Abstract

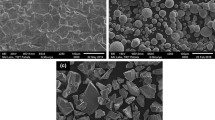

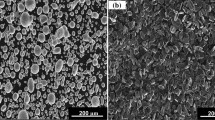

In the present investigation, composite clads of Ni + 20% WC8Co and Ni + 30% WC8Co were developed on austenitic stainless steel (SS-316) using microwave energy. Experiments trials were carried out inside a domestic microwave oven with a frequency range of 2.45 GHz and variable power level of 180–900 W. The exposure time and power level for developing clads were optimized. The microwave processed clads were further characterized through SEM/EDS, XRD, and measurement of Vicker’s microhardness. Microstructural results revealed that the clads of approximately 0.7 mm thickness were free from any type of interfacial cracks and voids. WC particles were uniformly distributed inside soft Ni matrix. The presence of NiSi, Co3W3C, Fe6W6C, NiW, NiCr, and FeNi3 phases was observed during phase analysis of developed composite clads. Microhardness of the Ni + 20% WC8Co and Ni + 30% WC8Co was found to be 810 ± 75 and 923 ± 65 HV, respectively.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Adachi, S., Ueda, N.: Surface hardness improvement of plasma-sprayed AISI 316L stainless steel coating by low-temperature plasma carburizing. Adv. Powder Technol. 24, 818–823 (2013)

M’Saoubi, R., Alm, O., Andersson, J.M., Engstorm, H., Larsson, T., Joesaar, M.P., Schwind, M.: Microstructure and wear mechanisms of texture-controlled CVD α-Al2O3 coatings. Wear 376–377, 1766–1778 (2017)

Alidokht, S.A., Vo, P., Yue, S., Chromik, R.R.: Erosive wear behavior of cold-sprayed Ni-WC composite coating. Wear 376–377, 566–577 (2017)

Krishna, N.G., Thinaharan, C., George, R.P., Parvathavarthini, N., Mudali, U.K.: Surface modification of type 304 stainless steel with duplex coatings for corrosion resistance in sea water environments. Surf. Eng. 31, 39–47 (2015)

Kwok, C.T., Man, H.C., Cheng, F.T.: Cavitation erosion and pitting behaviour of laser surface-melted martensitic stainless steel UNS S42000. Surf. Coat. Technol. 126, 238–255 (2000)

St-Georges, L.: Development and characterization of composite Ni−Cr+WC laser cladding. Wear 263, 562–566 (2007)

Gupta, D., Sharma, A.K.: A method of cladding-coating of metallic and non-metallic powders on metallic substrate by microwave irradiation. Patent Application 527/Del, India (2010)

Kaushal, S., Gupta, D., Bhowmick, H.L.: Investigation of dry sliding wear behavior of composite cladding developed through microwave heating. J. Tribol. 139, 041603-1-9 (2017)

Kaushal, S., Sirohi, V., Gupta, D., Bhowmick, H.L., Singh, S.: Processing and characterization of composite cladding through microwave heating on martensitic steel. Mater. Des. Appl. https://doi.org/10.1177/1464420715616139 (2015, in press)

Singh, S., Gupta, D., Jain, V., Sharma, A.K.: Microwave processing of materials and applications in manufacturing industries: a review. Mater. Manufact. Process. 30, 1–29 (2014)

Kaushal, S., Gupta, D., Bhowmick, H.L.: On surface modification of austenitic stainless steel using microwave processed Ni/Cr3C2 composite cladding. Surf. Eng. https://doi.org/10.1080/02670844.2017.1362808 (2017, in press)

Kaushal, S., Gupta, D., Bhowmick, H.L.: On microstructure and wear behavior of microwave processed composite clad. J. Tribol. 139, 061602-1-8 (2017)

Kaushal, S., Gupta, D., Bhowmick, H.L.: On processing of Ni-WC based functionally graded composite clads through microwave heating. Mater. Manufact. Process. https://doi.org/10.1080/10426914.2017.1401724 (2017, in press)

Acknowledgements

The authors are grateful to Science and Engineering Research Board (SERB), India, for providing Authors the financial assistance under the project titled “Development of Microwave Processed Cavitation Erosion Resistant Cladding” File no.: EMR/2016/007964.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Singh, D., Kaushal, S., Gupta, D., Bhowmick, H.L., Jain, V. (2019). On Processing of Ni–WC8Co-based Composite Clads on Austenitic Stainless Steel Through Microwave Energy. In: Vijay Sekar, K., Gupta, M., Arockiarajan, A. (eds) Advances in Manufacturing Processes. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-13-1724-8_15

Download citation

DOI: https://doi.org/10.1007/978-981-13-1724-8_15

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-1723-1

Online ISBN: 978-981-13-1724-8

eBook Packages: EngineeringEngineering (R0)