Abstract

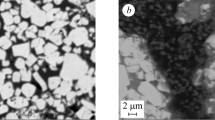

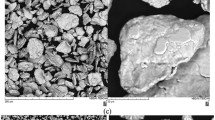

Wear-resistant cobalt-based alloys generally contain high chromium content so that the carbides in these alloys are mainly Cr-rich except the alloys which contain very high tungsten content. In this research an abnormal cobalt-based with very low chromium but very high tungsten content is created, in order to avoid Cr-rich carbide precipitation. The focus of the research is to investigate the effect of chromium and tungsten contents on the formation of carbides in cobalt-based alloys. Furthermore, the influence of heat treatment on the microstructure change of the new alloy is studied by aging the alloy at a temperature of 900 °C for 24 hours or at 980 °C for 350 hours. It is found that the heat treatments can cause dissolution of W-rich carbides and promote graphite separation from the carbides in the new alloy. The dry-sliding wear tests show that the presence of graphite improves the tribological properties of the new alloy due to reduction in friction. Aging time has influence on the dissolution of the carbides in the new alloy, thus affecting the amount of graphite precipitation during the heat treatment. Stellite 80, having the same carbon content but different chromium and tungsten contents with the new alloy, is studied in parallel for comparison.

Similar content being viewed by others

References

R. Liu, and M.X. Yao, High-Temperature Wear/Corrosion Resistant Stellite Alloys and Tribaloy Alloys, CRC Handbook on Aerospace and Aeronautical Materials, CRC Press, Taylor & Francis, 2012, p. 151–235

J.R. Davis, Cobalt-Base Alloys, Nickel, Cobalt, and Their Alloys, ASM International, Materials Park, 2000, p 362–406

R. Collier, R. Liu, X.J. Wu, X.Z. Zhang and M.X. Yao, Dry-Sliding Wear Performance of Molybdenum-Containing Stellite Alloys, Wear, 2020, 29, p 1384–1399.

K. Kamal, Y.P. Ding, R. Liu, J.H. Yao and M.X. Yao, Corrosion Performance of 700 Series Stellite Alloys in Various Media, J. Mater. Eng. Perform., 2019, 28(9), p 5605–5615.

Y. Li, R. Liu, G. McRae and M.X. Yao, Corrosion Performance of Valve Seat Hardfacing Materials in Amine Environment of Boiler Feed Water Service, Protect. Met. Phys. Chem. Surf., 2019, 55(2), p 377–388.

A. Nair and A. Khan, Studies on Effect of Laser Processed Stellite 6 Material and its Electrochemical Behavior, Optik, 2020, 220, p 165221.

C. Wang, K. Luo, X. Bu, Y. Su and J. Cai, Laser shock peening-induced surface gradient stress distribution and extension mechanism in corrosion fatigue life of AISI 420 stainless steel, Corros. Sci., 2020, 177, p 109027.

J. Lu, H. Lu, X. Xu, J. Yao, J. Cai and K. Luo, High-performance integrated additive manufacturing with laser shock peening–induced microstructural evolution and improvement in mechanical properties of Ti6Al4V alloy components, Int. J. Mach. Tools Manuf., 2020, 148, p 103475.

S. Nsoesie, R. Liu, K.Y. Chen and M.X. Yao, Erosion Resistance of Stellite Alloys under Solid-Particle Impact, J. Mater. Sci. Eng. B, 2013, 3(9), p 555–566.

S. Kapoor, R. Liu, X.J. Wu and M.X. Yao, Microstructure and Wear Resistance Relations of Stellite alloys, Inter. J. Adv. Mater. Sci., 2013, 4(3), p 231–248.

J.H. Yao, Y.P. Ding, R. Liu, Q.L. Zhang and L. Wang, Wear and Corrosion Performance of Laser-Clad Low-Carbon High Molybdenum Stellite Alloys, Opt. Laser Technol., 2018, 107, p 32–45.

B.A. Boeck, T.H. Sanders Jr., V. Anand, A.J. Hickl and P. Kumar, Relationships Between Processing, Microstructure, and Tensile Properties of a Co-Cr-Mo Alloy, Powd. Metall., 1985, 28(2), p 1–10.

W.H. Jiang, X.D. Yao and Z.Q. Hu, Secondary M6C Precipitation in a Cobalt-Base Superalloy, J. Mater. Sci. Lett., 1999, 18(4), p 303–305.

R. Ahmed and H.L. De Villiers Lovelock, Friction and Wear of Cobalt-Base Alloys, Frict. Lubr. Wear Technol., 2017, 18, p 487–501.

E. Lassner and W.D. Schubert, The Element Tungsten, Tungsten: Properties, Chemistry, Technology of the Element, Alloys, and Chemical Compounds, Kluwer Academic/Plenum Publishers, New York, 1999, p 1–59

S.H.M. Anijdan, A. Bahrami, N. Varahram and P. Davami, Effects of Tungsten on Erosion-Corrosion Behavior of High Chromium White Cast Iron, Mater. Sci. Eng. A, 2007, 454–455, p 623–628.

R. Liu, X.J. Wu, S. Kapoor, M.X. Yao and R. Collier, Effects of Temperature on the Hardness and Wear Resistance of High-Tungsten Stellite Alloys, Metall. Mater. Trans. A, 2015, 46(2), p 587–599.

R. Liu, J.H. Yao, Q.L. Zhang, M.X. Yao and R. Collier, Sliding Wear and Solid-Particle Erosion Resistance of a Novel High-Tungsten Stellite Alloy, Wear, 2015, 322–323, p 41–50.

F. Abe, Effect of Boron on Microstructure and Creep Strength of Advanced Ferritic Power Plant Steels, Procedia Eng., 2011, 10, p 94–99.

W.Y. Ning, N. Muhamad, A.B. Sulong, A. Fayyaz and M.R. Raza, Effects of Vanadium Carbide on Sintered WC-10%Co Produced by Micro-Powder Injection Molding, Sains Malaysiana, 2015, 44(8), p 1175–1181.

ASTM G 99–17, Standard Test Method for Wear Testing with a Pin-on-Disc Apparatus, American Society for Testing and Materials, West Conshohocken, Pennsylvania, 2017

R. Liu, M.X. Yao, P.C. Patnaik and X.J. Wu, Effects of Heat Treatment on Mechanical and Tribological Properties of Laves Intermetallic Cobalt-Based Alloys, J. Mater. Eng. Perform., 2005, 14(5), p 634–640.

P. Huang, R. Liu, X.J. Wu and M.X. Yao, Effects of Molybdenum Content and Heat Treatment on Mechanical and Tribological Properties of a Low-Carbon Stellite Alloy, J. Eng. Mater. Technol., 2007, 129(4), p 523–529.

K. Jiang, R. Liu, K.Y. Chen and M. Liang, Microstructure and Tribological Properties of Solution-Treated Tribaloy Alloy, Wear, 2013, 307, p 22–27.

K. Rajan, Thermodynamics Assessment of Heat Treatments for a Co-Cr-Mo Alloy, J. Mater. Sci., 1983, 18, p 257–264.

E.L. Furman, E.A. Usoltsev, I.S. Bakhteev, I.E. Furman and A.V. Shak, Effect of Laser Heat Treatment on Structure and Wear Resistance of Cobalt Stellite, J. Phys. Conf. Ser., 2019, 1396(1), p 012016.

W.D. Callister Jr. and D.G. Rethwisch, The Structure of Crystalline Solids, Materials Science and Engineering—An Introduction, Wiley, New York, 2010, p 48–91

D. Coutsouradis, A. Davin and M. Lamberigts, Cobalt-Based Superalloys for Applications in Gas Turbines, Mater. Sci. Eng., 1987, 88, p 11–19.

H. Sueyoshi, K. Suenaga and R. Tanaka, Graphite Precipitation from Austenite in Hypo-Eutectoid Steel, J. Japan Inst. Met., 1985, 49(1), p 20–25.

I.V. Mikhailova, S.I. Rudyuk and A.I. Savon, Effect of Alloying Elements on the Structure of Cast Hypereutectoid Steels after Heat Treatment, Met. Sci. Heat Treat., 1987, 29(7–8), p 634–637.

L. Pang and K.S. Kumar, Effect of Heat Treatment on the Microstructure of an Fe-40Al-0.7C-0.5B Alloy, Mater. Sci. Eng. A, 1998, 258(1–2), p 161–166.

V.I. Bidash and A.I. Prikhodko, Graphitization of Low-Carbon Steel During a Spheroidizing Anneal, Met. Sci. Heat Treat., 1987, 29(1–2), p 116–119.

T. Sunil, M. Sandeep, R. Kumaraswami and A. Shravan, A Critical Review on Solid Lubricants, Inter. J. Mech. Eng. Technol., 2016, 7(5), p 193–199.

Acknowledgments

The authors are grateful for financial support from the Key R&D Program of Zhejiang Province, China (Grant No. 2019C04004), the Natural Science & Engineering Research Council of Canada (NSERC), financial and in-kind support of Kennametal Stellite Inc., as well as the financial support from the China Scholarship Council and the Cultivation Fund of Zhejiang University of Technology for Excellent Doctoral Dissertation. Mr. Jiajin Sheng and Chenggan Xue also contributed to the experiments of this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ding, Y., Liu, R., Zhang, X. et al. Study of Carbide Precipitation in Two Cobalt-Based Alloys with Distinct Chromium and Tungsten Contents. J. of Materi Eng and Perform 30, 5962–5973 (2021). https://doi.org/10.1007/s11665-021-05786-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05786-1