mater. Heat Treat, 2014, 35, p 66–69. (in Chinese)

A. Inoue and T. Masumoto, Carbide reactions (M3C→M7C3→M23C6→M6C) During Tempering of Rapidly Solidified High Carbon Cr-W and Cr-Mo Steels, Metall Trans A, 1980, 11(5), p 739–747.

D. Kaiser, J. Damon, F. Mühl, B. de Graaff, D. Kiefer, S. Dietrich and V. Schulze, Experimental Investigation and Finite-Element Modeling of the Short-Time Induction Quench-and-Temper Process of AISI 4140, J. Mater. Proc. Tech., 2020, 279, p 116458.

Y. Kryzhanivskyy, L. Poberezhny, P. Maruschak, M. Lyakh, V. Slobodyan and V. Zapukhliak, Influence of Test Temperature on Impact Toughness of X70 Pipe Steel Welds, Proc Struct Integr, 2019, 16, p 237–244.

J.H. Hollomon and L.D. Jaffe, Time-Temperature Relations in Tempering Steel, Trans AIME., 1945, 162, p 223.

N. Fujita and H.K.D.H. Bhadeshia, Modelling Simultaneous Alloy Carbide Sequence in Power Plant Steels: Transformations and Microstructures, ISIJ Int, 2002, 42(7), p 760–769.

E. Virtanen, C.J. Van Tyne, B.S. Levy and G. Brada, The tempering parameter for evaluating softening of hot and warm forging die steels, J. Mater. Process. Tech., 2013, 213(8), p 1364–1369.

C. Gomes, A.L. Kaiser, J.P. Bas, A. Aissaoui and M. Piette, Predicting the Mechanical Properties of a Quenched and Tempered Steel Thanks to a “Tempering Parameter,” Revue de Métallurgie, 2012, 107(7–8), p 293–302.

E. Nelson, A. Kohli and D.R. Poirier, Hardness of H13 Tool Steel After Non-isothermal Tempering, J Mater. Eng. Perform., 2018, 27(6), p 2766–2771.

B. Hutchinson, J. Hagstrom, O. Karlsson, D. Lindell, M. Tornberg, F. Lindberg and M. Thuvander, Microstructures and Hardness of As-Quenched Martensites (0.1–0.5%C), Acta. Mater., 2011, 59(14), p 5845–5858.

G. Krauss, Solidification, Segregation, and Banding in Carbon and Alloy Steels, Metall. Mater. Trans. B, 2003, 34(6), p 781–792.

W. Yan, S.Y. Gao, Q.A. Tai, H. Guan, Y.H. Li and X.B. Ding, Microstructure and Mechanical Properties of 4Cr5W2VSi Mold Steel, Heat Treat. Met., 2017, 42(03), p 113–119. (in Chinese)

G.F. Sun, K. Wang, R. Zhou, Z.P. Tong and X.Y. Fang, Effect of ANNEALING on Microstructure and Mechanical Properties of Laser deposited Co-285+WC Coatings, Opt. Laser Technol., 2015, 66, p 98–105.

Y.J. Zhao, X.P. Ren, Z.L. Hu, Z.P. Xiong, J.M. Zeng and B.Y. Hou, Effect of Tempering on Microstructure and Mechanical Properties of 3Mn-Si-Ni Martensitic Steel, Mater. Sci. Eng. A, 2018, 711, p 397–404.

G. Krauss, Tempering of Martensite, Encyclopedia of Materials: Science and Technology, 2nd ed. Pergamon Press Ltd., Oxford, 2001, p 9093–9097

L.Q. Xu, D.T. Zhang, Y.C. Liu, B.Q. Ning, Z.X. Qiao, Z.S. Yan and H.J. Li, Precipitation Behavior and Martensite Lath Coarsening During Tempering of T/P92 Ferritic Heat-Resistant Steel, Int. J. Min. Met. Mater., 2014, 21(5), p 438–447.

C. Rikio, T. Hiroshi, Y. Yuzuru, F. Kazuo and U. Ryuji, Development of Fire-Resistant Steel for Building Construction, Shinnittetsu Giho, 1993, 32(6), p 432–434.

P. Michaud, D. Delagnes, P. Lamesle, M.H. Mathon and C. Levaillant, The Effect of the Addition of Alloying Elements on Carbide Precipitation and Mechanical Properties in 5% Chromium Martensitic Steels, Acta Mater., 2017, 55(14), p 4877–4889.

K.S. Chandravathi, K. Laha, C.S. Sasmal, P. Parameswaran, M. Nandagopal, H.M. Tailor, M.D. Mathew, T. Jayakumar and E.R. Kumar, Response of Phase Transformation Inducing Heat Treatments on Microstructure and Mechanical Properties of Reduced Activation Ferritic-Martensitic Steels of Varying Tungsten Contents, Metall. Trans. A, 2014, 45(10), p 4280–4292.

S. Li, X.C. Wu, X.X. Li and X.J. He, High Temperature Performance of a Mo-W Type Hot Work Die Steel of High Thermal Conductivity, Chin. J. Mater. Res., 2017, 31(01), p 32–40. (in Chinese)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiang, S., Wu, R., Li, W. et al. Improved Red Hardness and Toughness of Hot Work Die Steel through Tungsten Alloying. J. of Materi Eng and Perform 30, 6146–6159 (2021). https://doi.org/10.1007/s11665-021-05793-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05793-2