Abstract

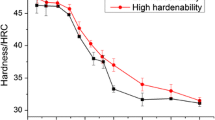

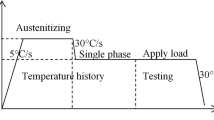

The hardenability of gear steel is dependent on the composition of alloying elements and is one of important criteria to assess process of phase transformation. The variation of hardenability has to be considered in control of the microstructures and distortion during gear quenching. In this paper, the quantitative effect of hardenability has been investigated on phase transformations of spiral bevel gears in die quenching. The hardenability deviation of 22CrMoH steel was assessed by using Jominy test. The dilatometry experiments were conducted to build phase transformation kinetic models for steels with low and high hardenability, respectively. The complete die quenching process of spiral bevel gear was modeled to reveal the significant difference on microstructures and temperature history with variation of hardenability. The final microstructures of the gear are martensite in surface layer after quenching process. There are bainite inside the gear tooth and the mixture of bainite and ferrite inside gear for the gear with low hardenability. The microstructure is bainite inside the gear with high hardenability.

Similar content being viewed by others

References

Z. Li et al., Modeling the Effect of Carburization and Quenching on the Development of Residual Stresses and Bending Fatigue Resistance of Steel Gears, J. Mater. Eng. Perform., 2013, 22(3), p 664–672

S. Wei et al., Experimental Study on Vacuum Carburizing Process for Low-Carbon Alloy Steel, J. Mater. Eng. Perform., 2014, 23(2), p 545–550

C.A. Siebert, D.V. Doane, and D.H. Breen, The Hardenability of Steels: Concepts, Metallurgical Influences, and Industrial Applications, Am. Soc. Met. Met. Park, 1977, p 96

G. Wang, R.D. Sisson, Development of Simulation Tool for Prediction and Optimization on Carburizing Processes, Heat Treating Proceedings of the 25th ASM Heat Treating SOCIETY Conference, 2009, p 91–95

K.O. Lee et al., A Study on the Mechanical Properties for Developing a Computer Simulation Model for Heat Treatment Process, J. Mater. Process. Technol., 2007, 182(1-3), p 65–72

A. Yamanaka, T. Takaki, and Y. Tomita, Elastoplastic Phase-Field Simulation of Martensitic Transformation with Plastic Deformation in Polycrystal, Int. J. Mech. Sci., 2010, 52(2), p 245–250

W.E. Jominy and A.L. Boegehold, A Hardenability Test for Carburizing Steel, Trans. ASM, 1938, 26, p 574–606

C.M. Amey, H. Huang, and P.E.J. Rivera-Díaz-del-Castillo, Distortion in 100cr6 and Nanostructured Bainite, J. Mater. Des., 2012, 35, p 66–71

B. Hwang, D. Suh, and S. Kim, Austenitizing Temperature and Hardenability of Low-Carbon Boron Steels, Scr. Mater., 2011, 64(12), p 1118–1120

B. Demir and M. Erdoğan, The Hardenability of Austenite with Different Alloy Content and Dispersion in Dual-Phase Steels, J. Mater. Process. Technol., 2008, 208(1-3), p 75–84

Z. Li, B. Ferguson, and A. Freborg, Data Needs for Modeling Heat Treatment of Steel Parts, Proceedings of Materials Science & Technology Conference, 2004, p 219–226

Z. Li and B.L. Ferguson, Computer Modeling and Validations of Steel Gear Heat Treatment Processes Using Commercial Software DANTE, J. Shanghai Jiaotong Univ. (Sci.), 2011, 16(2), p 152–156

P. Du, et al., A FEM-Based Inverse Calculation Method for Determination of Heat Transfer Coefficient in Liquid Quenching Process, TMS 2014 143th Annual Meeting & Exhibition, 2014, p 309–315

V. Warke, R. Sisson, and M. Makhlouf, FEA Model for Predicting the Response of Powder Metallurgy Steel Components to Heat Treatment, Mater. Sci. Eng. A, 2009, 518(1-2), p 7–15

Srinivasan et al., Numerical Simulation of Immersion Quenching Process of an Engine Cylinder Head, J. Appl. Math. Model., 2010, 34(8), p 2111–2128

R.N. Penha et al., Effect of Chemical Banding on the Local Hardenability in AISI, 4340 Steel Bar, Eng. Fail. Anal., 2015, 53, p 59–68

Acknowledgment

This research has been financially supported by Natural Science Foundation of China (Project U1537202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Shi, W., Yang, L. et al. The Effect of Hardenability Variation on Phase Transformation of Spiral Bevel Gear in Quenching Process. J. of Materi Eng and Perform 25, 2727–2735 (2016). https://doi.org/10.1007/s11665-016-2125-1

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-016-2125-1