Abstract

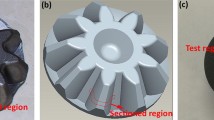

Obtaining excellent mechanical properties of spur bevel gear has been widely emphasized, owing to its indispensable effect on momentum. However, the conventional long-time and high-temperature heat treatment can cause microstructure coarsening, which dramatically decreases the mechanical properties. Since the normalizing process can significantly modulate the mechanical properties of spur bevel gears by adjusting their microstructure and crystallography behaviors, in the present study, the normalizing before or after carburizing heat treatment processes (NBCP and NACP, respectively) were proposed. The effect of heat treatment processes on the microstructure and crystallography of gear specimens was investigated. The results show that both NBAP and NACP had a strong effect on microstructure refinement and hardness improvement compared to the conventional process. NBCP raised the tendency for AlN precipitation, which could retard the microstructure coarsening during carburizing. Furthermore, NACP directly promoted the precipitation of globular Cr-rich M3C carbides which achieved the strongest pinning effect and brought about extremely fine microstructure. For crystallographic analysis, the 24 martensite variants in all gear specimens held Kurdjumov–Sachs orientation relationship to parent austenite. The orientations of martensite variants in gear specimens applying conventional process and NBCP were distributed regularly. However, the orientations of martensite variants in NACP gear specimen did not follow the strict rule for variant selection inside prior austenite grains owing to the distortive effect of diffuse M3C carbides on the matrix, and the adjacent martensite variants possessed less sharing of {110} habit plane compared to NBCP and conventional process.

Similar content being viewed by others

References

X.B. Deng, L. Hua, X.H. Han, and Y. Song, Numerical and Experimental Investigation of Cold Rotary Forging of a 20CrMnTi Alloy Spur Bevel Gear, Mater. Des., 2011, 32, p 1376–1389

T. Henke, M. Bambach, and G. Hirt, Quantification of Uncertainties in Grain Size Predictions of a Microstructure-Based Flow Stress Model and Application to Gear Wheel Forging, CIRP Annu. Manuf. Technol., 2013, 62, p 287–290

X. Hu, L. Hua, and X.H. Han, Study on the Microstructure and Texture Evolution of Hot Forged 20CrMnTiH Steel Spur Bevel Gear by Simulation and Experiment, J. Mater. Eng. Perform., 2020, 29, p 3688–3701

Y. Wei, L. Zhang, and R.D. Sisson, Jr., Modeling of Carbon Concentration Profile Development During Both Atmosphere and Low Pressure Carburizing Processes, J. Mater. Eng. Perform., 2013, 22, p 1886–1891

B. Jiang, Z. Mei, L.Y. Zhou, G.L. Liu, Z.L. Wang, B. Huang, and Y.Z. Liu, High Toughness and Multiphase Microstructure Transition Product of Carburizing Steel by a Novel Heat Treatment Cooling Process, Mater. Sci. Eng. A, 2016, 675, p 361–370

O. Asi, A.Ç. Can, J. Pineault, and M. Belassel, The Effect of High Temperature Gas Carburizing on Bending Fatigue Strength of SAE 8620 Steel, Mater. Des., 2009, 30, p 1792–1797

Y.F. Ivanov, N.N. Koval, S.V. Gorbunov, S.V. Vorobyov, S.V. Konovalov, and V.E. Gromov, Multicyclic Fatigue of Stainless Steel Treated by a High-Intensity Electron Beam: Surface Layer Structure, Russ. Phys. J., 2011, 54, p 575–583

J.L. Pacheco and G. Krauss, Microstructure and High Bending Fatigue Strength in Carburized Steel, J. Heat Treat., 1989, 7, p 77–86

K.O. Lee, S.K. Hong, Y.K. Kang, H.J. Yoon, and S.S. Kang, Grain Refinement in Bearing Steels Using a Double-Quenching Heat-Treatment Process, Int. J. Automot. Technol., 2009, 10, p 697–702

R.P. Brobst and G. Krauss, The Effect of Austenite Grain Size on Microcracking in Martensite of an Fe-1.22C Alloy, Metall. Mater. Trans. B, 1974, 5, p 457–462

Y.L. Chang, P.Y. Chen, Y.T. Tsai, and J.R. Yang, Crystallographic Analysis of Lenticular Martensite in Fe-1.0C-17Cr Stainless Steel by Electron Backscatter Diffraction, Mater. Charact., 2016, 113, p 17–25

H. Kitahara, R. Ueji, N. Tsuji, and Y. Minamino, Crystallographic Features of Lath Martensite in Low-Carbon Steel, Acta Mater., 2006, 54, p 1279–1288

N.M. Ryzhov, M.Y. Semenov, R.S. Fakhurtdinov, and A.E. Smirnov, A Model of Diffusion Growth of Carbide-Phase Particles in the Carburized Layer of Heat-Resistant Steels, Met. Sci. Heat Treat., 1998, 40, p 374–377

J. Wang, Z. Sun, R. Zuo, C. Li, B. Shen, S. Gao, and S. Huang, Effects of Secondary Carbide Precipitation and Transformation on Abrasion Resistance of the 16Cr-1Mo-1Cu White Iron, J. Mater. Eng. Perform., 2006, 15, p 316–319

S.H. Choi, E.Y. Kim, W. Woob, S.H. Han, and J.H. Kwak, The Effect of Crystallographic Orientation on the Micromechanical Deformation and Failure Behaviors of DP980 Steel During Uniaxial Tension, Int. J. Plast., 2013, 45, p 85–102

T.H. Lee, C.S. Oh, S.H. Ryu, and J.T. Kim, Crystallography and Morphology of Carbides in a Low-Cycle Fatigued 1Cr-1Mo-0.25V Steel, Metall. Mater. Trans. A, 2010, 42, p 147–157

Y. Fang, X. Chen, B. Madigan, H. Cao, and S. Konovalov, Effects of Strain Rate on the Hot Deformation Behavior and Dynamicrecrystallization in China Low Activation Martensitic Steel, Fusion Eng. Des., 2016, 103, p 21–30

L. Jena and P. Heich, Microcracks in Carburized and Hardened Steel, Metall, Mater. Trans. B, 1972, 2, p 592–594

K.O. Lee, S.K. Hong, Y.K. Kang, H.J. Yoon, and S.S. Kang, Grain Refinement in Bearing Steels Using a Double-Quenching Heat-Treatment Process, Int. J. Auto. Tech-Kor, 2009, 6, p 697–702

T. Fujimatsu, M. Nishikawa, K. Hashimoto, and A. Yamamoto, Influence of Repeated Quenching After Carburizing on Prior Austenite Grain Size, Mater. Sci. Forum, 2007, 561–565, p 2345–2348

M. Abbasi, D.I. Kim, T.W. Nelson, and M. Abbasi, EBSD and Reconstruction of Pre-Transformation Microstructures, Examples and Complexities in Steels, Mater. Charact., 2014, 95, p 219–231

M. Eskandari, M.A. Mohtadi-Bonab, R. Basu, M. Nezakat, A. Kermanpur, J.A. Szpunar, S. Nahar, and A.H. Baghpanah, Preferred Crystallographic Orientation Development in Nano/Ultrafine-Grained 316L Stainless Steel During Martensite to Austenite Reversion, J. Mater. Eng. Perform., 2015, 24, p 644–653

H. Kitahara, R. Ueji, M. Ueda, N. Tsuji, and Y. Minamino, Crystallographic Analysis of Plate Martensite in Fe-28.5 at.% Ni by FE-SEM/EBSD, Mater. Charact., 2005, 54, p 378–386

T.N. Durlu, Strain-Induced Martensite Formation During the Intersection of Plate Martensites in Fe-17.1 wt% Ni-0.81 wt.% C alloy, J. Mater. Sci. Lett., 1996, 15, p 1412–1415

C. Wang, H. Qiu, Y. Kimura, and T. Inoue, Morphology, Crystallography, and Crack Paths of Tempered Lath Martensite in a Medium-Carbon Low-Alloy Steel, Mater. Sci. Eng. A, 2016, 669, p 48–57

B. Mintz, S. Tajik, and R. Vipond, Influence of Microalloying Additions on Thickness of Grain Boundary Carbides in Ferrite-Pearlite Steels, Mater. Sci. Technol., 1994, 10, p 89–96

M. Hillert, Inhibition of Grain Growth by Second-Phrase Particles, Acta Metall., 1988, 36, p 3177–3181

W. Xu, P.E.J. Rivera-Dίaz-del-Castillo, W. Yan, K. Yang, D.S. Martίn, L.A.I. Kestens, and S. van der Zwaag, A New Ultrahigh-Strength Stainless Steel Strengthened by Various Coexisting Nanoprecipitates, Acta Mater., 2010, 58, p 4067–4075

J. Dong, C. Liu, Y. Liu, C. Li, Q. Guo, and H. Li, Effects of Two Different Types of MX Carbonitrides on Austenite Growth Behavior of Nb-V-Ti Microalloyed Ultra-High Strength Steel, Fusion Eng. Des., 2017, 125, p 415–422

J. Dong, X. Zhou, Y. Liu, C. Li, C. Liu, and Q. Guo, Carbide Precipitation in Nb-V-Ti Microalloyed Ultra-High Strength Steel During Tempering, Mater. Sci. Eng. A, 2017, 683, p 215–226

T. Kozmel and S. Tin, Effects of Carbides on the Microstructural Evolution in Sub-Micron Grain 9310 Steel During Isothermal Heat Treatment, Metall. Mater. Trans. A, 2015, 46, p 3208–3219

L.D. Liu and F.S. Chen, Super-Carburization of Low Alloy Steel in a Vacuum Furnace, Surf. Coat. Technol., 2004, 183, p 233–238

M. Nurbanasari, P. Tsakiropoulos, and E.J. Palmiere, A Study of Carbide Precipitation in a H21 Tool Steel, ISIJ Int., 2014, 54, p 1667–1676

N. Saini, C. Pandey, and M.M. Mahapatra, Characterization and Evaluation of Mechanical Properties of CSEF P92 Steel for Varying Normalizing Temperature, Mater. Sci. Eng. A, 2017, 688, p 250–261

T. Giordani, T.R. Clarke, C.E.F. Kwietniewski, M.A. Aronov, N.I. Kobasko, and G.E. Totten, Mechanical and Metallurgical Evaluation of Carburized, Conventionally and Intensively Quenched Steels, J. Mater. Eng. Perform., 2013, 22, p 2304–2313

I. Fedorova, F. Liu, F.B. Grumsen, Y. Cao, O.V. Mishin, and J. Hald, Fine (Cr, Fe)2B Borides on Grain Boundaries in a 10Cr-0.01B Martensitic Steel, Script. Mater., 2018, 156, p 124–128

K.P. Cooper and H.N. Jones, III, Phase Transformation-Induced Grain Refinement in Rapidly Solidified Ultra-High-Carbon Steels, Metall. Mater. Trans. A, 2002, 33, p 2789–2799

L. Zhang, T. Ohmura, A. Shibata, and K. Tsuzaki, Characterization of Local Deformation Behavior of Fe-Ni Lenticular Martensite by Nanoindentation, Mater. Sci. Eng. A, 2010, 527, p 1869–1874

H.K.D.H. Bhadeshia, M. Déchamps, and L.M. Brown, The Structure of Twins in Fe-Ni Martensite, Acta Matell., 1981, 29, p 1473–1474

S. Allain, J.-P. Chateau, O. Bouaziz, S. Migot, and N. Guelton, Correlations Between the Calculated Stacking Fault Energy and the Plasticity Mechanisms in Fe-Mn-C Alloys, Mater. Sci. Eng. A, 2004, 387–389, p 158–162

Y.I. Ustinovshikov, Precipitation in Solids, J. Mater. Sci., 1992, 27, p 3993–4002

S. Morito, H. Tanaka, R. Konishi, T. Furuhara, and T. Maki, The Morphology and Crystallography of Lath Martensite in Fe-C Alloys, Acta Mater., 2003, 51, p 1789–1799

N. Nakada, Direct Observation of Martensitic Reversion from Lenticular Martensite to Austenite in Fe-Ni Alloy, Mater. Lett., 2017, 187, p 166–169

J. Hidalgo and M.J. Santofimia, Effect of Prior Austenite Grain Size Refinement by Thermal Cycling on the Microstructural Features of As-Quenched Lath Martensite, Metall. Mater. Trans. A, 2016, 47, p 5288–5301

P. Hua, S. Mironov, Y.S. Sato, H. Kokawa, S.H.C. Park, and S. Hirano, Crystallography of Martensite in Friction-Stir-Welded 12Cr Heat-Resistant Steel, Metall. Mater. Trans. A, 2019, 50, p 3158–3163

D.V. Shtansky, K. Nakai, and Y. Ohmori, Decomposition of Martensite by Discontinuous-Like Precipitation Reaction in an Fe-17Cr-0.5C Alloy, Acta mater., 2000, 48, p 969–983

T.E. Mitchell, R.G. Castro, J.J. Petrovic, S.A. Maloy, O. Unal, and M.M. Chadwick, Dislocations, Twins, Grain Boundaries and Precipitates in MoSi2, Mater. Sci. Eng. A, 1992, 155, p 241–249

P. Shanthraj and M.A. Zikry, The Effects of Microstructure and Morphology on Fracture Nucleation and Propagation in Martensitic Steel Alloys, Mech. Mater., 2013, 58, p 110–122

A. Stormvinter, P. Hedström, and A. Borgenstam, A Transmission Electron Microscopy Study of Plate Martensite Formation in High-Carbon Low Alloy Steels, J. Mater. Sci. Technol., 2013, 29, p 373–379

P. Michaud, D. Delagnes, P. Lamesle, M.H. Mathon, and C. Levaillant, The Effect of the Addition of Alloying Elements on Carbide Precipitation and Mechanical Properties in 5% Chromium Martensitic Steels, Acta Mater., 2007, 55, p 4877–4889

T. Maki and C.M. Wayman, Substructure of Ausformed Martensite in Fe-Ni and Fe-Ni-C Alloys, Metall. Trans. A, 1976, 7, p 1511–1518

Acknowledgments

The authors would like to thank the National Natural Science Foundation of China (No. 51575416), 111 Project (B17034), Innovative Research Team Development Program of Ministry of Education of China (No. IRT_17R83), Science and Technology Support Program of Hubei Province (No. 2015BAA039), Wuhan Youth Science and Technology Plan (No. 2016070204010126), Independent Innovation Foundation of Wuhan University of Technology (2019IVA102) and The fellowship of China Postdoctoral Science Foundation (2020M672429) for the support given to this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, X., Hua, L., Han, X. et al. Effect of Heat Treatment Process on Microstructure and Crystallography of 20CrMnTiH Spur Bevel Gear. J. of Materi Eng and Perform 29, 6468–6483 (2020). https://doi.org/10.1007/s11665-020-05169-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05169-y