Abstract

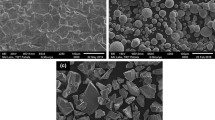

This study focused on the development of microwave composite cladding of a Ni-based alloy reinforced with varying proportions (wt.%) of B4C such as 0, 5, 10 and 20% on a SS-304 steel substrate. Clads showed metallurgical bonding with the substrate by the partial dilution of the materials. Various techniques of characterization confirmed the formation of hard phases of borides and carbides such as Fe23B6, Fe5C2, Cr7C3, Cr7BC4 and their distribution in the Ni matrix throughout the clad volume. Flexural performance tests of the clads were done using a three-point bend test at a deformation rate of 0.5 mm/min, and composite clad reinforced with 10% B4C showed the highest flexural strength that was observed to be 479 ± 13 MPa. Clads failed in the upper transition load, and a sudden load drop was observed at the failure points of the clads. Fractography revealed that reinforced phases provided sufficient strength to the Ni-based ductile matrix because crack propagation in the clads was arrested by these hard phases while deformation.

Similar content being viewed by others

References

C.R.C. Lima, J. Nin, and J.M. Guilemany, Evaluation of Residual Stresses of Thermal Barrier Coatings with HVOF Thermally Sprayed Bond Coats Using the Modified Layer Removal Method (MLRM), Surf. Coat. Technol., 2006, 200, p 5963–5972

A.K. Krella, An Approach to Evaluate the Resistance of Hard Coatings to Shock Loading, Surf. Coat. Technol., 2010, 205, p 2687–2695

H. Zhu, Y. Niu, C. Lin, L. Huang, H. Ji, and X. Zheng, Microstructures and Tribological Properties of Vacuum Plasma Sprayed B4C-Ni Composite Coatings, Ceram. Int., 2013, 39, p 101–110

H.S. Grewal, H.S. Arora, A. Agrawal, H. Singh, and S. Mukherjee, Slurry Erosion of Thermal Spray Coatings: Effect of Sand Concentration, Procedia Eng., 2013, 68, p 484–490

M. Rafiei, M. Salehi, M. Shamanian, and A. Motallebzadeh, Preparation and Oxidation Behavior of B4C-Ni and B4C-TiB2-TiC-Ni Composite Coatings Produced by an HVOF Process, Ceram. Int., 2014, 40, p 13599–13609

V.M. Fomin, A.A. Golyshev, V.F. Kosarev, A.G. Malikov, A.M. Orishich, N.S. Ryashin, A.A. Filippov, and V.S. Shikalov, Creation of Heterogeneous Materials on the Basis of B4C and Ni Powders by the Method of Cold Spraying with Subsequent Layer-by-layer Laser Treatment, J. Appl. Mech. Tech. Phys., 2017, 58, p 947–955

S. Zafar and A.K. Sharma, Microstructure and Mechanical Properties of Microwave Post-Processed Ni Coating, J. Mater. Eng. Perform., 2017, 26, p 1382–1390

L. Zhong, Y. Yan, V.E. Ovcharenko, X. Cai, X. Zhang, and Y. Xu, Microstructural and Mechanical Properties of In Situ WC-Fe/Fe Composites, J. Mater. Eng. Perform., 2015, 24, p 4561–4568

M.S. Raza, M. Hussain, V. Kumar, and A.K. Das, In Situ Production of Hard Metal Matrix Composite Coating on Engineered Surfaces Using Laser Cladding Technique, J. Mater. Eng. Perform., 2017, 26, p 76–83

M.J. Chao, X. Niu, B. Yuan, E.J. Liang, and D.S. Wang, Preparation and Characterization of In Situ Synthesized B4C Particulate Reinforced Nickel Composite Coatings by Laser Cladding, Surf. Coat. Technol., 2006, 201, p 1102–1108

M. Afzal, A.N. Khan, T.B. Mahmud, T.I. Khan, and M. Ajmal, Effect of Laser Melting on Plasma Sprayed WC-12 wt.% Co Coatings, Surf. Coat. Technol., 2015, 266, p 22–30

D. Deschuyteneer, F. Petit, M. Gonon, and F. Cambier, Processing and Characterization of Laser Clad NiCrBSi/WC Composite Coatings—Influence of Microstructure on Hardness and Wear, Surf. Coat. Technol., 2015, 283, p 162–171

D. Gupta and A.K. Sharma, Development and Microstructural Characterization of Microwave Cladding on Austenitic Stainless Steel, Surf. Coat. Technol., 2011, 205, p 5147–5155

D. Gupta and A.K. Sharma, Microwave Cladding: A New Approach in Surface Engineering, J. Manuf. Proc., 2014, 16, p 176–182

A. Pathania, S. Singh, D. Gupta, and V. Jain, Development and Analysis of Tribological Behavior of Microwave Processed EWAC + 20% WC10Co2Ni Composite Cladding on Mild Steel Substrate, J. Manuf. Proc., 2015, 20, p 79–87

A. Bansal, S. Zafar, and A.K. Sharma, Microstructure and Abrasive Wear Performance of Ni-WC Composite Microwave Clad, J. Mater. Eng. Perform., 2015, 24, p 3708–3716

H. Wu, F. Chen, and J. Xu, Preparation and Characterization of (Mo, W) Si2-SiC Composites by In Situ Microwave Reaction Sintering, J. Mater. Eng. Perform., 2017, 26, p 3239–3244

D. Gupta and A.K. Sharma, Microstructural Characterization of Cermet Cladding Developed Through Microwave Irradiation, J. Mater. Eng. Perform., 2012, 21, p 2165–2172

D. Jhodkar, M. Amarnath, H. Chelladurai, and J. Ramkumar, Experimental Investigations to Study the Effects of Microwave Treatment Strategy on Tool Performance in Turning Operation, J. Mater. Eng. Perform., 2018, 27, p 6374–6388

M. Minhaj, B. Singh, and S. Zafar, Slurry Erosion Performance of Ni + B4C Microwave Composite Clads, J. Tribol., 2020, 142, art. no. 051702

A.K. Sharma and D. Gupta, On Microstructure and Flexural Strength of Metal-Ceramic Composite Cladding Developed Through Microwave Heating, Appl. Surf. Sci., 2012, 258, p 5583–5592

H.E.M. Sallam, K. Abd El-Aziz, H. Abd El-Raouf, and E.M. Elbanna, Flexural Strength and Toughness of Austenitic Stainless Steel Reinforced High-Cr White Cast Iron Composite, J. Mater. Eng. Perform., 2013, 22, p 3769–3777

S. Zafar and A.K. Sharma, Structure-Property Correlations in Nanostructured WC-12Co Microwave Clad, Appl. Surf. Sci., 2016, 370, p 92–101

S. Zafar and A.K. Sharma, Investigations on Flexural Performance and Residual Stresses in Nanometric WC-12Co Microwave Clads, Surf. Coat. Technol., 2016, 291, p 413–422

S. Kaushal, D. Gupta, and H. Bhowmick, On Processing and Flexural Behaviour of Functionally Graded Clads Developed Through Microwave Irradiation, Mater. Res. Express, 2019, 6, p 076405

Y. Luo, Y. Wu, D. Xiao, K. Tang, C. Huang, R.K. Fu, S. Zheng, and P.K. Chu, Al2O3 Coating for Densification of SiC Ceramics and Sintering Kinetics, Surf. Coat. Technol., 2019, 374, p 603–609

S.I. Aoqui, H. Miyata, T. Ohshima, T. Ikegami, and K. Ebihara, Preparation of Boron Carbide Thin Film by Pulsed KrF Excimer Laser Deposition Process, Thin Solid Films, 2002, 407, p 126–131

J.D. Katz, R.D. Blake, J.J. Petrovic, and H. Sheinberg, Microwave Sintering of Boron Carbide, Met. Powd. Rep., 1988, 43, p 835–837

Funding

Science and Engineering Research Board (SERB), Department of Science and Technology (DST), Government of India (ECR/2016/001276; Funder ID: https://doi.org/10.13039/501100001843).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Minhaj, M., Zafar, S. Influence of B4C Content on Flexural Performance of Ni + B4C Microwave Composite Clads. J. of Materi Eng and Perform 30, 165–176 (2021). https://doi.org/10.1007/s11665-020-05373-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05373-w