Abstract

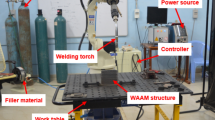

This work investigates the effects of Ar-based shielding gases on the microstructure and phase balance of duplex stainless steel (DSS) depositions. The results are then used for fabrication of DSS walls using wire arc additive manufacturing (WAAM), and the microstructural characteristics and mechanical performance of the products are assessed. WAAM currently poses as one of the most interesting methods of manufacturing by enabling joining of materials to fabricate structures layer by layer. However, the extreme conditions imposed by the process, such as high heat inputs and re-melt and solidification of the deposited layers, could compromise the performance of the products. A detailed microstructural analysis is conducted on single layer and double layer depositions of DSS to assess the effects of different shielding gases on the ferrite/austenite phase balance in the specimens. The results show that the depositions shielded with a small fraction of carbon dioxide (CO2) present better microstructural features in comparison to depositions shielded with the other selected gases. A mixture of 98%Ar + 2%CO2 was employed for fabrication of a 60-layer DSS WAAM-made wall and some mechanical characteristics were studied. The mechanical examinations demonstrate that the properties of the parts fabricated using WAAM are comparable with their wrought counterparts.

Similar content being viewed by others

References

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley, 2005.

S.J. Morrow, Materials Selection for Seawater Pumps, Proceedings of the 26th International Pump Users Symposium, 2010, Turbomachinery Laboratory, Texas A&M University

G. Krolczyk, P. Nieslony, S. Legutko and I. Samardzic, Investigation of the Physical Parameters of Duplex Stainless Steel (DSS) Surface Integrity After Turning, Metalurgija, 2015, 54(1), p 87–90.

V.A. Hosseini, M. Thuvander, S. Wessman and L. Karlsson, Spinodal Decomposition in Functionally Graded Super Duplex Stainless Steel and Weld Metal, Metall. Mater. Trans. A, 2018, 49(7), p 2803–2816.

B. Messer, V. Opera, and A. Wright, Duplex Stainless Steel Welding: Best Practices, Stainless Steel World, 2007

T.F.A. Santos, R.R. Marinho, M.T.P. Paes and A.J. Ramirez, Microstructure Evaluation of UNS S32205 Duplex Stainless Steel Friction Stir Welds, REM Rev. Esc. Minas, 2013, 66(2), p 187–191.

S. Kou, Welding Metallurgy, Wiley, 2003.

B. Varbai and K. Majlinger, Thermoelectric Power Measurements on Duplex Stainless Steel Weldments, May 23-25, 2018, (Miskolc), 2nd International Conference on Vehicle and Automotive Engineering, p 789–99

M.A. García-Rentería, V.H. López-Morelos, R. García-Hernández, L. Dzib-Pérez, E.M. García-Ochoa and J. González-Sánchez, Improvement of Localised Corrosion Resistance of AISI 2205 Duplex Stainless Steel Joints Made by Gas Metal Arc Welding Under Electromagnetic Interaction of Low Intensity, Appl. Surf. Sci., 2014, 321, p 252–260. https://doi.org/10.1016/j.apsusc.2014.10.024

H. Geng, J. Li, J. Xiong, X. Lin and F. Zhang, Geometric Limitation and Tensile properties of Wire and Arc Additive Manufacturing 5A06 Aluminum Alloy Parts, J. Mater. Eng. Perform., 2017, 26(2), p 621–629.

M. Abbaszadeh, J.R. Hönnige, F. Martina, L. Neto, N. Kashaev, P. Colegrove, S. Williams and B. Klusemann, Numerical Investigation of the Effect of Rolling on the Localized Stress and Strain Induction for Wire + Arc Additive Manufactured Structures, J. Mater. Eng. Perform., 2019, 28(8), p 4931–4942.

V. Manvatkar, A. De and T. Debroy, Spatial Variation of Melt Pool Geometry, Peak Temperature and Solidification Parameters During Laser Assisted Additive Manufacturing Process, Mater. Sci. Technol., 2015, 31(8), p 924–930.

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

W.J. Sames, F.A. List, S. Pannala, R.R. Dehoff and S.S. Babu, The Metallurgy and Processing Science of Metal Additive Manufacturing, Int. Mater. Rev., 2016, 61(5), p 315–360.

M.A. Makhdoom, A. Ahmad, M. Kamran, K. Abid and W. Haider, Microstructural and Electrochemical Behavior of 2205 Duplex Stainless Steel Weldments, Surfac. Interfaces, 2017, 9, p 189–195.

M. Eriksson, M. Lervåg, C. Sørensen, A. Robertstad, B.M. Brønstad, B. Nyhus, R. Aune, X. Ren, and O.M. Akselsen, Additive Manufacture of Superduplex Stainless Steel Using WAAM, MATEC Web Conference, EDP Sciences, 2018, p 188

G. Posch, K. Chladil and H. Chladil, Material Properties of CMT—Metal Additive Manufactured Duplex Stainless Steel Blade-Like Geometries, Weld World, 2017, 61(5), p 873–882.

V.A. Hosseini, M. Högström, K. Hurtig, M.A.V. Bermejo, L.E. Stridh and L. Karlsson, Wire-Arc Additive Manufacturing of a Duplex Stainless Steel: Thermal Cycle Analysis and Microstructure Characterization, Weld World, 2019, 63(4), p 975–987.

A. Vinoth Jebaraj, L. Ajaykumar, C.R. Deepak and K.V.V. Aditya, Weldability, Machinability and Surfacing of Commercial Duplex Stainless Steel AISI2205 for Marine Applications—A Recent Review, J. Adv. Res., 2017, 8(3), p 183–199.

Z.H. Rao, S.M. Liao and H.L. Tsai, Effects of Shielding Gas Compositions on Arc Plasma and Metal Transfer in Gas Metal Arc Welding, J. Appl. Phys., 2010, 107(4), p 044902.

J. Norrish, Advanced Welding Processes, Elsevier, Amsterdam, 2006.

F. Hejripour, F. Binesh, M. Hebel and D.K. Aidun, Thermal Modeling and Characterization of Wire Arc Additive Manufactured Duplex Stainless Steel, J. Mater. Process. Technol., 2019, 272, p 58–71.

G.R. Mohammed, M. Ishak, S.N. Aqida and H.A. Abdulhadi, Effects of Heat Input on Microstructure, Corrosion and Mechanical Characteristics of Welded Austenitic and Duplex Stainless Steels: A Review, Metals, 2017, 7(2), p 39.

J. Nowacki and A. Lukojc, Structure and Properties of the Heat-Affected Zone of Duplex Steels Welded Joints, J. Mater. Process. Technol., 2005, 164, p 1074–1081.

E.G. Betini, F.C. Cione, C.S. Mucsi, M.A. Colosio, J.L. Rossi, and M.T.D. Orlando, Experimental Study of the Temperature Distribution in Welded Thin Plates of Duplex Stainless Steel for Automotive Exhaust Systems, SAE 2016 World Congress and Exhibition, 2016, 2016-01-0503

V.A. Hosseini, L. Karlsson, D. Engelberg and S. Wessman, Time-Temperature-Precipitation and Property Diagrams for Super Duplex Stainless Steel Weld Metals, Weld. World, 2018, 62(3), p 517–533.

L. Karlsson, Intermetallic Phase Precipitation in Duplex Stainless Steels and Weld Metals Metallurgy, Influence on Properties and Welding Aspects, Weld. World, 1999, 43(5), p 20–41.

M.A. Valiente Bermejo, K. Hurtig, D. Eyzop and L. Karlsson, A New Approach to Study of Multi-pass Welds Microstructure and Properties of Welded 20-Mm-Thick Super Duplex Stainless Steel, Appl. Sci., 2019, 9(6), p 1050.

D. Arun, K.D. Ramkumar and R. Vimala, Multi-Pass Arc Welding Techniques of 12 mm Thick Super-Duplex Stainless Steel, J. Mater. Process. Technol., 2019, 271, p 126–143.

J. Verma and R.V. Taiwade, Effect of Welding Processes and Conditions on the Microstructure, Mechanical Properties and Corrosion Resistance of Duplex Stainless Steel Weldments—A Review, J. Manuf. Process., 2017, 25, p 134–152.

B. Lee, H. Lee and Y. Shin, Intergranular Corrosion Characteristics of Duplex Stainless Steel at Various Interpass Temperatures, Int. J. Electrochem. Sci., 2015, 10, p 7535–7547.

EN ISO 6947, Welding and Allied Processes—Welding Positions, 2011

K. Singh, V. Sahni and S. Pandey, Slag Recycling in Submerged Arc Welding and Its Influence on Chemistry of Weld Metal, Asian J. Chem., 2009, 21(10), p 47–51.

S. Rhee and E. Kannatey-Asibu Jr., Observation of Metal Transfer during Gas Metal Arc Welding, Weld. J., 1992, 71, p 381.

S. Lu, H. Fujii and K. Nogi, Marangoni Convection and Weld Shape Variations in Ar–O2 and Ar–CO2 Shielded GTA Welding, Mater. Sci. Eng. A, 2004, 380(1–2), p 290–297.

X. Xu, J. Ding, S. Ganguly, C. Diao and S. Williams, Preliminary Investigation of Building Strategies of Maraging Steel Bulk Material Using Wire + Arc Additive Manufacture, J. Mater. Eng. Perform., 2019, 28(2), p 594–600.

E. Brandl, A. Schoberth and C. Leyens, Morphology, Microstructure, and Hardness of Titanium (Ti-6Al-4V) Blocks Deposited by Wire-Feed Additive Layer Manufacturing (ALM), Mater. Sci. Eng. A, 2012, 532(3), p 295–307.

G.P. Dinda, A.K. Dasgupta and J. Mazumder, Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability, Mater. Sci. Eng. A, 2009, 509(1), p 98–104.

X. Xing, G. Qin, Y. Zhou, H. Yu, L. Liu, L. Zhang and Q. Yang, Microstructure Optimization and Cracking Control of Additive Manufactured Bainite Steel by Gas Metal Arc Welding Technology, J. Mater. Eng. Perform., 2019, 28(8), p 5138–5145.

H. Sieurin, Fracture Toughness Properties of Duplex Stainless Steels, Royal Institute of Technology, Stockholm, 2006.

V. Muthupandi, P.B. Srinivasan, S.K. Seshadri and S. Sundaresan, Effect of Weld Metal Chemistry and Heat Input on the Structure and Properties of Duplex Stainless Steel Welds, Mater. Sci. Eng. A Struct., 2003, 358, p 9–16.

Aircraft Materials, Stainless Steel ER2209 Technical Data Sheet, 2018, https://www.aircraftmaterials.com/data/weld/er2209.html

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Binesh, F., Bahrami, A., Hebel, M. et al. Preservation of Natural Phase Balance in Multi-pass and Wire Arc Additive Manufacturing-Made Duplex Stainless Steel Structures. J. of Materi Eng and Perform 30, 2552–2565 (2021). https://doi.org/10.1007/s11665-021-05593-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05593-8