Abstract

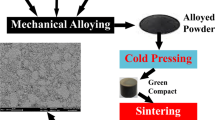

In the current study, the effect of Mo content (1-10 wt.%) on the microstructure, hardness, bending and wear properties of Ti6Al4V-xMo alloys was investigated. The pre-alloyed and Plasma Rotating Electrode Process (PREP) atomized Ti6Al4V alloy powders and elemental Mo particles were mechanically mixed for 45 min in a zirconia jar. A uniaxial vacuum hot pressing was applied at 950°C for 30 min under 50 MPa pressure. The Ti6Al4V-xMo alloys were prepared metallographically and characterized by optical and scanning electron microscopy. The chemical composition of the different zones in the structure was determined using energy-dispersive x-ray (EDX) analysis. Mo appeared among the TiAl64V alloy particles and caused the formation of different diffusion zones. The formation of grain boundary α was effectively prevented, and instead, fine α’ and β zones were formed. Various phases formed along the particle boundaries of the Ti6Al4V alloy, and effective improvements in hardness, bending and wear resistance were obtained. However, the highest Mo content caused a decrease in mechanical properties. Ti6Al4V-5Mo alloy showed superior hardness and wear resistance.

Similar content being viewed by others

References

D. Zhou, W. Zeng, J. Xu, S. Wang and W. Chen, Evolution of equiaxed and lamellar α during hot compression in a near alpha titanium alloy with bimodal microstructure, Mater. Charact., 2019, 151, p 103–111.

I. Ansarian, M.H. Shaeri, M. Ebrahimi, P. Minárik and K. Bartha, Microstructure evolution and mechanical behaviour of severely deformed pure titanium through multi directional forging, J. Alloy. Compd., 2019, 776, p 83–95.

X.J. Tian, S.Q. Zhang, A. Li and H.M. Wang, Effect of annealing temperature on the notch impact toughness of a laser melting deposited titanium alloy Ti–4Al–1.5Mn, Mater. Sci. Eng. A, 2010, 527, p 1821–1827.

C. Martínez, C. Guerra, D. Silva, M. Cubillos, F. Briones, L. Muñoz, M.A. Páez, C. Aguilar and M. Sancy, Effect of porosity on mechanical and electrochemical properties of Ti–6Al–4V alloy, Electrochim. Acta, 2020, 338, art. no. 135858.

W. Chen, C. Li, X. Zhang, C. Chen, Y.C. Lin and K. Zhou, Deformation-induced variations in microstructure evolution and mechanical properties of bi-modal Ti-55511 titanium alloy, J. Alloy. Compd., 2019, 783, p 709–717.

R. Yamanoglu, N. Gulsoy, E.A. Olevsky and H.O. Gulsoy, Production of porous Ti5Al2.5Fe alloy via pressureless spark plasma sintering, J. Alloys Compd., 2016, 680, p 654–658.

R. Yamanoglu, I. Daoud and E.A. Olevsky, Spark plasma sintering versus hot pressing—densification, bending strength, microstructure, and tribological properties of Ti5Al2.5Fe alloys, Powder Metall., 2018, 61(2), p 178–186.

B. Pazhanivel, P. Sathiya and G. Sozhan, Ultra-fine bimodal (α + β) microstructure induced mechanical strength and corrosion resistance of Ti-6Al-4V alloy produced via laser powder bed fusion process, Optics Laser Technol, 2020, 125, art. no. 106017

J. Zhang, X. Li, D. Xu and R. Yang, Recent progress in the simulation of microstructure evolution in titanium alloys, Prog. Natural Sci. Mater. Int., 2019, 29(3), p 295–304.

K. Tesař, V. Gärtnerová, M. Němec and A. Jäger, Fe-stabilized duplex α/β microstructure containing γ titanium hydride in Ti grade 2 obtained by volumetrically incomplete phase transition, Mater. Charact., 2019, 153, p 128–135.

P.L. Narayana, S. Lee, S.-W. Choi, C.-L. Li, C.H. Park, J.-T. Yeom, N.S. Reddy and J.-K. Hong, Microstructural response of β-stabilized Ti–6Al–4V manufactured by direct energy deposition, J. Alloys Compd., 2019, 811, art. no. 152021

J. Gou, Z. Wang, S. Hu, J. Shen, Y. Tian, G. Zhao and Y. Chen, Effects of trace Nb addition on microstructure and properties of Ti–6Al–4V thin-wall structure prepared via cold metal transfer additive manufacturing, J. Alloys Compd., 2020, 829, art. no. 154481

Z. Lei, P. Gao, H. Li, Y. Cai and M. Zhan, On the fracture behavior and toughness of TA15 titanium alloy with tri-modal microstructure, Mater. Sci. Eng., A, 2019, 753, p 238–246.

N.T.C. Oliveira, G. Aleixo, R. Caram and A.C. Guastaldi, Development of Ti–Mo alloys for biomedical applications: microstructure and electrochemical characterization, Mater. Sci. Eng., A, 2007, 452–453, p 727–731.

E. Delvat, D.M. Gordin, T. Gloriant, J.L. Duval and M.D. Nagel, Microstructure, mechanical properties and cytocompatibility of stable beta Ti-Mo-Ta sintered alloys, J. Mech. Behav. Biomed. Mater., 2008, 1(4), p 345–351.

D.R.N. Correa, P.A.B. Kuroda and C.R. Grandini, Structure, microstructure, and selected mechanical properties of Ti-Zr-Mo alloys for biomedical applications, Adv. Mater. Res., 2014, 922, p 75–80.

A. Kaouka, K. Benarous, A. Daas and S.A. Tsipas, The effects of Nb and Mo addition on microstructure and mechanical behaviour of Ti-6Al-4V alloy, J. Surf. Sci. Technol., 2017, 33(1–2), p 53–62.

B. Song, W. Xiao, C. Ma and L. Zhou, Influence of phase transformation kinetics on the microstructure and mechanical properties of near β titanium alloy, Mater. Charact., 2019, 148, p 224–232.

J. Fan, J. Li, H. Kou, K. Hua, B. Tang and Y. Zhang, Influence of solution treatment on microstructure and mechanical properties of a near β titanium alloy Ti-7333, Mater. Des., 2015, 83, p 499–507.

L. Bolzoni, I.M. Meléndez, E.M. Ruiz-Navas and E. Gordo, Microstructural evolution and mechanical properties of the Ti–6Al–4V alloy produced by vacuum hot-pressing, Mater. Sci. Eng., A, 2012, 546, p 189–197.

R. Yamanoglu, E. Efendi, F. Kolayli, H. Uzuner and I. Daoud, Production and mechanical properties of Ti-5Al-2.5Fe-xCu alloys for biomedical applications, Biome. Mater., 2018, 13(2), art. no. 025013

R. Yamanoglu, R.M. German, S. Karagoz, W.L. Bradbury, M. Zeren, W. Li and E.A. Olevsky, Microstructural investigation of as cast and PREP atomised Ti–6Al–4V alloy, Powder Metall., 2013, 54(5), p 604–607.

I. Yadroitsava, S. Grewar, D. Hattingh and I. Yadroitsev, Residual Stress in SLM Ti6Al4V Alloy Specimens, Mater. Sci. Forum, 2015, 828–829, p 305–310.

H.K. Rafi, N.V. Karthik, H. Gong, T.L. Starr and B.E. Stucker, Microstructures and mechanical properties of Ti6Al4V Parts fabricated by selective laser melting and electron beam melting, J. Mater. Eng. Perform., 2013, 22(12), p 3872–3883.

L.E. Murr, S.M. Gaytan, D.A. Ramirez, E. Martinez, J. Hernandez, K.N. Amato, P.W. Shindo, F.R. Medina and R.B. Wicker, Metal fabrication by additive manufacturing using laser and electron beam melting technologies, J. Mater. Sci. Technol., 2012, 28(1), p 1–14.

N. Kazantseva, P. Krakhmalev, M. Thuvander, I. Yadroitsev, N. Vinogradova and I. Ezhov, Martensitic transformations in Ti-6Al-4V (ELI) alloy manufactured by 3D Printing, Mater. Charact., 2018, 146, p 101–112.

Z. Tarzimoghadam, S. Sandlöbes, K.G. Pradeep and D. Raabe, Microstructure design and mechanical properties in a near-α Ti–4Mo alloy, Acta Mater., 2015, 97, p 291–304.

M. Yan and P. Yu, An Overview of Densification, Microstructure and Mechanical Property of Additively Manufactured Ti-6Al-4V—Comparison among Selective Laser Melting, Electron Beam Melting, Laser Metal Deposition and Selective Laser Sintering, and with Conventional Powder, Sintering Techniques of Materials, 2015. https://doi.org/10.5772/59275

W.-D. Zhang, Y. Liu, H. Wu, M. Song, T.-Y. Zhang, X.-D. Lan and T.-H. Yao, Elastic modulus of phases in Ti–Mo alloys, Mater. Charact., 2015, 106, p 302–307.

F.X. Xie, X.B. He, S.L. Cao, X. Lu and X.H. Qu, Structural characterization and electrochemical behavior of a laser-sintered porous Ti–10Mo alloy, Corros. Sci., 2013, 67, p 217–224.

L. Jia, X. Chang-qing and G. Yi, Effect of temperature on microstructure of molybdenum coating on titanium substrate, J. Cent. South. Unıv. Technol., 2004, 11(1), p 15–18.

T. Aoki, I.C.I. Okafor, I. Watanabe, M. Hattori, Y. Oda and T. Okabe, Mechanical properties of cast Ti-6Al4-4V-xCu alloys, J. Oral Rehailit., 2004, 31, p 1109–1114.

B. Vrancken, L. Thijs, J.-P. Kruth and J. Van Humbeeck, Heat treatment of Ti6Al4V produced by selective laser melting: Microstructure and mechanical properties, J. Alloy. Compd., 2012, 541, p 177–185.

P.J. Arrazola, A. Garay, L.M. Iriarte, M. Armendia, S. Marya and F. Le Maître, Machinability of titanium alloys (Ti6Al4V and Ti5553), J. Mater. Process. Technol., 2009, 209(5), p 2223–2230.

P.J. Bania, Beta titanium alloys and their role in the titanium industry, JOM, 1994, 46, p 16–19.

C.M.F.A. Cossú, E.D. Vicente, I.G.R. Cardoso, Y.S. Schettini, J.d.A.G. Precioso, C.A. Nunes, L.H.d. Almeida, S. Borborema, Mechanical and Microstructural Characterization of AS-CAST Ti-12Mo-xNb Alloys for Orthopedic Application, Mater. Res., 2019, 22(suppl 1), p 1–5.

Q. Li, X. Yuan, J. Li, P. Wang, M. Nakai, M. Niinomi, T. Nakano, A. Chiba, X. Liu and D. Pan, Effects of Fe on Microstructures and Mechanical Properties of Ti–15Nb–25Zr–(0, 2, 4, 8)Fe Alloys Prepared by Spark Plasma Sintering, Mater. Trans., 2019, 60(9), p 1763–1768.

Y.-Y. Chen, L.-J. Xu, Z.-G. Liu, F.-T. Kong and Z.-Y. Chen, Microstructures and properties of titanium alloys Ti-Mo for dental use, Trans. Nonferrous Metals Soc. China, 2006, 16, p s824–s828.

M.K. Han, J.Y. Kim, M.J. Hwang, H.J. Song and Y.J. Park, Effect of Nb on the Microstructure, Mechanical Properties, Corrosion Behavior, and Cytotoxicity of Ti-Nb Alloys, Mater. (Basel), 2015, 8(9), p 5986–6003.

Y.L. Kao, G.C. Tu, C.A. Huang and T.T. Liu, A study on the hardness variation of α- and β-pure titanium with different grain sizes, Mater. Sci. Eng., A, 2005, 398(1–2), p 93–98.

W. Xu, M. Chen, X. Lu, D.-W. Zhang, H.-P. Singh, Y. Jian-shu, Y. Pan, X.-H. Qu and C.-Z. Liu, Effects of Mo content on corrosion and tribocorrosion behaviours of Ti-Mo orthopaedic alloys fabricated by powder metallurgy, Corros. Sci., 2020, 168, art. no. 108557

C.M. Lee, C.P. Ju and J.H.C. Lin, Structure-property relationship of cast Ti-Nb alloys, J. Oral Rehailit., 2002, 29, p 314–322.

R. Yamanoglu, Network distribution of molybdenum among pure titanium powders for enhanced wear properties, Met. Powder Rep., 2021, 76(1), p 32–39.

W.F. Ho, C.P. Ju and J.H.C. Lin, Structure and properties of cast binary Ti-Mo alloys, Biomaterials, 1999, 20, p 2115–2122.

G. Lütjering, J. Albrecht, C. Sauer and T. Krull, The influence of soft, precipitate-free zones at grain boundaries in Ti and Al alloys on their fatigue and fracture behavior, Mater. Sci. Eng. A, 2007, 468–470, p 201–209.

U. Krupp, W. Floer, J. Lei, Y. Hu, H.-J. Christ, A. Schick and C.-P. Fritzen, Mechanisms of short-fatigue-crack initiation and propagation in a β-Ti alloy, Philos. Mag. A, 2002, 82(17–18), p 3321–3332.

J.W. Foltz, B. Welk, P.C. Collins, H.L. Fraser and J.C. Williams, Formation of grain boundary α in β Ti Alloys: Its Role in DEFORMATION and fracture behavior of these alloys, Metall. Mater. Trans. A, 2010, 42(3), p 645–650.

M. Vakili-Azghandi, M. Roknian, J.A. Szpunar and S.M. Mousavizade, Surface modification of pure titanium via friction stir processing: microstructure evolution and dry sliding wear performance, J. Alloys Compd., 2020, 816, art. no. 152557

H. Li, M. Ramezani and Z.W. Chen, Dry sliding wear performance and behaviour of powder bed fusion processed Ti–6Al–4V alloy, Wear, 2019, 440–441, art. no. 203103

R. Yamanoglu, Production and characterization of Al-xNi in situ composites using hot pressing, J. Min. Metall.Sect. B., 2014, 50(1), p 45–52.

R. Yamanoglu and E. Efendi, Enhanced surface properties of iron by in situ hard nickel coating, Mater. Test., 2016, 58(2), p 151–154.

Y. Zhu, J. Zou and H.-Y. Yang, Wear performance of metal parts fabricated by selective laser melting: a literature review, J. Zhejiang Univ.-Sci. A, 2018, 19(2), p 95–110.

C. Yan, Q. Zeng, Y. Xu and W. He, Microstructure, phase and tribocorrosion behavior of 60NiTi alloy, Appl. Surf. Sci., 2019, 498, art. no. 143838

M. Bai, R. Namus, Y. Xu, D. Guan, M.W. Rainforth and B.J. Inkson, In-situ Ti-6Al-4V/TiC composites synthesized by reactive spark plasma sintering: processing, microstructure, and dry sliding wear behaviour, Wear, 2019, 432–433, art. no. 202944

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yamanoglu, R., Bahador, A. & Kondoh, K. Effect of Mo Addition on the Mechanical and Wear Behavior of Plasma Rotating Electrode Process Atomized Ti6Al4V Alloy. J. of Materi Eng and Perform 30, 3203–3212 (2021). https://doi.org/10.1007/s11665-021-05631-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05631-5